Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62 results about "Amorphism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An Amorphism, in chemistry, crystallography and, by extension, to other areas of the natural sciences is a substance or feature that lacks an ordered form. In the specific case of crystallography, an amorphic material is one that lacks long range (significant) crystalline order at the molecular level. In the history of chemistry, amorphism was recognised even before the discovery of the nature of the exact atomic crystalline lattice structure. The concept of amorphism can also be found in the fields of art, biology, archaeology and philosophy as a characterisation of objects without form, or with random or unstructured form.

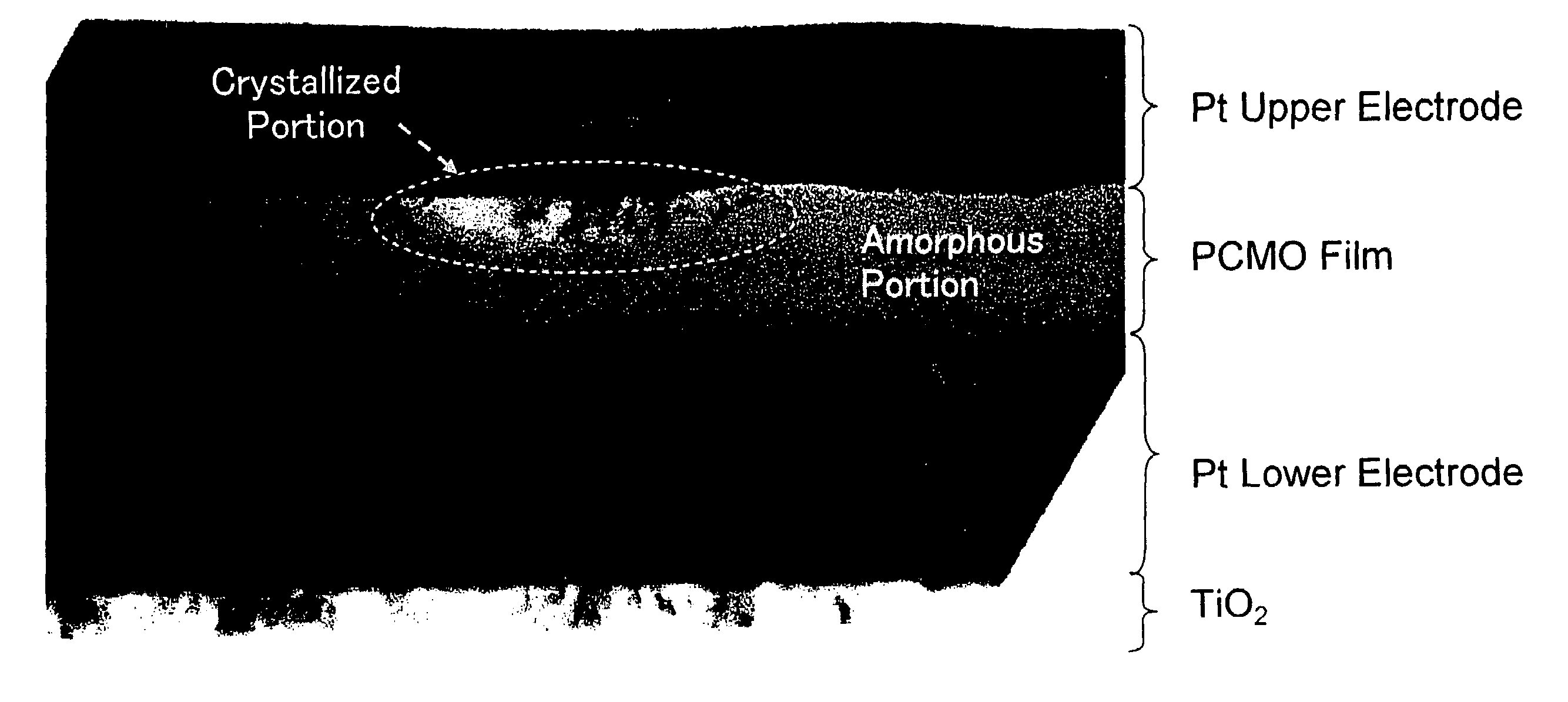

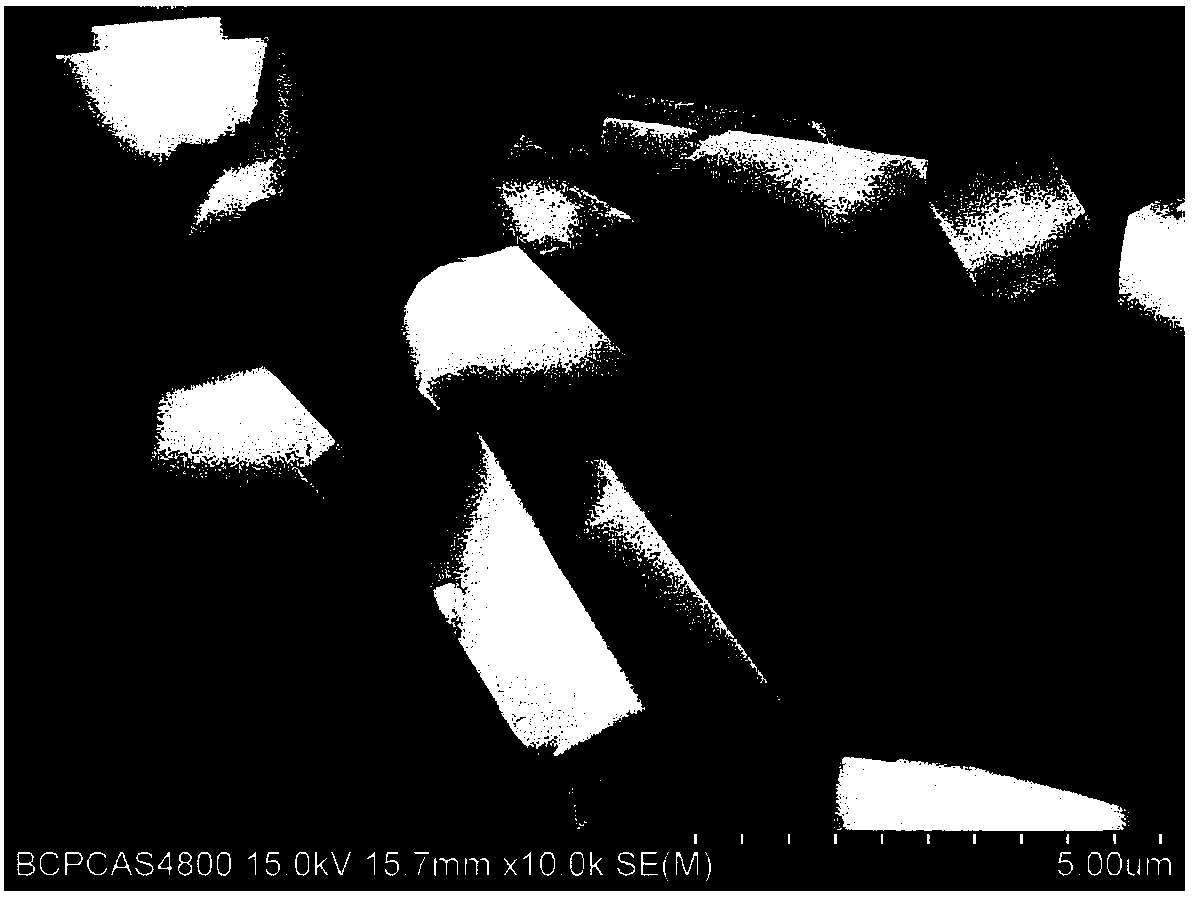

Nonvolatile semiconductor memory device

A nonvolatile memory element is formed by layering a lower electrode, a variable resistor and an upper electrode in sequence. The variable resistor is formed in which crystallinity and amorphism are mixed. Thus, the nonvolatile memory element is formed. More preferably, the variable resistor is a praseodymium-calcium-manganese oxide represented by a general formula, Pr1-xCaxMnO3, that has been formed at a film forming temperature from 350° C. to 500° C. Alternatively, the variable resistor is formed as a film at a film forming temperature that allows the variable resistor to become of an amorphous state or a state where crystallinity and amorphism are mixed and, then, is subjected to an annealing process at a temperature higher than the film forming temperature, in a temperature range where the variable resistor can maintain the state where crystallinity and amorphism are mixed.

