Metal powder injection molding inductor and processing method thereof

A technology of metal powder and injection molding, which is applied in the manufacture of inductors/transformers/magnets, transformer/inductor coils/windings/connections, inductors with magnetic cores, etc., which can solve the problems of poor electrical performance consistency and production costs of power inductors Advanced problems, to achieve the effect of light weight, no harmful substances, and clean production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

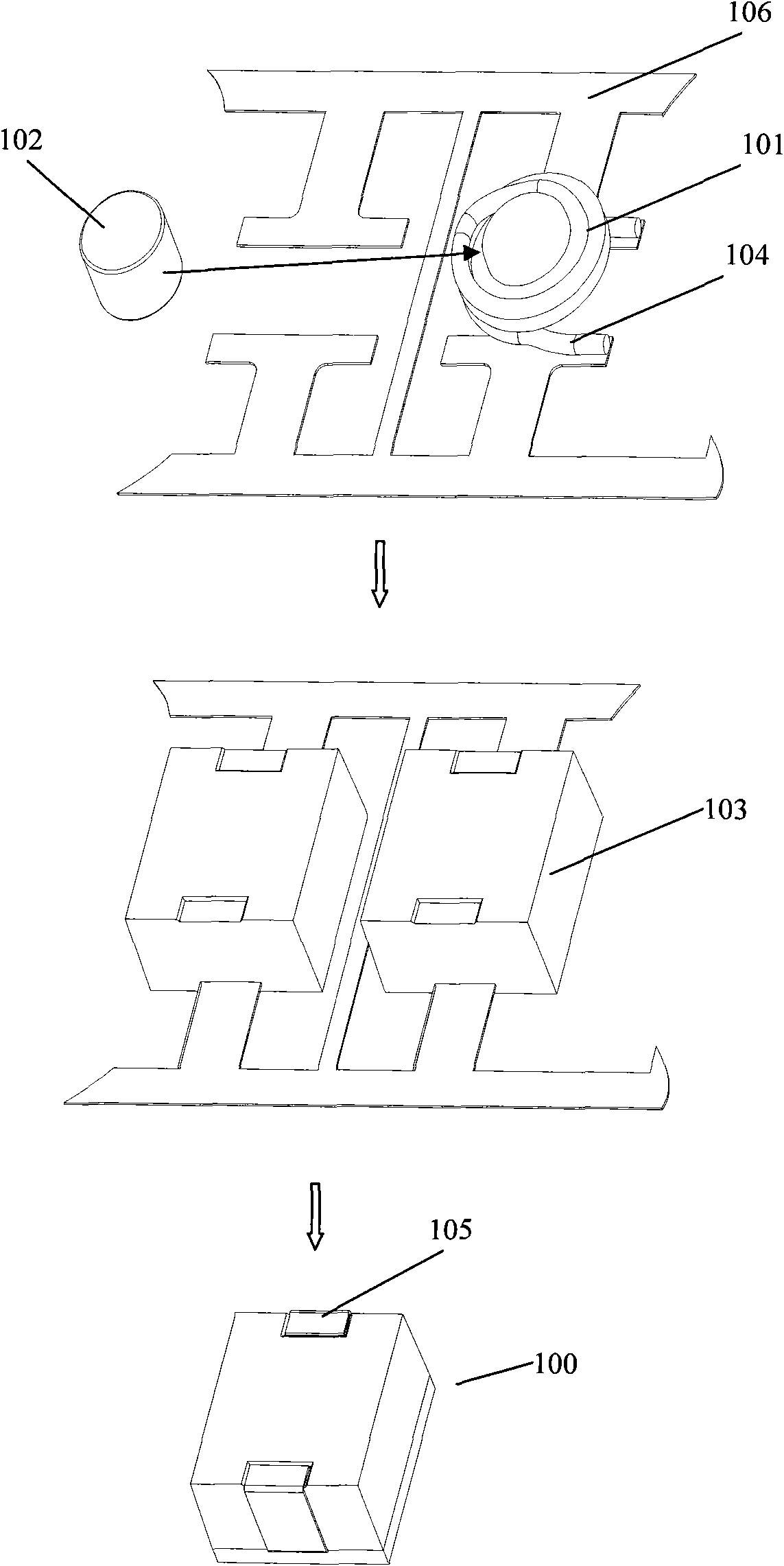

