Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Lithium tungstate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium tungstate is the inorganic compound with the formula Li₂WO₄. It is a white solid that is soluble in water. The compound is one of the several orthotungstates, compounds that feature the tetrahedral WO₄²⁻ anion.

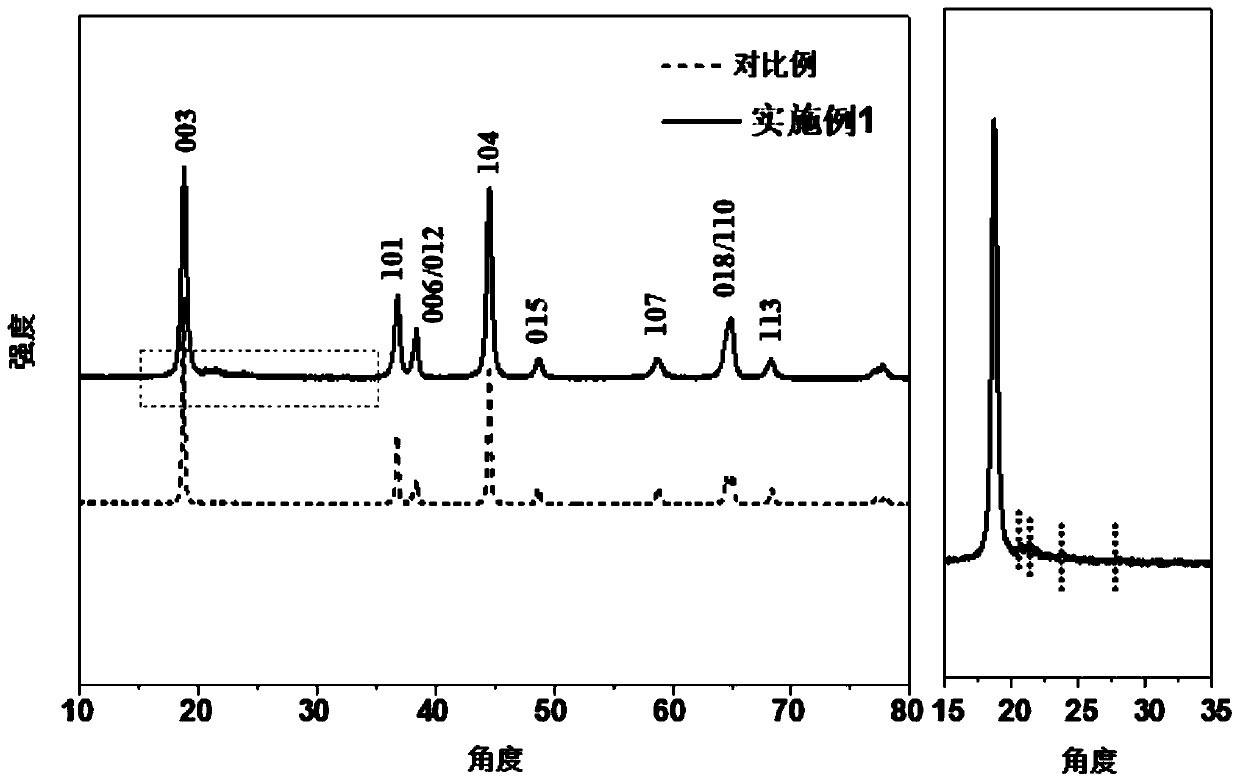

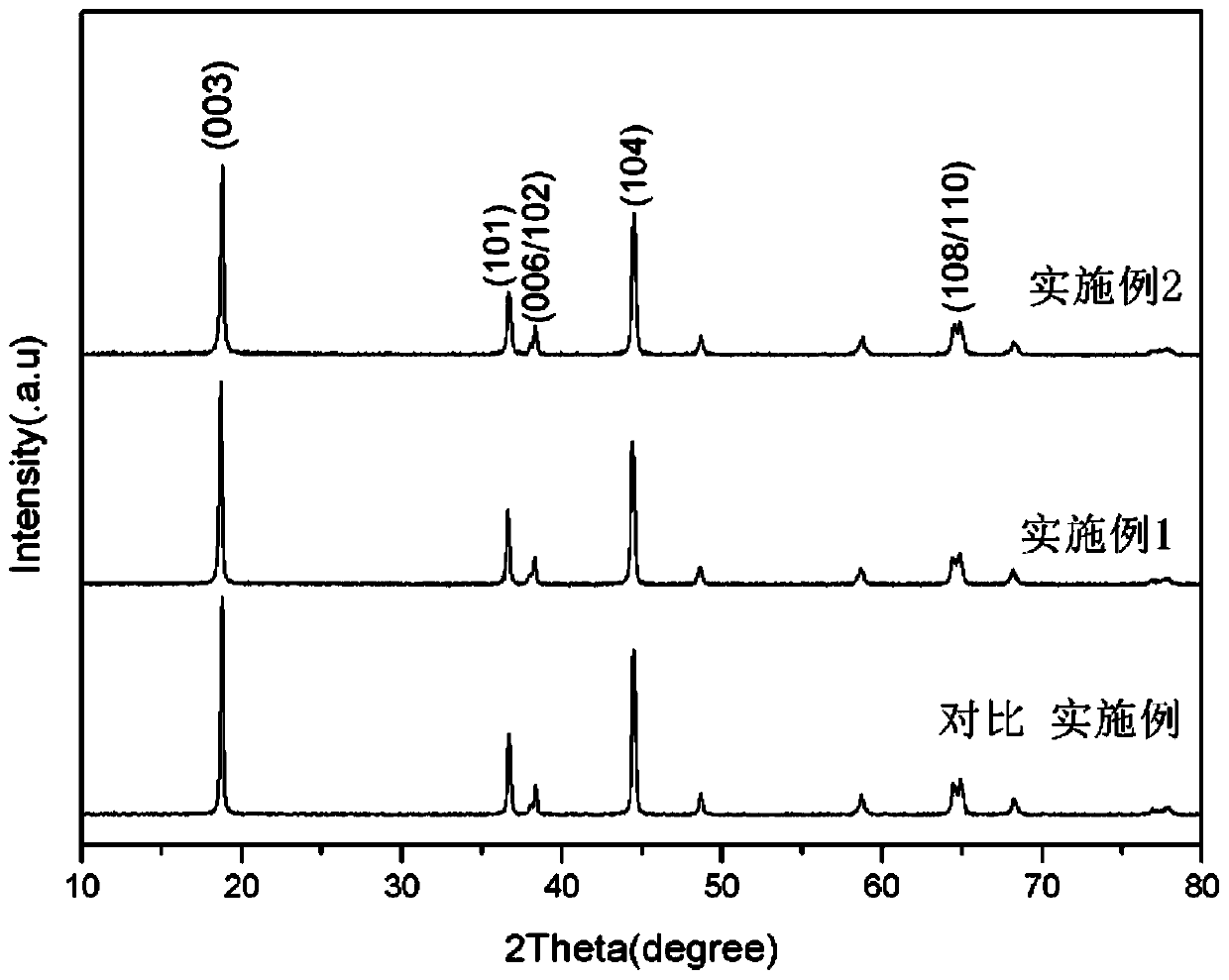

