GaN-based light-emitting diode structure improving light extraction rate and preparation method

A light-emitting diode, gallium nitride-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low sub-concentration, low light extraction efficiency, uneven current distribution, etc., to overcome the complexity of the process and improve the current carrying capacity Sub concentration, the effect of improving the uniformity of current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

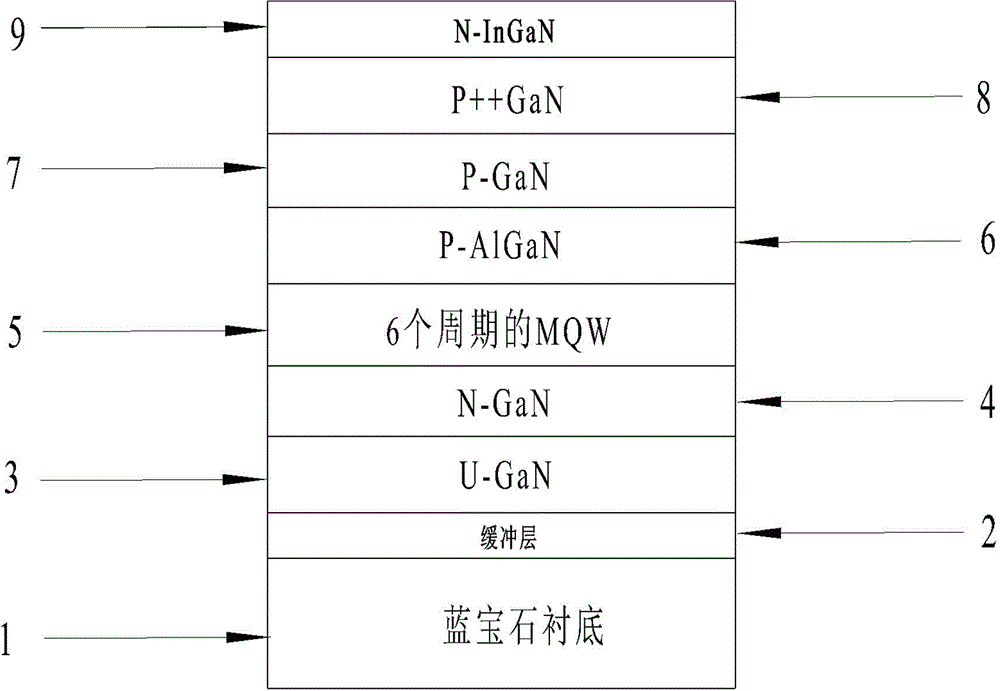

[0033] A gallium nitride-based light-emitting diode structure that improves the light extraction rate, the light-emitting diode structure includes: a substrate 1; a GaN buffer layer 2 grown on the substrate 1; a non-doped GaN buffer layer grown on the GaN buffer layer 2 a GaN layer 3; a Si-doped GaN layer 4 grown on the non-doped GaN layer 3; a 6-period multi-quantum well structure 5 grown on the Si-doped GaN layer 4, wherein the thickness of the well layer is 2.7nm, The thickness of the first five barrier layers is 13nm, and the thickness of the last barrier layer is 17nm; the p-AlGaN electron blocking layer 6 grown on the multi-quantum well structure 5; the Mg-doped p-type GaN layer grown on the p-AlGaN electron blocking layer 6 7; a heavily doped p-type GaN layer 8 grown on the Mg-doped p-type GaN layer 7; an n-type InGaN layer 9 grown on the heavily doped p-type GaN layer 8.

[0034] The substrate 1 is a sapphire substrate.

[0035] A method for preparing a gallium nitrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrier concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com