Owner:XENOGENIC DEV LLC

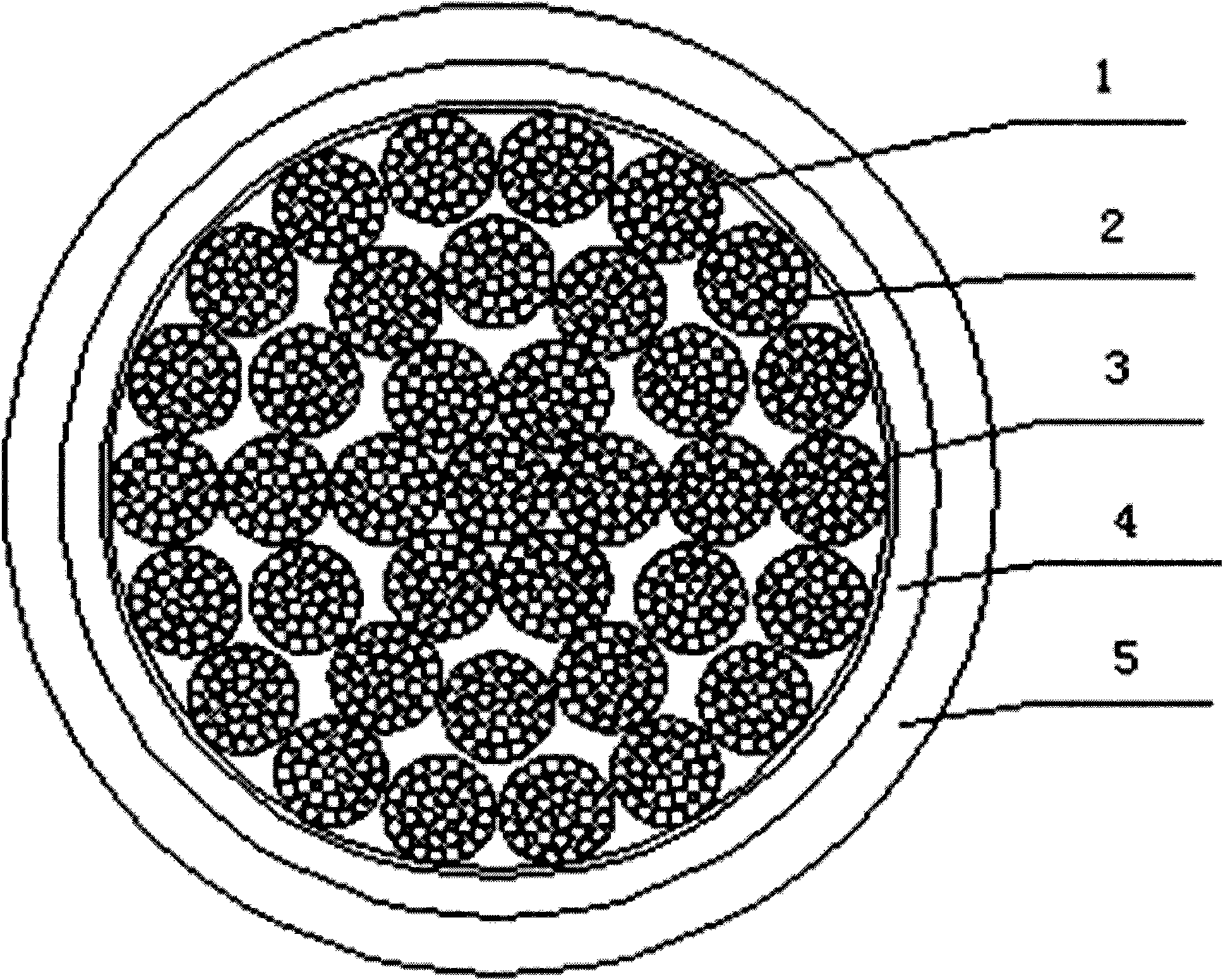

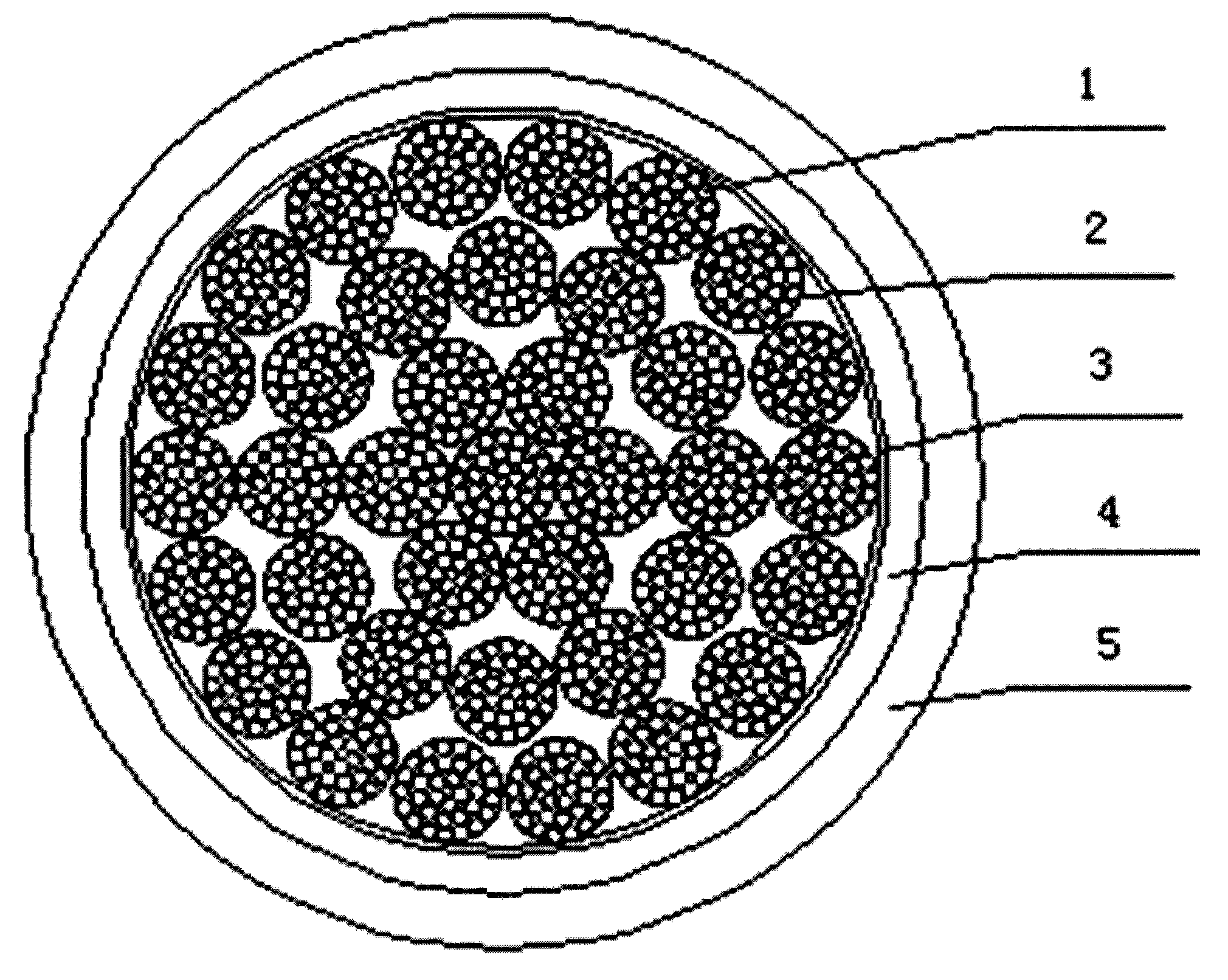

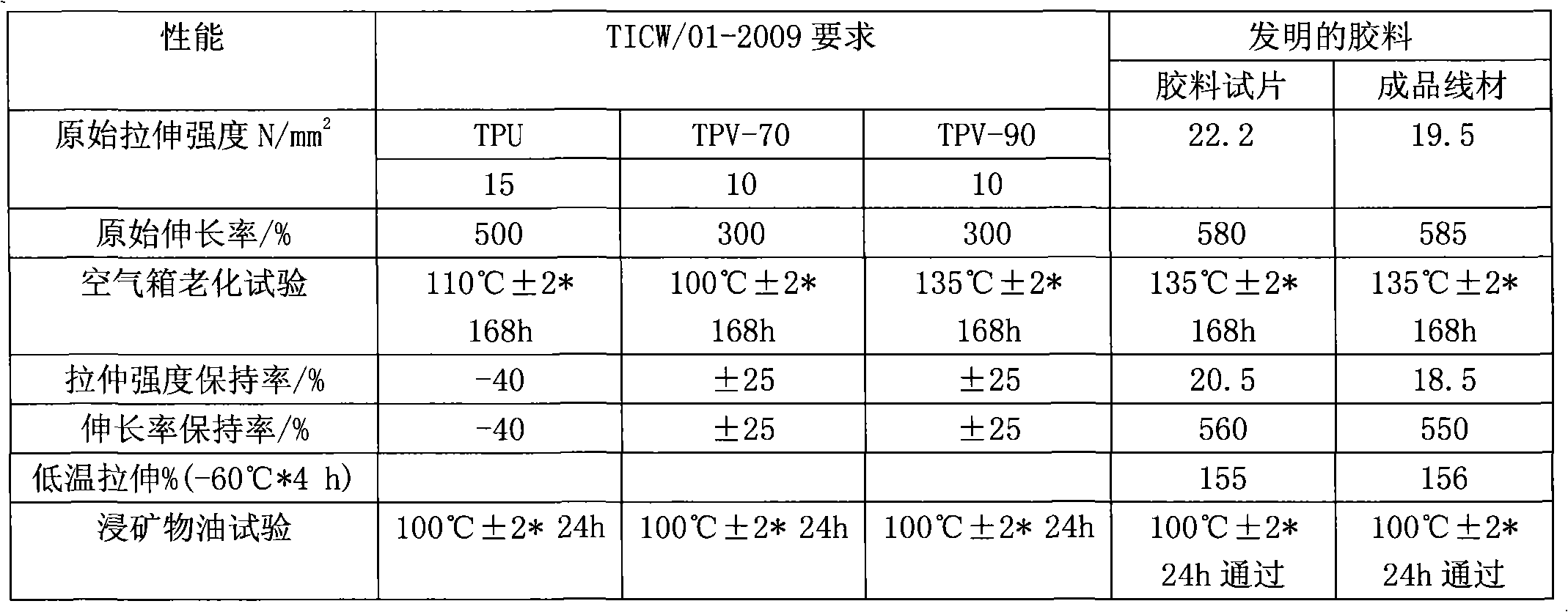

Distortion-resistance wind power generation cable sheath materials and cable

InactiveCN101838424AImproves UV resistanceFunction increasePlastic/resin/waxes insulatorsFlexible cablesElastomerCross-link

The invention discloses a distortion-resistance wind power generation cable sheath material and a cable. The cable material comprises the following components in weight parts: 100 parts of chlorinated polyethylene, 10-30 parts of amorphism copolymer, 10-20 parts of cold-resistant plasticizer, 40-80 parts of reinforcing filler, 5-15 parts of nanosacle inorganic active agent, 2.5-5 parts of cross-linking agent, 2-5 parts of cross-linking assistant agent, 1-2.5 parts of antioxidant antiager and 10-30 parts of inorganic fire retardant, wherein the amorphism copolymer is a mixture of amorphism polyolefin thermoplastic elastomer and chlorinated polyethylene elastic body; and the nanoscale inorganic active agent is nanoscale zinc oxide and magnesium oxide. The cable of the invention has low-temperature resistance (-60DEG C)and distortion resistance, excellent flexibility, improves the homogenisieren property of the other materials by adding the nanoscale inorganic active materials, improves the molecular structure, has better flexibility because of the uvio-resistance, and has the characteristics of distortion, cold, oil and corrosion resistance and the like.

Owner:江苏凯诺电缆集团有限公司

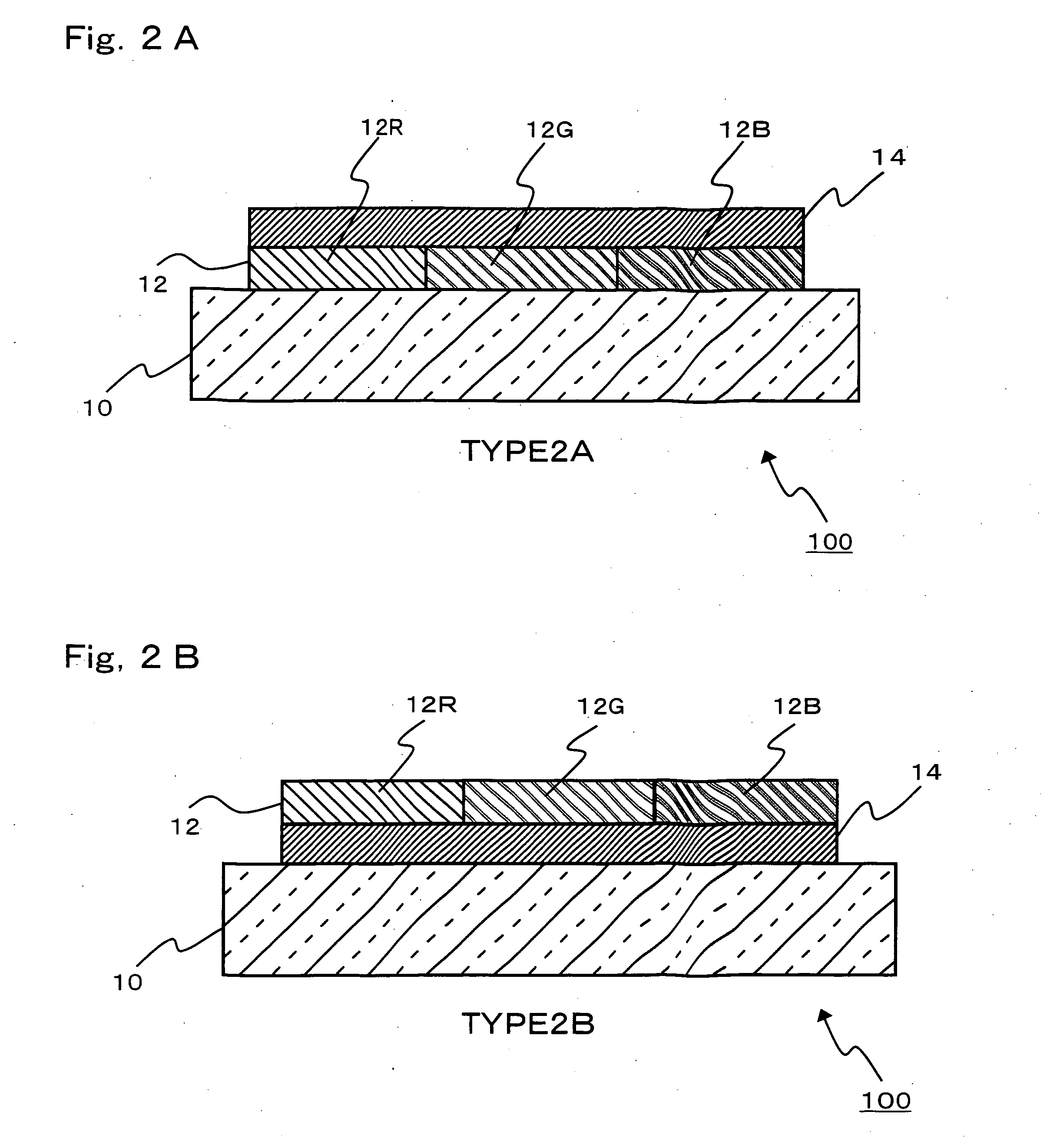

Amorphous transparent conductive film, sputtering target as its raw material, amorphous transparent electrode substrate, process for producing the same and color filter for liquid crystal display

InactiveUS20070117237A1High resistivitySufficient advantageous effectConductive materialVacuum evaporation coatingIndiumLiquid-crystal display

A transparent conductive film of low resistivity excelling in transparency and etching properties; a sputtering target as its raw material; an amorphous transparent electrode substrate having the transparent conductive film superimposed on a substrate; and a process for producing the same. In particular, an amorphous transparent conductive film comprising at least indium oxide and zinc oxide, which contains at least one third metal selected from among Re, Nb, W, Mo and Zr and satisfies the formulae: 0.75≦[In] / ([In]+[Zn])≦0.95 (1) 1.0×10−4≦[M] / ([In]+[Zn]+[M])≦1.0×10−2 (2) wherein [In][Zn] and [M] represent the atomicity of In, atomicity of Zn and atomicity of third metal, respectively. This amorphous transparent conductive film exhibits amorphism ensuring excellent etching processability and exhibits low specific resistance and high mobility.

