Shrinkproof treatment technology for cashmere

A technology of anti-shrinkage treatment and process, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

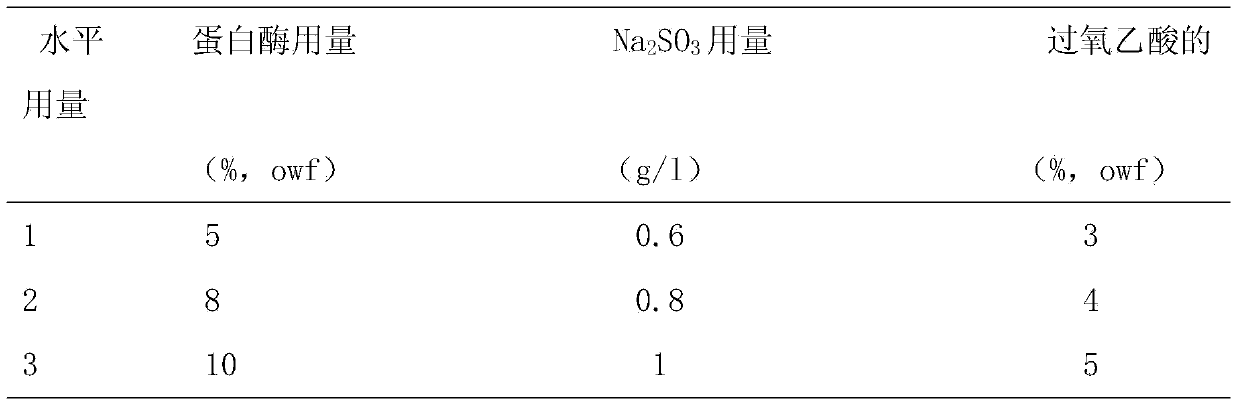

Examples

Embodiment 1

[0060] The cashmere anti-shrinkage treatment process is as follows: soak the cashmere fibers in warm water at 30°C for 25 minutes, dehydrate them, put them in a 10% owf protease enzyme solution, treat them at a temperature of 50°C for 50 minutes, and place them in a water bath at 80°C Treat in medium for 10 minutes, dehydrate with centrifuge; place in 3% owf peracetic acid solution, treat for 40 minutes at a temperature of 30-60°C, keep the pH value at about 4, and then dehydrate with a centrifuge; place in 1g / Na of L 2 SO 3 In the reduction treatment solution, treat at 30°C for 15 minutes, then wash with water three times at 25°C, and dry to obtain. In the above solutions, the bath ratio is 1:50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com