Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Good shrink resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional fiber inorganic composite product and production method thereof

ActiveCN102296776AMeet a wide range of needsImprove plasticityCovering/liningsCement compositesReinforced concrete

The invention relates to a three-dimensional fiber inorganic composite (FCC: Fiber Cement Composite) product and a production method thereof, and the three-dimensional fiber inorganic composite product comprises a decorative layer and a three-dimensional fiber-reinforced cement structure layer. The decorative layer is prepared from decorative mortar and can be subjected to fiber reinforcement; and the structure layer is prepared from the fiber with high elastic modulus, the fiber with low elastic modulus and reinforced concrete mortar in three-dimensional distribution, and 0-3 layers of reticular reinforcing material is further laid. The decorative layer and the structure layer are compounded in a mold with the decorative effect and can be prepared by adopting an integral formula and process. The product is prepared through the fiber mixing technology and the premixing and forming technology, a high-performance novel material applied to the fields of building decoration engineering, anti-cracking engineering construction, building exterior wall repair and the like is realized, the product has the advantages of light weight, high strength, high durability, anti-cracking property and the like, and fiber-reinforced exterior wall plates, decoration members and other products in complex shapes and fineness can be further manufactured. Simultaneously, as the production process is simple, the degree of mechanized production is high, the production cost is low and the range of market applications is broad.

Owner:江苏倍立达新材料科技有限公司

Plasma and enzyme combined anti-felting method for tidying wool knitted fabric

InactiveCN101177915AProcess for improving felting resistanceBurst downBiochemical fibre treatmentUltrasonic/sonic fibre treatmentEngineeringEnzyme

The invention relates to an antifelting finish method of wool knits combining plasma and bio-enzyme, comprising the steps that: wool washing, plasma treatment, protease treatment, water washing, Transglutaminase treatment, water washing, and drying. The invention can lead wool knits to reach machine washable standard (with a felting rate less than 2 percent) while the intensity is ensured (intensity damage is less than 10 percent), and has little damage during the finish process, with safety and environmental protection performance, and is an energy-conservation and clean wool post-treatment technique.

Owner:DONGHUA UNIV

Ready-made clothes after-finishing process

InactiveCN101265661AImprove waterproof performanceGood oil proofDry-cleaning apparatus for textilesNatural fibresEngineeringSoil resistance

The invention relates to a post-finishing process for ready-made clothes, which adopts the one-step method of one-bath in the following working procedures of desizing, unwatering, soaking in treatment fluid, re-drying, pressing and baking for setting, and cooling. In preparing the treatment fluid, resin 5-10%, OLEOPHOBOL 4-8%, penetrant 0.1-0.25%, and catalyst 1-2.5% are included. After finishing, the ready-made clothes with no ironing and washing for 30 times can achieve the crease shedding of level 4, water resistance of level 5, oil resistance of level 5, and soil resistance of level 5, thereby having excellent water-washing serviceability, durability and shrink resistance. The formaldehyde content is lower than 75ppm. The post-finishing process has the advantages of little pollution, obvious effects of water resistance, oil resistance, soil resistance, and no ironing, good durability and so on, thereby being applied to the ready-made clothes made of natural fibers such as cotton, hemp, tencel and so on.

