Shrinking-proof polyethylene terephthalate (PET) laser transfer base film and method for preparing same

A technology of laser transfer and anti-shrinkage, which is applied in the direction of chemical instruments and methods, flat products, and other household appliances, etc., can solve the problems that affect the wide application of PET laser transfer film products, increase the waste rate of cigarette packs, and inconvenient production and processing, etc., to achieve Excellent anti-shrinkage performance, good thermal stability, clear embossing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

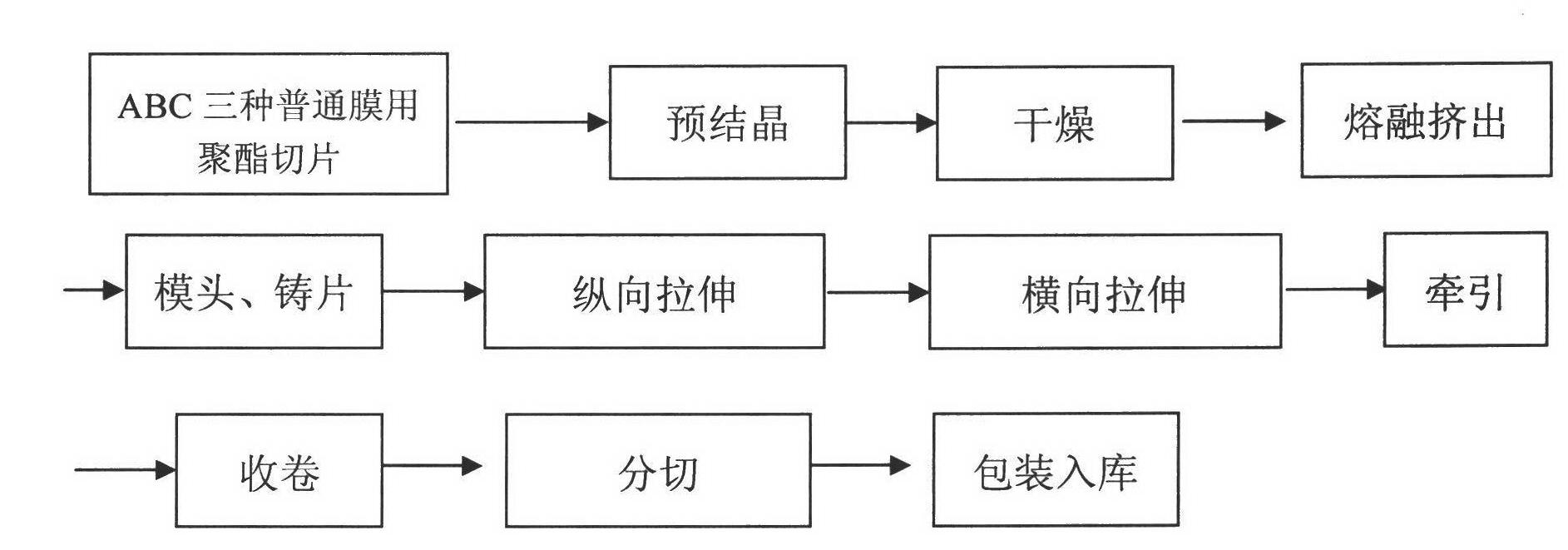

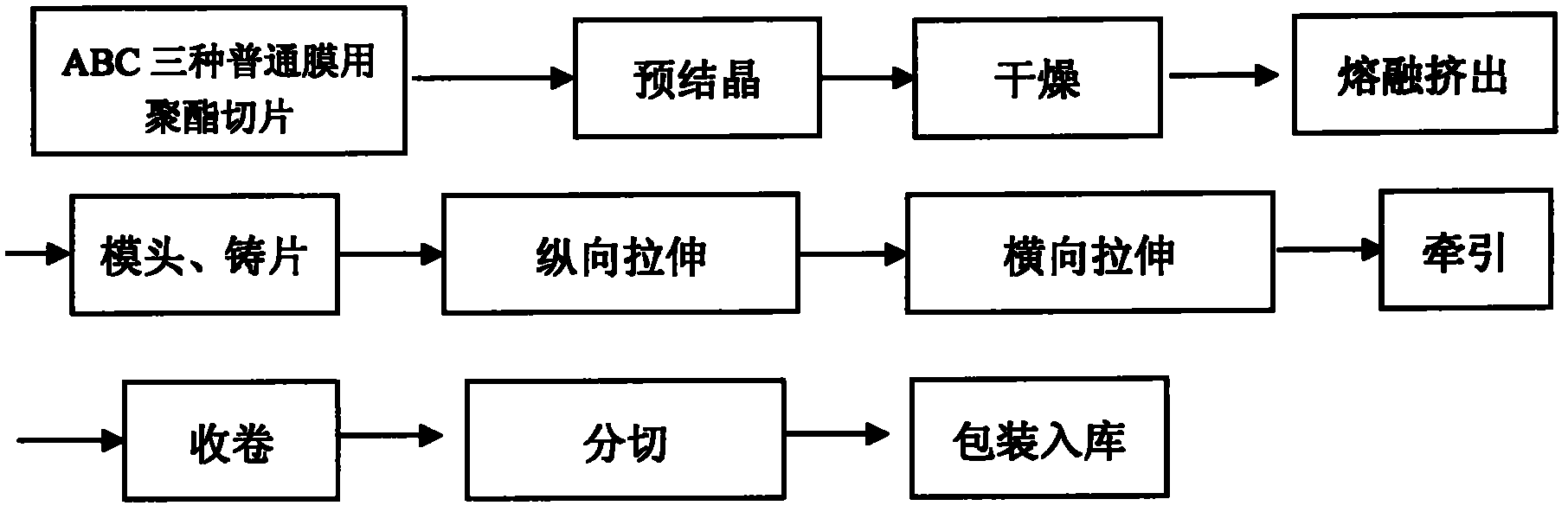

[0045] 1. Slicing and mixing:

[0046] Using polyester chips for films containing 25% anti-adhesive agents, polyester chips for films containing 20% anti-adhesive agents and polyester chips for films containing 20% thermally stable anti-adhesive agents as raw materials, through pre-processing crystallization, drying;

[0047] 2. Melting and extrusion:

