Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "High decolorizing power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190BStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberSodium Bentonite

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190AStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberAdhesive

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

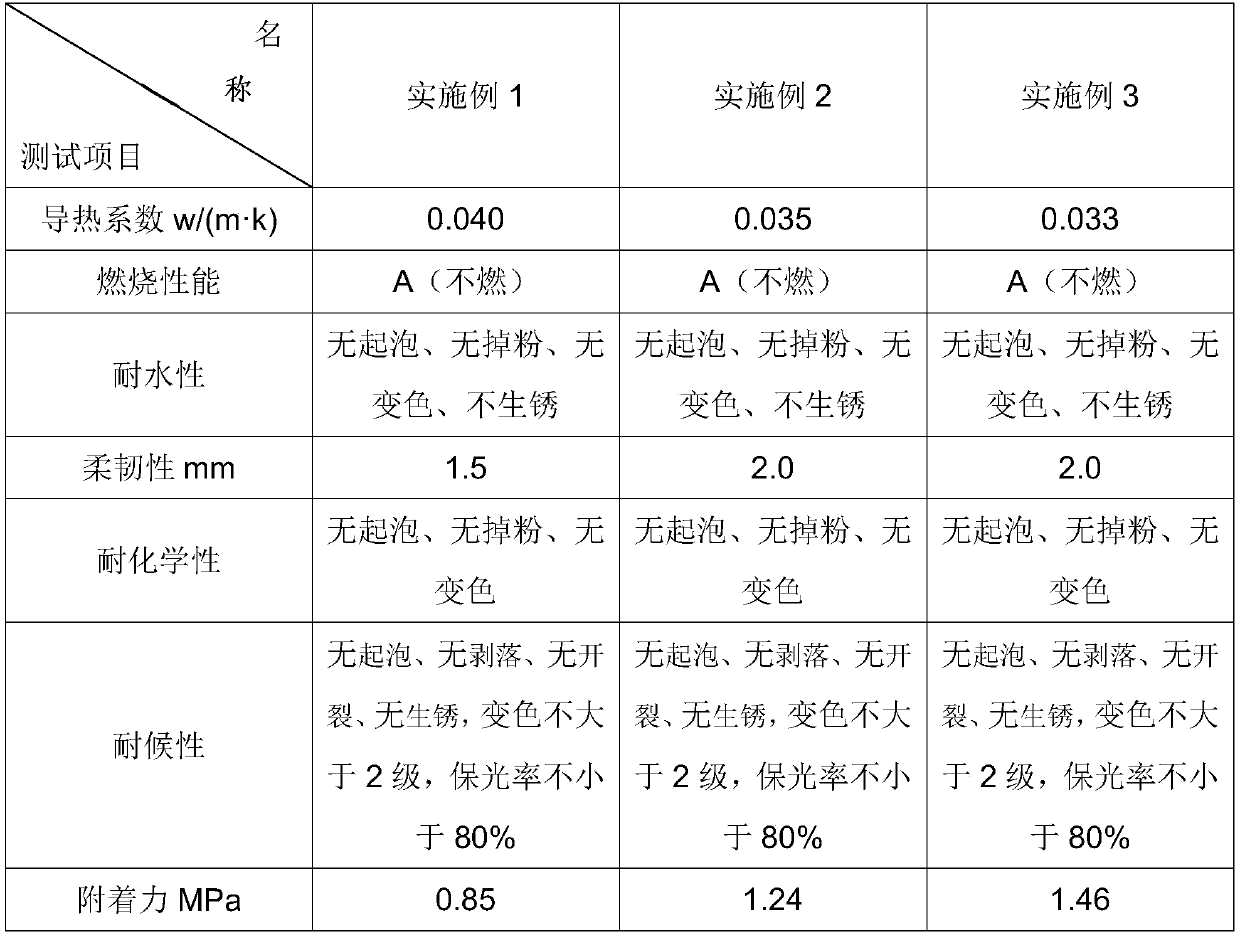

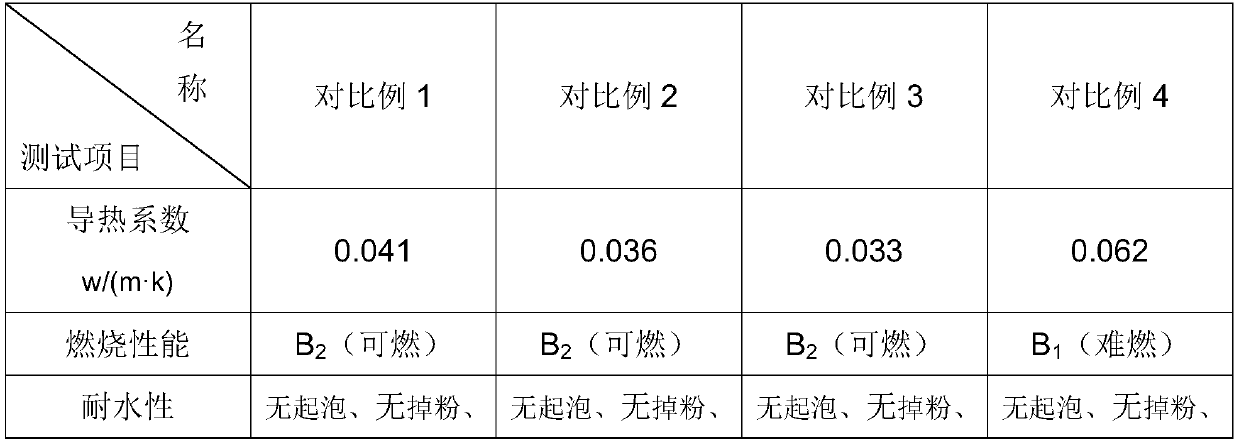

Water-based nano thin-coating heat preservation paint and preparation method thereof

InactiveCN110791159AImprove physical and chemical propertiesHigh chemical stabilityAnti-corrosive paintsWeather resistanceCorrosion