Owner:翁卫东

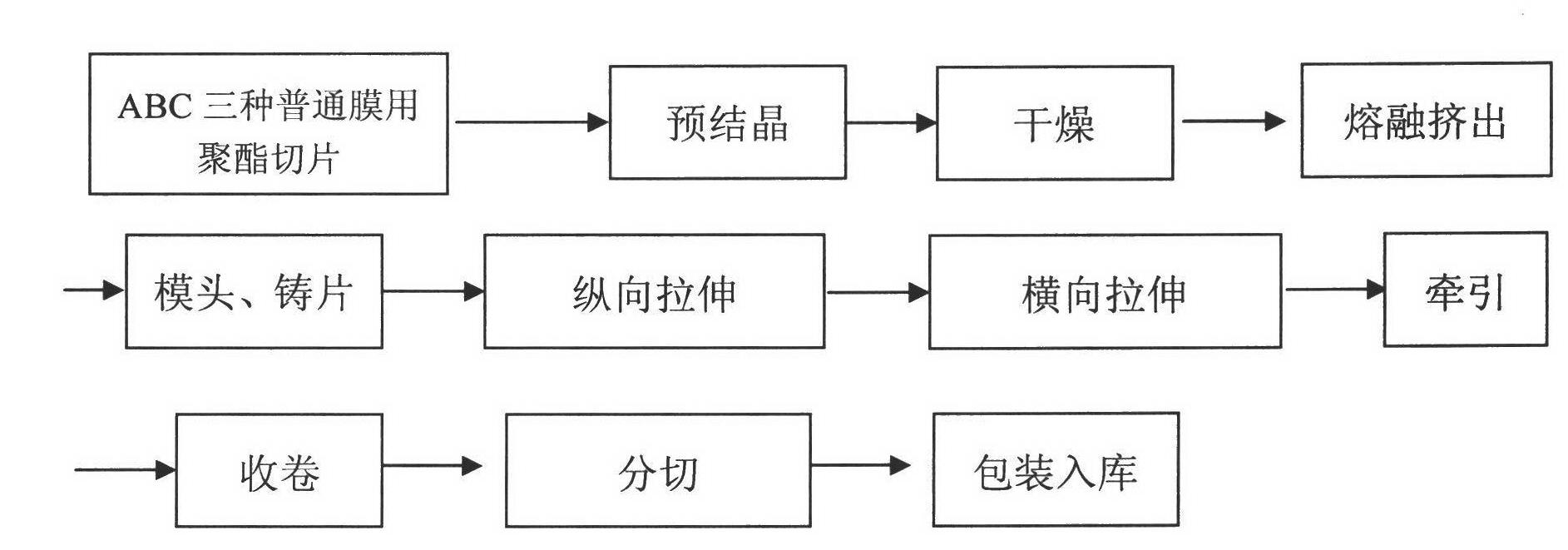

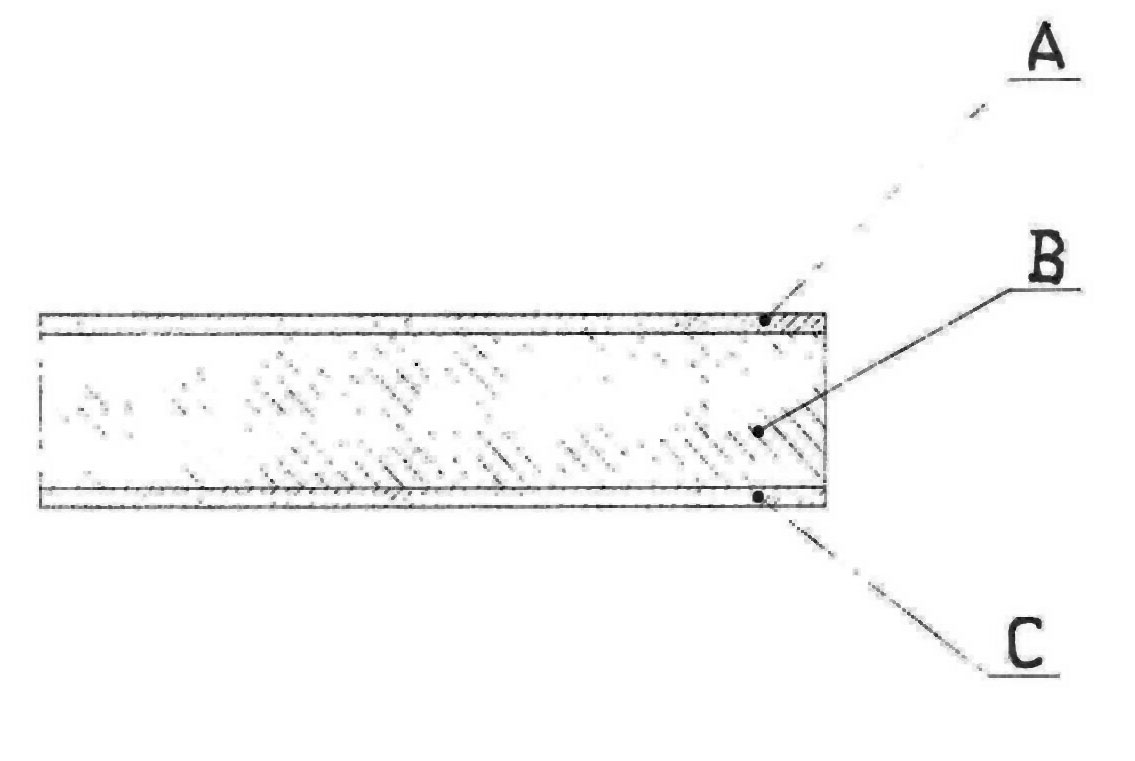

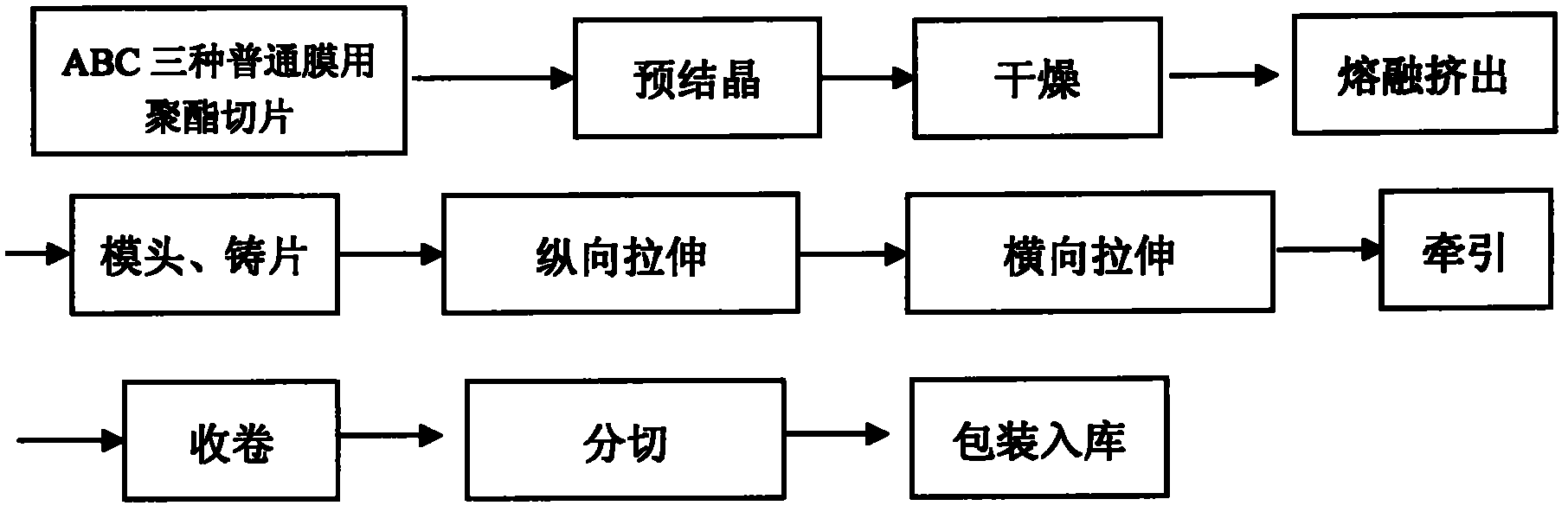

Shrinking-proof polyethylene terephthalate (PET) laser transfer base film and method for preparing same

ActiveCN102582189AReduce coefficient of frictionMeet the requirements of producing high-grade positioning laser transfer base filmSynthetic resin layered productsFlat articlesPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a shrinking-proof PET laser transfer base film and a method for preparing the same. The weight ratio of components of raw materials of layer A, layer B and layer C are as follows: layer A: 75% of polyester used for films, 25% of a caking inhibiter; layer B: 85% of film polyester, 15% of a thermal stability caking inhibiter; and layer C: 80% of film polyester, 20% of the caking inhibiter. The method for preparing the shrinking-proof PET laser transfer basement film comprises the steps of cutting materials into pieces and mixing the materials; performing fusion and extrusion; performing die head piece casting; drawing longitudinally; drawing transversely; performing traction and side shearing; winding; slitting and finishing products. Compared with conventional laser transfer base films, the shrinking-proof PET laser transfer base film has the advantages that the shrinking-proof performance is excellent, the thermal stability is good, the stamping effect is good, the transfer is complete, and the thickness is uniform. The shrinking-proof PET laser transfer base film can meet requirements of users for production of high-end positioning laser transfer base films and is applicable to manufacture of laser transfer aluminum plating packaging materials which have certain anti-counterfeiting functions.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

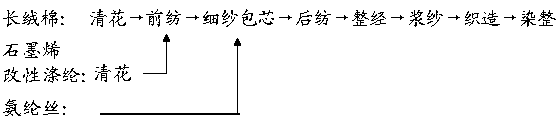

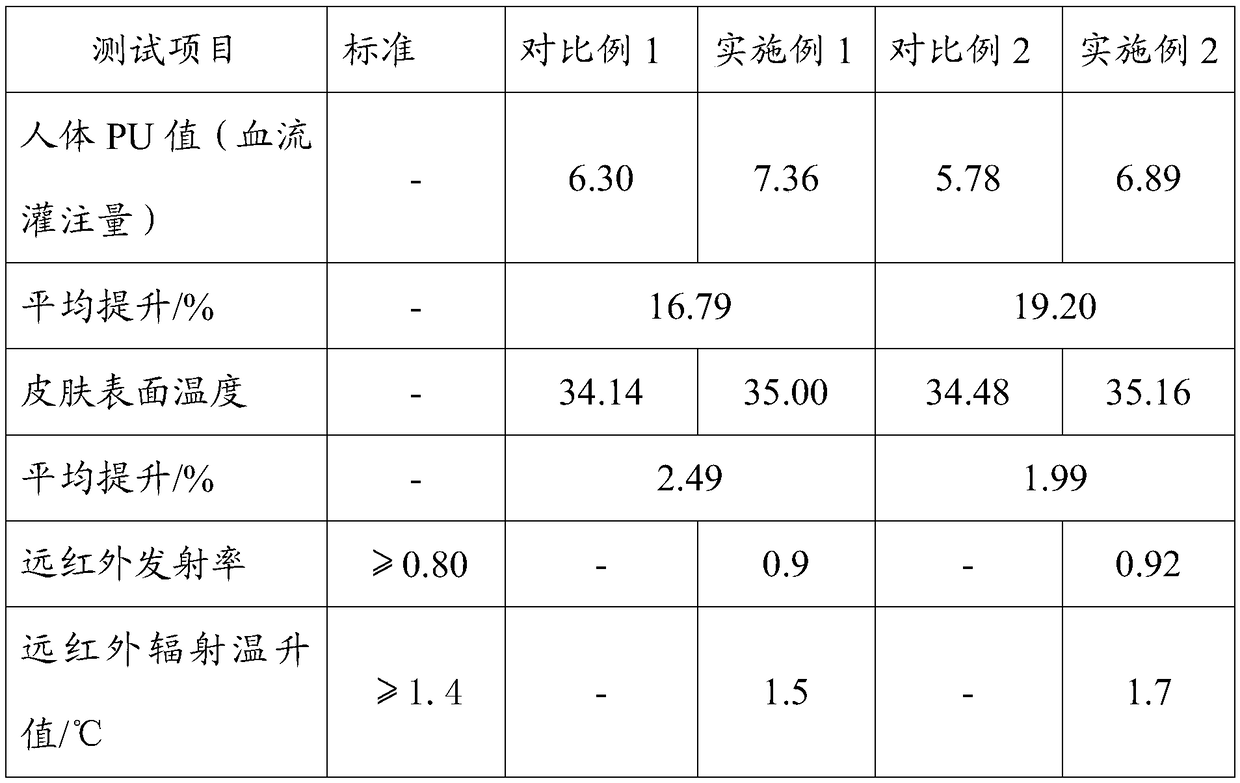

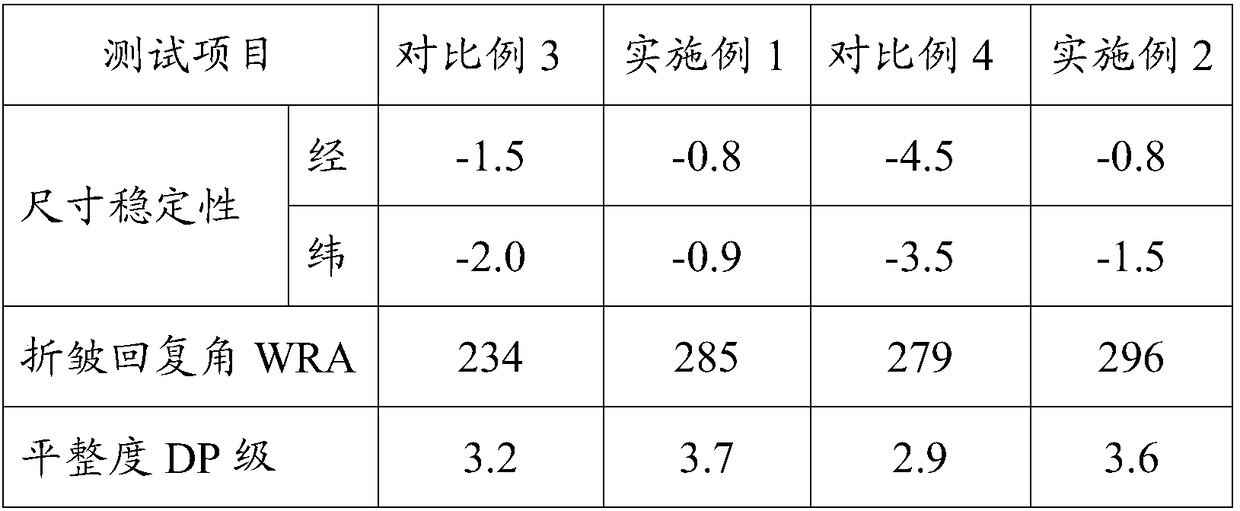

Production method of graphene-modified fiber core-spun elastic yarn and graphene-modified fiber core-spun elastic fabric

ActiveCN108823718AImproves shrink resistanceImprove wrinkle resistanceWeft knittingWarp knittingPolyesterFiber

The invention discloses a production method of graphene-modified fiber core-spun elastic yarn and graphene-modified fiber core-spun elastic fabric. The graphene-modified fiber core-spun elastic yarn is a core-spun spandex filament obtained by blending graphene-modified polyester fibers and combed cotton. The graphene-modified fiber core-spun elastic fabric comprises a woven elastic fabric body anda knitted elastic fabric body. The fabric has the functions of resisting bacteria, achieving far-infrared heating, promoting micro-circulation, preventing ultraviolet radiation and the like and has good creasing resistance and shape retention performance. The graphene-modified fiber core-spun elastic yarn and the graphene-modified fiber core-spun elastic fabric can be applied to the field of woven garments and knitting sports, and the market of elastic functional products is developed.

