Cloth strap

A tape and zipper technology, applied in fabrics, textiles, clothing, etc., can solve the problems of increased cost, difficult to penetrate effectively, and limited bonding force between injection molding zipper elements and tape, and achieves easy positioning and improved bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

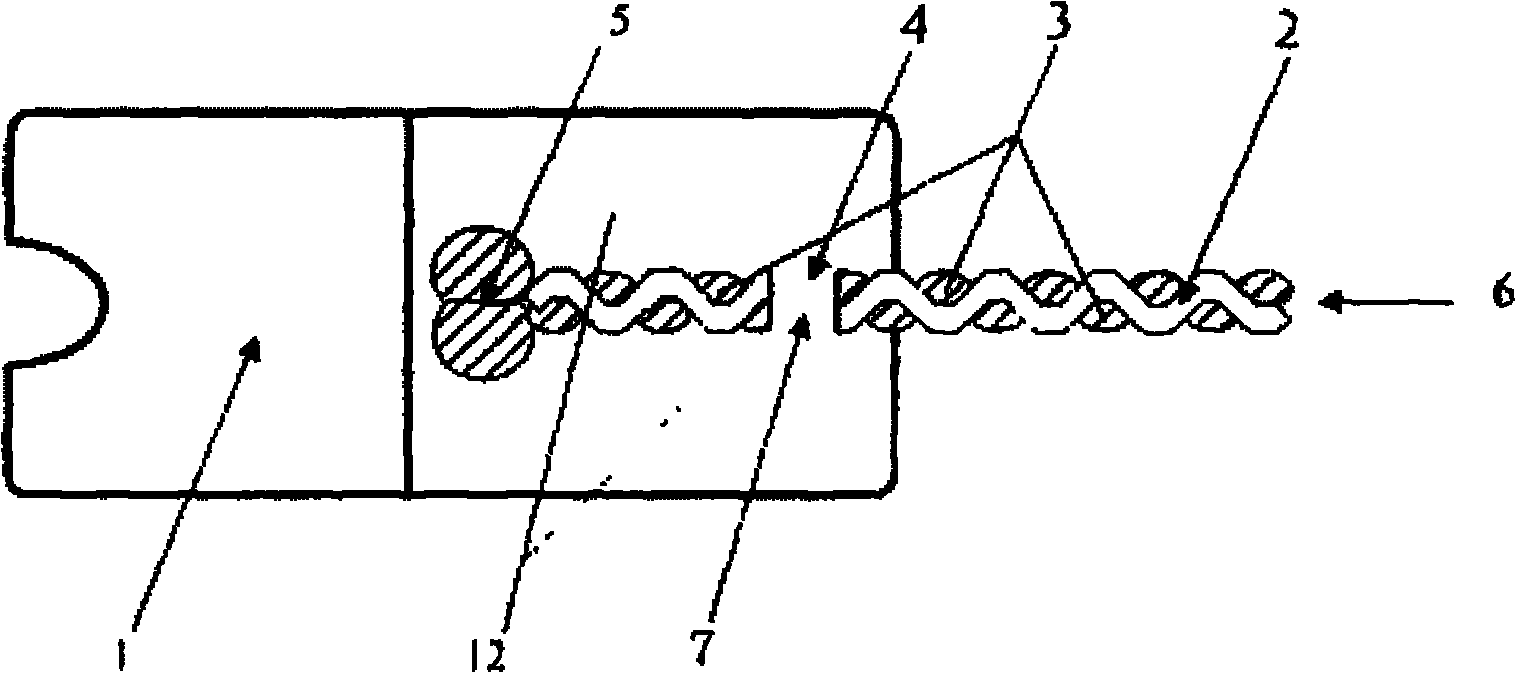

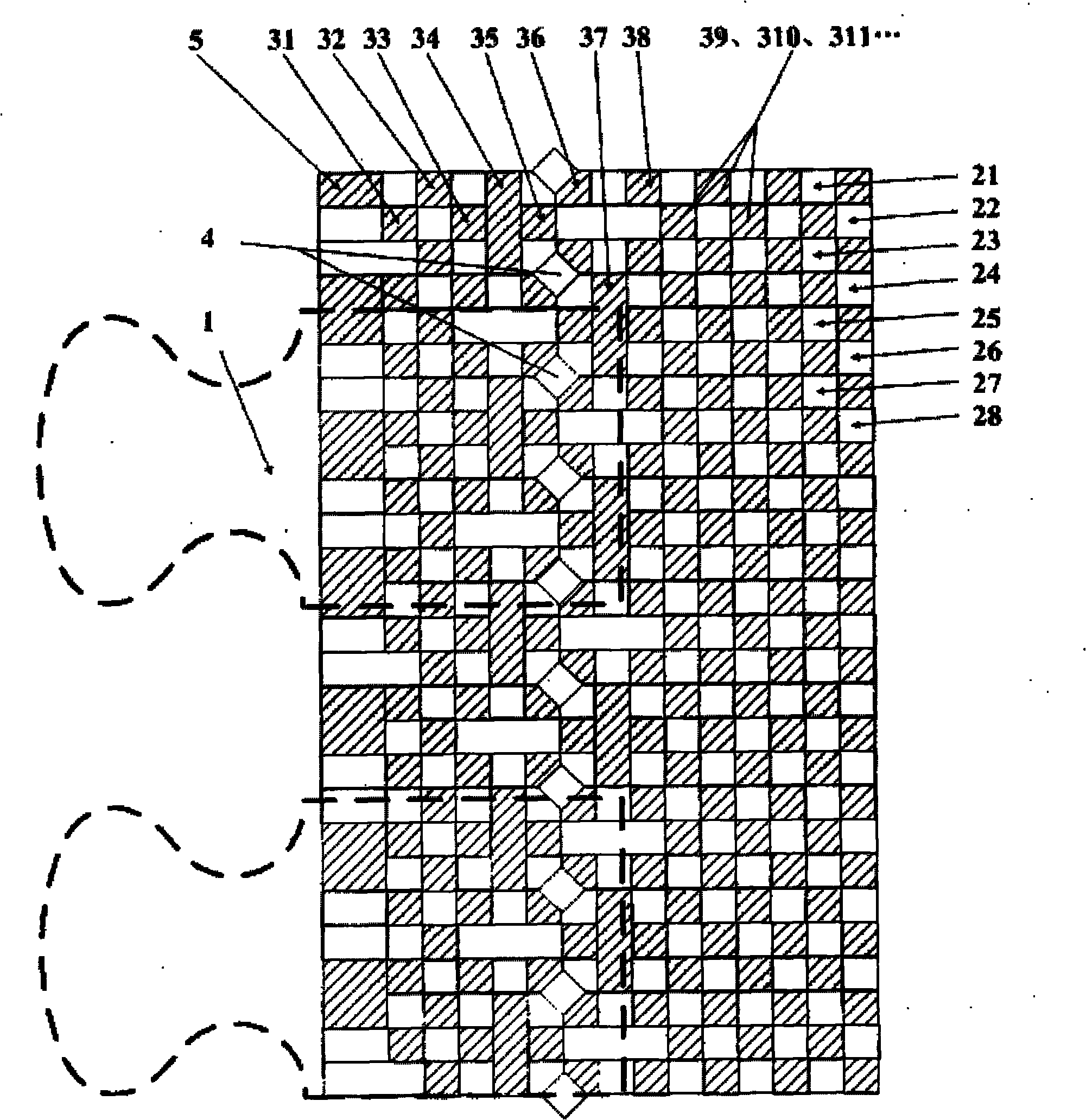

[0045] Depend on figure 2 It can be seen that the injection molded zipper tape 6 of the structure of the present invention includes: the center line 5 of the edge of the tape, a group of warp yarns 3 and continuous weft yarns 2; figure 2 The centerline 5 and some warp yarns such as 31, 32...36, 37 are located in the area of the joint surface between the tape 6 and the fastener element 1, and the rest of the warp yarns 38, 39... are located outside the joint surface. Such as figure 2 As shown, the warp yarns 33 and 35 are set to a structure of one up and one down circulation, and the middle warp yarn 34 is set to a structure of three down and three up cycles; while the warp yarns 36, 38 and 37 are opposite to the warp yarns 33, 35 and 34 , set to a structural organization of one-up-one-up and three-up-three-down cycles. The fabric tape woven under such a structural structure, due to the influence of the warp yarn tension, the interweaving points of the weft yarns 21, 23 ...