Owner:IDEMITSU KOSAN CO LTD

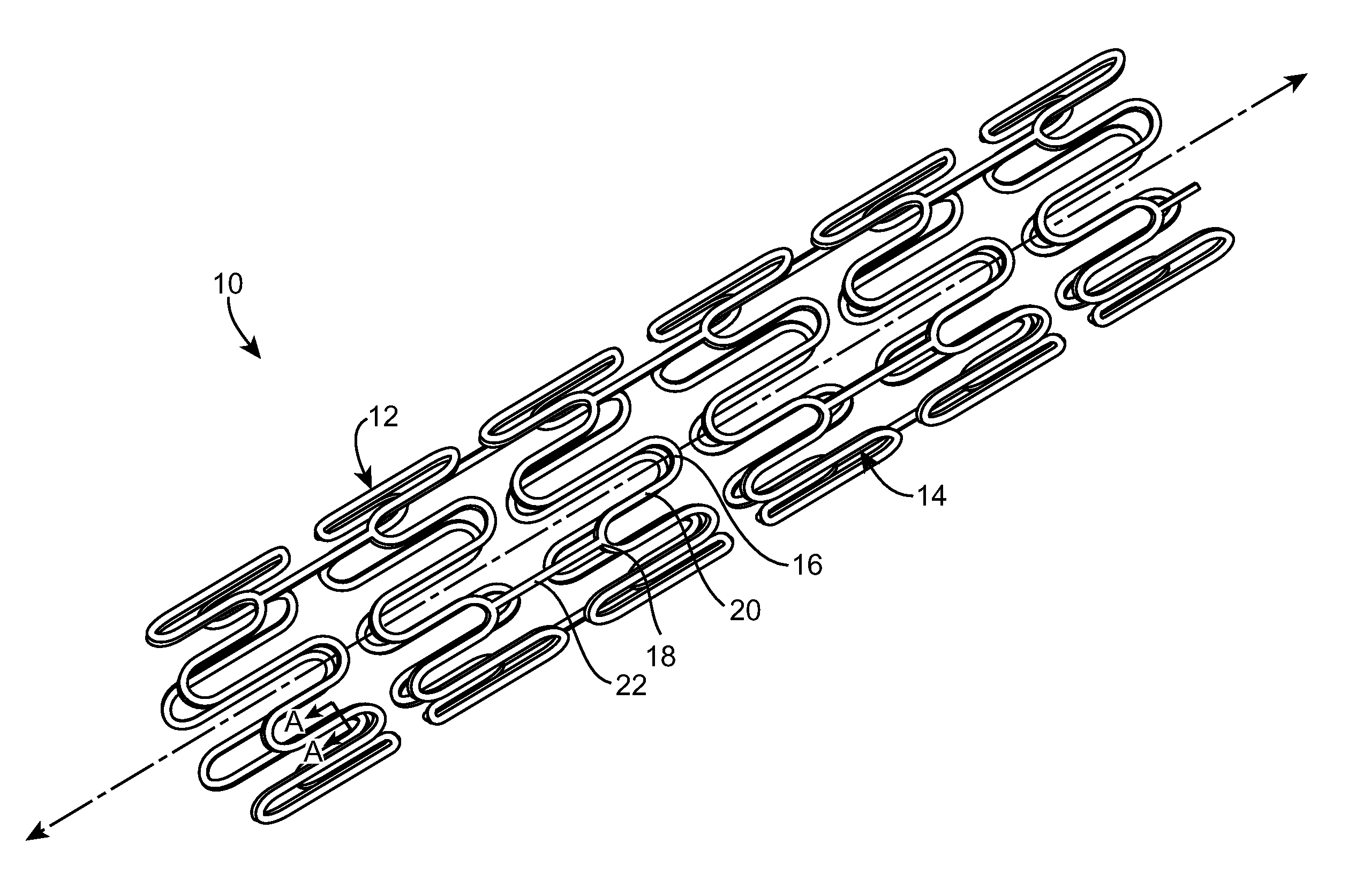

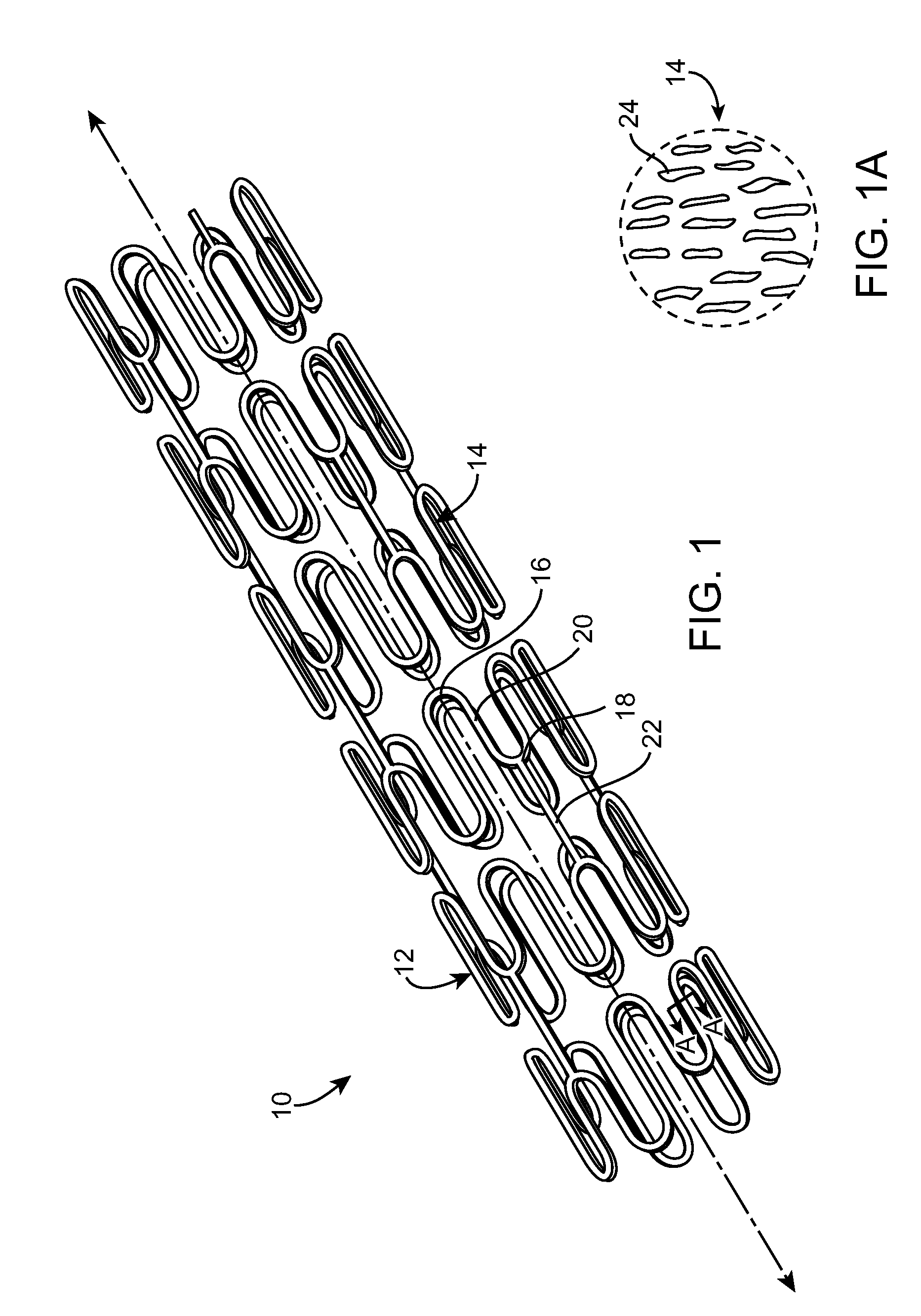

Stent Having Controlled Porosity for Improved Ductility

An endoluminal prosthesis for placement in a body lumen of a metallic material having controlled porosity for improved ductility. The metallic material may be formed into a stent structure or a wire or sheet, which may then be formed into the stent structure. The porous network of the stent includes pores that range from nanometer scale to micron scale. The controlled porosity accommodates volume changes as well as provides a barrier to crack propagation to allow alloy steels and amorphous metal materials, which would otherwise be considered too brittle for the demands of intraventional use, to be utilized in a stent.

Owner:MEDTRONIC VASCULAR INC

Nonvolatile semiconductor memory device

ActiveUS7259387B2Improve variationSmall sizeSemiconductor/solid-state device detailsSolid-state devicesAmorphismEngineering

A nonvolatile memory element is formed by layering a lower electrode, a variable resistor and an upper electrode in sequence. The variable resistor is formed in which crystallinity and amorphism are mixed. Thus, the nonvolatile memory element is formed. More preferably, the variable resistor is a praseodymium-calcium-manganese oxide represented by a general formula, Pr1-xCaxMnO3, that has been formed at a film forming temperature from 350° C. to 500° C. Alternatively, the variable resistor is formed as a film at a film forming temperature that allows the variable resistor to become of an amorphous state or a state where crystallinity and amorphism are mixed and, then, is subjected to an annealing process at a temperature higher than the film forming temperature, in a temperature range where the variable resistor can maintain the state where crystallinity and amorphism are mixed.

Owner:XENOGENIC DEV LLC

Preparation method of ferric phosphate and product thereof

ActiveCN101913586AImprove the operating environmentCell electrodesPhosphorus compoundsOrganic solventAmorphism

The invention discloses a preparation method of ferric phosphate and a product thereof. The preparation method comprises the following steps of: (1) introducing a ferric iron source solution into an acid resistant reaction kettle by using a metering pump, and then adding a certain dosage of phosphoric acid solution and stirring for 1h; (b) adding a certain dosage of organic solvent to the acid resistant reaction kettle, and preserving heat at 15-98 DEG C and aging for 0.5-24h; and (c) carrying out washing, filtering and spray drying on the obtained ferric phosphate slurry to obtain a final ferric phosphate product, wherein the proportion by weight of the water to the iron to the phosphoric acid to the organic solvent is 100:1-20:1-30:1-500. In the method, the traditional alkali is replaced by the organic solvent to prepare the ferric phosphate; and because the organic solvent has milder property and no harm to the human body, and the operating environment is beneficially improved after mass production. The ferric phosphate of two different crystal forms of amorphism and orthorhombic systems can be prepared by adopting the method.