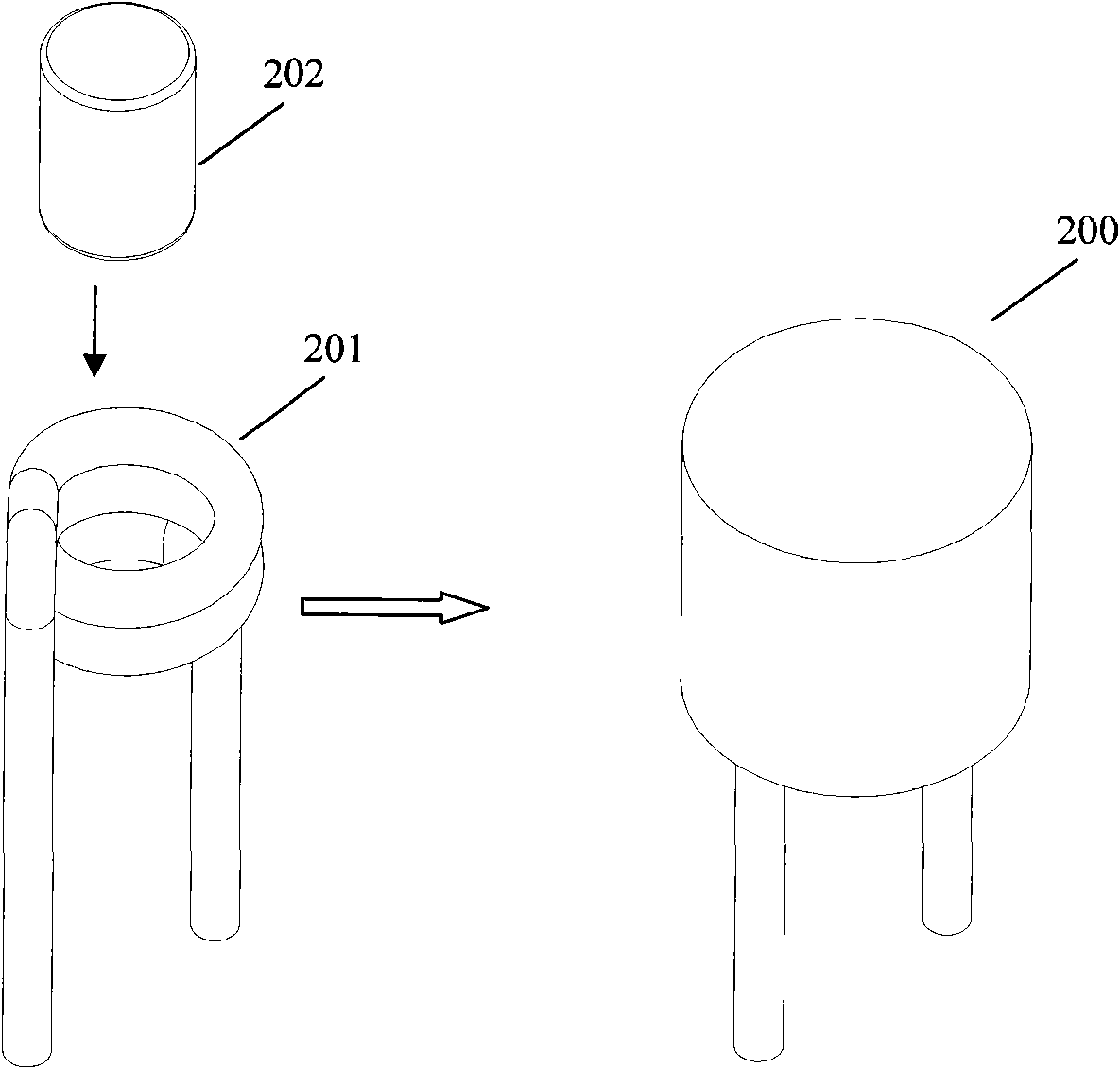

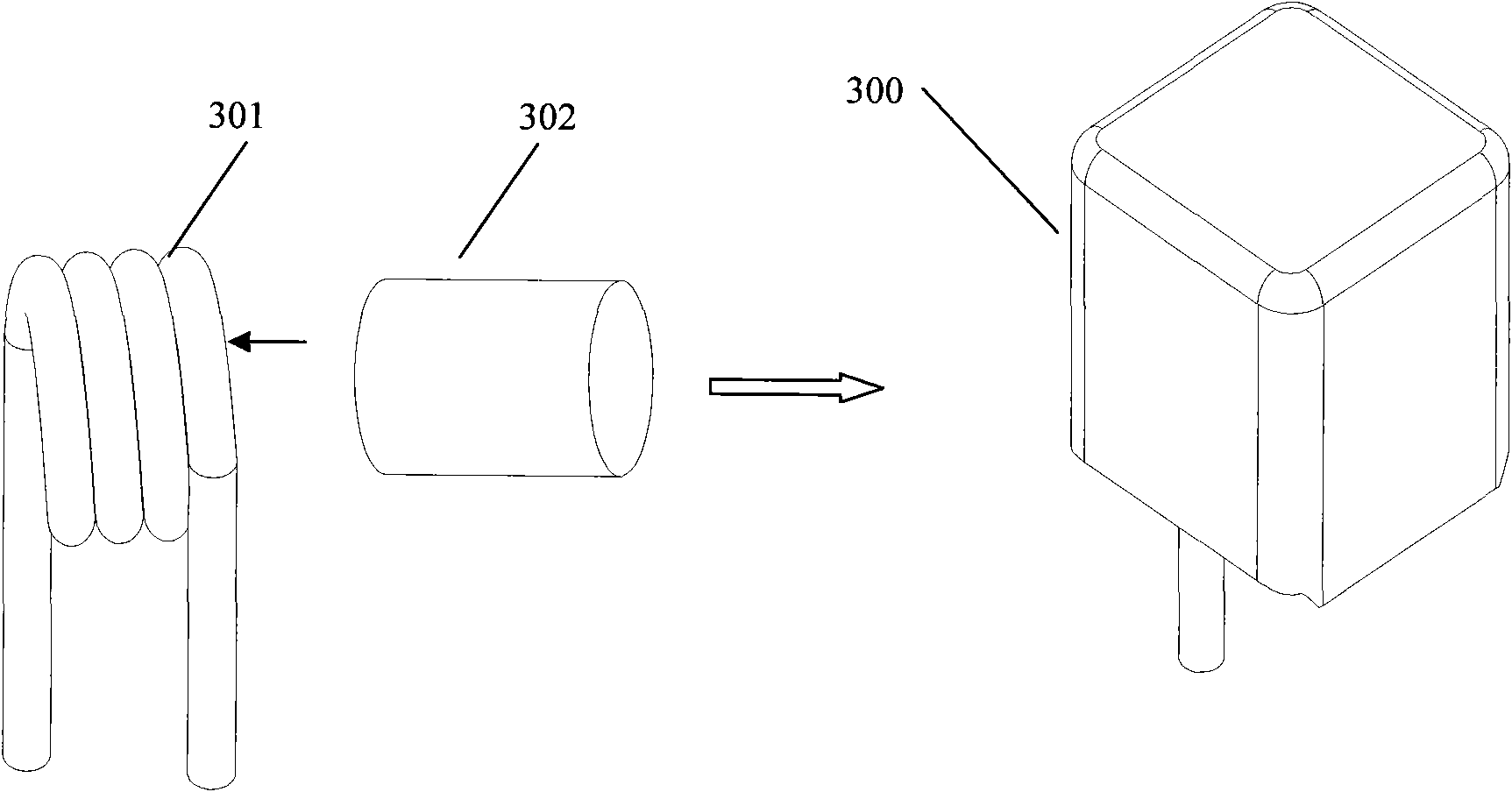

[0021] 70% of the main performance of the inductor depends on the material selection of the inner space of the coil, and the outer material of the coil is mainly used to form a closed magnetic circuit, realize electromagnetic shielding, reduce eddy current, and realize physical insulation and heat dissipation , resistance to welding heat, and the realization of mechanical coating protection. The magnetoelectric properties of the metal powder core made of metal powder mainly depend on the magnetic permeability of the metal powder; and the saturation magnetic induction value of the widely used metal powder material is about 1.4T, and the magnetic permeability ranges from 22-100 , such a low magnetic permeability limits its application range. If you want to choose a material with a magnetic permeability above 100, you can only choose fragile ferrite at present. The present invention skillfully utilizes the complementarity of the characteristics of ferrite and iron powder core, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com