Method for making shutter blade

A shutter and blade technology, applied in the field of shutter blades, can solve the problems that textiles do not have and cannot use shutters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

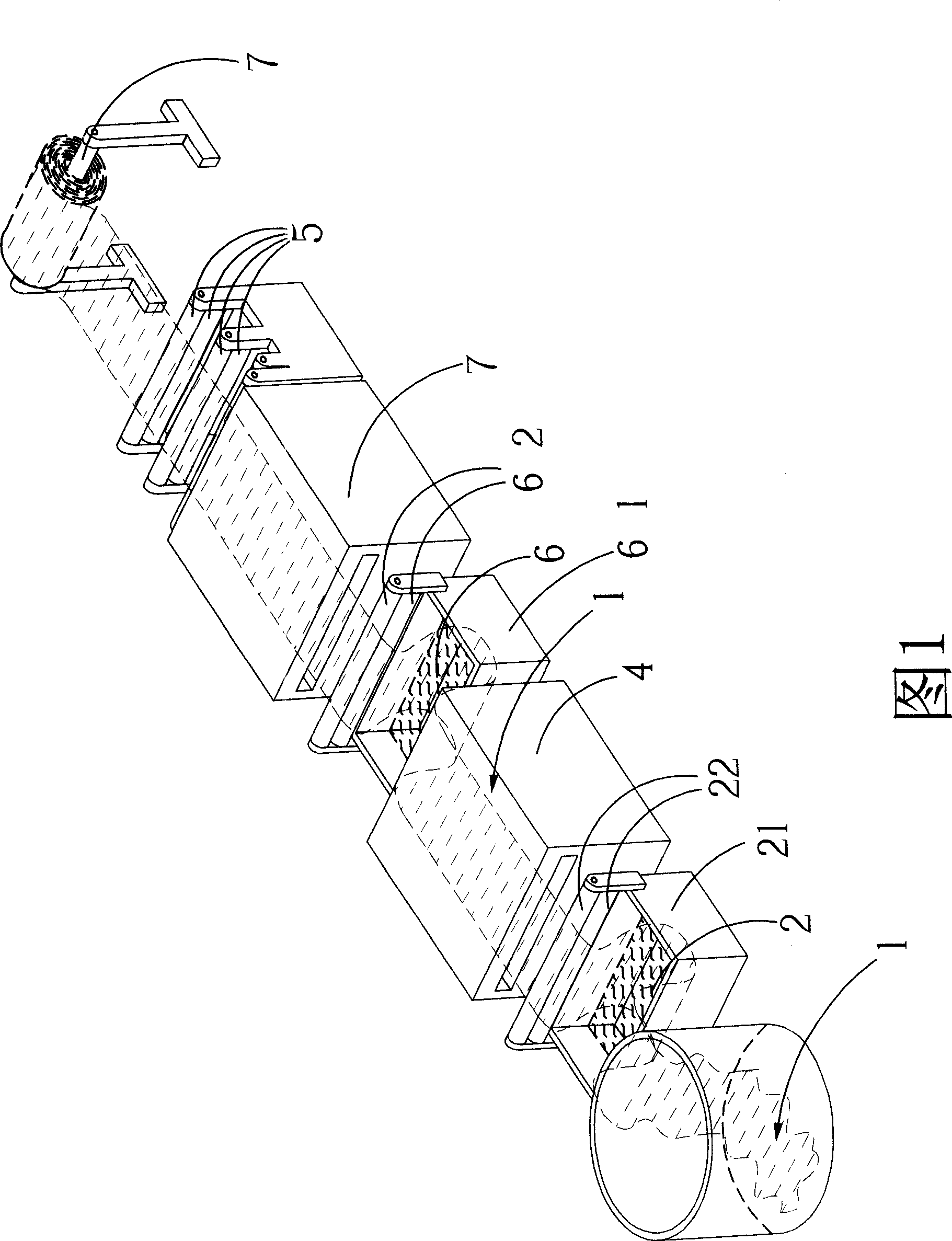

[0028] Please refer to Fig. 1, the present invention provides a method for making louver blades, which overcomes the softness of general textiles, and has what the louver blades made of general hard materials do not have, including the following steps:

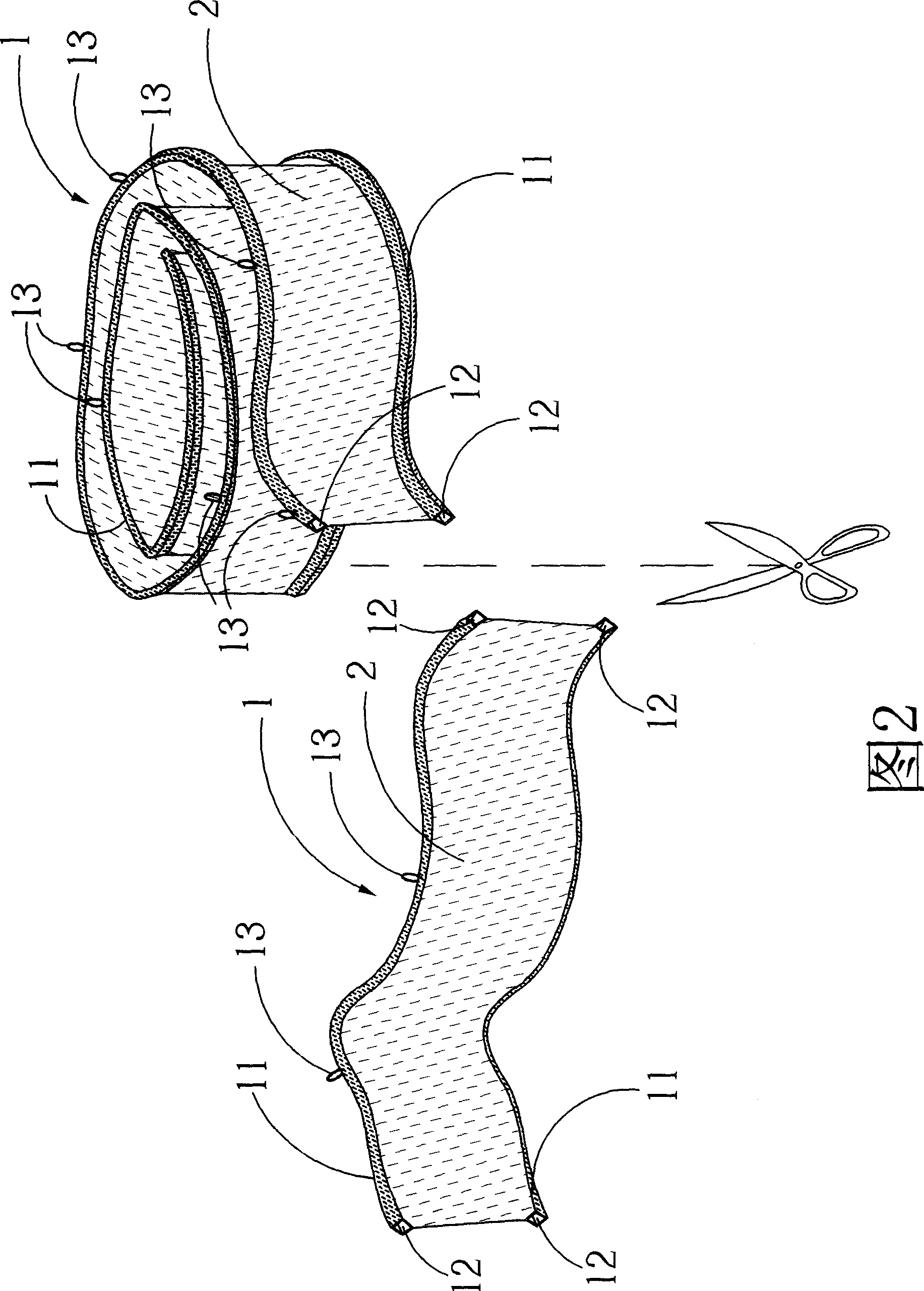

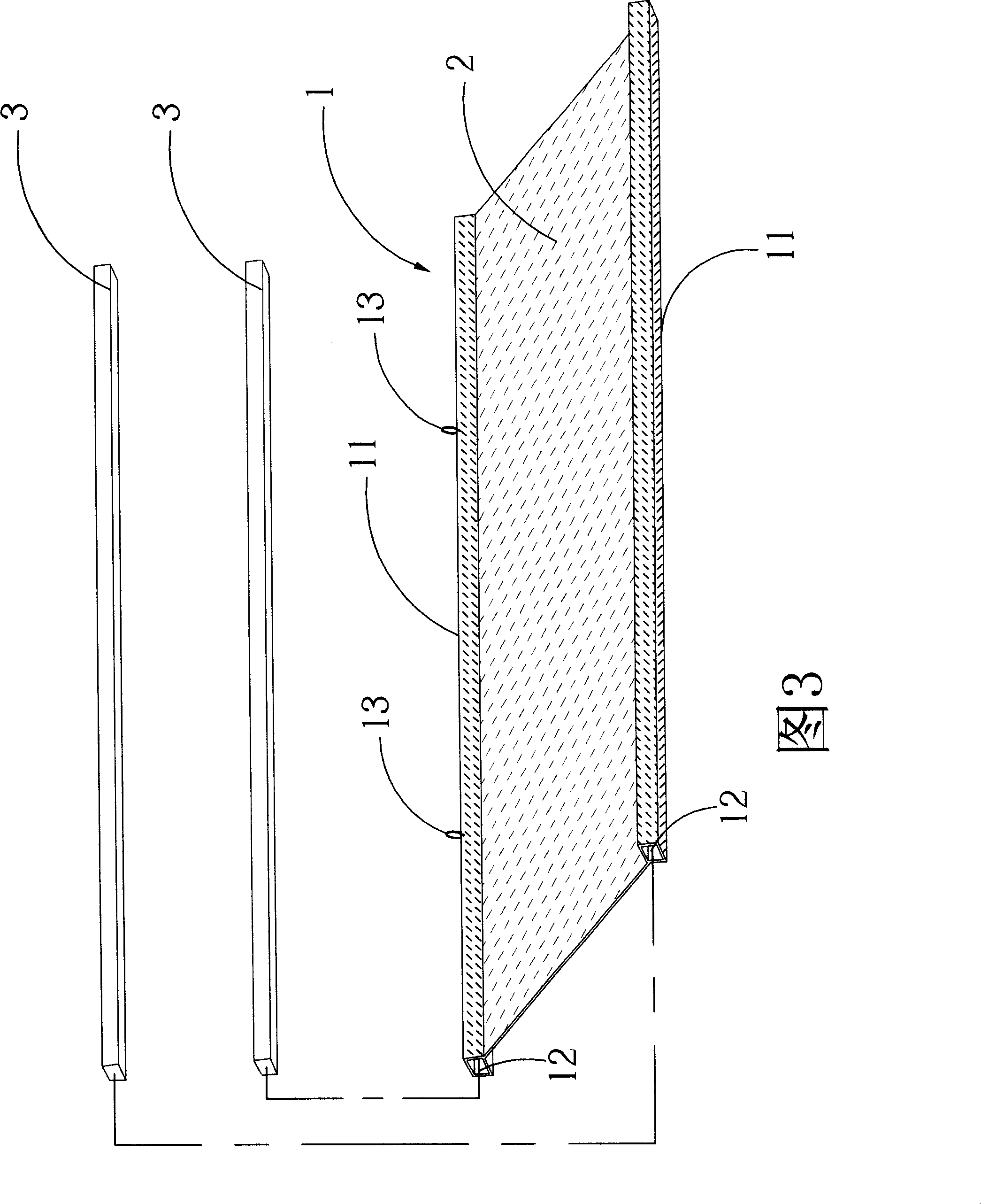

[0029] (a) braiding a strip-shaped textile 1, wherein the two long edges 11 of the textile are woven into double layers, thereby forming a strip-shaped internal space 12;

[0030] (b) immerse the strip-shaped textile 1 in the stiffening agent 2, wherein the strip-shaped textile passes through the stiffening agent 2 at a predetermined speed;

[0031] (c) extruding the soaked textile so that the hardener is evenly distributed inside the textile;

[0032] (d) drying the textile fabric 1 impregnated with the stiffening agent 2 at a high temperature in the range of 100-180 degrees Celsius; and

[0033] (e) High-temperature setting The textile 1 is dried at high temperature to make it flat, so that it can be used as horizontal or v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com