Embodiment 2

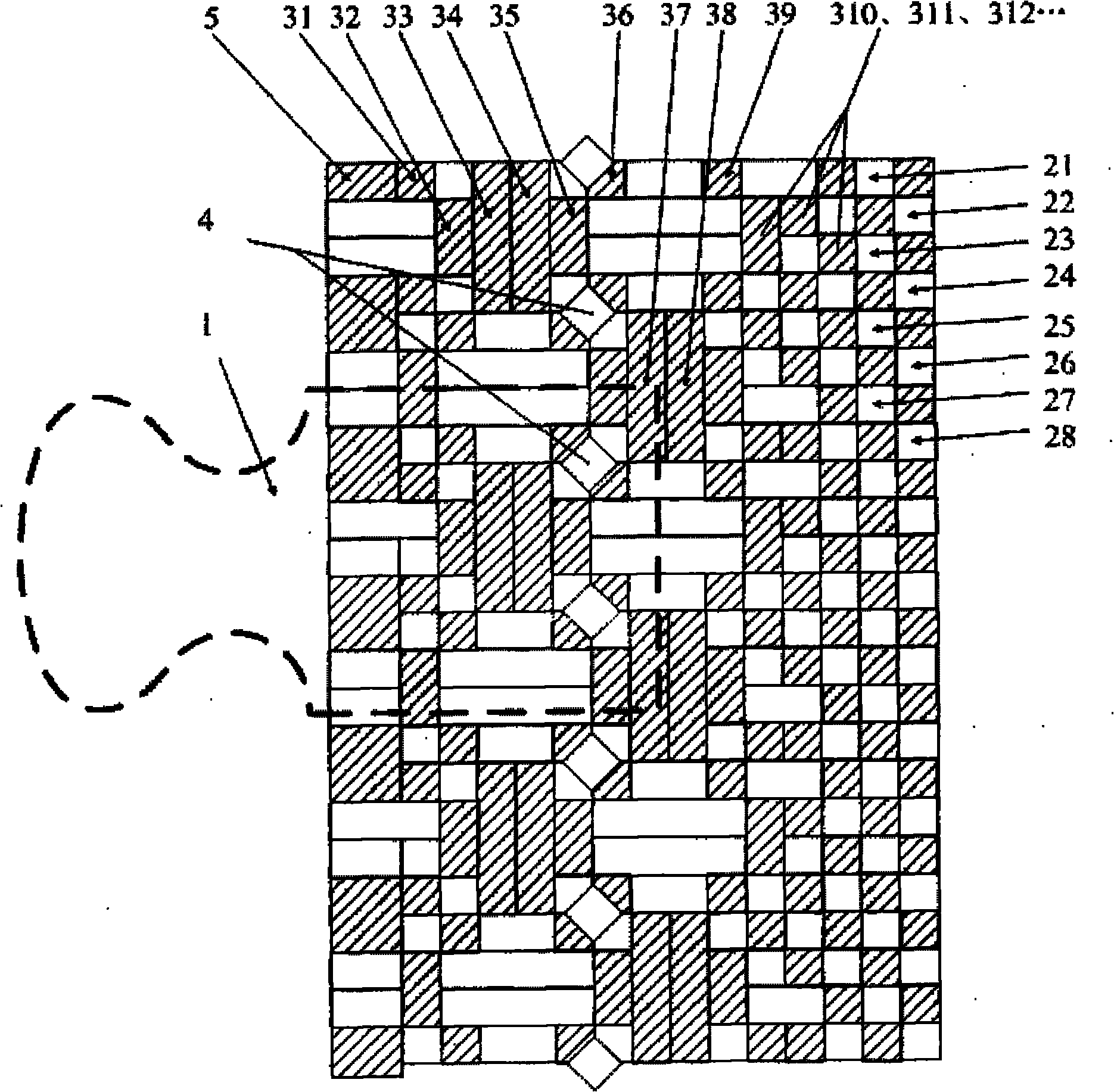

[0047] As a further improvement of the structural cloth tape of the present invention, another improved setting is made to the warp structure in the area of the joint surface of the cloth tape and the zipper element, and the structural organization of the three warp and weft threads is formed into a small hole, which is improved to The structure of four warp yarns and weft yarn loops forms small holes; image 3 As shown, the warp yarns 32, 35 are set to a structure of one up, two, one, up, two, up, and down cycles, and the middle warp yarns 33, 34 are set to a four-down, four-up cycle structure; and the warp yarns 36, 39 and 37, 38 is opposite to warp yarns 32, 35 and 33, 34, and is set to a structure of one, two, one, one, two, one, four, four, four. The cloth tape woven under the same principle as in Example 1, due to the influence of warp and weft tension, the interweaving points of warp yarns 35, 36 and weft yarns 24, 25 are shifted, and small holes 4 are formed in the m...

Embodiment 3

[0049] As a further improvement of the structural cloth tape of the present invention, the warp yarns in the area of the joint surface of the cloth tape and the zipper elements are thinned. Change it to 167dtex, so that the number of warp yarns in the joint area will increase; as Figure 4 As shown, warp yarns 31, 32...310, 311 are located in the joint surface area, and warp yarns 33, 34, 35, 36, 37, 38, 39, 310, 311 are set according to embodiment 1; The cloth tape that weaves out after fixing forms two rows of small holes between warp yarns 35,36 and 38,39, and two rows all form intervals every three weft yarns evenly, and the size is consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com