Owner:山东宏儒纺织科技有限公司

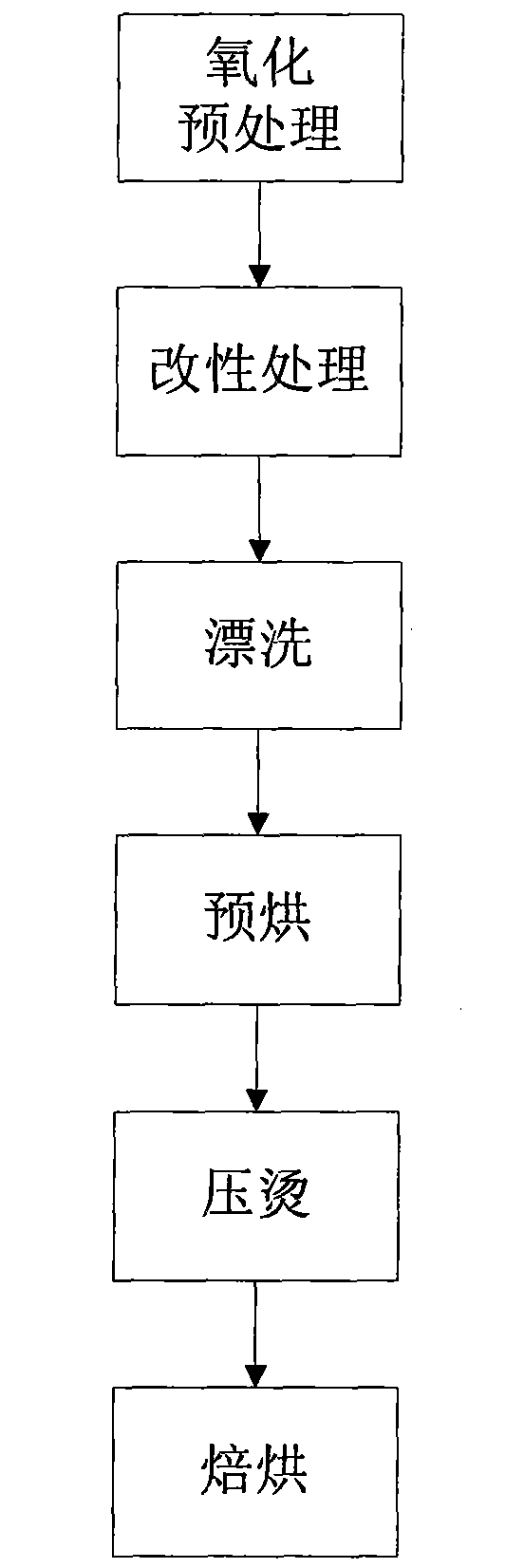

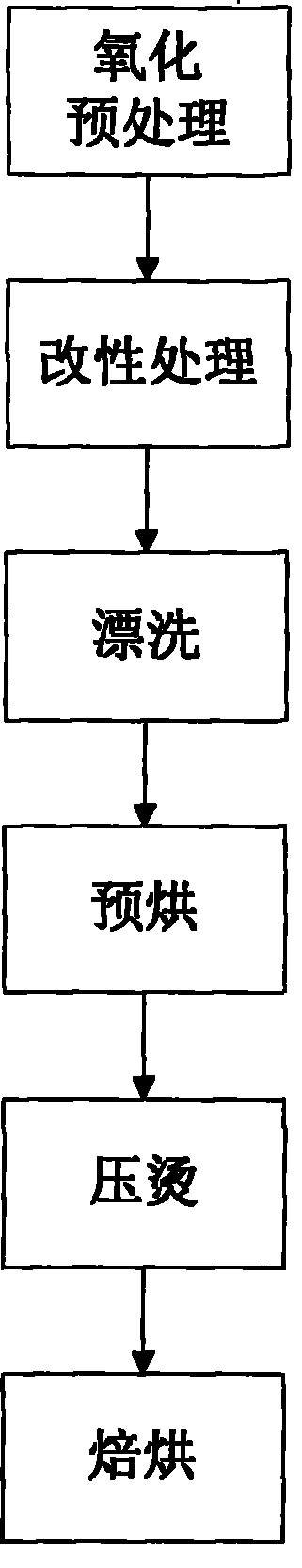

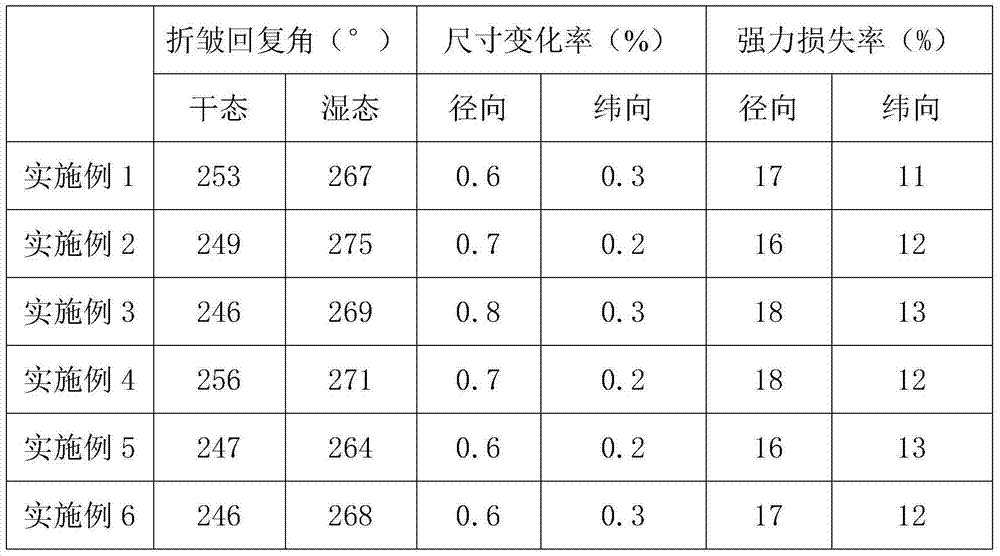

Shrink-resistance treatment method of wool textiles

InactiveCN102465443AGood shrink resistanceWill not cause pollutionBiochemical fibre treatmentLiquid/gas/vapor removalMedicineHazardous substance

The invention discloses a shrink-resistance treatment method of wool textiles. The shrink-resistance treatment method comprises the following specific steps of: oxidization pretreatment; modifying treatment; rinsing; prebaking; ironing; and baking. According to the invention, an oxidant is used for treating the wool textiles first so as to facilitate decrement activity of protease to wool. Long-carbon-chain lipoid on the surface of the wool can be removed by oxidant pretreatment, so that scales are loose, expansive and soft, and protease molecules easily enter inside for hydrolyzing wool scales during protease treatment, and the shrink resistance effect after finishing is good; meanwhile, in the whole treating process, the advantages of low temperature, less energy consumption, no toxic and harmful matters and no environment pollution are achieved.

Owner:CHANGSHU ZHUOHUI TEXTILE

Noniron finishing method of silk fabric

InactiveCN104762821AGood shrink resistanceGuaranteed feelBiochemical fibre treatmentAnimal fibresWarm waterEngineering

The invention discloses a noniron finishing method of a silk fabric. The noniron finishing method particularly comprises the following steps: moistening and rinsing the silk fabric with warm water twice, refining and expanding the silk fabric by using a biological enzyme, after rinsing with warm water, padding the expanded silk fabric in a wash and wear finisher containing silk fibroin, citric acid and chitosan quaternary ammonium salt, then predrying the silk fabric, tentering at constant temperature, baking at high temperature, washing with water and drying, and pressing-packaging to obtain the noniron finished silk fabric. According to the noniron finishing method, a biological enzyme technology is combined with a padding technology, the silk fabric is subjected to noniron finishing by using the silk fibroin, the citric acid and the chitosan quaternary ammonium salt, so that the noniron finishing method has the advantages of simple and effective, environmental-friendly and biological effects. The silk fabric prepared by adopting the noniron finishing method reaches a noniron degree, and has a good crease-resisting and deformation-resisting capabilities; the dyeing performance of the fabric is improved; the handfeel, the style and the mechanical property of the fabric are reserved, and thus the noniron finishing method is an ideal noniron finishing method of the silk fabric.

Owner:SUZHOU WILDER IND & TRADE

Method for processing no-iron 100% bombast

ActiveCN1932137AGood flexibilityDimensionally stableBiochemical fibre treatmentVegetal fibresYarnAfter treatment

The present invention discloses a processing method of all-flax flexible self-smoothing face fabric. It is characterized by adding the processes of tensionless desizing and enzyme treatment in the face fabric finishing stage, and its whole processing method includes the following several steps: loosening yarn, pretreatment, dyeing, after-treatment, coning, weaving, gray inspection, singeing, tensionless desizing, enzyme treatment, liquid ammonia finishing, finalizing design and re-shrinking.

Owner:盛泰智造集团股份有限公司

Waterborne binder for tile

InactiveCN106566441AGood anti-sag effectImprove shrinkage resistanceCellulose adhesivesHydrocarbon polymer adhesivesHydroxypropylmethyl celluloseEmulsion

The invention discloses a waterborne binder for tile. The waterborne binder comprises an acrylic pressure-sensitive adhesive, hydroxypropyl methyl cellulose, polyvinyl alcohol (PVA) powder, water, an antifoaming agent, an antiseptic, a styrene-acrylic emulsion and an antifreezing agent. The above components are subjected to mechanical processing so as to prepare the waterborne binder for tile. The waterborne binder for tile has good thixotropic performance, improved shrinkage and cracking resistance, enhanced surface quality, improved bonding strength, good smoothness in brushing and excellent tile wettability and spreadability; with the binder, the tile is hard to slide and not prone to the phenomena of hollowing, tile falling and the like after bonded onto a wall; and the binder has good bonding performance, high strength, good resistance to water, freezing and thawing and ageing and allows the surface of the bonded tile to be easy to clean due to usage of the antifoaming agent as the component.

Owner:沈屏

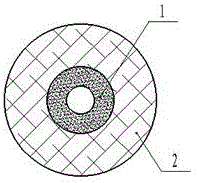

Shrink-proof wool core-spun yarn

The invention discloses a shrink-proof wool core-spun yarn, comprising: a core thread and a covering yarn; the core thread is a polyester thread, the covering yarn is a wool blended yarn made by twisting multiple wool fibers, cotton fibers and bamboo fibers, the wool blended yarn covers the polyester yarn, the wool fibers are special-shaped wool fibers having triangular cross section, and the cotton fibers are special-shaped cotton fibers having Y-shaped cross section. In this way, by covering the polyester core thread by using the wool blended yarn as the covering yarn with the wool blended yarn made by twisting the special-shaped wool fibers, the special-shaped cotton fibers and the bamboo fibers, the wool core-spun yarn is made which has excellent shrink-proof performance, good surface gloss, good softness and is resistant to picking and pilling.

