Integrated nano inorganic wall light heat insulation facing section bar and preparation thereof

A nano-inorganic, integrated technology, applied in the field of building wall insulation materials, can solve the problems of unsafe construction, falling off, easy cracking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

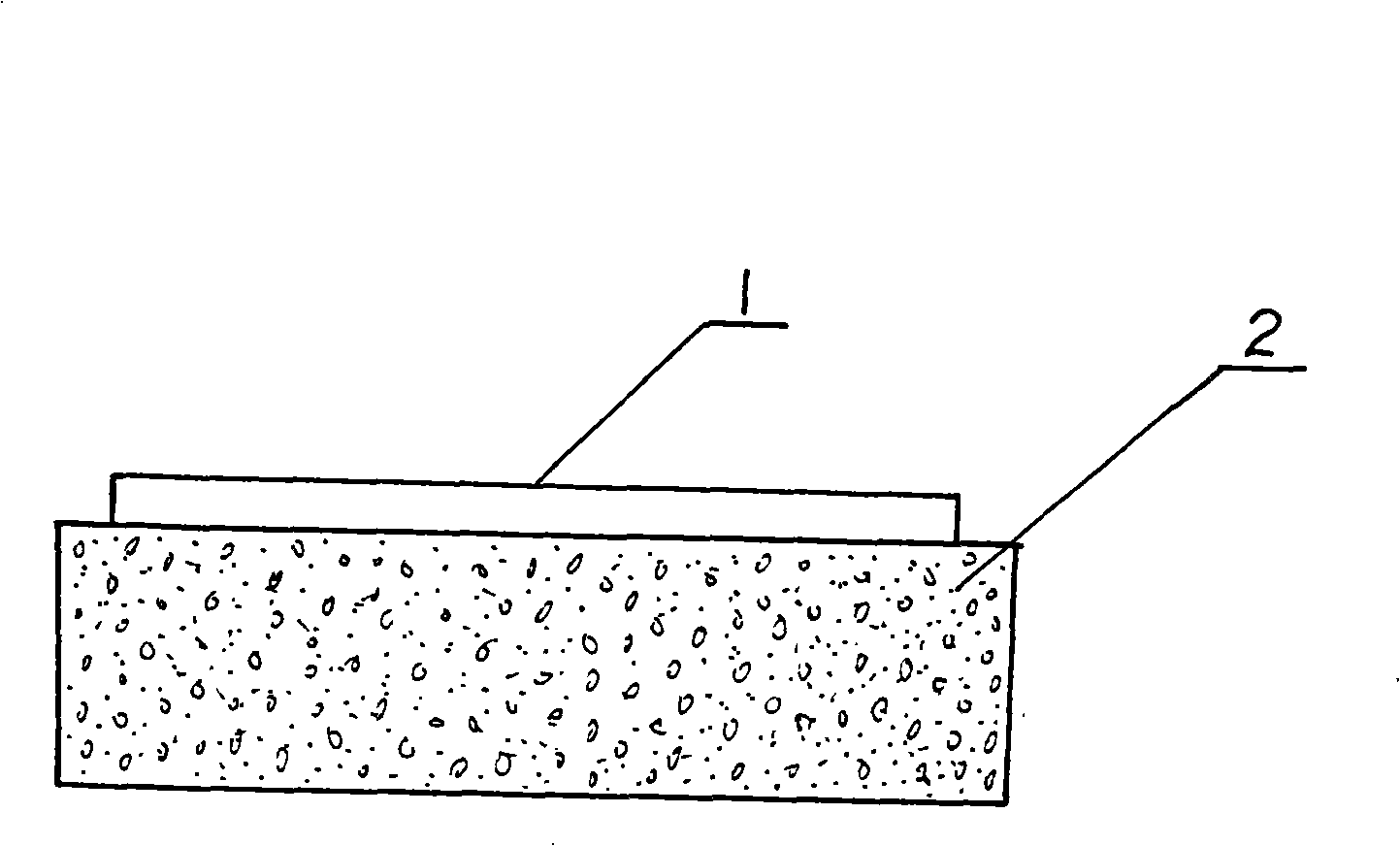

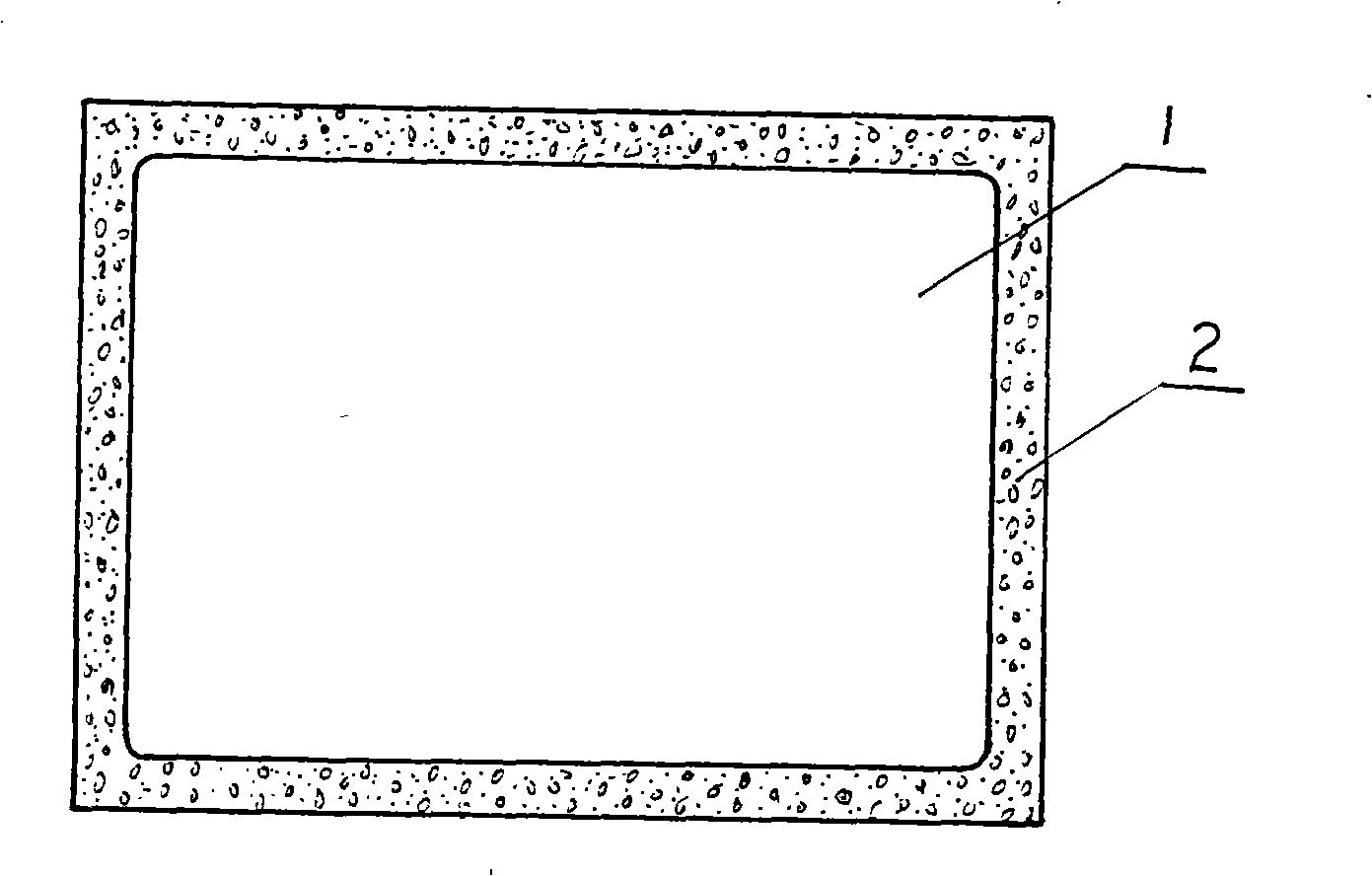

[0033] In the integrated nano-inorganic wall light heat-preservation facing profile of the present invention, the weight ratio of each component raw material in the heat-resisting matrix 2 can be: 50 parts of fruit shell type expanded perlite light aggregate, 8 parts of cement, oxidized 3 parts of silicon micropowder, 3 parts of wood fiber micropowder, 0.5 part of organic silicon emulsion, 1 part of cement reinforcing agent; the weight ratio of each component raw material in the facing layer 1 can be: 40 parts of quartz sand, 8 parts of calcium carbonate, 8 parts of calcium oxide, 8 parts of cement, 3 parts of silicon oxide micropowder, 0.8 part of wood fiber micropowder; the weight ratio of the dry material state between the heat preservation matrix 2 and the finish layer 1 can be: heat preservation matrix: finish layer=100:5 . Wherein the silicon oxide micropowder and wood fiber micropowder can adopt the nanoscale superfine micropowder whose particle diameter is 50nm.

[00...

Embodiment 2

[0037] In the integrated nano-inorganic wall light-weight heat-preservation facing profile of the present invention, the weight ratio of each component raw material in the heat-insulation matrix 2 can be: 60 parts of fruit shell type expanded perlite light aggregate, 12 parts of cement, oxidized 4 parts of silicon