Cleanable pigment capable of being applied to silicone rubber and not prone to falling off and preparation method of cleanable pigment

A production method and technology of silicone rubber, which can be applied in the direction of pigment slurry, art paint, coating, etc., can solve the problems of difficult coloring, ineffective cleaning, poor painting performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

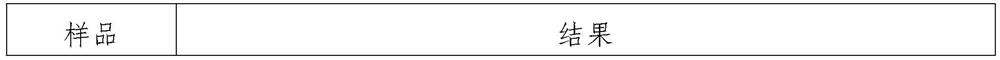

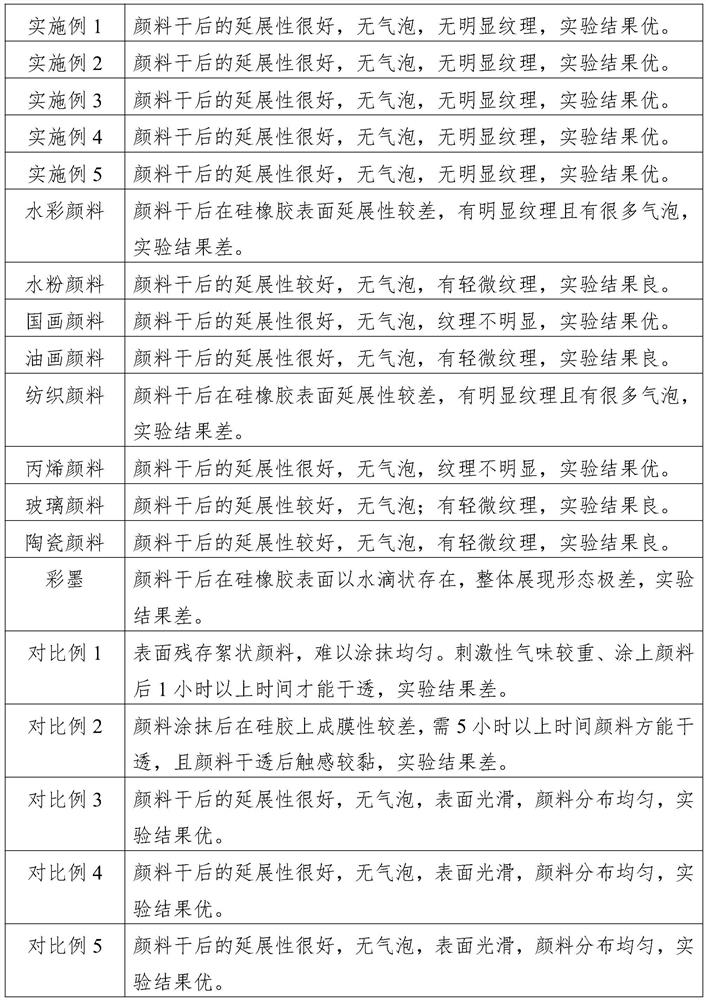

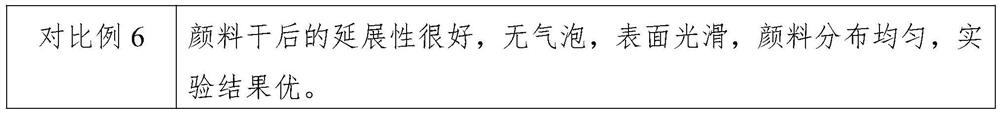

Examples

Embodiment 1

[0031] The preparation method of the pigment that can be painted on the silicone rubber that is not easy to fall off and can be cleaned up in this embodiment comprises the following steps:

[0032] S1. Add 16.75% acrylic resin and 0.1% polyethylene glycol in sequence in the batching tank, turn on the high-speed disperser, control the speed at 1200r / min, and stir for 6 minutes;

[0033] S2, then add 15.5% titanium dioxide, 55.25% water, and disperse at high speed for 25 minutes;

[0034] S3, then add 1% propylene glycol, 0.2% triethanolamine, 0.1% sodium secondary alkyl sulfonate, 9.88% polymethacrylate, 0.4% polyether sulfonate, 0.25% branched chain alkyl Sodium benzenesulfonate, 0.4% fatty alcohol polyoxyethylene ether, 0.12% fatty alcohol polyoxyethylene ether carboxylate, 0.05% nonylphenol polyoxyethylene ether, stirred for 10 minutes, and stood still for 25 minutes.

Embodiment 2

[0036] The preparation method of the pigment that can be painted on the silicone rubber that is not easy to fall off and can be cleaned up in this embodiment comprises the following steps:

[0037] S1. Add 16.05% acrylic resin and 0.095% polyethylene glycol in sequence in the batching tank, turn on the high-speed disperser, control the speed at 1000r / min, and stir for 8 minutes;

[0038] S2. Make the fineness of Pigment Red P.R.112 reach 10-15 microns by grinding, add 0.6% Pigment Red P.R.112, and stir for 25 minutes;

[0039] S3, then add 15.6% titanium dioxide, 55.5% water, and disperse at high speed for 20 minutes;

[0040] S4, then add 0.8% propylene glycol, 0.125% triethanolamine, 0.077% sodium alkane sulfonate, 9.95% polymethacrylate, 0.38% polyether sulfonate, 0.25% branched chain alkyl Sodium benzenesulfonate, 0.4% fatty alcohol polyoxyethylene ether, 0.125% fatty alcohol polyoxyethylene ether carboxylate, 0.048% nonylphenol polyoxyethylene ether, stirred for 12 minut...

Embodiment 3

[0042] The preparation method of the pigment that can be painted on the silicone rubber that is not easy to fall off and can be cleaned up in this embodiment comprises the following steps:

[0043] S1. Add 16.5% acrylic resin and 0.05% polyethylene glycol in sequence in the batching tank, turn on the high-speed disperser, control the speed at 1500r / min, and stir for 6 minutes;

[0044] S2. Make the fineness of Pigment Yellow P.Y.151 reach 10-15 microns by grinding, add 1.0% Pigment Yellow P.Y.151, and stir for 20 minutes;

[0045] S3, then add 15.5% titanium dioxide and 55.2% water, and disperse at high speed for 20-30 minutes;

[0046] S5, then add 0.75% propylene glycol, 0.2% triethanolamine, 0.05% sodium alkane sulfonate, 9.87% polymethacrylate, 0.25% polyether sulfonate, 0.2% branched chain alkyl Sodium benzenesulfonate, 0.3% fatty alcohol polyoxyethylene ether, 0.075% fatty alcohol polyoxyethylene ether carboxylate, 0.055% nonylphenol polyoxyethylene ether, stirred for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com