Owner:SUZHOU WEIJIE TEXTILE

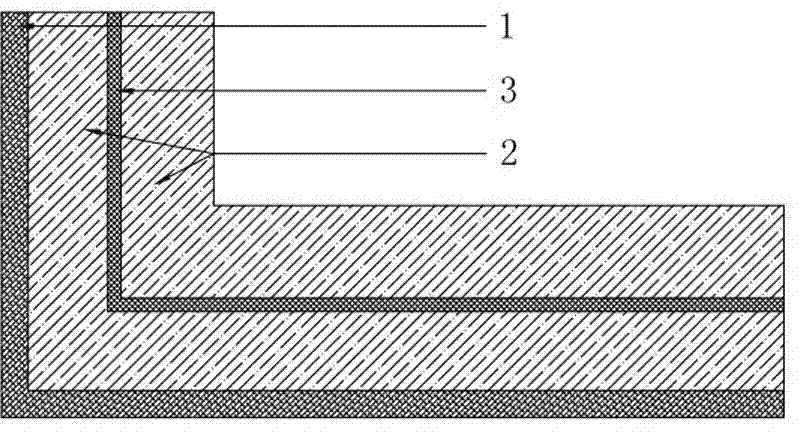

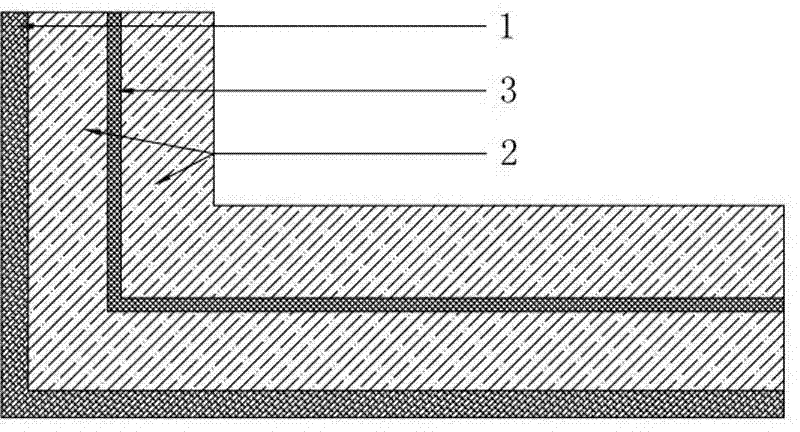

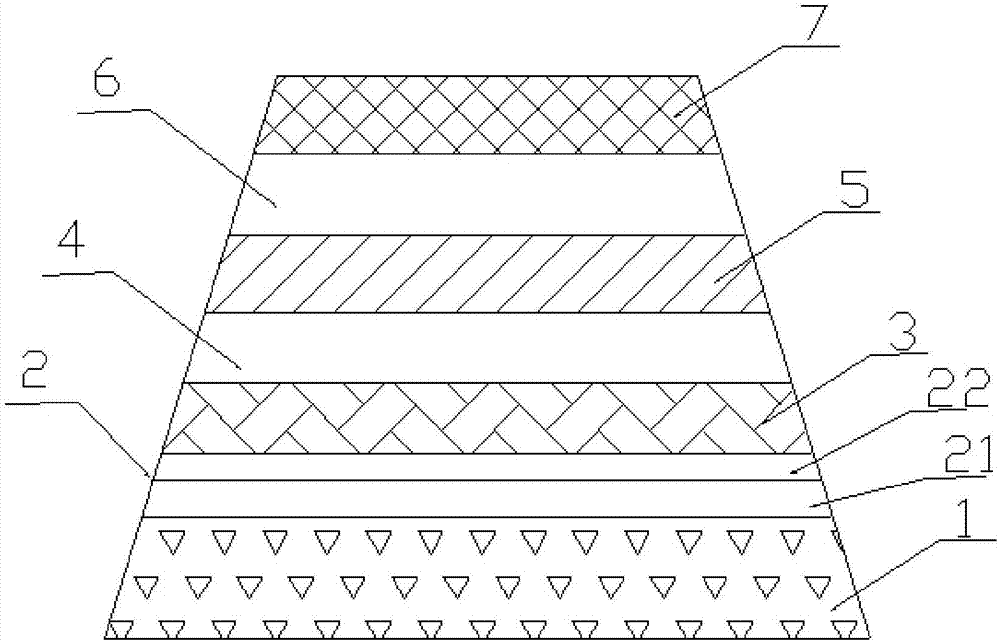

Asphalt pavement structure suitable for Tibet plateau area and construction method thereof

PendingCN106868972AImprove road performanceImprove bending deformationIn situ pavingsCushionSubgrade

The invention relates to an asphalt pavement structure suitable for the Tibet plateau area and a construction method thereof. The asphalt pavement structure suitable for the Tibet plateau area sequentially comprises a cushion layer, a semi-rigid base layer, a penetrable layer, an SBR emulsified asphalt lower sealing layer, a lower surface layer, a bonding layer and an upper surface layer from bottom to top. The construction method of the asphalt pavement structure suitable for the Tibet plateau area comprises the following steps of (1) tamping and leveling a roadbed, (2) laying the cushion layer on the roadbed, (3) laying a cement stabilized sand gravel layer on the cushion layer, (4) flatly laying a low-shrinkage super-early-strength cement stabilized macadam layer, (5) laying the penetrable layer, (6) laying the SBR emulsified asphalt lower sealing layer, (7) laying the lower surface layer, (8) laying the bonding layer, and (9) laying the upper surface layer.

Owner:青海省交通科学研究院 +1

Method for preparing wool anti-shrinking agent by using epoxy resin-modified waterborne polyurethane

The invention provides a method for preparing a wool anti-shrinking agent by using epoxy resin-modified waterborne polyurethane. The method comprises the following steps of: carrying out a reaction on toluene diisocynate (TDI) and polyethylene glycol (PEG2000) for 2 hours at 75-80 DEG C; cooling to 70-75 DEG C and then adding a chain extender 1,4-butanediol (BDO), and reacting for 1-2 hours; then adding epoxy resin E-44, a hydrophilic chain extender dimethylolpropionic acid (DMPA) and N-methylpyrrolidone, reacting for 3 hours at 65-70 DEG C, and adding an appropriate amount of acetone to control the viscosity of the reaction system; and cooling to 40 DEG C, adding triethylamine to neutralize, emulsifying in normal-temperature water, adding a chain extender ethylenediamine, adding water in the obtained emulsion to prepare aqueous solution in a solid content of 20-30%, thus obtaining the wool anti-shrinking agent. In the method provided by the invention, waterborne polyurethane is modified by epoxy resin, so that the anti-shrinking agent is good in water resistance, weather resistance and film-forming strength; wool after anti-shrinking finishing is scrub-resistant, good in anti-shrinking performance, and soft in hand feel.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

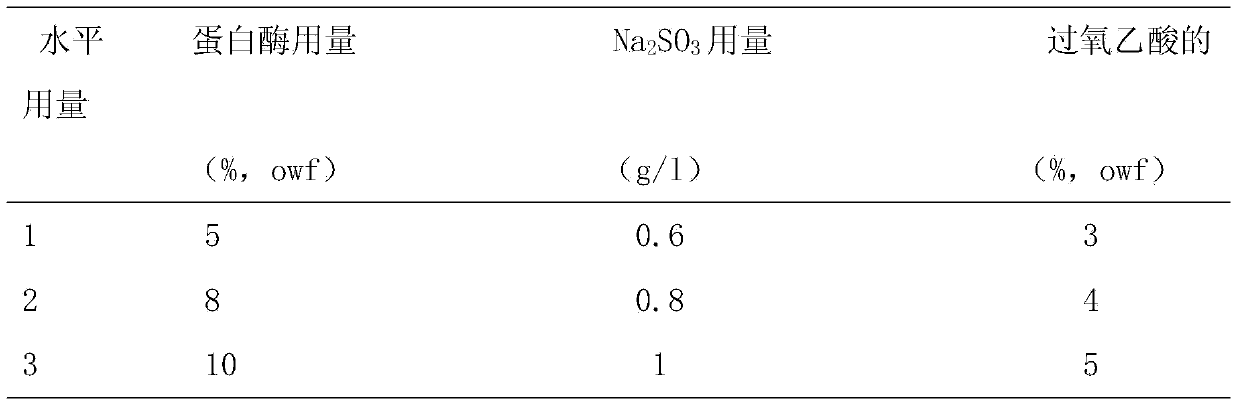

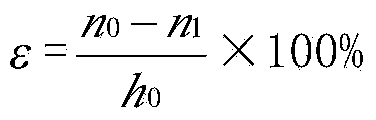

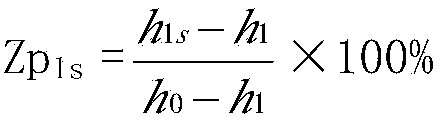

Shrinkproof treatment technology for cashmere

InactiveCN103952919AIncrease frictionImprove tensile propertiesBiochemical fibre treatmentAnimal fibresFiberWater baths

The invention provides a shrinkproof treatment technology for cashmere. The technology comprises the steps of immersing cashmere fibers in warm water, dewatering the cashmere fibers, treating the cashmere fibers in a protease solution, then dewatering the fibers after the fibers are subjected to a water bath, treating the cashmere fibers through a peracetic acid solution, and finally treating the cashmere fibers through Na2SO3 reducing treatment liquid. The cashmere is treated by the combination of protease and peracetic acid, so that an extremely good shrinkproof effect can be achieved; a treated wool product is high in friction performance, stretching performance and shrinkproof performance; furthermore, balling of a cashmere fabric can be reduced, the cashmere fabric is endowed with machine-washable and shrinkproof properties, the performance of the cashmere fabric is enhanced, and thus requirements of customers can be met.

