Antibacterial anti-shrinkage finishing process of wool fabric

A technology of anti-shrinkage finishing and fabric, which is applied in the field of antibacterial and anti-shrinkage finishing technology and functional wool fabrics, which can solve the problems that wool textiles cannot be combined and reacted, and antibacterial wool textiles have not been commercialized on a large scale, so as to achieve good antibacterial and anti-shrinkage Excellent performance, antibacterial durability and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

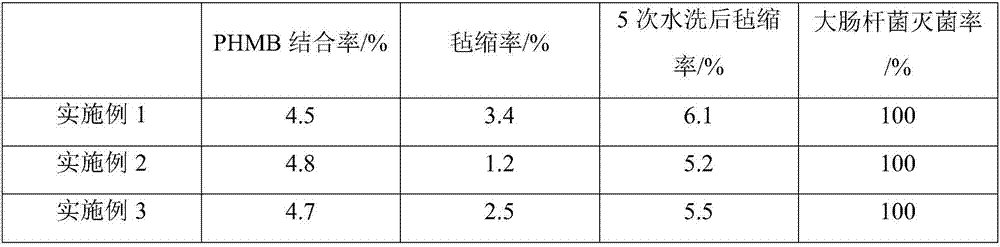

Examples

Embodiment 1

[0016] A kind of antibacterial anti-shrinkage finishing technology of wool fabric, described technology comprises the following steps:

[0017] (1) The wool fabric is placed in a 16% aqueous solution of sodium hydroxide, and carried out an alkalization reaction at room temperature for 1.5 hours. After the reaction, adding a volume fraction of 4% hydrochloric acid neutralizes the residual sodium hydroxide , repeatedly washed with deionized water, and dried naturally;

[0018] (2) Immerse the wool fabric treated in step (1) in the finishing solution A, the bath ratio of the fabric and the finishing solution A is 1:25, the reaction temperature is 25°C, the pH is 8.0, and the reaction time is 30min. Rinse with deionized water and dry at 80°C;

[0019] (3) Soak the wool fabric finished in step (2) in the finishing solution B, the bath ratio of the fabric to the finishing solution B is 1:40, the reaction temperature is 40°C, the reaction time is 25min, and immediately put it in an ...

Embodiment 2

[0026] A kind of antibacterial anti-shrinkage finishing technology of wool fabric, described technology comprises the following steps:

[0027] (1) The wool fabric is placed in a 28% sodium hydroxide aqueous solution by mass fraction, and carried out an alkalization reaction at room temperature for 2.5 hours. After the reaction, adding a volume fraction of 7% hydrochloric acid to neutralize the residual sodium hydroxide , repeatedly washed with deionized water, and dried naturally;

[0028] (2) Immerse the wool fabric treated in step (1) in the finishing solution A, the bath ratio of the fabric and the finishing solution A is 1:28, the reaction temperature is 30°C, the pH is 8.3, and the reaction time is 45min. Rinse with deionized water and dry at 80°C;

[0029] (3) Dip the woolen fabric finished in step (2) into the finishing solution B, the bath ratio of the fabric to the finishing solution B is 1:45, the reaction temperature is 45°C, the reaction time is 30min, and immedi...

Embodiment 3

[0036] A kind of antibacterial anti-shrinkage finishing technology of wool fabric, described technology comprises the following steps:

[0037] (1) The wool fabric is placed in a 40% aqueous sodium hydroxide solution by mass fraction, and carried out an alkalization reaction at room temperature for 4 hours. After the reaction, adding a volume fraction of 11% hydrochloric acid to neutralize residual sodium hydroxide , repeatedly washed with deionized water, and dried naturally;

[0038] (2) Immerse the wool fabric treated in step (1) in the finishing solution A, the bath ratio of the fabric and the finishing solution A is 1:30, the reaction temperature is 35°C, the pH is 8.5, and the reaction time is 60min. Rinse with deionized water and dry at 80°C;

[0039] (3) Soak the woolen fabric finished in step (2) in the finishing solution B, the bath ratio of the fabric to the finishing solution B is 1:50, the reaction temperature is 50°C, the reaction time is 40min, and it is placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com