The invention discloses a water-based nano thin-coating heat preservation paint and a preparation method thereof. The paint comprises the following raw materials by weight: 30-40 parts of an acrylic emulsion, 5-10 parts of titanium dioxide, 20-40 parts of hollow glass beads, 5-20 parts of aerogel and 5-10 parts of a film-forming assistant. According to the invention, the hollow glass beads and aerogel are used as the heat insulation basic raw materials, the heat conductivity coefficient of the paint is greatly reduced and is as low as 0.031-0.035W / m.K, and the paint can reach a remarkable heatinsulation effect under the condition of a very small construction thickness. Meanwhile, the hollow glass beads and the aerogel are conducive to improving the chemical stability of the paint itself,thus improving the covering power, lightening power, corrosion resistance, light resistance and weather resistance, and enhancing the mechanical strength of the paint; cellulose, a wetting dispersant,a defoaming agent and a preservative are mixed; by virtue of ethylene glycol, the acrylic emulsion and a pH regulator, the paint has excellent cohesiveness, weather resistance, film-forming properties, gloss and color retention and mechanical properties; and the use of a vinyl chloride-vinylidene chloride copolymer emulsion also can reach a grade A1 flame retardant effect.

Owner:重庆兴渝新材料研究院有限公司

Hydrolysis method for producing electronic-grade special titanium white by sulfuric acid process

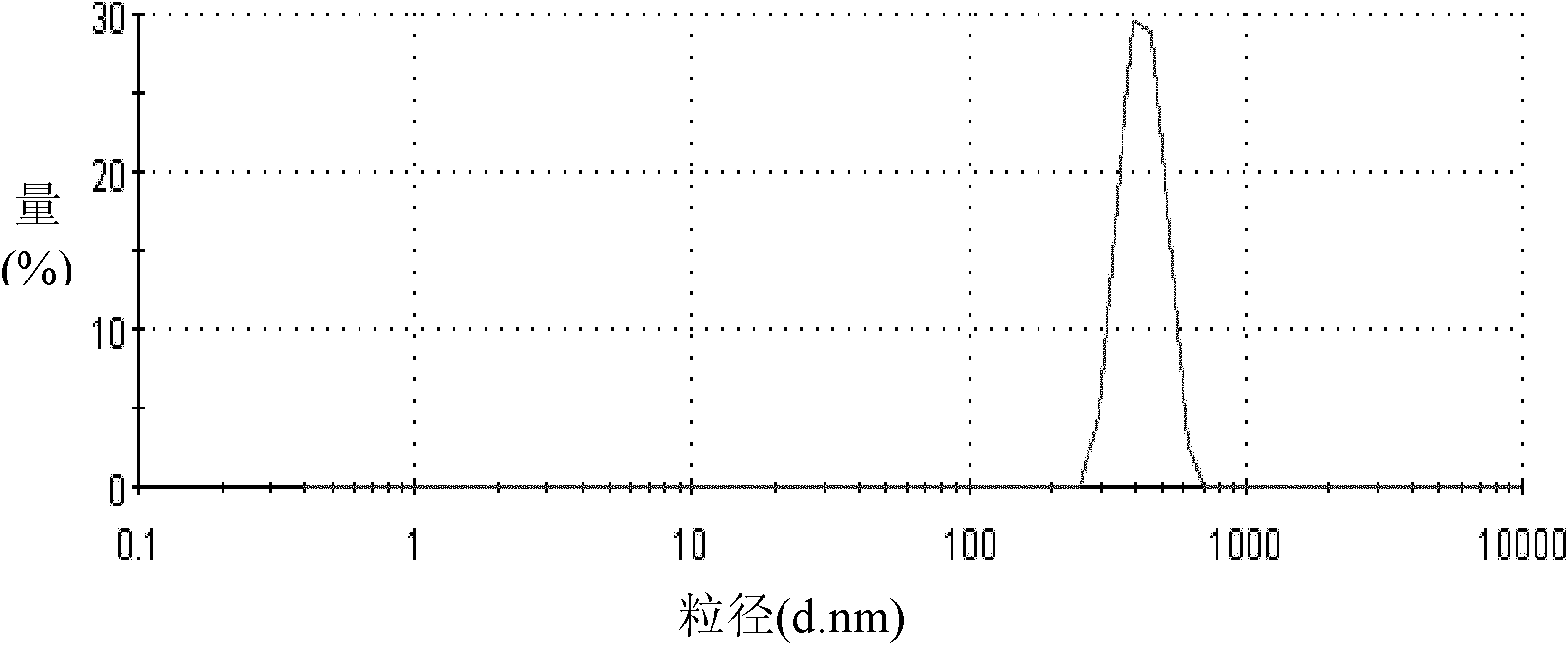

ActiveCN101913647ANarrow particle size distributionLow impurity contentTitanium dioxideNarrow rangeGranularity

The invention belongs to the field of chemical industry and relates to a hydrolysis method for producing electronic-grade special titanium white by a sulfuric acid process. The technical problem to be solved is that the electronic-grade special titanium white with narrow particle size distribution and low impurity content is prepared by the sulfuric acid process. The method improves the hydrolysis method in the sulfuric acid process, and the improved hydrolysis method comprises the following steps of: A, adding titanium liquid with the concentration of 140 to 190g / L which is preheated to the temperature of between 75 and 95 DEG C into water which is preheated to the temperature of between 80 and 95 DEG C; B, heating the system to boil, and keeping the system boiling; C, when the hydrolysis system becomes steel grey, continuously keeping boiling for 5 to 25 minutes, stopping heating and stirring, and curing; and D, heating the system to boil with stirring, and keeping the system slightly boiling until the hydrolysis is finished. The obtained titanium white has the mean grain size of 800 to 1,200nm, the half-peak width of 70 to 98nm, narrow range of particle size distribution and low impurity content, and can be used as electronic-grade special titanium white.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