Owner:HUZHOU FORNICE TEXTILE

Anti-crease and anti-shrink finishing process for wool fabric

InactiveCN105177989AImprove hydrophilicityGood shrink resistancePhysical treatmentAnimal fibresGlutaminaseEngineering

The invention relates to an anti-crease and anti-shrink finishing process for a wool fabric, which comprises an anti-crease and anti-shrink finishing step, a water washing step and a natural drying step and is characterized in that the anti-crease and anti-shrink finishing step comprises the procedures of firstly pretreating the wool fabric through plasma, and then treating the wool fabric pretreated by the plasma by adopting transglutaminase, wherein in transglutaminase treatment, the transglutaminase concentration is 13-25%(o.w.f), the treatment temperature is 30-45 DEG C, the treatment time is 30-50 minutes, and the treatment bath ratio is (1:15)-(1:20); and then carrying out anti-crease finishing on the wool fabric by using a specific durable anti-crease and anti-shrink finishing agent and adopting a two-soaking and two-rolling finishing process. According to the invention, the specific durable anti-crease finishing agent is added for treating the wool fabric in the anti-crease finishing process, so that the crease resistance is increased, the felting shrinkage is less than 2%, and the burst is reduced to be lower than 10%. Moreover, the finishing process is safe and environment-friendly and is an energy-saving clean wool after-finishing process.

Owner:张作玮

Green phosphate-free laundry detergent powder, and preparation method thereof

InactiveCN106854513AImprove surface activityGood ecological securityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsChemical industryPhosphate

The invention belongs to the field of daily chemical industry, and relates to a green phosphorus-free washing powder and a preparation method thereof. It is made of the following raw materials in the following weight ratio: 10-30 parts of sodium alkylbenzene sulfonate, 10-30 parts of alkyl glycoside 20 parts, 10-30 parts of sodium percarbonate, 15-25 parts of anhydrous sodium sulfate, 5-10 parts of sodium carbonate, 3-8 parts of sodium silicate, 0.5-2 parts of sodium carboxymethyl cellulose, 1-5 parts of zeolite part, 0.1-0.3 part of fluorescent whitening agent, 0.2-0.4 part of protease, and 0-0.2 part of essence. drying, pulverizing and sieving to obtain the green phosphorus-free washing powder. The invention has the advantages of low cost and simple process, and the prepared washing powder has good hard water resistance, strong decontamination ability, rich foam, mild hand washing, clean and bright clothes after washing, and long-lasting fragrance. It adopts green and environmental protection formula, and the degradation rate of raw materials is high.

Owner:XIAN WANGQING BIOTECH CO LTD

Shrinkage and pilling resistant finishing agent and preparation method thereof

ActiveCN103757889AGood shrink resistanceGood anti-pillingVegetal fibresSulfonatePolypropylene glycol

The invention provides a shrinkage and pilling resistant finishing agent and a preparation method thereof. The shrinkage and pilling resistant finishing agent comprises the following components in parts by weight: 4-6 parts of petroleum sodium sulfonate, 1-2 parts of polypropylene glycol diglycidyl ether, 3-5 parts of alanine, 2-3 parts of dioctadecyl dimethyl ammonium chloride, 7-8 parts of pentanol, 2-3 parts of potassium phosphate, 1-2 parts of sodium sulfate and 230-240 parts of water. The finishing agent is prepared by mixing and stirring the components of the finishing agent. The prepared finishing agent can be used for finishing cotton clothes and can endow the cotton clothes with good shrinkage and pilling resistance.

Owner:吴江市鼎能纺织整理有限公司

Environment-friendly PVC sealing strip and preparation method thereof

The invention provides an environment-friendly low-shrinkage PVC sealing strip. The sealing strip comprises 100 parts of PVC, 15-30 parts of EPDM rubber, 80-100 parts of a plasticizer, 8-18 parts of calcium carbonate, 8-16 parts of zinc oxide, 15-25 parts of carbon black, 6-10 parts of chlorinated paraffin, 5-8 parts of a calcium-zinc stabilizer, 0.5-2 parts of a bis(benzenesulfonyl hydrazide) ether foaming agent and 1-5 parts of a flame retardant. By unique process control in the preparation process of the sealing strip, the VOC content is reduced, and the mechanical property and the shrinkage resistance of the sealing strip are improved.

Owner:温州包鹿新材料有限公司

Slag cement modification strengthening agent

The invention relates to a steel slag cement active enhancer. The steel slag cement active enhancer is composed of potassium aluminum sulfate, ammonium aluminum sulfate, sodium metesilicate, ferrous sulfate and melamine resin, thereby leading the early stage hydration process to timely generate appropriate amount of ettringite, calcium silicate hydrate, xonotlite, gyrolite, thomsonite, natrolite, analcime, calcium iron sulfide hydrate, calcium sulphoaluminate hydrate and others to form a cross-linked frame structure and allowing the later stage to be continuously strengthened and meet the comprehensive requirements of the use. The steel slag cement active enhancer is characterized in that: the reflected strength, the coagulation time and other performances of the early stage frame structure can achieve or be higher than the performances of the same-stage general portland cement; multi-center substances which are formed by the secondary reaction and the continuous hydration and are penetrated and connected can ensure the calcium complex salt structure to be continuously thickened and strengthened; the early stage strength is high, the coagulation time is moderate, hardened cement paste and the prepared concrete have better workability, compactibility, durability, impermeability, anti-shrinkage property, corrosion resistance, anti-freeze-thaw property, anti-carbonization property and the like; the mixing amount is less, the performance to price ratio is low, the steel slag cement active enhancer has low alkali, no chlorine, no toxicity and no side effects; and the application range is wide.