Owner:铜陵纳源材料科技有限公司

TS-1 zeolite material with multi-level pores and preparation method of TS-1 zeolite material

ActiveCN108658087AGuarantee structureUniform structureMolecular sieve catalystsMolecular-sieve silicatesMolecular sieveVapor phase

The invention discloses a TS-1 zeolite material with multi-level pores. The TS-1 zeolite material comprises TS-1 zeolite and a TiO2-SiO2 carrier, and a weight ratio of the TS-1 zeolite to the TiO2-SiO2 carrier is 1:(4.8-9); the zeolite material is an integral forming material having macropores of 0.20-2 [mu]m, mesopores of 2-15 nm and micropores of 0.5-2 nm, a crystal lattice structure of the zeolite material is that a part of Ti<4+> enters a molecular sieve skeleton, a part of Ti<4+> is uniformly embedded in a SiO2 skeleton in a manner of an anatase crystal form, and SiO2 exhibits an amorphous state. The zeolitic material disclosed by the invention adopts a TiO2-SiO2 material as the carrier, a silicon source and a titanium source, under the vapor phase condition, the skeleton is partiallyconverted into the TS-1 zeolite, and a micron-sized through-hole skeleton structure of the carrier is maintained; and the prepared TS-1 zeolite has an uniform and stable structure and the multi-levelpores communicating with one another, thereby having very important significance for a macromolecular catalytic reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

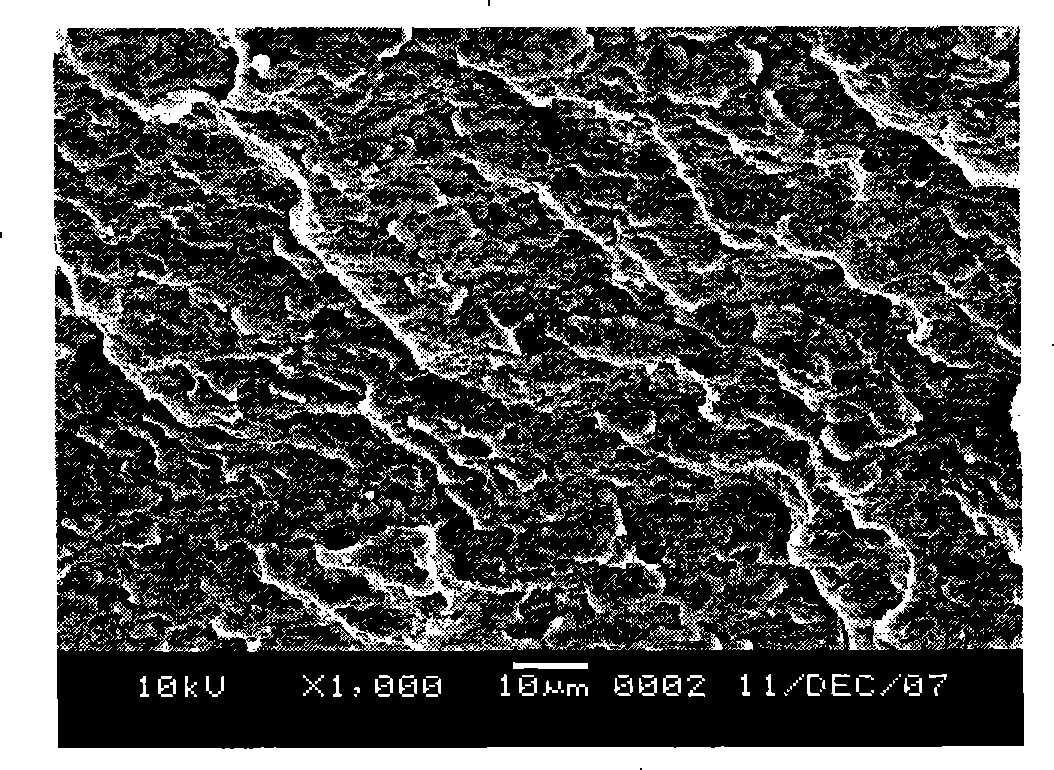

Femtosecond laser amorphism fine machining method for amorphous alloy

InactiveCN1966203AShort durationHigh peak powerOther manufacturing equipments/toolsLaser beam welding apparatusAmorphismOptoelectronics

The invention relates to a non-crystal fine processing method which uses femtosecond laser to process non-crystal alloy, wherein said method uses femtosecond laser to make hole, etch, and cut the non-crystal alloy, while the impulse energy density of femtosecond laser is 50-100H / cm2 and the impulse width is 45-100fs in holing; the impulse energy density is 3-15J / cm2, the impulse width is 45-100fs, and the scanning speed is 100-200 mum / s in etching line; the impulse energy density is 75-110J / cm2, the impulse width is 45-100fs, and the scanning speed is 100-200 mum / s in cutting. The invention can realize sub-micron processing accuracy, without crystallization in etching area.

Owner:HUAZHONG UNIV OF SCI & TECH

Intensive-network self-optimizing switching method

ActiveCN104955116AImprove switching performanceHigh call drop rateWireless communicationFailure rateResource utilization

The invention provides an intensive-network self-optimizing switching method and belongs to the technical field of radio communication. According to the architecture characteristics of intensiveness, hierarchy and amorphism of an intensive heterogeneous honeycomb network and switching characteristics of high frequency and low performance, the intensive-network self-optimizing switching method includes firstly sensing passing-by rate, moving speed, acceptance and idle degrees of a target honeycomb of an MS (mobile station), acquiring of tendency of the MS to the target honeycomb by the passing-by rate and the speed based on FL (fuzzy logic), and acquiring affinity of the honeycomb towards new users by the acceptance and the idle degrees, and self-adaptively adjusting switching parameters based on Q-Learning algorithm by taking tendency and affinity as input and resource utilization rate, call drop rate, switching failure rate and ping-pong switching rate as instant awards, so as to optimize the switching failure rate, the ping-pong switching rate and the call drop rate. Compared with the prior art, the intensive-network self-optimizing switching method can remarkably improve high-switching failure rate, ping-pong switching rate and call drop rate of the MS under the intensive heterogeneous network.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Solid desulfurating agent

ActiveCN101591571AIncrease Fe contentImprove desulfurization efficiencyDispersed particle separationCombustible gas purificationCalcium hydroxideCubic crystal system

The invention relates to a solid desulfurating agent, comprising an active constitute cubic system crystalline phase Fe3O4, amorphism Fe2O3 and amorphism Fe2O3.H2O, and a paste product which is obtained from the reaction of assistant binder ferrous sulphate salt and calcium hydroxide; the invention further disclose a preparation method of the solid desulfurating agent on the basis of disclosing the constitutes of the solid desulfurating agent. The side pressure strength of the solid desulfurating agent prepared by the method in the invention can be as high as 85N / cm, and can be widely applied to the desulfurating technique of high temperature coal gasification materials.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for preparing magnesium diboride superconductive wire and strip

InactiveCN101279740AImprove compactnessFirmly connectedSuperconductors/hyperconductorsMetal boridesHigh magnesiumDiboride

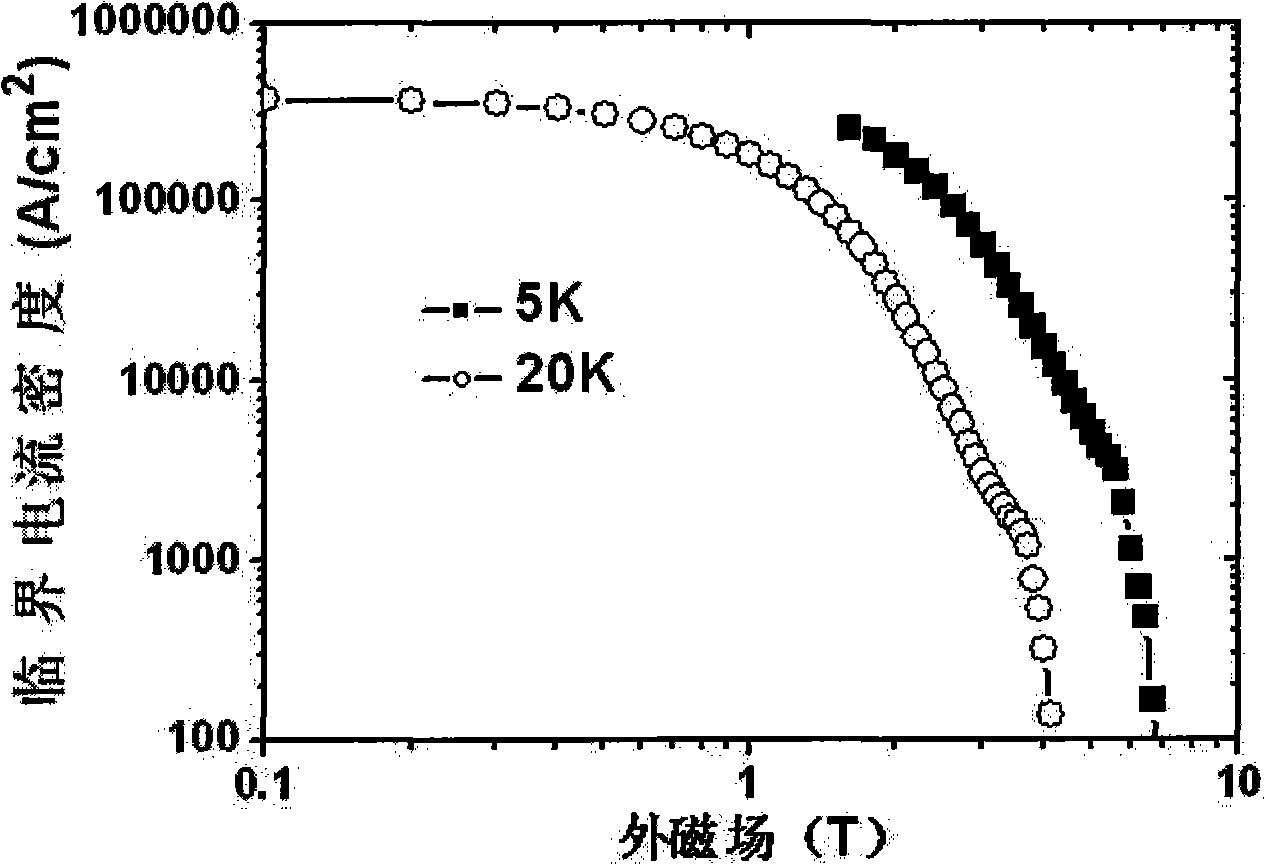

The invention relates to a method for preparing a magnesium boride superconducting line and belt material. The preparation method is that a. preparation of precursor powder: high magnesium diboride MgBx powder is taken as the precursor powder, wherein, x is more than or equal to 4 and less than or equal to 12; or magnesium powder and amorphism boron powder are mixed according to 1:3-20 of stoichiometric ratio between magnesium and boron to form the precursor powder; b. putting into a magnesium pipe: the precursor powder is put into a magnesium pipe, compacted and sealed; c. putting into a canning pipe: the magnesium pipe is put into a metal canning pipe and is sealed after the metal canning pipe is fully filled with metal powder as a barrier layer; or the magnesium pipe is first put into a barrier layer metal pipe and then is put into the metal canning pipe and the metal canning pipe is sealed; d. moulding treatment: the metal canning pipe is produced into line and belt material; e. heat treatment: the metal canning pipe is put into a pipe typed furnace and under the protection of argon, the temperature is raised to 700-1200 DEG C by the speed of 1-10 DEG C / minute, preserved for 1-30 hours and then cooled to room temperature. The MgB2 superconducting line and belt material prepared by the method has high compactability, good grain connectivity and even cross section.