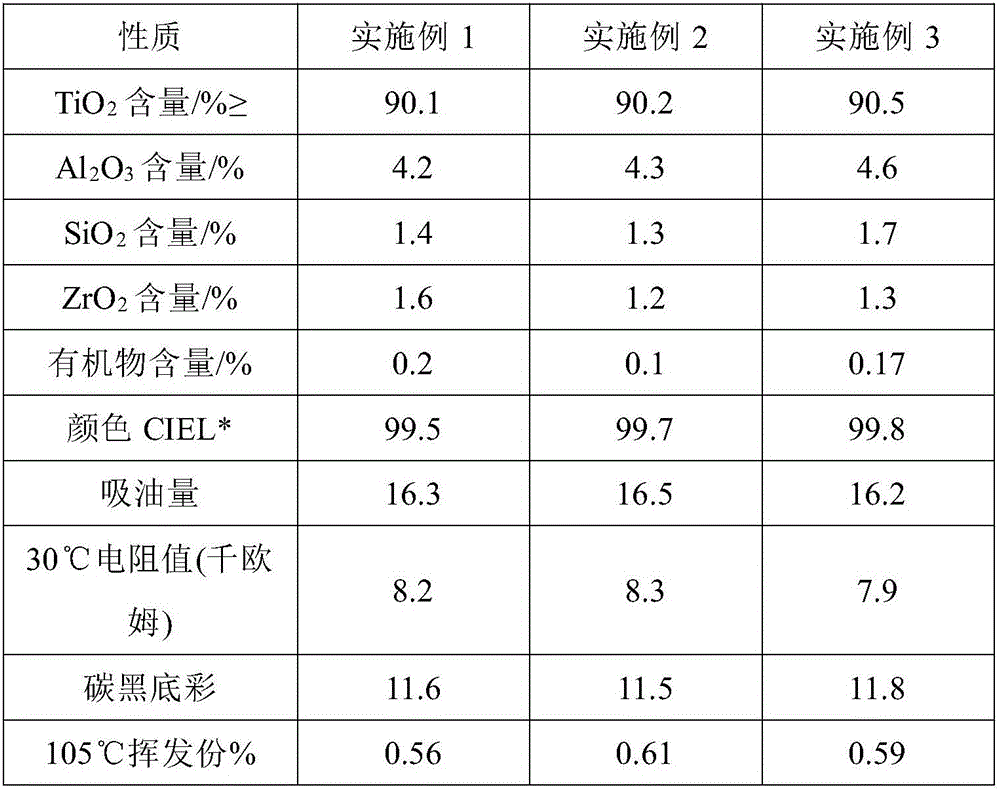

Method for coating titanium dioxide by using chloride by-product hydrochloric acid

ActiveCN105949823AReduce manufacturing costImprove dispersionPigment treatment with non-polymer organic compoundsChemistryAluminium

The invention discloses a method for coating titanium dioxide by using chloride by-product hydrochloric acid. The method comprises the steps of removing impurities of coarse hydrochloric acid for later use, wherein the coarse hydrochloric acid is recycled by washing chlorinated tail gas with water; inorganically coating the titanium dioxide by using zircon salt, silicon salt and aluminum salt, and then coating by using an organic coating agent to obtain a coated titanium dioxide product with good quality. According to the method for coating the titanium dioxide, the acid used by the method is the coarse hydrochloric acid recycled by washing chlorinated tail gas with water, and an inorganic and organic composite coating process is adopted, so that the hydrophilia, pulverization resistance, lightening power and color retention of the titanium dioxide are greatly improved; furthermore, the wetting property, dispersity and covering power of the titanium dioxide in a dispersion medium are improved.

Owner:YIBIN TIANYUAN GRP CO LTD +1

Preparation method of titanium dioxide made with compound coating chlorination process

InactiveCN106009783AImprove dispersionImproved chalking resistancePigment treatment with non-polymer organic compoundsAluminium saltsDioxide titanium

The invention discloses a preparation method of titanium dioxide made with a compound coating chlorination process. Firstly, zirconium salt, silicon salt and aluminium salt are adopted for inorganic coating of titanium dioxide, and then an organic coating agent is used for coating. According to the method, an inorganic and organic novel compound coating technology is utilized, titanium dioxide is greatly improved in hydrophilicity, chalking resistance, lightening power, and color retention, and meanwhile the wettability, dispersity and covering power of titanium dioxide in a dispersion medium are improved. Compared with individual organic and inorganic coating agents, the titanium dioxide has better comprehensive performance.

Owner:YIBIN TIANYUAN GRP CO LTD

High-strength and corrosion-resistant plastic and preparation method thereof

InactiveCN106633522AImprove bending strengthImprove temperature stabilityAntioxidantPolyvinyl chloride

The invention discloses high-strength and corrosion-resistant plastic. The high-strength and corrosion-resistant plastic is prepared from components in parts by mass as follows: 60-70 parts of polyvinyl chloride resin, 30-40 parts of ABS (acrylonitrile-butadiene-styrene), 5-10 parts of modified filler, 2-3 parts of nano calcium carbonate, 3-5 parts of silicon carbide, 7-8 parts of titanium dioxide, 2-3 parts of ethyl acetate, 10-11 parts of dioctyl phthalate, 3-5 parts of glass fibers, 2-4 parts of a curing agent, 4-5 parts of an interface coupling agent, 3-4 parts of a fire retardant, 2-3 parts of a stabilizing agent, 3-4 parts of a toughening agent and 4-5 parts of an antioxidant. The high-strength and corrosion-resistant plastic is high in strength, good in toughness, high in corrosion resistance and long in service life.