Owner:李长有

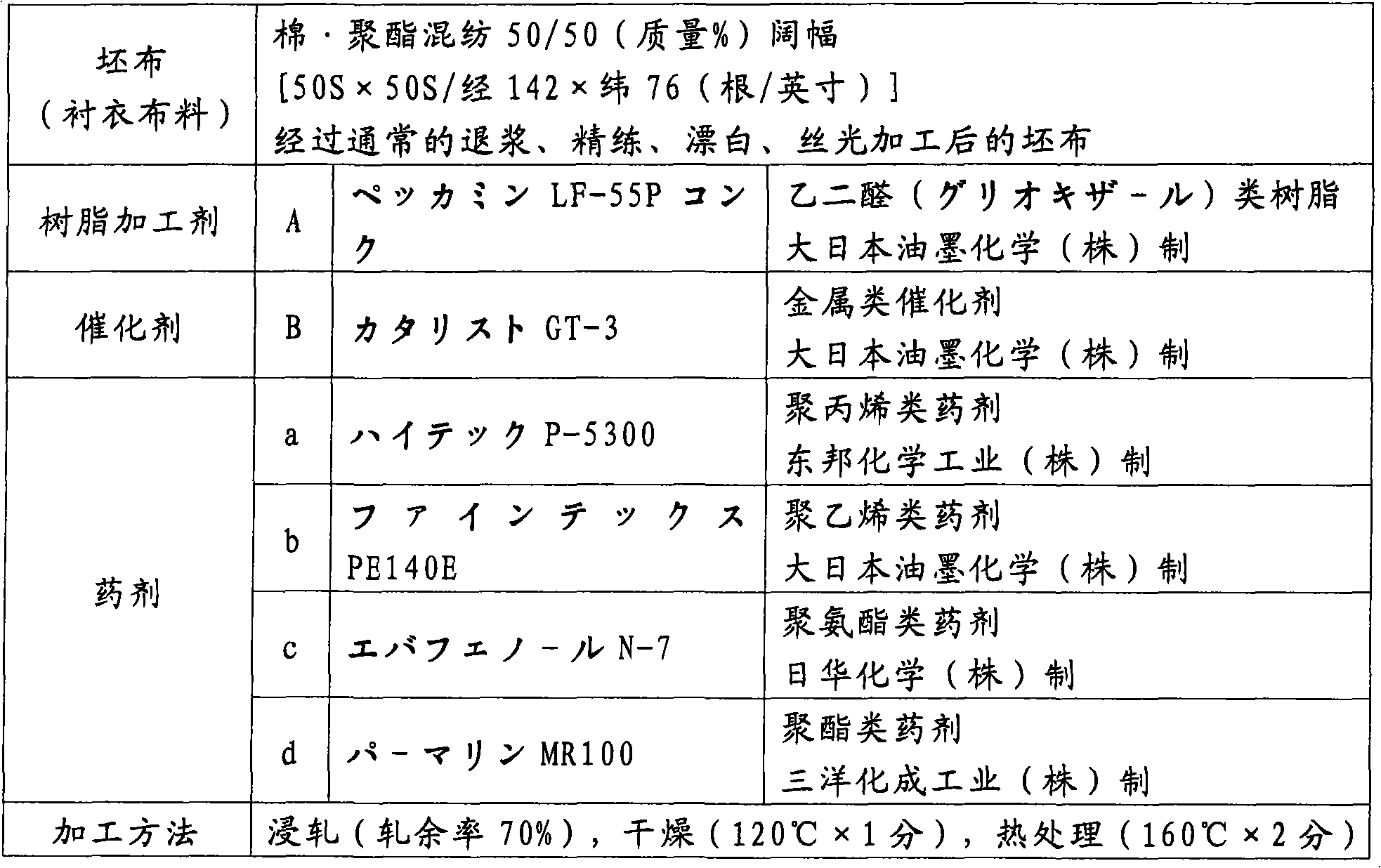

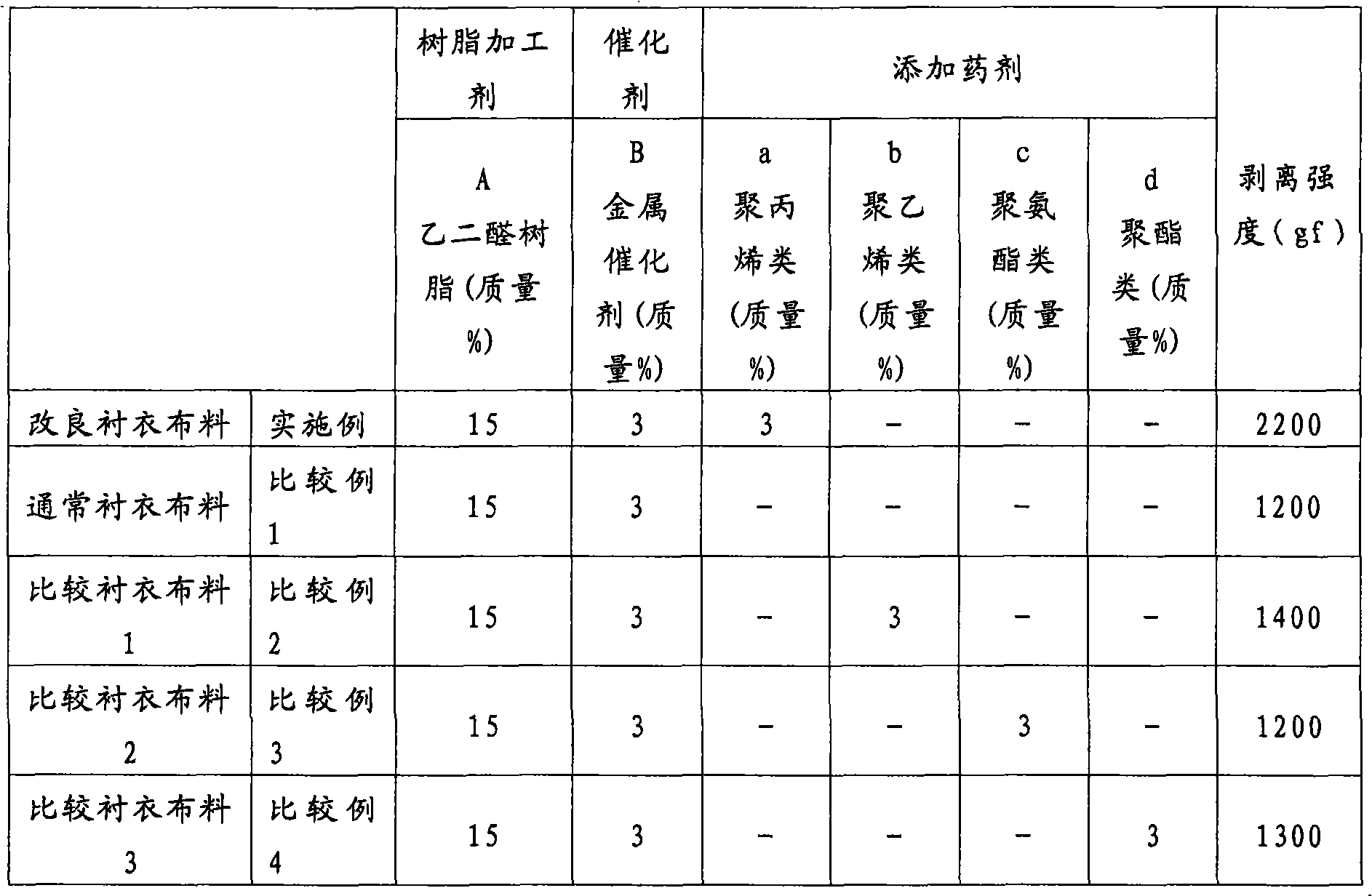

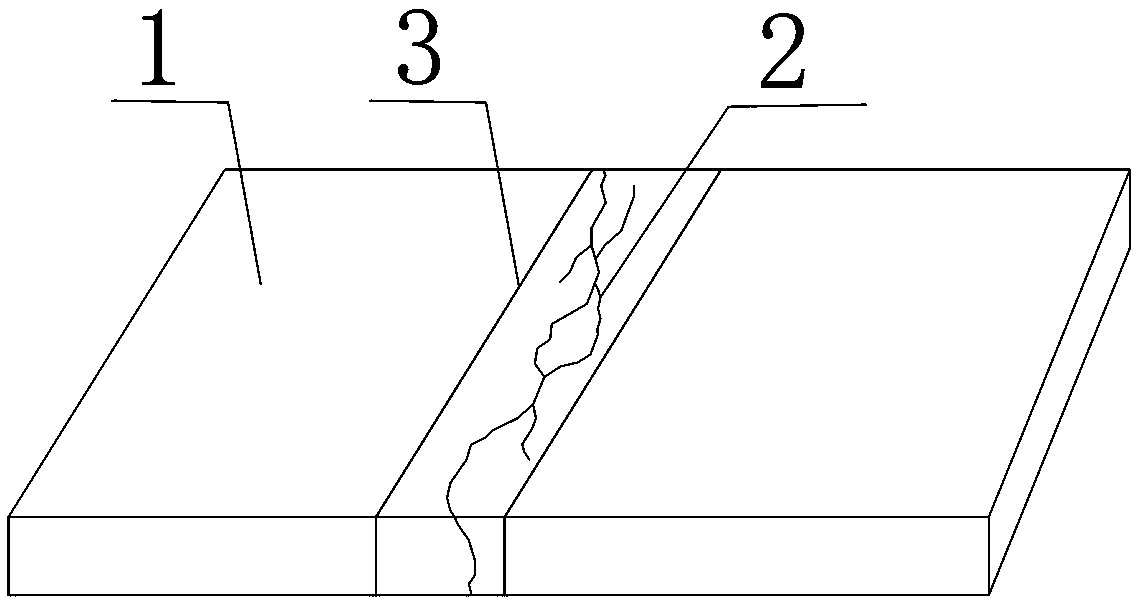

Fibre grey cloth, manufacturing method and fibre grey cloth with lapping cloth forming by bonding lapping cloth on the fibre grey cloth

The invention provides fiber grey cloth attached with given medicine and which is easy to fall off the perspiration and other dirt, has little effusion of the bond, has good contractibility to commercial washing, and has good bonding strength to lapping cloth using common bond, especially the polypropylene bond, a preparing method and the fiber grey cloth stuck with lapping cloth formed by bonding the lapping cloth on the fiber grey cloth. The solving method adopted by the invention is to use a fiber grey cloth attached with medicine having high bonding strength to the lapping cloth; the invention is characterized by attaching a medicine on the fiber grey cloth for bonding the lapping cloth by the bond; the medicine comprises polymer the same with the main component polymer of the bond.

Owner:NISSHINBO IND INC

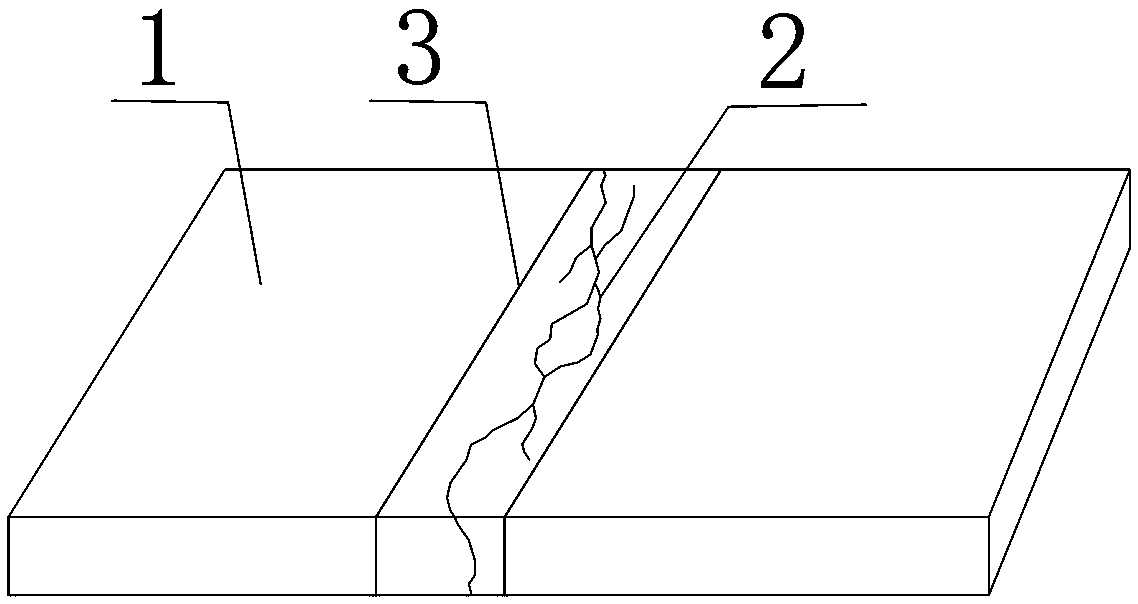

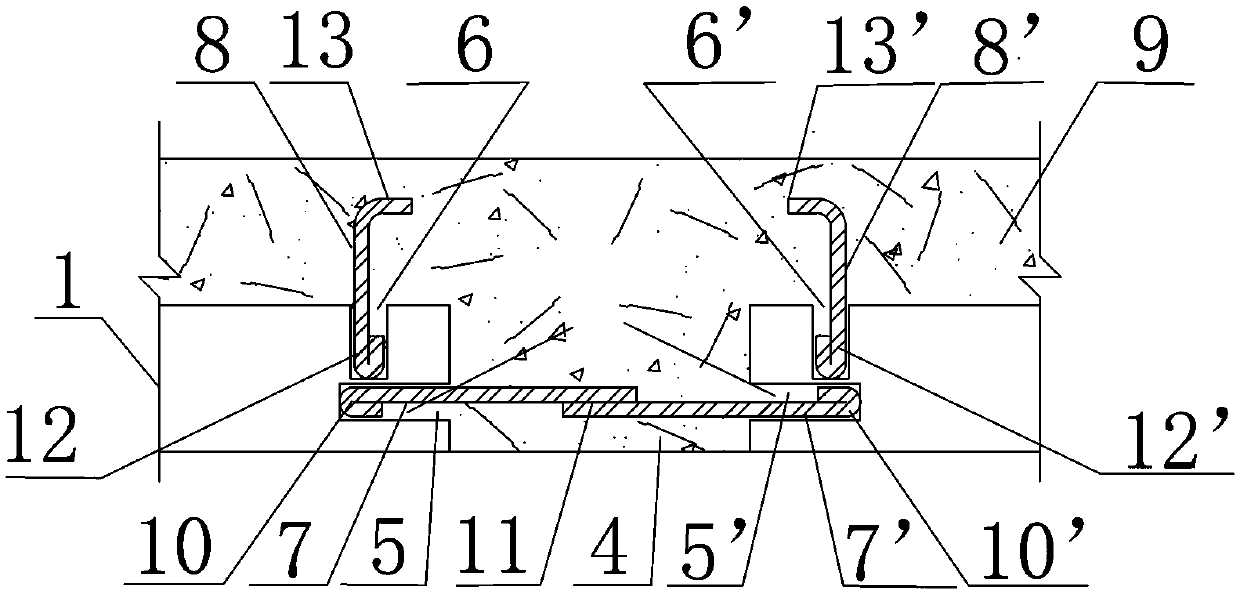

Damaged concrete pavement panel reinforcing structure and method

InactiveCN105507109ASmall shrinkage deformationImprove tensile propertiesPaving detailsWork performanceRoad surface