Owner:SOUTHWEST JIAOTONG UNIV

Image processing system, toner and processing cartridge

InactiveCN101458483ANo filming issuesGood temperature fixabilityElectrographic process apparatusDevelopersInfraredImaging processing

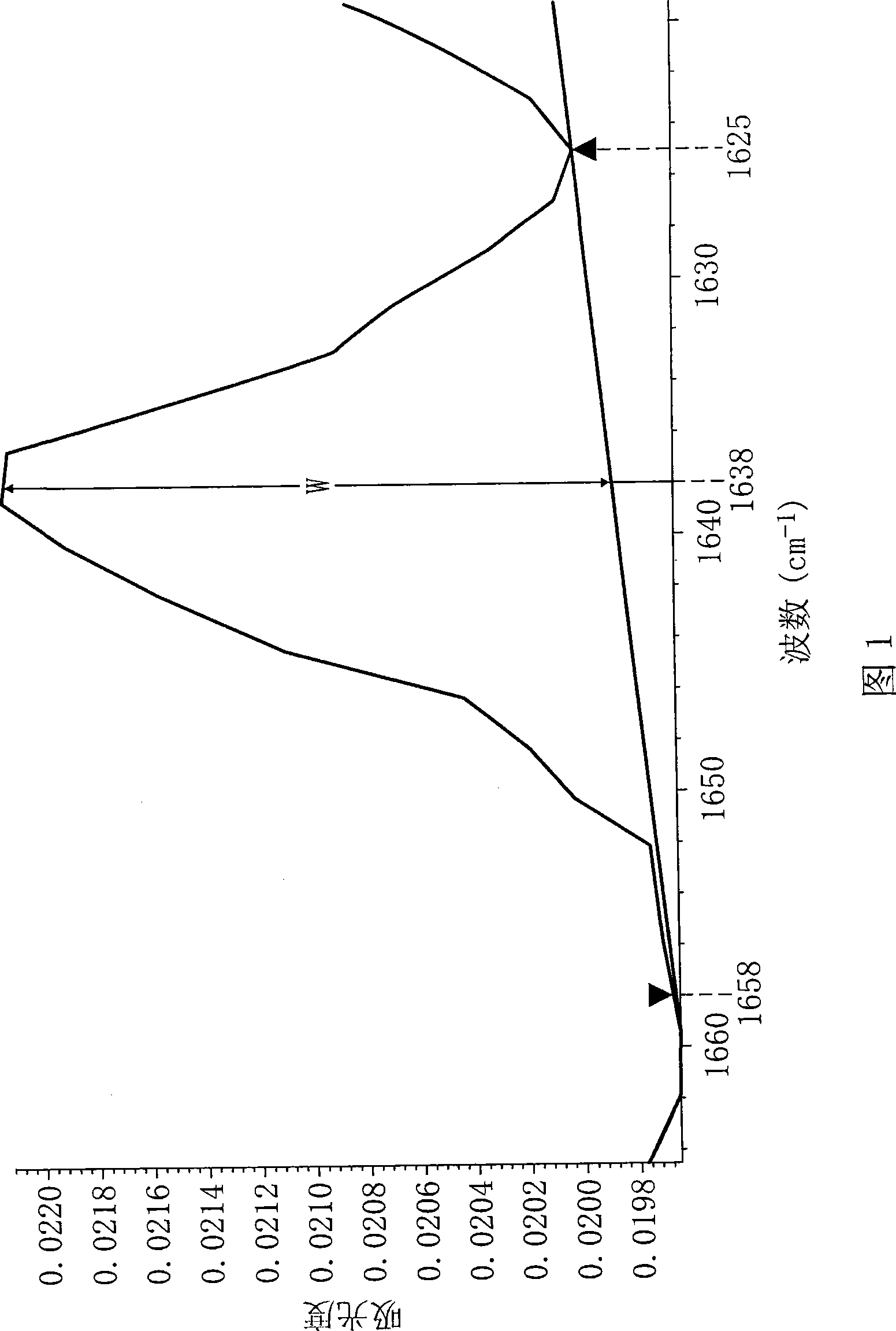

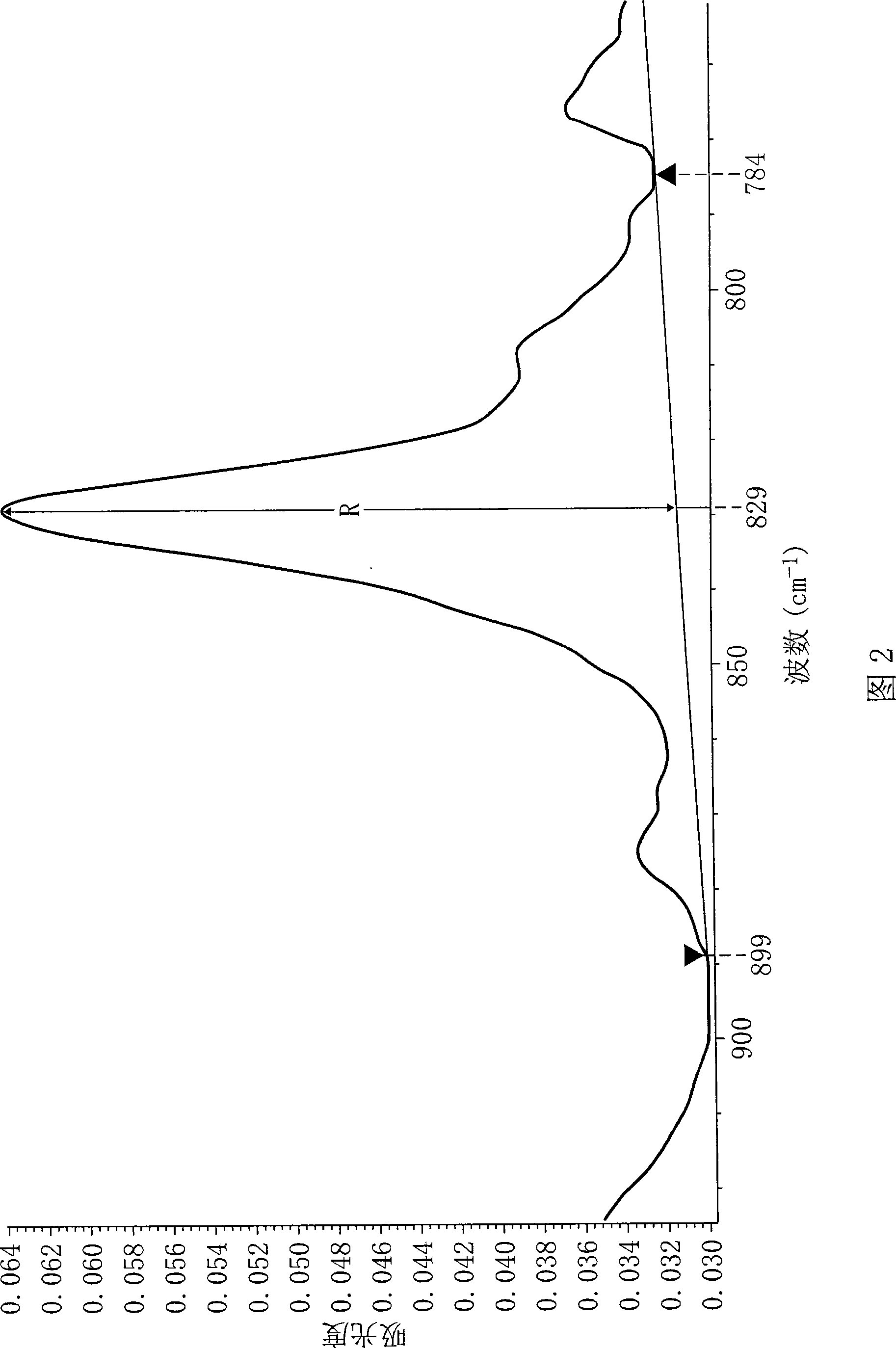

The invention provides an imaging forming device that includes a fixing device for fixing a toner image on a recording medium. The fixing device includes a hear roller and an oil applying device. The oil applying device is used for applying silicon oil on the heat roller. The image forming device has a system rate 500-1700 mm / sec and uses toner. The toner includes adhesive resin, crystal vibrin and amorphism resin; aliphatic series sulfonamide compound; and toner. Ratio of the height (W) showing aliphatic series sulfonamide compound that is obtained in absorption spectrum by ARR method of infrared spectrophotometer with Fourier to W / R showing amorphism resin height (R) is 0.010-0.040.

Owner:RICOH KK

Magnetic rheological fluid containing superfine amorphous muterial

InactiveCN1776835AHigh yield stressGood yield stressMagnetic liquidsInorganic material magnetismAlpha-olefinMaterials science

Chemical composition (in volume úÑ) of magnetic rheology liquid of containing superfine amorphous material is as following: magnetic particle 10-50úÑ is as reduced carbonyl iron in crystalline state and iron based amorphous soft magnetic alloys; carrier liquid 45-89úÑ is poly alpha olefin with viscosity as 1-300mPa.s under room temperature; surfactant 1-5úÑ is as titanate coupler and composite aluminium-titanium coupler. In the said magnetic particle, the reduced carbonyl iron in crystalline state (90-95úÑ of the magnetic particle)is spheroidal particle with size range 1-30 micro; and iron based amorphous soft magnetic alloys (5-10úÑ of the magnetic particle)is acicular particles. Comparing prior art, the invention possesses advantages of lower viscosity coefficient in zero field, high yield stress, fine antiflooding stability and excellent magnetic performance.

Owner:北京钢研高纳科技有限责任公司

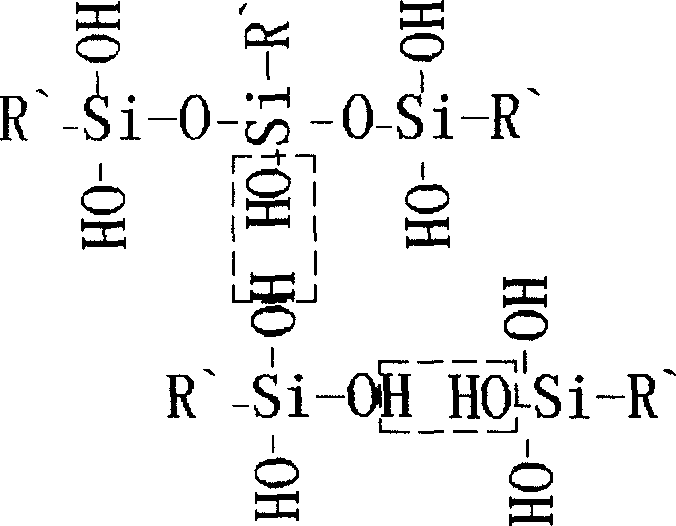

Method for preparing superhard waterproof substances used for spectacle lens

InactiveCN1877368AImprove friction resistanceImprove wear resistanceOptical elementsGramBoiling point

The invention discloses a method for making super hard water-proof medicine. The method comprises steps of: 1) selecting perfluoroalkylsulfonyl propyl trlethyloxy sllane as main material, adding 160ml~240ml isopropyl alcohol, and 18~22 grams water in per 100 grams perfluoroalkylsulfonyl propyl trlethyloxy sllane, and stirring uniformly; 2) stirring the solution and adding 8~12 grams acid solution, heating to 55~65 centigrade and sealed reacting 6~8 hours; 3) filtering and air-drying the reacted solution and getting light yellow amorphism crystal which molecular weight is 20000~40000 and boiling point is 300~400 centigrade; 4) crashing the crystal into 20 categories and mixing with perfluoroalkylsulfonyl quaternary amnonium iodides in proportion of 7:2~7:4 to obtain super hard water-proof medicine powder; 5)making the medicine powder into particles.