micropowder, 4 parts of wood fiber micropowder, 0.7 part of organic silicon emulsion, 2 parts of cement reinforcing agent; 12 parts of calcium oxide, 12 parts of cement, 4 parts of silica micropowder, 1.0 part of wood fiber micropowder; the weight ratio of the dry material state between the heat preservation matrix and the finish layer can be: heat preservation matrix: finish layer=100:10. Wherein the silicon oxide micropowder and wood fiber micropowder can adopt the nanoscale superfine micropowder whose particle diameter is 100nm.

[0038] The preparation method of this thermal insulation facing profile is basically the same as that of Example 1, the only difference...

Embodiment 3

[0040] In the integrated nano-inorganic wall light heat-preservation facing profile of the present invention, the weight ratio of each component raw material in the heat-resisting matrix 2 can be: 70 parts of fruit shell type expanded perlite light aggregate, 15 parts of cement, oxidized 5 parts of silicon micropowder, 5 parts of wood fiber micropowder, 0.8 part of organic silicon emulsion, 3 parts of cement reinforcing agent; 15 parts of calcium oxide, 15 parts of cement, 5 parts of silicon oxide micropowder, 1.2 parts of wood fiber micropowder; the weight ratio of the dry material state between the heat preservation matrix 2 and the finish layer 1 can be: heat preservation matrix: finish layer=100:20 . Wherein the silicon oxide micropowder and lignofiber micropowder can adopt the nanoscale superfine micropowder whose particle diameter is 1000nm.

[0041] The preparation method of this thermal insulation facing profile is basically the same as that of Example 1, the only dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com