Owner:SUZHOU JIN YUAN OIL MACHINERY

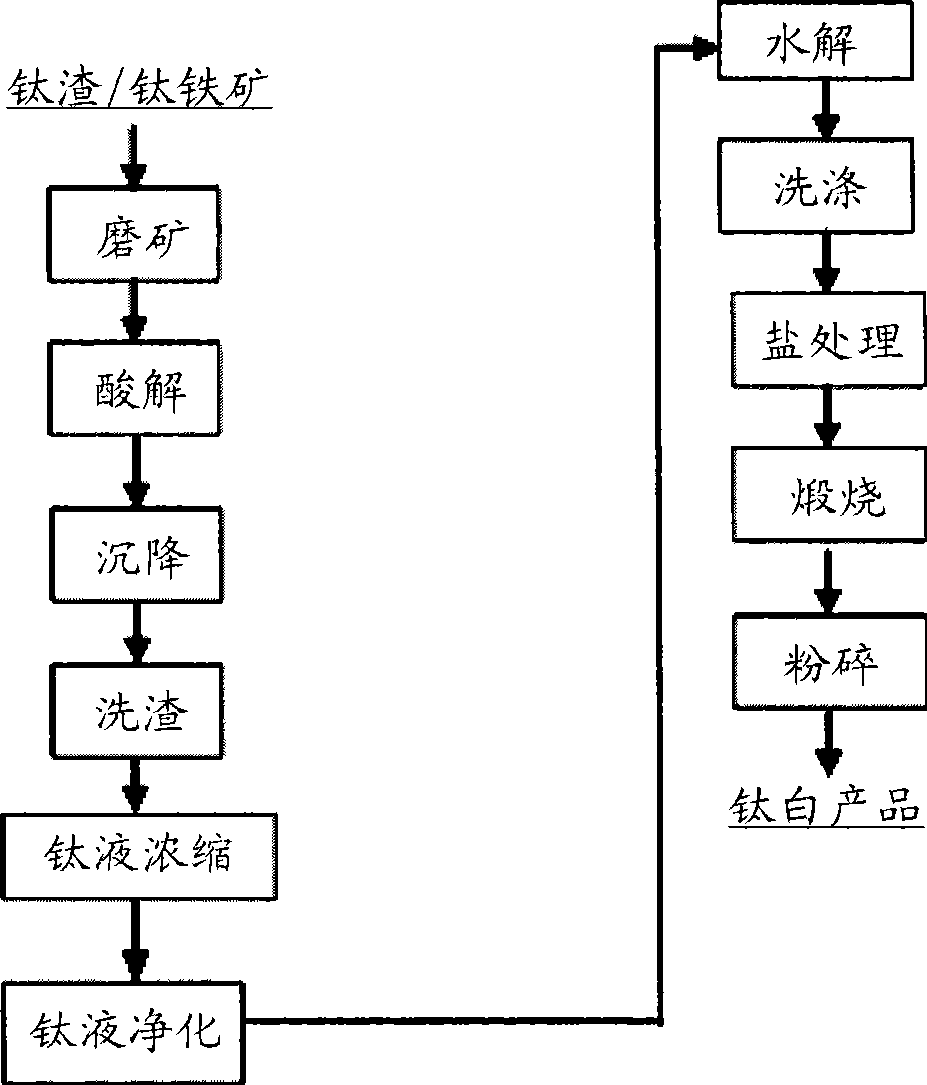

Method for preparing high quality titanium white

InactiveCN101357777AGood removal effectUniform particle size distributionTitanium dioxideDecompositionFiltration

The invention provides a method for preparing high-quality titanium dioxide and includes the technological processes of grinding, acid decomposing, settling, residue washing, titanium liquid concentrating, hydrolyzing, washing, salt treating, calcining and crashing of raw materials containing titanium; wherein, a solid filtration medium is adopted to process concentrated titanium liquid with purifying treatment before the hydrolysis to remove colloids and solid impurities in the titanium liquid, and the colloids and solid impurities are produced in the processes of acid decomposition and concentration. As the colloids and solid impurities in the titanium liquid can be better removed with the method, both the achromic ability and whiteness of the prepared high-quality titanium dioxide are obviously improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Method for treating rutile titanium dioxide waste water

ActiveCN104108814AImprove recycling efficiencySignificant economic and environmental benefitsFerroso-ferric oxidesMultistage water/sewage treatmentEnvironmental chemistryPolyacrylamide

The invention discloses a method for treating rutile titanium dioxide waste water. The method comprises the following three steps of: (1) mixing acid waste water and alkaline waste water, stirring, then naturally depositing to obtain a supernatant and bottom deposits, and controlling mixing temperature to 50-60 DEG C, wherein the pH value of a solution is 7-8 after mixing; (2) adding polyacrylamide to the supernatant obtained in the step (1) according to the concentration ratio of 5-10ppm, stirring, and depositing; (3) carrying out aeration, filter pressing and drying on the lower deposits obtained in the step (1) to obtain iron oxide black, wherein filter liquor obtained through the filter pressing can be directly discharged. The method disclosed by the invention can be used for recovering insoluble titanium from the rutile titanium dioxide waste water as much as possible and reducing the discharge amount of the rutile titanium dioxide waste water, thereby recycling the water resources and further creating great economic benefit and environmental protection benefit to enterprises.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Process for producing rutile titanium dioxide by using low-grade titanium ore

The invention relates to a process for producing rutile titanium dioxide by using low-grade titanium ore and belongs to the technical field of production of titanium dioxide. The process is a sulfuric acid method. The improvement is as follows: the acid-ore ratio is 1.55-1.61:1; the warp / weft ratio of filtering cloth of a washing leaf filter is 519 / 220; in the process of salt treatment, the added amount of zinc oxide is 0.2-0.5%; the calcination temperature is 800-1200 DEG C. When the high-grade titanium ore is used, the calcination temperature of a rotary kiln is 900-1300 DEG C; since the content of phosphorus in the low-grade titanium ore is high, in order to reach the same conversion rate with the high-grade titanium ore, the calcination temperature of the rotary kiln needs to be improved. But since the addition amount of zinc oxide is increased in the process of salt treatment, even though the calcination temperature of the rotary kiln is reduced to 800-1200 DEG C, the conversion rate can reach more than 98%, and simultaneously the sintering of materials due to overhigh conversion rate is avoided; the prepared titanium dioxide can reach the national standards.

Owner:JINAN YUXING CHEM

Preparation technology of special titanium dioxide for plastic color master batch

The invention discloses a preparation technology of special titanium dioxide for plastic color master batch. The preparation technology is characterized by comprising the following steps: (1) raw oregrinding; (2) acidolysis; (3) leaching; (4) reducing; (5) settling; (6) concentration of titanium liquid; (7) hydrolysis; (8) concentration of liquid titanium; (7) hydrolysis; (8) washing and bleaching; (9) salt treatment; (10) filtering, calcining and surface treatment; (11) drying and dust removal.