Owner:温州绿宝视光科技有限公司 +2

Method for rapid detecting ISO 9080 grade of PVC pipe material

InactiveCN101025413APerform online analysisEffective evaluationMaterial testing goodsContent distributionAmorphism

The invention discloses a method to quickly detect polyethylene pipe material rank of ISO9080, it includes (1) detect polyethylene pipe material structure distribution in condensation state, the structure distribution in condensation state includes mass per centum content distribution of crystal phase, interface phase and amorphism phase;(2)compute the mass per centum content distribution of crystal phase, interface phase and amorphism phase;(3) bases the result of the (2)step, process the ISO9080 ratings of the polyethylene pipe material: the mass per centum content of crystal phase is 50-90%for polyethylene pipe material with PE80 rank and more than it, the mass per centum content of interface phase is 5-45%, the mass per centum content of amorphism phase is 0-15%. Compared to pipe certification authority hydrostatic test rating, This method has advantages of convenient, fast, and saving money, accelerate the new pipe material products into research development process, and with high accuracy, wide adaptation.

Owner:ZHEJIANG UNIV

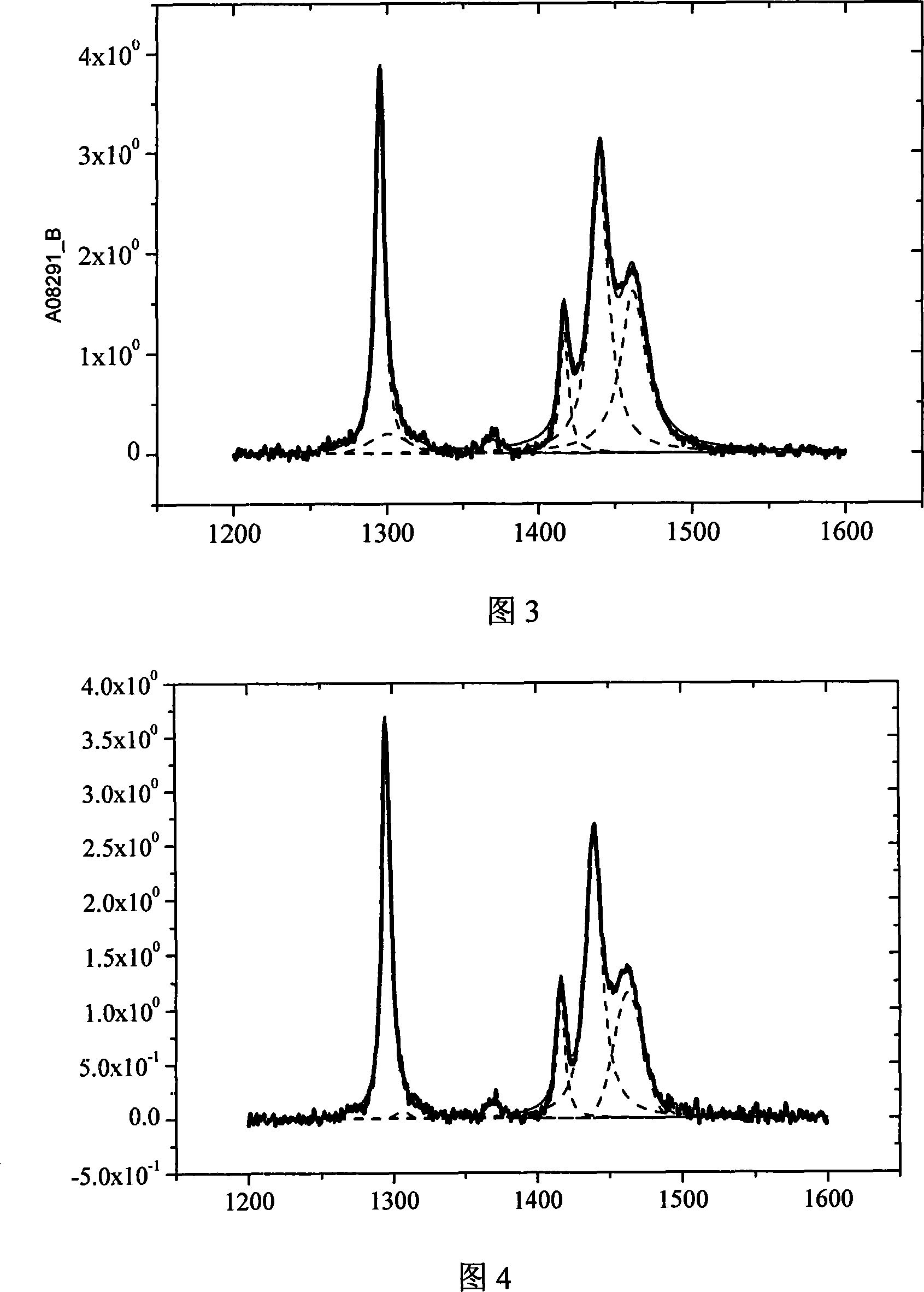

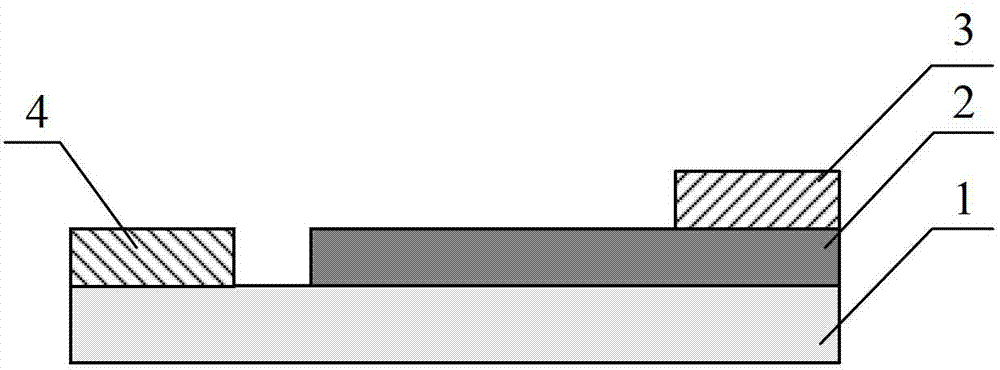

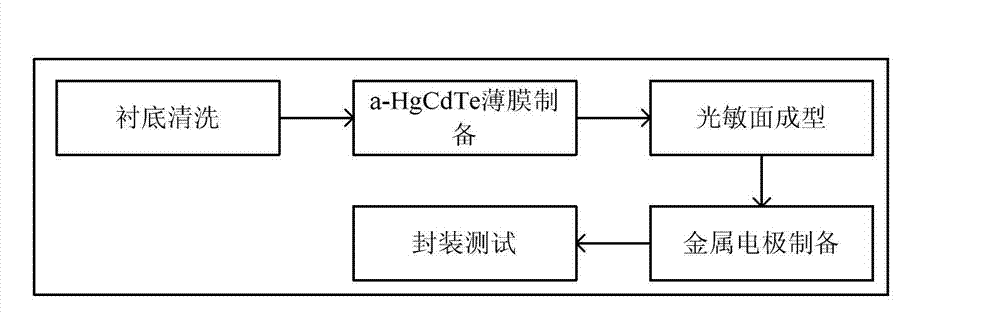

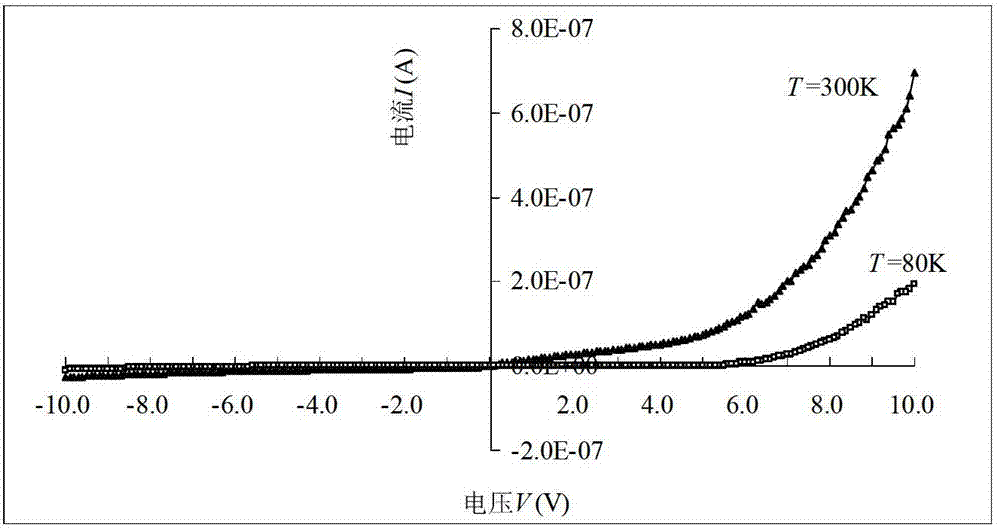

Amorphous tellurium-cadmium-mercury/crystalline silicon heterojunction infrared-detector and manufacturing method thereof

InactiveCN102903783AGood lattice matchingNo choiceFinal product manufacturePhotovoltaic energy generationHeterojunctionWorking temperature

The invention relates to an amorphous tellurium-cadmium-mercury / crystalline silicon heterojunction infrared-detector, which is characterized by being composed of a crystalline silicon substrate, amorphous tellurium-cadmium-mercury, a first metal electrode and a second metal electrode, wherein the amorphous tellurium-cadmium-mercury and the crystalline silicon substrate form heterojunction, the first metal electrode is connected with the amorphous tellurium-cadmium-mercury, and the second metal electrode is connected with the crystalline silicon substrate. The preparation process comprises the following steps of substrate cleaning, amorphous tellurium-cadmium-mercury film preparation, photosensitive surface forming, metal electrode preparation and package test; or substrate cleaning, second metal electrode preparation, amorphous tellurium-cadmium-mercury film preparation, photosensitive surface forming, first metal electrode preparation and package test. The amorphous semiconductor material has no selectivity for the substrate, the lattice matching performance between materials forming heterojunction is better, and the significant photoelectric response exists. The optimum working temperature of the detector is close to room temperature, two stages of semiconductors are utilized for refrigeration, and the weight, the power consumption and the manufacturing cost of the infrared detector assembly are reduced.

Owner:KUNMING INST OF PHYSICS

Method for making amorphism polymer material form tablet layer micromechanism

The invention relates to a method for leading amorphous macromolecule materials to form lamellar microstructure and the amorphous macromolecule materials are led to form novel micro 'lamellar structure' by the method; different morphological structures can be obtained by changing the temperatures of contour machining and the combination of pressure and time. The performance of the materials, more particularly the anti-impact performance of the materials can be greatly improved by forming the lamellar microstructure. The method which is characterized by simple molding technology and low energy consumption, etc. has lower temperature in the manufacturing process, thus reducing the energy consumption of polymers in the machine-shaping process and improving the performance of products. As the molding is carried out at low temperature, the addition of a plurality of addition agents in the processing is reduced, thus saving the cost and reducing the environmental pollution in the circle.

Owner:DONGHUA UNIV

High-oxygen-content iron-based amorphous composite powder and preparation method thereof

The invention discloses high-oxygen-content iron-based amorphous composite powder and a preparation method thereof. The preparation method comprises the following steps: proportioning the following materials in atom percentage: 74-78at.% of Fe, 4-6at.% of Cu, 7-9at.% of P, 5-7at.% of C, 1-3at.% of B and 4-6at.% of O; mixing; and performing high-energy ball milling to obtain the high-oxygen-content iron-based amorphous composite powder, wherein the volume fraction of an amorphous phase exceeds 90%, and the microstructure takes the amorphous phase as the base and takes alpha-Fe nanocrystal as a second phase. According to the invention, the designed composite powder has high amorphism forming capacity, a wide supercooled liquid phase region is obtained, and the adverse effect of oxygen on iron-based alloy amorphism forming is overcome, thereby being beneficial to the design of a new alloy system. The method is simple and convenient to operate, and can provide a raw material for the preparation of a high-density big amorphous composite material based on a sintering method.

