Noniron finishing method of silk fabric

A non-iron finishing and silk technology, applied in fiber treatment, animal fiber, biochemical fiber treatment, etc., can solve the problems of ineffectiveness and great influence on silk performance, and achieve the advantages of improving wrinkle resistance, retaining hand feeling, and improving mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

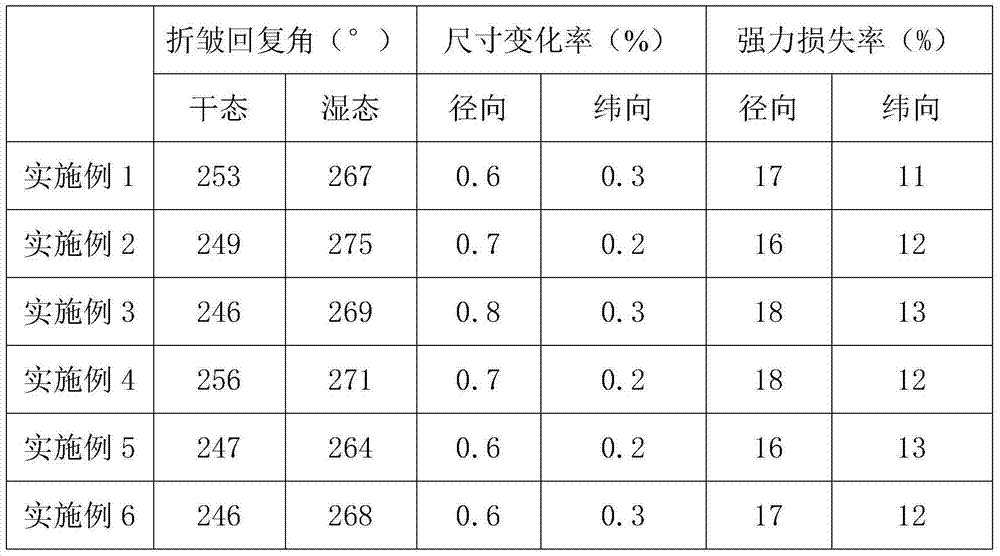

Examples

Embodiment 1

[0028] Wash the silk fabric twice with water at 45°C, refine and puff it with a pH value of 6.5, 2% (owf) IndisAeg super enzyme solution at 60°C for 20 minutes, and then rinse it with water at 35°C for 3 minutes to obtain puffed silk fabrics .

[0029] Dissolve the waste silk to obtain a 3% silk fibroin solution with a molecular weight of 50-100kDa, add 3% citric acid and 5g / L quaternary ammonium chitosan, mix well, and then add a penetrant in an amount of 5g / L , the consumption of softening agent is 2g / L, stirs to obtain non-ironing finishing agent.

[0030] Immerse the puffed silk fabric in the non-ironing finishing agent, bath ratio 1:30, dip for 5 minutes at 25°C, the padding rate is 70%, pre-steam the padded silk fabric with a mixture of ethanol and water at 75°C Bake for 5 minutes, the water content of the silk fabric is 15%, then the silk fabric is subjected to constant temperature tentering at 120° C. for 10 seconds, then baked at 120° C. for 3 minutes, finally washed...

Embodiment 2

[0032] The silk fabric was washed twice with water at 55°C, refined and puffed with a 3% (owf) trypsin solution at 60°C for 20 minutes with a pH value of 6.5, and then rinsed with water at 40°C for 2 minutes to obtain puffed silk fabrics.

[0033] Dissolving waste silk to obtain a 5% silk fibroin solution with a molecular weight of 50-100kDa, adding 4% citric acid and 5g / L quaternary ammonium chitosan, mixing evenly, and stirring to obtain a non-ironing finishing agent.

[0034] Immerse the puffed silk fabric in the non-ironing finishing agent, bath ratio 1:30, dip for 5 minutes at 30°C, the padding rate is 85%, pre-steam the padded silk fabric with a mixture of ethanol and water at 75°C Bake for 5 minutes, the moisture content of the silk fabric is 20%, then the silk fabric is subjected to constant temperature tentering at 100° C. for 10 seconds, then baked at 120° C. for 2 minutes, finally washed, dried, ironed and packaged to obtain a non-ironing silk fabric.

Embodiment 3

[0036] The silk fabric was washed twice with 50°C water, refined and puffed at 60°C with a pH value of 6.5, 2.5% (owf) trypsin solution at 60°C for 20 minutes, and then rinsed with 36°C water for 2 minutes to obtain puffed silk fabrics.

[0037] Dissolve the waste silk to obtain a 4% silk fibroin protein solution with a molecular weight of 50-100kDa, add 3% citric acid, 5g / L quaternary ammonium chitosan, mix well, and then add a penetrating agent in an amount of 2g / L , the consumption of softening agent is 1g / L, stirs to obtain non-ironing finishing agent.

[0038] Immerse the puffed silk fabric in the non-ironing finishing agent, bath ratio 1:30, dip for 5 minutes at 25°C, the padding rate is 80%, pre-steam the padded silk fabric with a mixture of ethanol and water at 75°C Bake for 5 minutes, the moisture content of the silk fabric is 17%, then the silk fabric is subjected to constant temperature tentering at 115° C. for 11 seconds, then baked at 120° C. for 2 minutes, finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com