Schottky diode and manufacturing method thereof

A Schottky diode and Schottky contact technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of not fully utilizing the voltage resistance potential of the overall epitaxial layer, the current transmission capacity has a greater impact, and increase stability. The difficulty of maintaining stability and other issues can achieve the effects of good current transmission capacity and stability, low production cost, and reduced performance impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

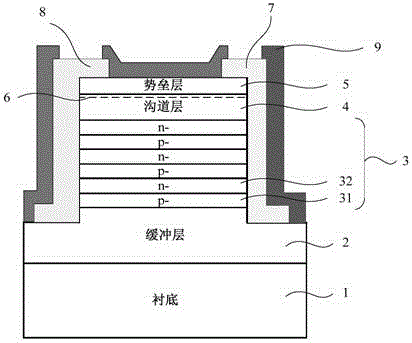

[0061] In this embodiment, a Schottky diode, such as image 3 As shown, it includes: a substrate 1, a buffer layer 2, an epitaxial structure, a Schottky contact metal 7, and an ohmic contact metal 8, and the substrate 1, the buffer layer 2, and the epitaxial structure are sequentially stacked;

[0062] The epitaxial structure includes a superjunction layer 3, a GaN channel layer 4 and a barrier layer 5 stacked in sequence, and the superjunction layer 3 is formed by alternately stacking a plurality of p-type GaN layers 31 and n-type GaN layers 32;

[0063] The Schottky contact metal 7 and the ohmic contact metal 8 are respectively symmetrically disposed on opposite side surfaces of the epitaxial structure, and one end extends to the upper surface of the epitaxial structure, and the other end extends to the buffer layer 2 .

[0064] In the Schottky diode, the Schottky contact metal 7 and the ohmic contact metal 8 are respectively arranged symmetrically on opposite sides of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com