Owner:SOUTH CHINA UNIV OF TECH

Planarization method of magnetic tunnel junction

ActiveCN108695431ALarge magnetoresistance performanceGood Magnetic StabilityMagnetic-field-controlled resistorsGalvano-magnetic device manufacture/treatmentAmorphismAmorphous silicon

The invention provides a planarization method of a magnetic tunnel junction. The magnetic tunnel junction comprises an amorphous iron-cobalt-boron layer. The method is characterized in that the methodcomprises the step that ion or plasma beams are adopted to bombard the amorphous iron-cobalt-boron layer. According to the planarization method of the invention, low-power ion or plasma beam bombardment is adopted, so that surface atoms can acquire a certain kinetic energy but cannot escape, and therefore, a material can be shifted from rough protrusions to troughs, and an MTJ (magnetic tunnel junction) multilayer film deposition of atomic-level smoothness can be obtained.

Owner:SHANGHAI CIYU INFORMATION TECH

Process for preparing modified starch

This invention relates to a method for preparing modified starch. The method solves the problems of high energy consumption, long reaction time, low controllability, complex process, low efficiency and unstable quality faced by the present techniques. The method utilizes vibrational ultrafine pulverizer to realize ultrafine pulverization of starch by high-frequency multi-dimensional vibration. One or more metal materials are used as the grinding medium. The method changes the morphologies and sizes of starch particles, increases the specific surface area and porosity, transforms starch from pleomorphism into amorphism, and changes molecular weight distribution and linear chain / branched chain ratio. Modified starch has such advantages as low gelatinization temperature, high light transmittance, high freeze-thaw stability, high water absorbency and low viscosity.

Owner:HAOYUAN BIOLOGICAL IND GROUP

Cable sheath material for wind power generation

InactiveCN105153520AResistant to twistingGood flexibilityPlastic/resin/waxes insulatorsInsulated cablesActive agentAmorphism

The invention discloses a cable sheath material for wind power generation and belongs to the field of cable sheath materials. The cable sheath material is prepared from, by weight, 70-85 parts of HDPE, 15-30 parts of modifying agent, 15-25 parts of amorphism copolymer, 20-25 parts of acetylene carbon black, 10-20 parts of cold-resistant plasticizer, 20-35 parts of reinforcing filler, 5-15 parts of nano-scale inorganic active agent, 1-3 parts of cross-linking agent, 2-5 parts of auxiliary cross-linking agent, 1-3 parts of anti-aging agent and 10-20 parts of inorganic flame retardant. The cable material has low-temperature resistant and distortion resistant performance and good flexibility, and is suitable for distortion resistant cables, drag chain cables and control cables for wind power generation.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Crystallization-amorphism-crystallization stereo triblock polybutadiene and preparation method thereof

The invention relates to crystalline-noncrystalline-crystalline stereotriblock polybutadiene, which belongs to the technical field of the high molecular material synthesis and the preparation. The invention is characterized in that the polymer has the following symmetric structure: HTBR-LCBR-HTBR, wherein, HTBR is high trans-1,4-polybutadiene block, LCBR is low cis-polybutadiene block, the numberaverage molecular weight of stereoblock polymer is 5*10 <4> to 55*10 <4>, the block ratio of HTBR / LCBR is 10 / 90 to 60 / 40 (weight ratio), the general range of 1, 2-structural content in the LCBR block is 5 percent to 55 percent (weight percentage), and the general range of trans-1, 4-structural content in the HTBR block is 50 percent to 95 percent (weight percentage). The invention has the advantages that the preparation method for the crystalline-noncrystalline-crystalline stereotriblock polybutadiene is provided, and important promotion effect to the characterization research work of the crystalline and noncrystalline polymer is realized.

Owner:大连广盛元实业有限公司

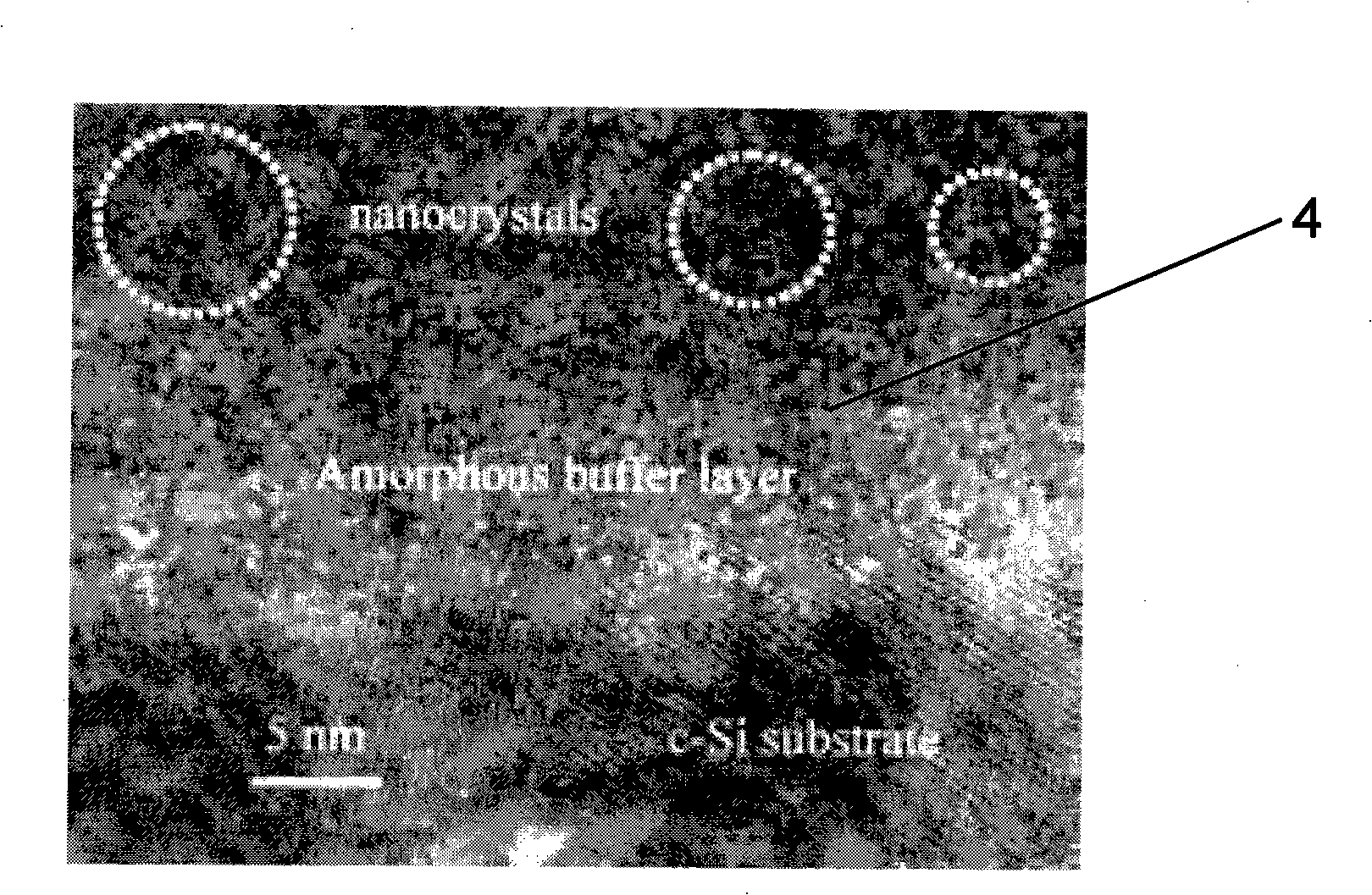

Nanometer silicon hetero-junction bidirectional tunneling diode

InactiveCN101257050AWith differential negative resistance effectSequential resonance tunnelingDiodeHeterojunctionDifferential coefficient

The present invention discloses a nano silicon hetero-junction bidirectional tunnel diode which includes a monocrystalline silicon substrate, a electric pole, a nano silicon thin film deposited at the monocrystalline silicon substrate includes nano silicon grain embedded in the hydrogenization amorphism silicon organize, the nano silicon thin film and the heterojunction structure configured with the nano silicon monocrystalline silicon, which is characterized in that the grain diameter of the nano silicon grain is 4-6nm, and the grain diameter sizes of different nano silicon grain are approach. The present invention has differential coefficient dynatron effect caused by the forward bias tunnel, meanwhile also has sequence resonance tunnel phenomenon of quantization energy level of multi- nanocrystal under back bias voltage, in addition breakdown reverse voltage is improved greatly to arrive more than -37V.

Owner:韦文生

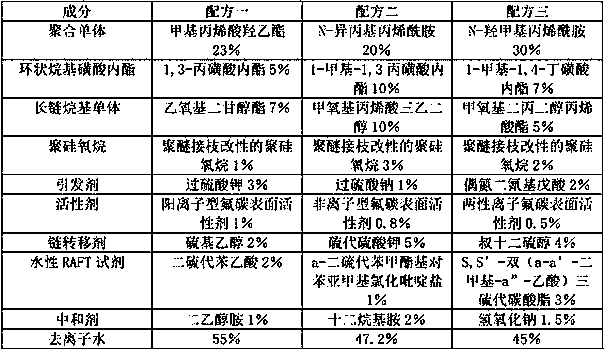

Environment-friendly waterborne block copolymer dispersant and preparation method thereof

InactiveCN109354688AStable storageScattered long termTransportation and packagingMixingPolymer scienceLacquer

An embodiment of the invention relates to an environment-friendly waterborne block copolymer dispersant and a preparation method thereof. The environment-friendly waterborne block copolymer dispersantis made from, by mass, 20-30% of a polymerization monomer, 5-10% of cyclic alkyl sultone, 5-10% of a long-chain alkyl monomer, 1-3% of polysiloxane, 1-3% of an initiator, 0.5-1% of an activator, 2-5%of a chain transfer agent, 1-3% of waterborne RAFT (reversible addition-fragmentation chain transfer polymerization) agent, 1-2% of a neutralizer, and 45-55% of deionized water. The environment-friendly waterborne block copolymer dispersant provided by an embodiment of the invention has the special structure block copolymer and allows characteristics of different homopolymers to be integrated, amorphism and elasticity of flexible block and crystallinity and rigidity of rigid block help pigment-filler and mineral powdery particles to dispersedly suspend in the solutions, such as a paint base,for long time, macroscopic separation can be prevented, secondary flocculation is avoided, and a prepared colored paint system has good storage stability and brighter color that lasts for long time.