Owner:GUANGXI JINMAO TITANIUM

Inner wall putty with antibacterial and odor removing effects and preparation method thereof

The invention discloses inner wall putty with antibacterial and odor removing effects and a preparation method of the inner wall putty with the antibacterial and odor removing effects. The inner wall putty is prepared from the following components calculated in parts by weight: 150 to 200 parts of calcium carbonate, 10 to 12 parts of titanium dioxide, 6 to 8 parts of cellulose, 40 to 50 parts of ash calcium powder, 100 to 150 parts of white cement, 30 to 45 parts of expanded perlite, 5 to 8 parts of charcoal dust, 8 to 10 parts of preservatives and 3 to 5 parts of mould inhibitors. The inner wall putty disclosed by the invention has the advantages of being high in strength, anti-cracking, good in insulation performance, high in flexibility and the like, and is capable of carrying out sterilization and removing odors, and further can adjust the indoor humidity to improve indoor air environment. In addition, the invention further provides the preparation method of the inner wall putty with the antibacterial and odor removing effects. The inner wall putty prepared by the preparation method is small in particle size and easy to mix and does not drop dregs and peel off and has no expansion while meeting dampness and water.

Owner:ZHONGSHAN MOORE CHEM IND CO LTD

Method for conducting amorphous TiO2 pulsed chemical vapor phase deposition on TiO2 particle surfaces

ActiveCN108866510AGood weather resistanceHigh decolorizing powerChemical vapor deposition coatingGas phaseRefractive index

The invention discloses a method for conducting amorphous TiO2 pulsed chemical vapor phase deposition on TiO2 particle surfaces. By covering titanium dioxide with inert materials of SiO2, Al2O3 and the like, the photocatalytic activity of titanium dioxide can be effectively inhibited, in current industrial application, normally, the surface of TiO2 is covered through a liquid phase deposition technology, however, according to a liquid phase covering method, the thickness and the evenness of thin film cannot be controlled precisely. A vapor phase atom titanium dioxide film covering method is provided before, wherein a layer of SiO2 thin film with the thickness of 3 nm is deposited on TiO2 particle surfaces; however, excessive SiO2 covering can cause decline of the lightening power of TiO2 due to the fact that a refractive index (1.46) of SiO2 is lower than that (2.55) of anatase TiO2. The invention provides a pulsed chemical vapor phase deposition method, wherein TiCl4 is used as a Ti precursor, at the normal temperature, TiCl4 is reacted with surface hydroxyl of TiO2 to form an amorphous TiO2 thin film with even thickness of 3 nm; the photocatalytic activity of titanium dioxide covered with the amorphous TiO2 is effectively inhibited, and compared with a sample covered with SiO2, the lightening power of the titanium dioxide covered with the amorphous TiO2 is obviously enhanced.

Owner:SICHUAN UNIV

Hydrolysis method for producing electronic-grade special titanium white by sulfuric acid process

ActiveCN101913647BNarrow particle size distributionLow impurity contentTitanium dioxideChemical industryTitanium

The invention belongs to the field of chemical industry and relates to a hydrolysis method for producing electronic-grade special titanium white by a sulfuric acid process. The technical problem to be solved is that the electronic-grade special titanium white with narrow particle size distribution and low impurity content is prepared by the sulfuric acid process. The method improves the hydrolysis method in the sulfuric acid process, and the improved hydrolysis method comprises the following steps of: A, adding titanium liquid with the concentration of 140 to 190g / L which is preheated to the temperature of between 75 and 95 DEG C into water which is preheated to the temperature of between 80 and 95 DEG C; B, heating the system to boil, and keeping the system boiling; C, when the hydrolysis system becomes steel grey, continuously keeping boiling for 5 to 25 minutes, stopping heating and stirring, and curing; and D, heating the system to boil with stirring, and keeping the system slightly boiling until the hydrolysis is finished. The obtained titanium white has the mean grain size of 800 to 1,200nm, the half-peak width of 70 to 98nm, narrow range of particle size distribution and low impurity content, and can be used as electronic-grade special titanium white.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Method for improving weather resistance of decorative base paper titanium dioxide

ActiveCN107500348AReduce concentrationIncrease concentrationTitanium dioxideWeather resistancePotassium

The invention provides a method for improving weather resistance of decorative base paper titanium dioxide, and belongs to the technical field of decorative base paper titanium dioxide. The control is performed through salt treatment and calcination. The method comprises the following steps of A, using bleached slurry as raw materials; adding titanium dioxide sol into the raw materials; controlling the addition to meet the requirement that the proportion of TiO2 in the titanium dioxide sol to TiO2 in metatitanic acid is 2 to 6 percent; performing water washing; diluting the slurry subjected to water washing into 300 to 400g / L TiO2 slurry; B, adding potassium and phosphorus solution with the K2O / P2O5 ratio being 1.3 to 4.0 into the diluted slurry; performing stirring; adding aluminum-containing compound solution according to the Al2O3 to TiO2 proportion being 0.3 to 0.9 percent; performing stirring; C, performing pressurized filtering on the slurry material treated by the step B until the filter cake solid content is 45 to 55 percent; C, roasting the filter cake in the step C for 8 to 10h at the roasting temperature of 200 to 950 DEG C. Through the control on the salt treatment and roasting processes, the primary product weather resistance of the decorative base paper titanium dioxide is improved; the weather resistance of the decorative base paper titanium dioxide is further improved.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Preparation method of composite material for polypropylene modification, and product thereof

The invention provides a preparation method of a composite material for polypropylene modification. The preparation method comprises: blending wollastonite powder by using water to obtain a 50-60% slurry, and adding sodium stearate; preparing a 65-70% composite slurry from barium sulfate and titanium white powder according to a mass ratio of (4-6):1 by using water, and adding sodium stearate and a silane coupling agent; carrying out wet grinding on the prepared titanium white powder-barium sulfate composite slurry to 3000-4000 mesh; adding the prepared wollastonite slurry to the prepared titanium white powder-barium sulfate composite slurry according to a mass ratio of the titanium white powder-barium sulfate to the wollastonite of (10-12):1, and adding a silane coupling agent to coat; drying the composite slurry to obtain composite material dry powder; and beating and disaggregating the composite material dry powder to achieve the dispersed state, carrying out a cyclone grading treatment, and collecting the 2500-3000 mesh powder. According to the present invention, the composite material product with characteristics of high weather resistance, high gloss and high chemical stability can be obtained.