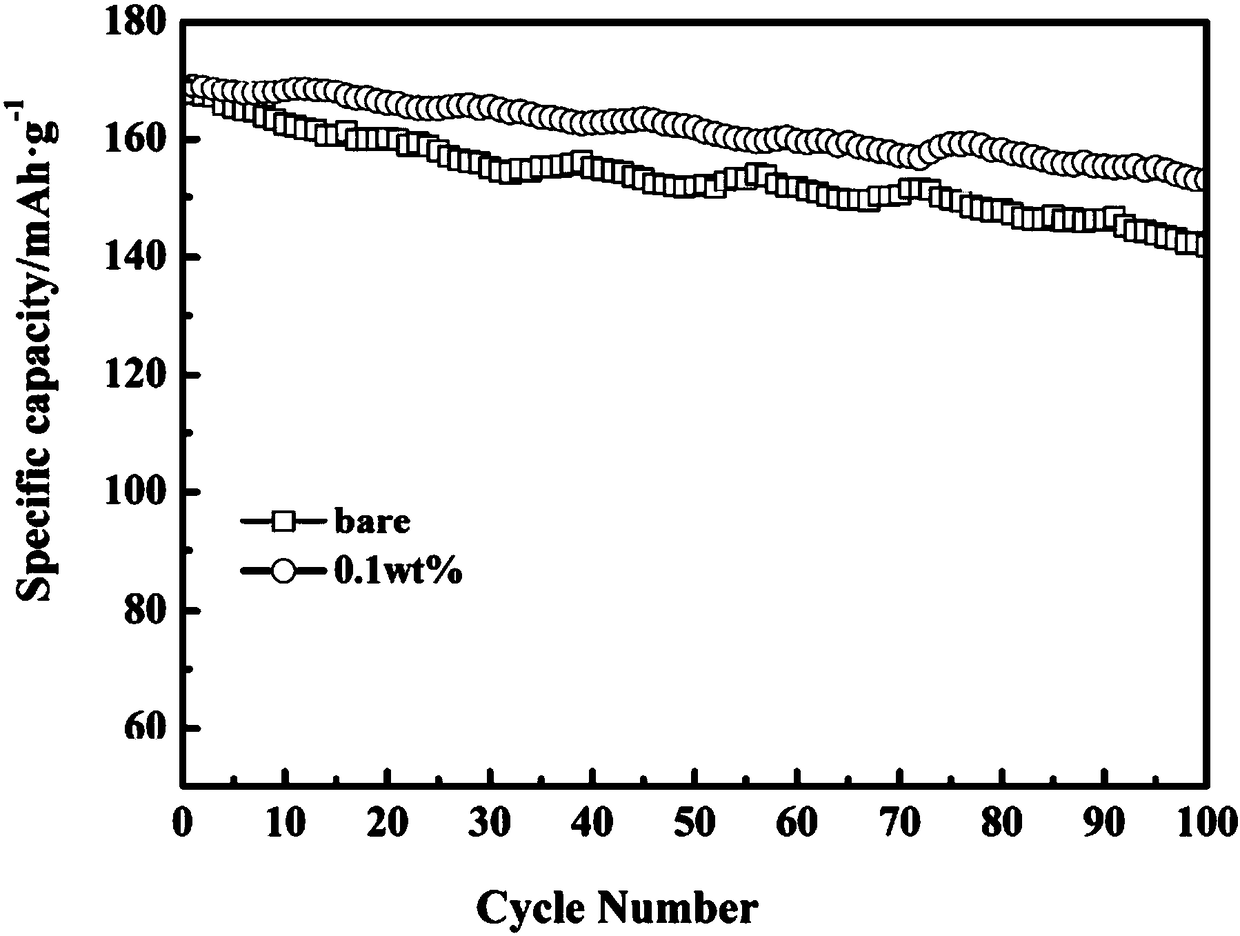

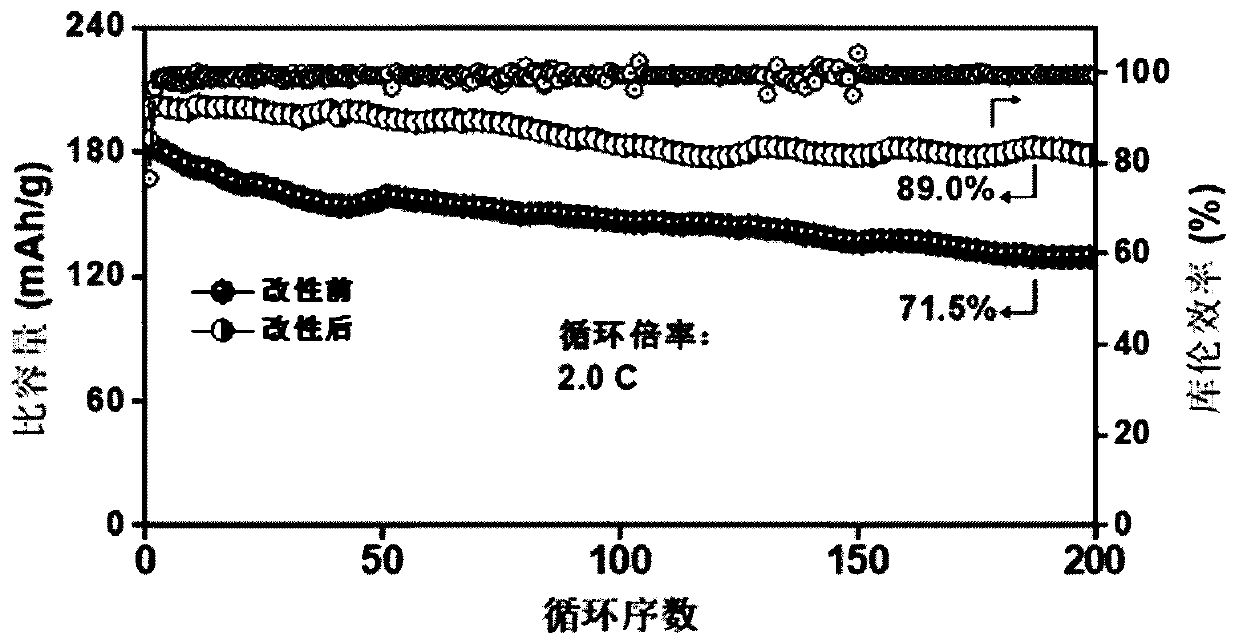

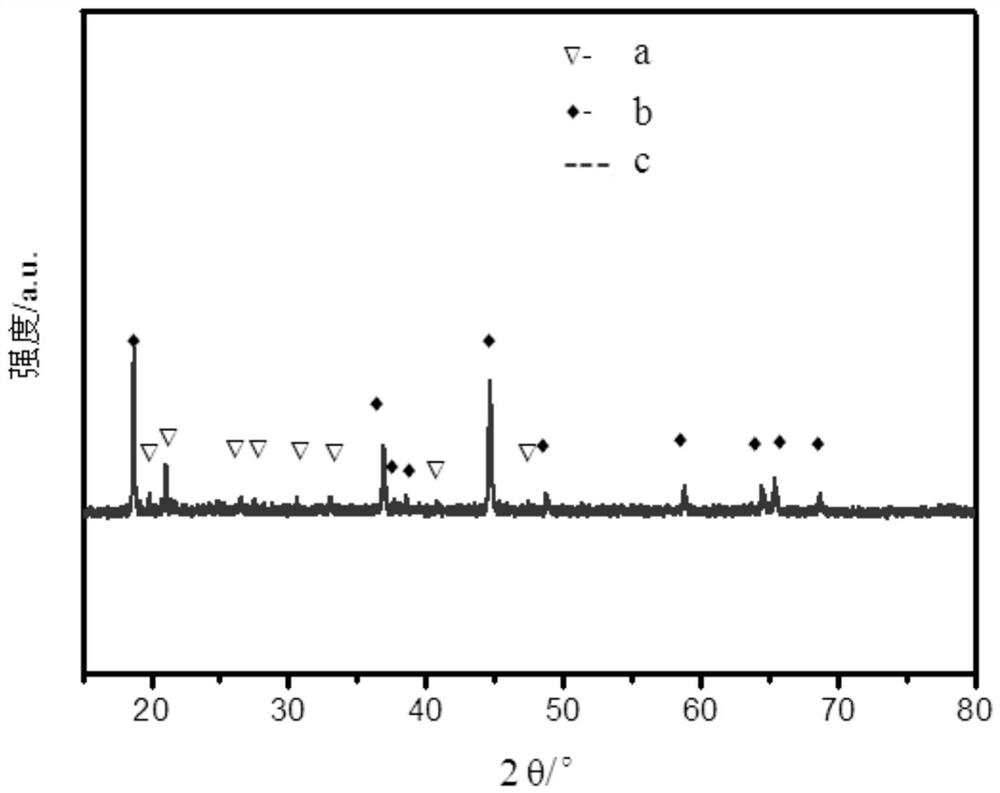

Ternary positive pole material with surface layer coated with lithium