The invention provides a damaged concrete pavement panel reinforcing structure and method. The structure comprises a concrete pavement panel, the concrete pavement panel is provided with a reinforcing groove, a plurality of pairs of horizontal steel bar embedding holes are formed in the two walls of the reinforcing groove, and horizontal steel bars are fixedly arranged in the horizontal steel bar embedding holes; a steel fiber reinforced concrete blanket is fixedly poured over the concrete pavement panel. The method comprises the steps of 1, conducting surface debristling; 2, making the reinforcing groove and drilling the plurality of pairs of horizontal steel bar embedding holes; 3, embedding the horizontal steel bars; 4, pouring steel fiber reinforced concrete to form the steel fiber reinforced concrete blanket. By combining the horizontal steel bars with steel fiber reinforced concrete, new cement concrete and old cement concrete cooperation work performance is improved, the bearing capacity of the concrete pavement panel reinforcing area is improved, and the service life and maintenance cycle of a road are prolonged.

Owner:ZHENGZHOU UNIV

Fibre composite phosphor aluminate cement and method for preparing slurry and concrete

The present invention discloses a fiber composite phosphorus aluminate cement and preparation method for slurry and concrete. The fiber composite phosphorus aluminate cement is mainly composed of the phosphorus aluminate cement and the fiber and the weight percentage of the phosphorus aluminate cement ranges from 95.00 to 99.96, and the weight percentage of the fiber ranges from 0.04 to 5.00. Compared with the prior art, the fracture properties, impact resistance, mechanical properties such as anti-permeability, anti-shearing, etc., of the fiber composite phosphorus aluminate cement concrete of the present invention are obviously improved.

Owner:SHENZHEN UNIV

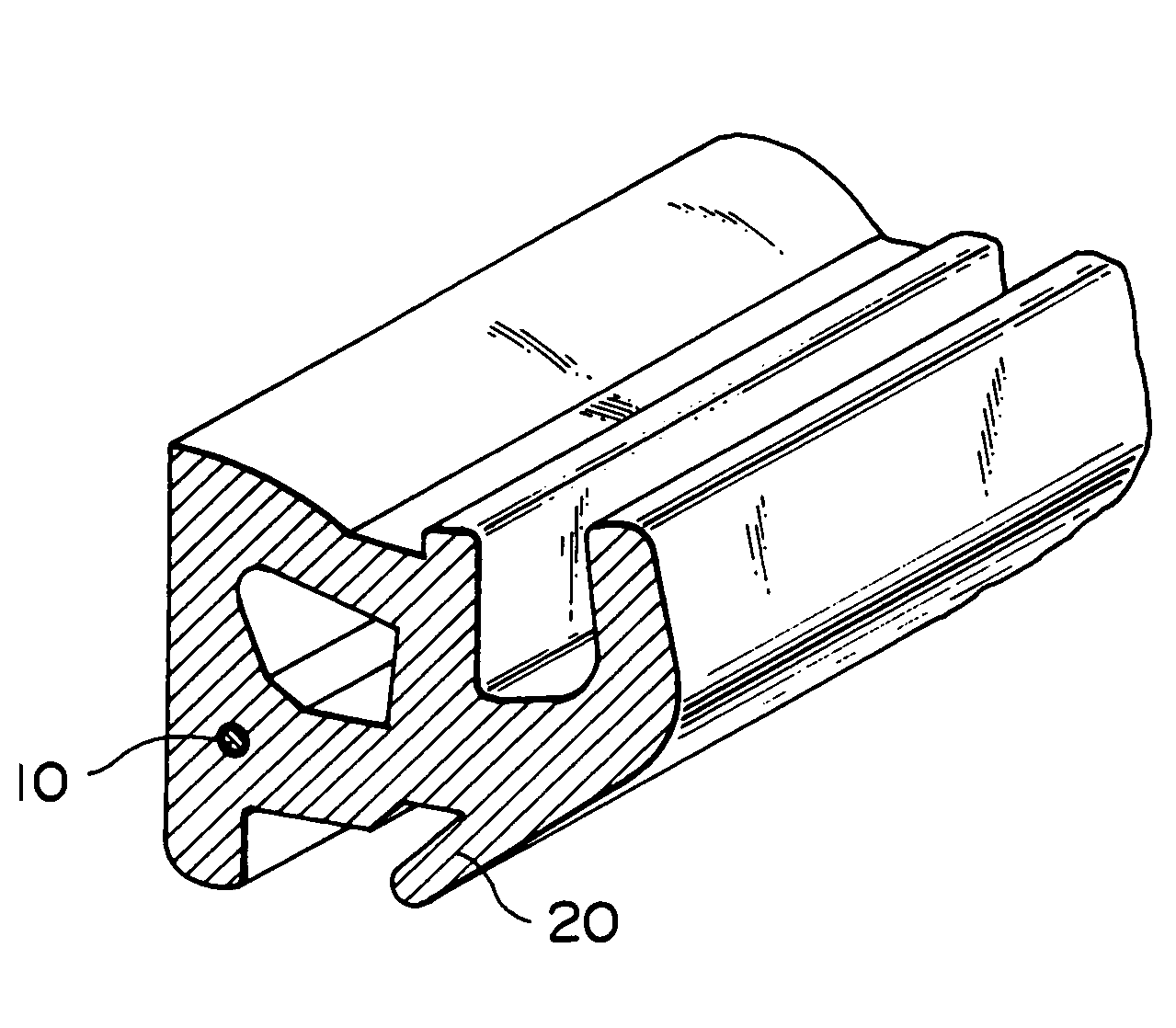

Solar-power-based sludge low-shrinkage energy-saving drying method

ActiveCN105645729APromote pore formationGood shrink resistanceSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPhotocatalytic reactionSludge

The invention relates to a solar-power-based sludge low-shrinkage energy-saving drying method. The method is characterized in that a bulking conditioner is added into sludge subjected to centrifugal dehydration, uniformly mixed and distributed, and the mixture enters a solar-power interlayer drying system; and the conditioning effect of the bulking conditioner is combined with the solar-power interlayer drying process to complete the framework establishment, bulking conditioner implantation and photocatalytic reaction, thereby implementing the low-shrinkage drying on the sludge on the premise of increasing the sludge drying rate. The bulking conditioner is formed by sufficiently and uniformly stirring the following components in percentage by mass: 40-60% of ammonium carbonate / ammonium bicarbonate, 10-20% of magnesium oxide / magnesium chloride / calcium oxide, 10-30% of Laminaria digitata powder / seaweed powder / blue algae powder and 5-10% of UEA calcium sulphoaluminate bulking agent. The addition amount of the bulking conditioner is 5-20% of the sludge on dry basis. The solar-power heating drying effect and the combined action of the bulking conditioner for conditioning the sludge are utilized, thereby establishing the sludge drying basic structure and being beneficial to the pore forming and shrinkage resistance in the subsequent sludge heat treatment.

Owner:SHANGHAI JIAO TONG UNIV

Wool fabric flame retardation finishing method

InactiveCN103981707AImprove flame retardant performanceGood shrink resistanceFibre treatmentEmulsionGraft reaction

The invention provides a wool fabric flame retardation finishing method, which comprises the following steps: A)pre-treating fabric, performing ultrasonic treatment for 30-60 minutes with frequency of 30-40 KHz; B)pre-emulsifying on a monomer: emulsifying a vinylphosphonic acid monomer by an emulsifier to form an emulsion, adjusting pH value of 3-4; C)performing a grafting reaction: heating a rolling groove filled with the monomer emulsion to the temperature of 80-90 DEG C, continuously heating to the temperature of 90-100 DEG C and reacting for 1-2 hours; D)washing; and E)drying. According to the wool fabric through the flame retardation finishing, the limited oxygen index after washing for 30 times is still at more than 27%, the wool fabric enables self-extinguishing while meeting fire, and has good perdurable flame resistance performance; the ultrasonic treatment is used for pretreatment, and is in favor of subsequent chemical grafting; simultaneously, the wool fabric through ultrasonic treatment has good shrinkproof performance and fluffy degree.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