Owner:JIANGXI GUANGYUAN CHEM

Flame-retardant masterbatch for reflective film

InactiveCN107141727AImprove flame retardant performanceStable manufacturingChemistryOptical brightener

The invention relates to a flame-retardant masterbatch for a reflective film. The masterbatch comprises the following components in parts by mass: 0-100 parts of carrier, 20-60 parts of toner, 5-10 parts of a flame retardant, 10-20 parts of a flame-retardant assistant, 1 part of a heat stabilizer and 2-4 parts of a dispersant, wherein the toner is acid-resistant organic or inorganic toner; the flame retardant is a brominated flame retardant; the flame-retardant assistant is a nano inorganic flame retardant; the part ratio of the flame retardant to the flame-retardant assistant is 1:2; the heat stabilizer is polyphosphate; the dispersant is an organic or inorganic dispersant; and a high-efficiency fluorescent brightener can also be added to the masterbatch. The masterbatch has the characteristic that the masterbatch can reach a requirement of the masterbatch for the reflective film by setting the components.

Owner:广州保亮得塑料科技有限公司

Titanium dioxide for extinction of chinlon chemical fibers and preparation method of titanium dioxide

ActiveCN114773882AEasy to anchorReduce photocatalytic activityPigment treatment with organosilicon compoundsArtifical filament manufactureFiberPhysical chemistry

The invention relates to composite titanium dioxide used as a nylon chemical fiber delustering agent, which is formed by mixing a meso-porous silicon coated superfine titanium dioxide main component and an amorphous silicon core aluminum-based titanium dioxide auxiliary component, and the mixed material is subjected to surface treatment. Wherein the weight ratio of the meso-porous silicon coated ultrafine titanium dioxide is not less than 50wt%; the particle size D90 of the meso-porous silicon coated ultrafine titanium dioxide is less than or equal to 0.3 mu m; d90 of the amorphous silicon-core aluminum-based titanium dioxide is less than or equal to 0.45 mu m. The particle size range of the composite titanium dioxide provided by the invention corresponds to about half of the wavelength of visible light, and the composite titanium dioxide has significantly improved particle uniformity and matting performance.

Owner:天泰(福建)新材料科技有限公司 +1

Formula and preparation method of color plastic pencil refill

InactiveCN108659625ASolve the hardnessSolve rigid problemsPencil leadsPolymer scienceManufacturing technology

The invention discloses a formula and a preparation method of a color plastic pencil refill, and relates to the technical field of pencil manufacturing. The formula of the pencil refill comprises thefollowing components in percentage by weight: 10 to 30 percent of PP plastic, 1 to 10 percent of PE plastic, 5 to 15 percent of aids, 5 to 10 percent of titanium dioxide, 30 to 60 percent of talcum powder and 10 to 20 percent of pigment. The preparation method comprises the following steps: step one, adding all raw materials into a banbury bin and continuously heating, stirring and carrying out banbury mixing; step two, cooling and granulating a banbury mixture obtained in the step one; step three, cooling refill particles obtained in the step two; step four, transferring the cooled refill particles obtained in the step three into core extrusion equipment and extruding out the color pencil lead through the core extrusion equipment. According to the preparation method disclosed by the invention, the problems of excessively-high hardness and insufficient rigidity of an existing color pencil refill are solved by reasonably matching the PP plastic and the PE plastic in the raw materials according to the proportions during the preparation of the pencil refill.

Owner:安徽得亿文教用品有限公司

Salt treatment method for rutile titanium dioxide and treated titanium dioxide initial product

The invention relates to a salt treatment method for rutile titanium dioxide and a treated titanium dioxide initial product, and belongs to the technical field of titanium dioxide production. The technical problem solved by the invention comprises that provided is the titanium dioxide initial product after salt treatment of rutile titanium dioxide. The titanium dioxide initial product is composed of the following components in parts by weight: 100 parts of titanium dioxide, 0.64-1.35 parts of potassium oxide, 0.28-0.38 part of phosphorus pentoxide, 0.13-0.24 part of tin oxide, 0.16-0.29 part of strontium oxide, 0.41-0.83 part of aluminum oxide, and 3-4 parts of a calcining crystal seed. Through the specific treatment agents and amount, the titanium dioxide initial product is obtained, the lightening power of titanium dioxide can be improved, and thus the quality of titanium dioxide is improved.

Owner:PANZHIHUA TAIDU CHEM

Method for treating salt during production of titanium dioxide

The invention relates to a method for treating salt during production of titanium dioxide, belongs to the technical field of titanium dioxide and solves the technical problems to provide the method for treating salt during production of titanium dioxide. By means of the method, the lightening power of titanium dioxide can be improved. The method comprises steps as follows: a, metatitanic acid is mixed with water and stirred for slurry production; b, specific amounts of potassium salt, phosphor salt, tin salt and aluminum salt are added to metatitanic acid slurry; c, a titanium dioxide primary product is obtained through filtration, filter cake taking and calcination. By means of the method, the lightening power of titanium dioxide obtained through treatment can be improved, and the quality of titanium dioxide is improved.