Owner:安徽广成新材料科技有限公司

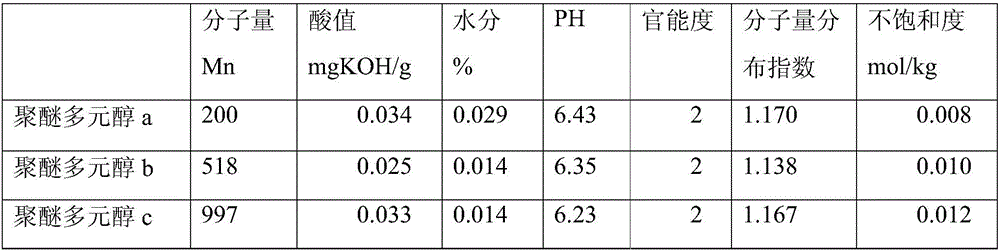

Preparation method preparation method of low-molecular-weight polyether polyol for polyetheramine

ActiveCN106242954AHigh viscosityLow melting pointEther preparation from oxiranesStructural regularityPolyol synthesis

The invention belongs to the technical field of polyether polyol synthesis and specifically relates to a preparation method of low-molecular-weight polyether polyol for polyetheramine. According to the preparation method, 2-methyl-1,3-propylene glycol, which is used as a starting agent, reacts with epoxide in the presence of an alkali metal catalyst at low temperature; and then, the reaction product is end-capped with epoxypropane at high temperature so as to obtain low-molecular-weight polyether polyol for polyetheramine. During the polymerization, 2-methyl-1,3-propylene glycol is used as the starting agent. Due to structural regularity and symmetry of 2-methyl-1,3-propylene glycol, activities at two ends are identical. During polymerization between 2-methyl-1,3-propylene glycol and the epoxide, polyether structure is more regular. During amino-capping, activities at two ends are consistent. The product has characteristics of amorphism, strong weatherability, tension resistance, strong bending resistance and the like. By the structure, polyetheramine can be endowed with characteristics of low melting point, low viscosity and good intersolubility with auxiliaries.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Amorphism of compound A benzoate, preparation method thereof, and amorphism-containing medicinal composition

ActiveCN106349215AHigh purityOptimizationOrganic chemistryMetabolism disorderCompound aDrug compound

The invention belongs to the field of preparation of medicinal compositions, and particularly relates to an amorphism of compound A benzoate, a preparation method thereof and an amorphism-containing medicinal composition.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

Preparation method of Si-doped low-Sm-content Sm-Co amorphous matrix magnetic alloy

ActiveCN105112816AIncrease contentExcellent Hard Magnetic PropertiesMagnetic materialsMagnetic transitionsRare earth

The invention provides a preparation method of a Si-doped low-Sm-content Sm-Co amorphous matrix magnetic alloy and relates to magnetic materials containing both rare-earth metals and magnetic transition metals. The preparation method comprises the following steps: preparing raw materials according to the raw material matching formula of (Sm12Co60Fe8Zr5Nb5Al6B4)(100-x)Six(X=0.1-8.0); melting the raw materials to prepare a master alloy ingot; preparing a (Sm12Co60Fe8Zr5Nb5Al6B4)(100-x)Six ribbon magnet; and performing isothermal annealing treatment of the Sm12Co60Fe8Zr5Nb5Al6B4)(100-x)Six ribbon magnet to finally obtain the Si-doped low-Sm-content Sm-Co amorphous matrix magnetic alloy. The preparation method overcomes the shortcoming in the prior art that amorphism is very hard to obtain during the preparation of a low-Sm-content Sm-Co amorphous magnetic alloy, and further improves the room-temperature coercivity of the Sm-Co amorphous alloy.

Owner:HEBEI UNIV OF TECH

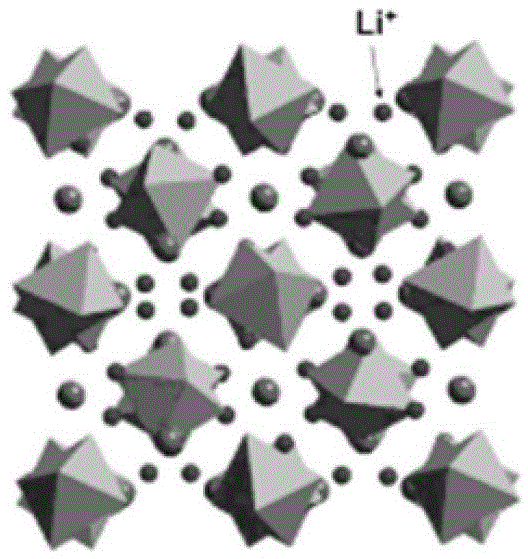

A solid-state electrolyte, a method for making the same, and an all-solid-state lithium battery

ActiveCN103904360BSmall resistanceCan undergo plastic deformationSolid electrolytesSecondary cellsSolid state electrolyteElectrical conductor

The invention relates to a solid electrolyte. The solid electrode comprises a substrate, and the substrate is a garnet type fast ion conductor Li7M3Zr2O12 or Li5Ta3M2O12, wherein the M can be one or more components selected from La, Al, Sr, Sc, Cr, Ba, Fe, Mo, and Y. The surface of the substrate is covered by a surface modification layer which can carry out plastic deformation, and the surface modification layer is made of non-crystal lithium silicate, lithium sulfate, or lithium tungstate. The invention also relates to a preparation method of the solid electrolyte. The solid electrolyte is covered by a surface modification layer made of non-crystal lithium silicate, lithium sulfate or lithium tungstate, and the non-crystal lithium silicate, lithium sulfate, and lithium tungstate are all flexible, can carry out plastic deformation, and all have a high ionic conductivity; so the surface modification layer can fully carry out surface contact with the garnet type fast ion conductor, thus the interfaces between the crystals in the solid electrolyte and the interfaces between the electrodes and the solid electrolyte are all improved, the interface impedance and grain resistance are low, and the durability and circulation performance are both prominently improved.

Owner:HUAWEI TECH CO LTD

Reversably removal lithium embedded material for cathode of lithium ion battery and its preparation

InactiveCN1300871CImprove cycle stabilityHigh lithium storage capacityElectrode manufacturing processesLithium compoundsDischarge efficiencySodium-ion battery

The chemical formula of the material is LixSiNy, or LixSiO2Ny, 0<x<9, 0<y<5, which possesses the network structure of Li-Si-O-N or Li-Si-N, and exists in the status of compound., After the first de-lithium processing, the material keeps in the amorphism status. According to the mechanical chemical method, the produced Li3N is mixed with the nanometer or micrometer powder. In the inert atmosphere, the convertible de-embedded lithium material is generated after the grinding processing. The Li3SiNy is produced (1.67<y<3), after 16 times recycling, the capability conability conservation rate is 80%.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

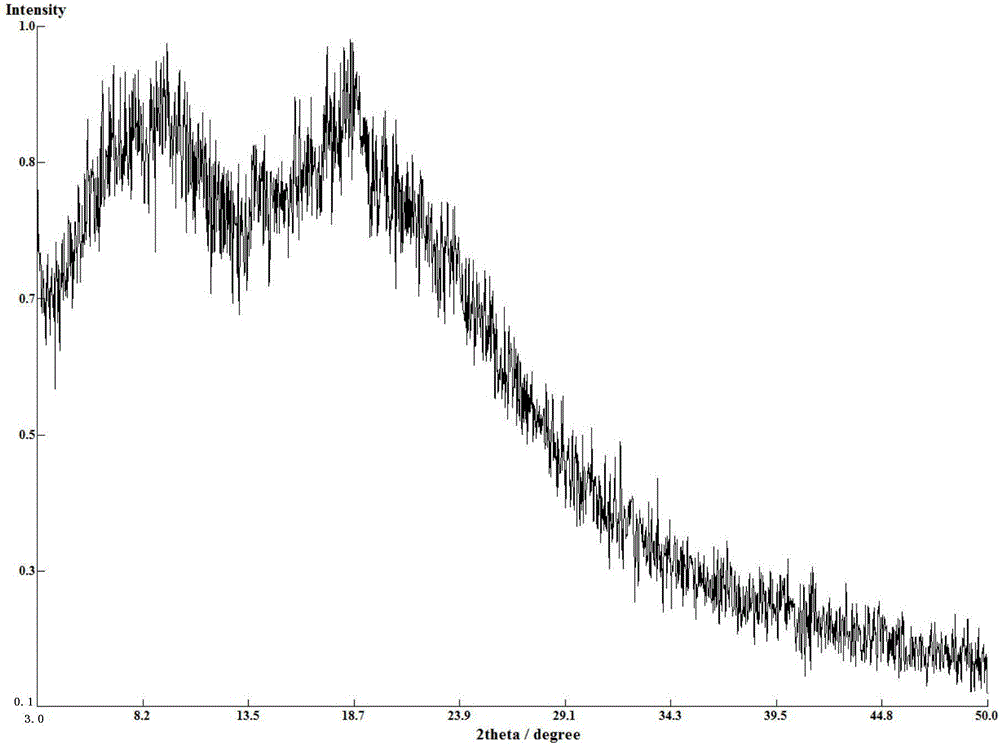

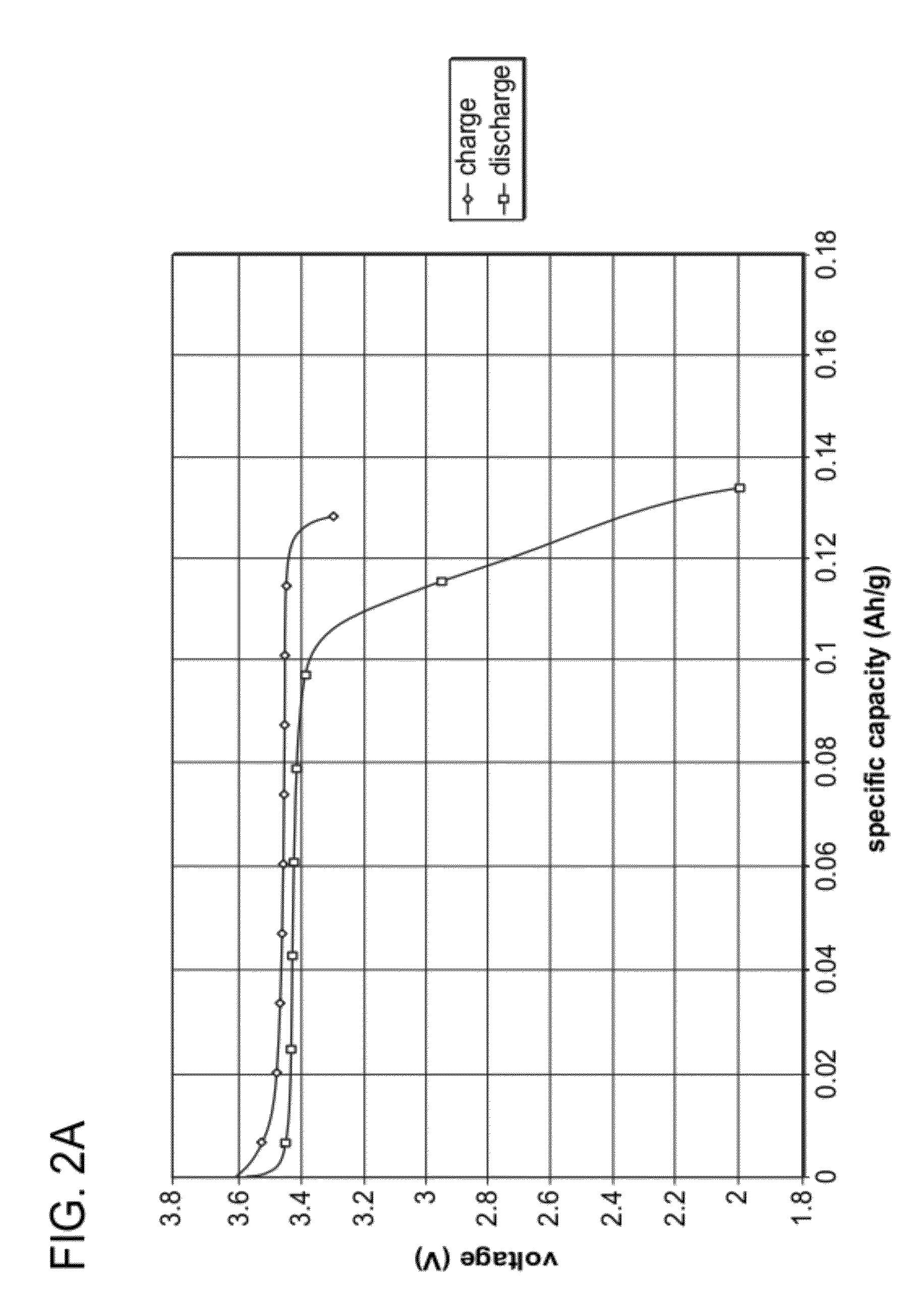

Amorphous and partially amorphous nanoscale ion storage materials

Amorphous or partially amorphous nanoscale ion storage materials are provided. For example, lithium transition metal phosphate storage compounds are nanoscale and amorphous or partially amorphous in an as-prepared state, or become amorphous or partially amorphous upon electrochemical intercalation or de-intercalation by lithium. These nanoscale ion storage materials are useful for producing devices such as high energy and high power storage batteries.

Owner:LITHIUM WERKS TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com