Method for Vectran carbon fiber surface modification of plasma coated with silicon dioxide colloidal sols by plasma treatment

A nano-silica, plasma technology, applied in the fiber type, fiber treatment, physical treatment and other directions, can solve the problem of not mentioning coating Vectran fiber, etc., to achieve fiber bulk performance optimization, composite performance improvement, wetting effect improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

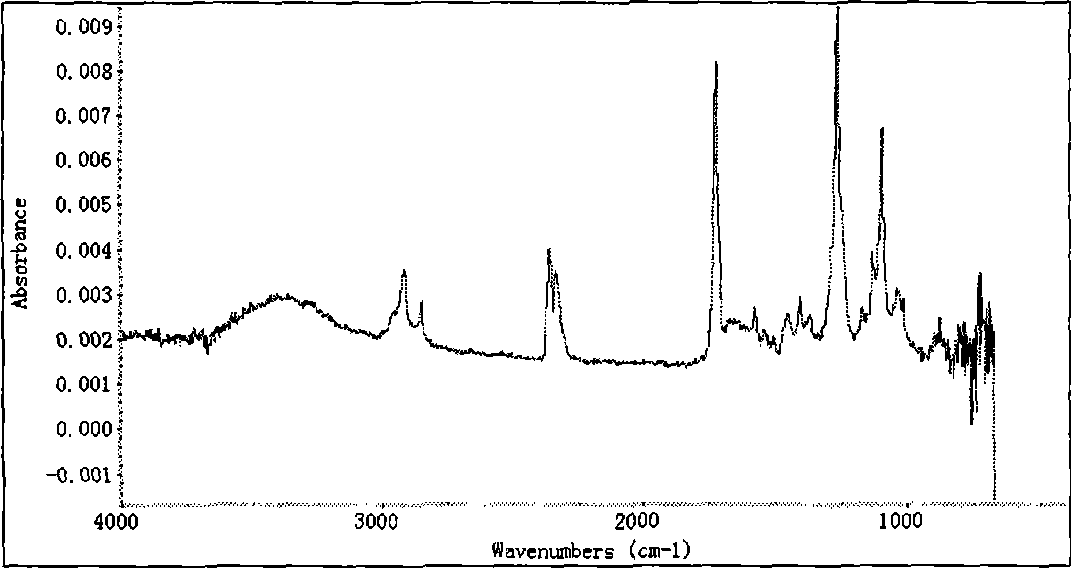

[0034] Nano-Silica Sol Coated VECTRAN Fibers Treated by Helium Plasma

[0035] see Figure 6 As shown, the VECTRAN fiber 1 to be treated is immersed in nano-silica sol (0.05%) along the outer circle of the flower basket of the sol padding device 2, and the padding process is carried out, and then the VECTRAN fiber is introduced into the drying device 3, at a specific temperature Dry and collect the solvent. Then the VECTRAN fiber is introduced into the plasma atmosphere area of the plasma nozzle 4 to carry out plasma surface modification (the upper surface of the fiber bundle is 5MM away from the nozzle, the lower surface of the fiber bundle is less than 20MM away from the nozzle, and it is processed under 40 watts of power and 2 seconds) , there is an automatic winder 5 at the rear, which can wind the processed VECTRAN fiber 1 online, and adjust the line speed of the VECTRAN fiber by adjusting the speed of the winding shaft. According to the needs of different processing t...

example 2

[0037] Oxygen plasma treatment of nano-silica sol coated VECTRAN fibers

[0038] see Figure 6 As shown, the VECTRAN fiber 1 to be treated is immersed in nano-silica sol (0.05%) along the outer circle of the flower basket of the sol padding device 2, and the padding process is carried out, and then the VECTRAN fiber is introduced into the drying device 3, at a specific temperature Dry and collect the solvent. Then the VECTRAN fiber is introduced into the plasma atmosphere area of the plasma nozzle 4 to carry out plasma surface modification (the upper surface of the fiber bundle is 5MM away from the nozzle, the lower surface of the fiber bundle is less than 20MM away from the nozzle, and it is processed under 40 watts of power and 2 seconds) , there is an automatic winder 5 at the rear, which can wind the processed VECTRAN fiber 1 online, and adjust the speed of the carbon fiber by adjusting the speed of the winding shaft. According to the needs of different processing techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com