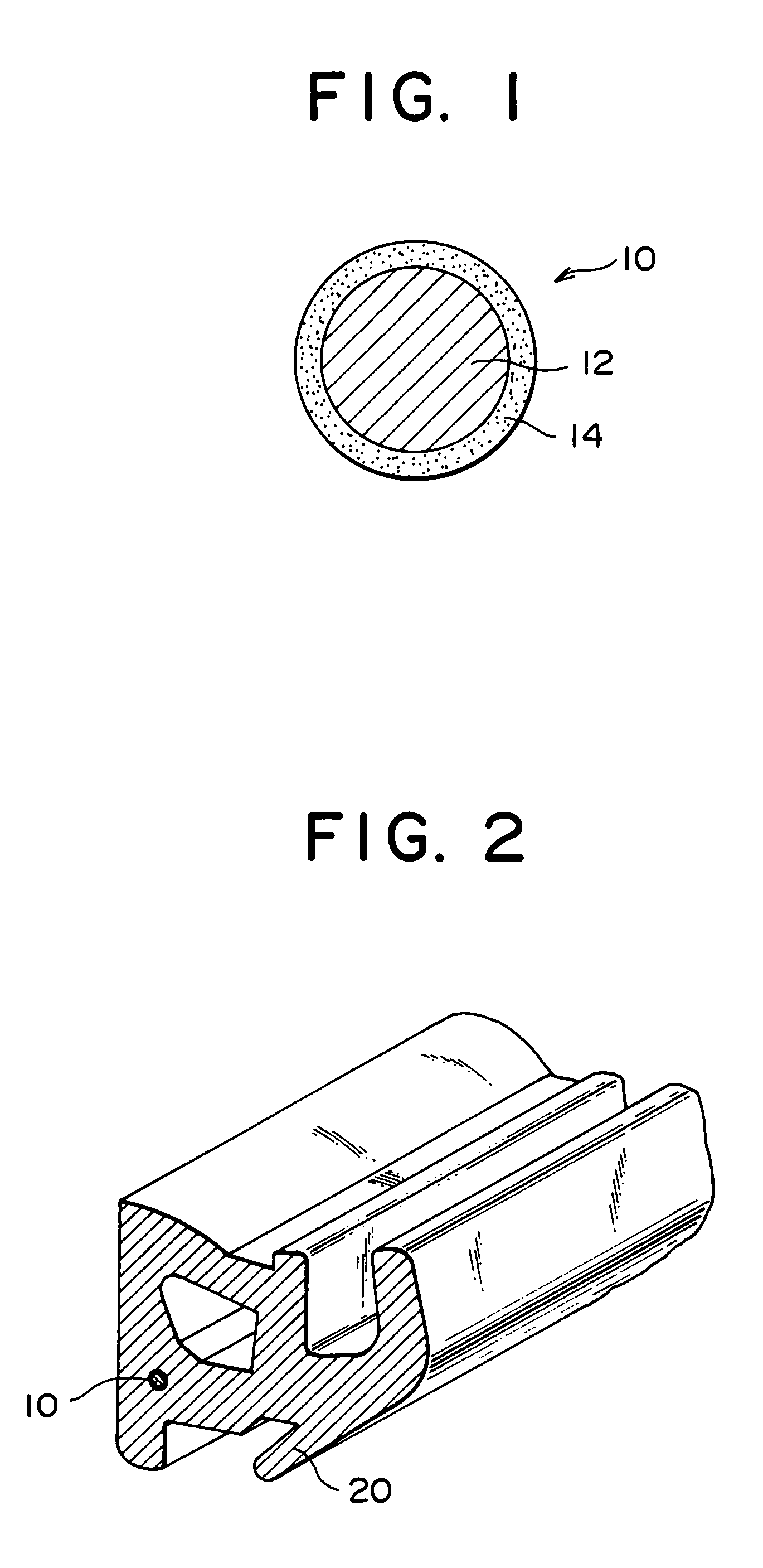

Shrinkage control material and elastomeric molding

InactiveUS6964799B1Good shrink resistanceImprove adhesionDoors/windowsCellulose adhesivesElastomerVulcanization

A shrinkage control material for elastomeric molding. On a surface of a resilient metal wire, an adhesive layer of a halogenated polymer-based or olefin-based adhesive is disposed. An elastomeric molding includes the shrinkage control material and a elastomeric extrusion formed around the shrinkage control material to cover, the elastomeric extrusion being bonded by vulcanization to the shrinkage control material.

Owner:NIPPON PURAI +1

Multifunctional after-finishing method for high count yarn tribute silk

The invention relates to a multifunctional after-finishing method for high count yarn tribute silk.The method comprises the following steps: padding a resin water repellent with the mangle expression of 85-90 percent, preliminary drying, tenter drying (the moisture content is controlled to be 10-15 percent during cropping), planishing, electric polishing, roasting at the temperature of 170-180 DEG C for 60-90 seconds, soaping, washing, neutralizing, padding in crease-resistant finishing solution, cold rolling and externally packing a plastic film, stacking at room temperature, loosening, standing for 24 hours, washing, drying, cutting, sewing, pressing at high temperature, open washing, dehydrating, and heat setting, thus obtaining the finished product. With the adoption of the working solution prepared from a mixed resin initial shrinkage body (HMM / DMEU being 1:4), a catalyst, organosilicon waterproofing agent emulsion (or water and oil repellent emulsion), the finished fabric is smooth in surface, bright, soft, smooth and real in handfeel and good in waterproof and crease-resistant properties.

Owner:GUANGZHOU GEFENG FASHION CO LTD

Reinforcing structure and method for damaged concrete pavement panel

InactiveCN105507110AImprove the anchoring effectEffective anchoringPaving detailsRoad surfaceFace sheet

The invention provides a reinforcing structure and method for a damaged concrete pavement panel. The reinforcing structure for the damaged concrete pavement panel comprises the concrete pavement panel with the planed surface, a reinforcing groove, multiple pairs of horizontal rebar embedding holes, and vertical rebar embedding holes. The horizontal rib embedding holes are formed in the two groove walls of the reinforcing groove, and the vertical rib embedding holes are formed in the concrete pavement panel. Horizontal rebars are fixedly arranged in the horizontal rebar embedding holes, vertical rebars are fixedly arranged in the vertical rebar embedding holes, and a steel fiber reinforced concrete cover is poured and fixed to the concrete pavement panel. The reinforcing method for the damaged concrete pavement panel includes the following steps that 1, surface planing is conducted; 2, the reinforcing groove is formed, and the multiple pairs of horizontal rebar embedding holes and the multiple pairs of vertical rebar embedding holes are drilled; 3, construction glue is poured, and the horizontal rebars and the vertical rebars are embedded; 4, steel fiber reinforced concrete is poured to form the steel fiber reinforced concrete cover. The bearing capacity of the concrete pavement panel is increased, the service life and the maintenance period of a road are prolonged, and the long-term use cost is reduced.

Owner:ZHENGZHOU UNIV

Anti-shrinkage anti-pilling wool fabric finishing agent and preparation method thereof

InactiveCN105019226AGood anti-pillingGood shrink resistanceFibre treatment(Hydroxyethyl)methacrylatePolyethylene glycol

The invention belongs to the field of finishing agents and discloses an anti-shrinkage anti-pilling wool fabric finishing agent and its preparation method. The finishing agent comprises 9-15 parts of sodium tripolyphosphate, 4-8 parts of fenugreek gum, 3-6 parts of polyethylene glycol, 5-11 parts of hydroxyethyl methylacrylate, 4-7 parts of allyl glycidyl ether, 4-9 parts of sodium N-oleoyl-N-methyl taurinate, 3-6 parts of n-butanol and 240-350 parts of water. The preparation method comprises the following steps: (1) sodium tripolyphosphate, fenugreek gum, polyethylene glycol, hydroxyethyl methylacrylate and allyl glycidyl ether are uniformly stirred to obtain a material A; (2) sodium N-oleoyl-N-methyl taurinate, n-butanol and water are uniformly mixed to obtain a material B; and (3) the material A obtained after uniformly-stirred in the step (1) is put into the material B to obtain a mixture, and the mixture is stirred, sheared and stored so as to obtain the anti-shrinkage anti-pilling wool fabric finishing agent.

Owner:SUZHOU INST OF TRADE & COMMERCE

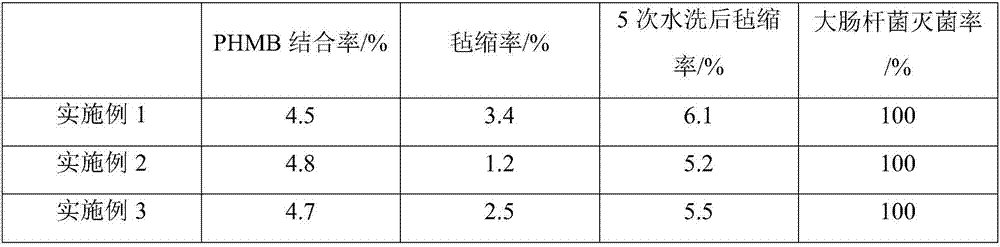

Antibacterial anti-shrinkage finishing process of wool fabric

InactiveCN107956109AImprove antibacterial propertiesGood shrink resistanceAnimal fibresEngineeringWool

The invention discloses an antibacterial anti-shrinkage finishing process of a wool fabric. The process comprises the steps of pretreatment, antibacterial finishing, anti-shrinkage finishing and the like. (1) According to the finishing process of the invention, an immersion treatment way is mainly used, an antibacterial anti-shrinkage finishing solution can be easily arranged on the surface of thewool fabric by virtue of a series of pretreatment steps; and (2) the wool fabric after being finished by the finishing process of the invention has good antibacterial and anti-shrinkage performance,and the antibacterial durability and size stability of the fabric after being repeatedly washed are relatively good.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

Fixing and suturing method for preventing wound skin shrinkage of rodents and application of fixing and suturing method

The invention provides a fixing and suturing method for preventing wound skin shrinkage of rodents and an application of the fixing and suturing method. The method comprises the following steps of annularly cutting off dartos of which the width is 2-3mm along the wound margins of the wound skin of the rodents, enabling the outer diamter of a steel ring to coincide with the edge of the cut-off dartos, and fixing the stell ring, the skin, the dartos and subcutaneous tissue in a suturing manner by a continuous hemstitch suturing method. The fixing and suturing method is notable in shrinkage preventing effects, can reduce the shrinkage of wound surfaces of rats to the maximum extent without influencing epithelium creepage, and does not influence the healing quality of the wound surfaces. A shrinkage preventing model prepared by the method can effectively simulate a wound healing mechanism, can accurately assess the crust creepage process of the wound healing process, can well observe the derma remodeling process, can be used as a good model for researching the wound healing, and can be used as a platform for assessing various factors influencing wound healing. The method has high application value in the respect of scientific research.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com