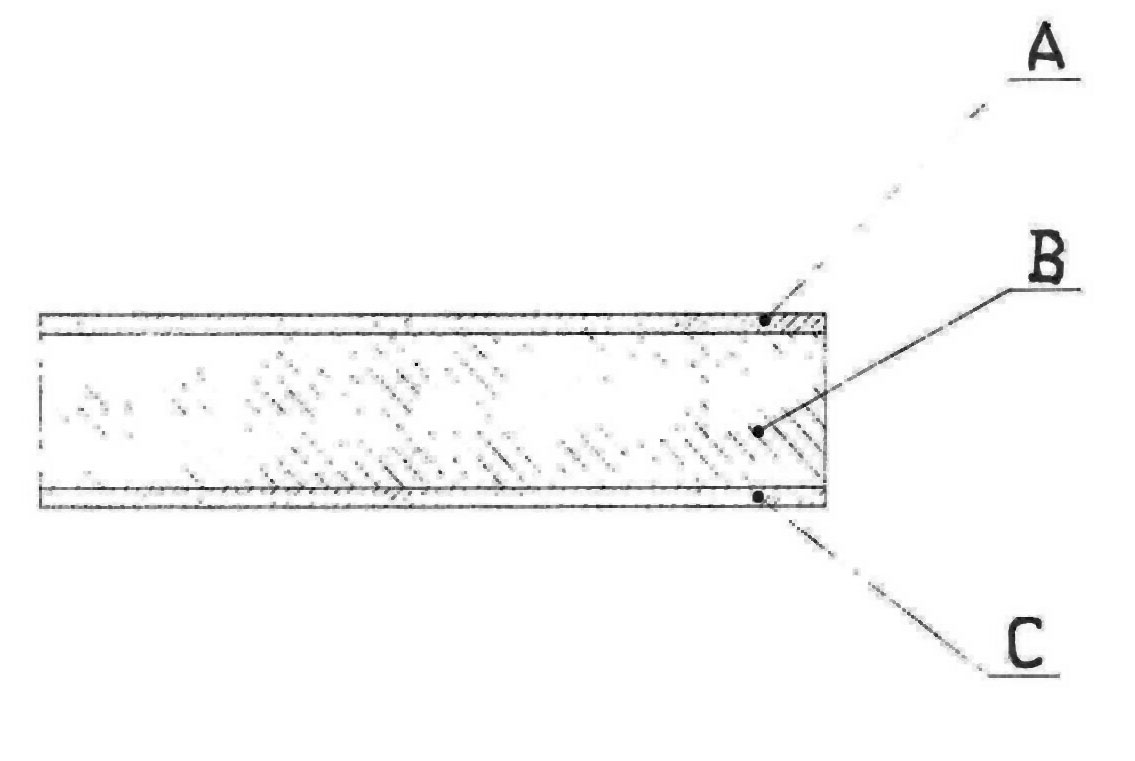

[0048] Put the components of A, B, and C layers into the corresponding twin-screw extruders according to the above weight percentages, and heat the heating zones of the main extruder and the auxiliary extruder to 275-285°C to make the raw materials Melt extrusion; the components of each layer are: A layer: 75% polyester for film; 25% anti-adhesive; B layer: 85% polyester for film; 15% thermally stable anti-adhesive; C layer : 80% polyester for film; 20% anti-adhesive;

[0049] 3. Die casting sheet:

[0050] The melt flowing out of the die is rapidly cooled and solidified on the surface of the casting roll to form a thic...

Embodiment 2

[0066] 1. Slicing and mixing:

[0067] It is made of polyester chips for film containing 35% anti-adhesive agent, polyester chip for film with 30% anti-adhesive agent and polyester chip for film with 17% heat-stable anti-adhesive agent. Pre-crystallized, dried,

[0068] 2. Melting and extrusion:

[0069] Put the components of A, B, and C layers into the corresponding twin-screw extruders according to the above weight percentages, and heat the heating zones of the main extruder and the auxiliary extruder to 275-285°C to make the raw materials Melt extrusion; the components of each layer are: A layer: 55% polyester for film; 45% anti-adhesive; B layer: 82% polyester for film; 20% thermally stable anti-adhesive; C layer : Film polyester 65%; anti-adhesive 35%;

[0070] 3. Die casting sheet:

[0071] The melt flowing out of the die is rapidly cooled and solidified on the surface of the casting roll to form a thick sheet;

[0072] 4. Longitudinal stretching:

[0073] Stretch ...

Embodiment 3

[0086] 1. Slicing and mixing:

[0087] It is made of polyester chips for films containing 45% anti-adhesive agent, polyester chips for films containing 35% anti-adhesive agent and polyester chips for film containing 15% thermally stable anti-adhesive agent. pre-crystallization, drying;

[0088] 2. Melting and extrusion:

[0089] Put the components of A, B, and C layers into the corresponding twin-screw extruders according to the above weight percentages, and heat the heating zones of the main extruder and the auxiliary extruder to 275-285°C to make the raw materials Melt extrusion; the components of each layer are: A layer: 55% polyester for film; 45% anti-adhesive; B layer: 82% polyester for film; 20% thermally stable anti-adhesive; C layer : Film polyester 65%; anti-adhesive 35%;

[0090] 3. Die casting sheet:

[0091] The melt flowing out of the die is rapidly cooled and solidified on the surface of the casting roll to form a thick sheet;

[0092] 4. Longitudinal stret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com