Owner:PANZHIHUA TAIDU CHEM

High-efficiency flame-retardant ceramic particle water-based thermal insulation coating and preparation method thereof

InactiveCN110964394AImprove flame retardant performanceFlame retardancy does not affectFireproof paintsAnti-corrosive paintsSolid componentMeth-

The invention provides a high-efficiency flame-retardant ceramic particle water-based thermal insulation coating, comprising a liquid component I, a liquid component II and a solid component which aremixed according to a mass ratio of 7: (0.2-0.4): (3-4). The liquid component I comprises the following components in percentage by mass: 35.0%-55.0% of an acrylate emulsion, 1.5%-3.0% of texanol, 0.5%-1.5% of 2-amino-2-methyl-1-propanol, 0.5%-1.0% of an antifoaming agent, 1.0%-2.0% of a wetting agent, 0.5%-1.5% of a leveling agent, 3.0%-6.0% of a dispersing agent, 10.0%-20.0% of a liquid flame retardant and the balance of water. The liquid component II comprises the following components in percentage by mass: 50% of a thickening agent and 50% of water. The solid component comprises the following components in percentage by mass: 10.0%-20.0% of talcum powder, 5.0%-15.0% of mica powder, 5.0%-15.0% of titanium dioxide, 15.0%-30.0% of heat insulation powder and 30.0%-60.0% of hollow ceramic particles. The flame retardant property of the thermal insulation coating can be remarkably improved, and meanwhile, the thermal insulation property of the coating is not influenced.

Owner:YUEYANG CHANGLING EQUIP RES INST

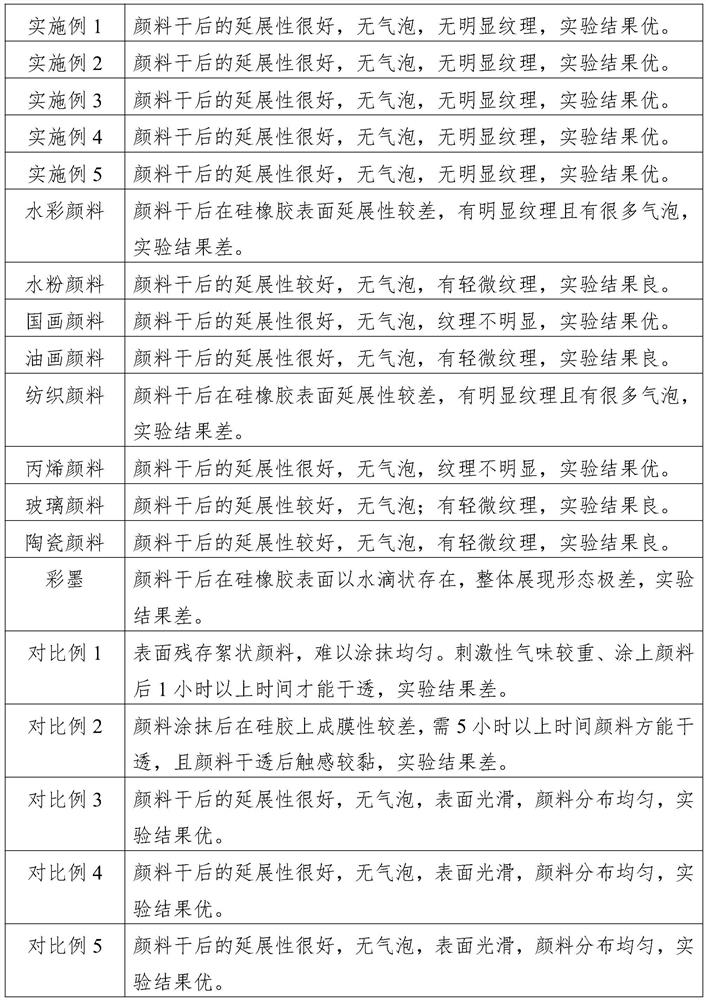

Cleanable pigment capable of being applied to silicone rubber and not prone to falling off and preparation method of cleanable pigment

InactiveCN113621285AMaintain humidityControl clotting timeArtist's paintsOrganic dyesPolymer scienceAcrylic resin

The embodiment of the invention discloses a cleanable pigment capable of being applied to silicone rubber and not prone to falling off and a preparation method of the cleanable pigment, and belongs to the technical field of pigments. The pigment is prepared from water, propylene glycol, titanium dioxide, acrylic resin, polymethacrylate, polyether sulfonate, branched chain sodium alkyl benzene sulfonate, fatty alcohol-polyoxyethylene ether, fatty alcohol-polyoxyethylene ether carboxylate, nonylphenol polyoxyethylene ether, secondary alkyl sodium sulfonate, polyethylene glycol and triethanolamine as raw materials. The pigment can be applied to silicon rubber, and has the characteristics of flexibility, difficulty in falling off and capability of being competent for the flexibility of the silicon rubber after being solidified. The silicon rubber is not dyed and can be repeatedly used after the pigment is cleaned, and the cost for purchasing a large number of silicon rubber substrates during silicon rubber painting is saved. The pigment fills the blank of pigment for silicon rubber, and has a wide market prospect.

Owner:BEIJING DUXIANG EDUCATION TECH CO LTD

A kind of method that chlorination by-product hydrochloric acid is used for coating of titanium dioxide

ActiveCN105949823BReduce manufacturing costHigh hiding powerPigment treatment with non-polymer organic compoundsDispersityZircon

The invention discloses a method for coating titanium dioxide by using chloride by-product hydrochloric acid. The method comprises the steps of removing impurities of coarse hydrochloric acid for later use, wherein the coarse hydrochloric acid is recycled by washing chlorinated tail gas with water; inorganically coating the titanium dioxide by using zircon salt, silicon salt and aluminum salt, and then coating by using an organic coating agent to obtain a coated titanium dioxide product with good quality. According to the method for coating the titanium dioxide, the acid used by the method is the coarse hydrochloric acid recycled by washing chlorinated tail gas with water, and an inorganic and organic composite coating process is adopted, so that the hydrophilia, pulverization resistance, lightening power and color retention of the titanium dioxide are greatly improved; furthermore, the wetting property, dispersity and covering power of the titanium dioxide in a dispersion medium are improved.

