Functional nylon 66 fiber and preparation method thereof

A functional, nylon technology, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., to achieve broad-spectrum antibacterial heat resistance, good uniformity, and good dyeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

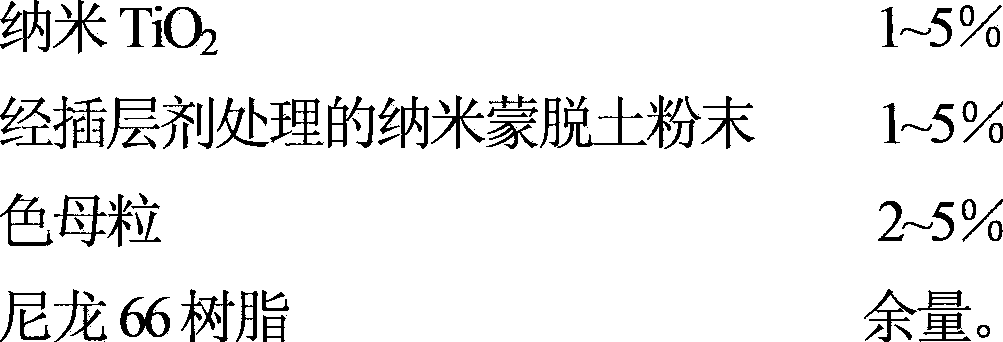

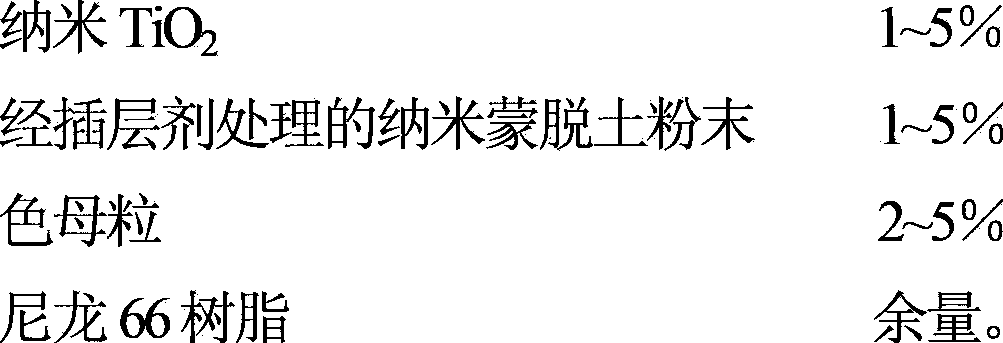

Embodiment 1

[0021] Nano-titanium dioxide (TiO2) with a particle size of ≤100nm 2 ) powder and 1kg of nano-montmorillonite powder treated with intercalation agent (quaternary ammonium salt surfactant) with a particle size of ≤100nm and 8kg of nylon 66 resin slices are mixed at high speed, and then sent to a twin-screw granulator for co-production. Melting granulation, blending 1kg of the obtained masterbatch with 9kg of nylon 66 resin slices and vacuum drying, the vacuum degree is <0.2mmHg, the drying temperature is 120°C, and the drying time is 4 hours; then mixed with a certain amount of masterbatch ( 3%) blending for melt spinning, and use a special-shaped spinneret to spin 50D / 18F, 100D / 48F POY or FDY.

[0022] The oxygen index (flame retardancy) of the tested fiber is 29-32%; the antibacterial performance is 92-96%; the anti-ultraviolet performance is 26-30 (UPF); the antistatic performance is <0.6μc; the fabric dyeing uniformity is grade 4 (gray card).

Embodiment 2

[0024] Nano-titanium dioxide (TiO2) with a particle size of ≤100nm 2 1.5kg of powder and 1kg of nano-montmorillonite powder treated with an intercalation agent (quaternary ammonium salt surfactant) with a particle size of ≤100nm and 8kg of nylon 66 resin slices are mixed at high speed and sent to a twin-screw granulator for Blending and melting granulation, blending 1kg of the obtained masterbatch with 9kg of nylon 66 resin slices and vacuum drying, the vacuum degree is <0.2mmHg, the drying temperature is 120°C, and the drying time is 4 hours; then mixed with a certain amount of color masterbatch (3%) blending for melt spinning, using a special-shaped spinneret to spin 50D / 18F, 100D / 48F POY or FDY.

[0025] The oxygen index (flame retardancy) of the tested fiber is 29-32%; the antibacterial performance is 94-96%; the anti-ultraviolet performance is 26-30 (UPF); the antistatic performance is <0.6μc; the fabric dyeing uniformity is 4.5 (gray card).

[0026] The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com