Owner:YIBIN TIANYUAN GRP CO LTD +1

Method for producing yellow attapulgite polymer clay mud

InactiveCN101973065AGood water dispersibilityGood optical performanceCeramic shaping apparatusPolymer scienceSilicone oil

The invention discloses a method for producing yellow attapulgite polymer clay mud, which is characterized by comprising the following steps: adding yellow granular attapulgite mixture into a running horizontal flour-mixing machine, and slowly adding sodium polyacrylate gel solution into the yellow granular attapulgite mixture, then stirring the obtained products so as to obtain yellow mud block shaped attapulgite mixture; spraying methyl-silicone oil on the yellow mud block shaped attapulgite mixture, and kneading the attapulgite mixture so as to obtain a semi-finished product of yellow attapulgite polymer clay mud; finally, pressing the semi-finished product of yellow attapulgite polymer clay mud into flattening yellow attapulgite polymer clay mud, and carrying out sealed package on the obtained flattening yellow attapulgite polymer clay mud so as to obtain the finished product of the yellow attapulgite polymer clay mud. The yellow attapulgite polymer clay mud produced by using the method of the invention has the characteristics of high viscosity, good soft plasticity, low shrinkage rate, no baking in the process of hardening after air drying, no cracking, no corrosivity, and no greasy feeling. When the yellow attapulgite polymer clay mud is mixed with the attapulgite polymer clay mud in other colors, handicraft products with clear patterns, bright colors and lifelike effects can be produced; and the yellow attapulgite polymer clay mud is suitable for shaping patterns, moulds and handicraft products.

Owner:JIANGSU DAHAI PLASTIC

Method for preparing rutile titanium dioxide with high tinctorial strength

InactiveCN111422902AUniform particle size distributionGood dispersionTitanium dioxideAluminium chlorideHydrolysate

The invention discloses a method for preparing rutile titanium dioxide with high tinctorial strength, which comprises the following steps: adding sulfuric acid into titanium concentrate for acidolysisto obtain a titanium suspension, and adding a flocculant composed of maleic anhydride-styrene sulfonic acid copolymer, sodium lignin sulfonate and polyaluminum chloride into the titanium suspension for impurity removal treatment to obtain a refined titanium solution; adding rutile seed crystals and a dispersing agent into the refined titanium solution for hydrolysis to obtain a hydrolysate; washing the hydrolysate with water, adding sulfuric acid for bleaching, and washing for a second time to obtain a slurry; adding a salt solution treating agent consisting of a phosphate solution, a zinc acetate solution and a yttrium nitrate solution into the slurry; and carrying out filter pressing on the slurry by using a filter press, calcining a filter cake in a rotary kiln, cooling, and crushing to obtain rutile titanium dioxide. The rutile content of the rutile titanium dioxide prepared through the method reaches 98.5% or above, the whiteness reaches 98% or above, the Tcs value reaches 2034 or above, the Scx value reaches 4.21 or above, and the product is uniform in particle size distribution and good in dispersity and is an excellent white pigment.

Owner:GUANGXI JINMAO TITANIUM

Special titanium dioxide for color masterbatch

The invention relates to special titanium dioxide for color masterbatch, wherein the content of titanium dioxide TiO2 is 95-97%, the rutile content is not less than 99.7%, the S element content is notmore than 3 ppm, the specific surface area is 350-370 m<2> / g, the agglomeration particle size D50 is 0.10-0.20 [mu]m, the agglomeration particle size D90 is less than or equal to 0.5 [mu]m, the volatile matter (105 DEG C, 2 h) is less than or equal to 1.5%, the burning loss (the sample is burned for 1 h after drying for 2 h at a temperature of 105 DEG C) is less than or equal to 8%, the pH valueof the aqueous suspension is 6.5-7.5, the water absorption is (30-35) g / 50 g, the 45 [mu]m sieve residue is less than or equal to 0.04%, the oil absorption is 23-25 (g / 100 g), Fe2O3 is less than or equal to 0.005%, and (K2O+Na2O) is less than or equal to 0.008%.

Owner:GUANGXI JINMAO TITANIUM

Preparation process of titanium dioxide for plastic masterbatch

ActiveCN107935038BImprove performanceInhibit conversion rateTitanium dioxideMasterbatchPhysical chemistry

Owner:GUANGXI JINMAO TITANIUM

a kind in tio 2 Pulse chemical vapor deposition of amorphous tio on particle surfaces 2 Methods

ActiveCN108866510BGood weather resistanceHigh decolorizing powerChemical vapor deposition coatingRefractive indexPhysical chemistry

The present invention discloses in TiO 2 Particle Surface Pulsed Chemical Vapor Deposition of Amorphous TiO 2 Methods. Coating SiO on the Surface of Titanium Dioxide 2 , Al 2 O 3 , and other inert materials can effectively inhibit its photocatalytic activity. At present, TiO is usually coated by liquid deposition technology in industrial applications. 2 surface, but the liquid-phase coating method cannot precisely control the thickness and uniformity of the film. We previously proposed a method for gas-phase atomic titanium dioxide coating on TiO 2 A layer of SiO with a thickness of 3 nm is deposited on the surface of the particles 2 film. However, excess SiO 2 Coating may also lead to TiO 2 The achromatic power is reduced because SiO 2 The refractive index of (1.46) is higher than that of anatase TiO 2 (2.55) low. The present invention proposes a method for pulsed chemical vapor deposition, using TiCl 4 It is the precursor of Ti, which is mixed with TiO at room temperature 2 The surface hydroxyl groups react to form uniform amorphous TiO with a thickness of 3 nm 2 film. Coated amorphous TiO 2 The photocatalytic activity of the titanium dioxide was effectively suppressed, and with the coated SiO 2 Compared with the latter sample, its achromatic power is obviously enhanced.

Owner:SICHUAN UNIV

Method for preparing high quality titanium white

InactiveCN101357777BGood removal effectUniform particle size distributionTitanium dioxideDecompositionFiltration

The invention provides a method for preparing high-quality titanium dioxide and includes the technological processes of milling grinding, acid decomposing, settling, residue washing, titanium liquid concentrating, hydrolyzing, washing, salt treating, calcining and crashing of raw materials containing titanium; wherein, a solid filtration medium is adopted to purify concentrated titanium liquid before the hydrolysis to remove colloids and solid impurities in the titanium liquid, and the colloids and solid impurities are produced in the processes of acid decomposition and concentration. As the colloids and solid impurities in the titanium liquid can be better removed with the method, both the achromic ability and whiteness of the prepared high-quality titanium dioxide are obviously improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com