tungstate and doped with W and preparation method

InactiveCN109742336ASimple methodReduce manufacturing costCell electrodesSecondary cellsCyclic processElectrochemistry

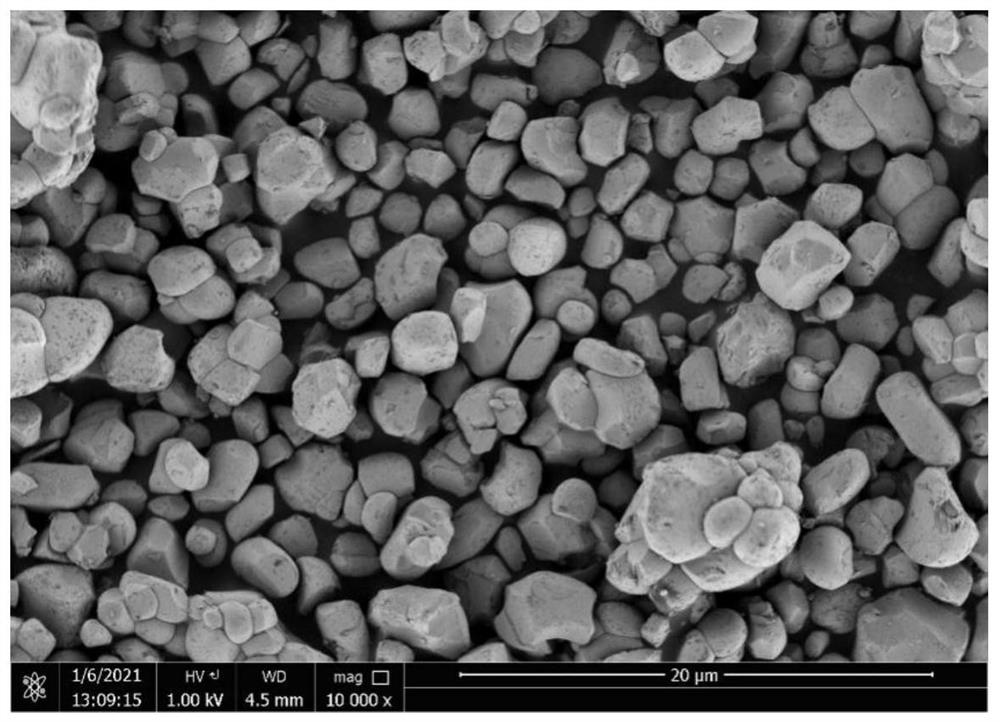

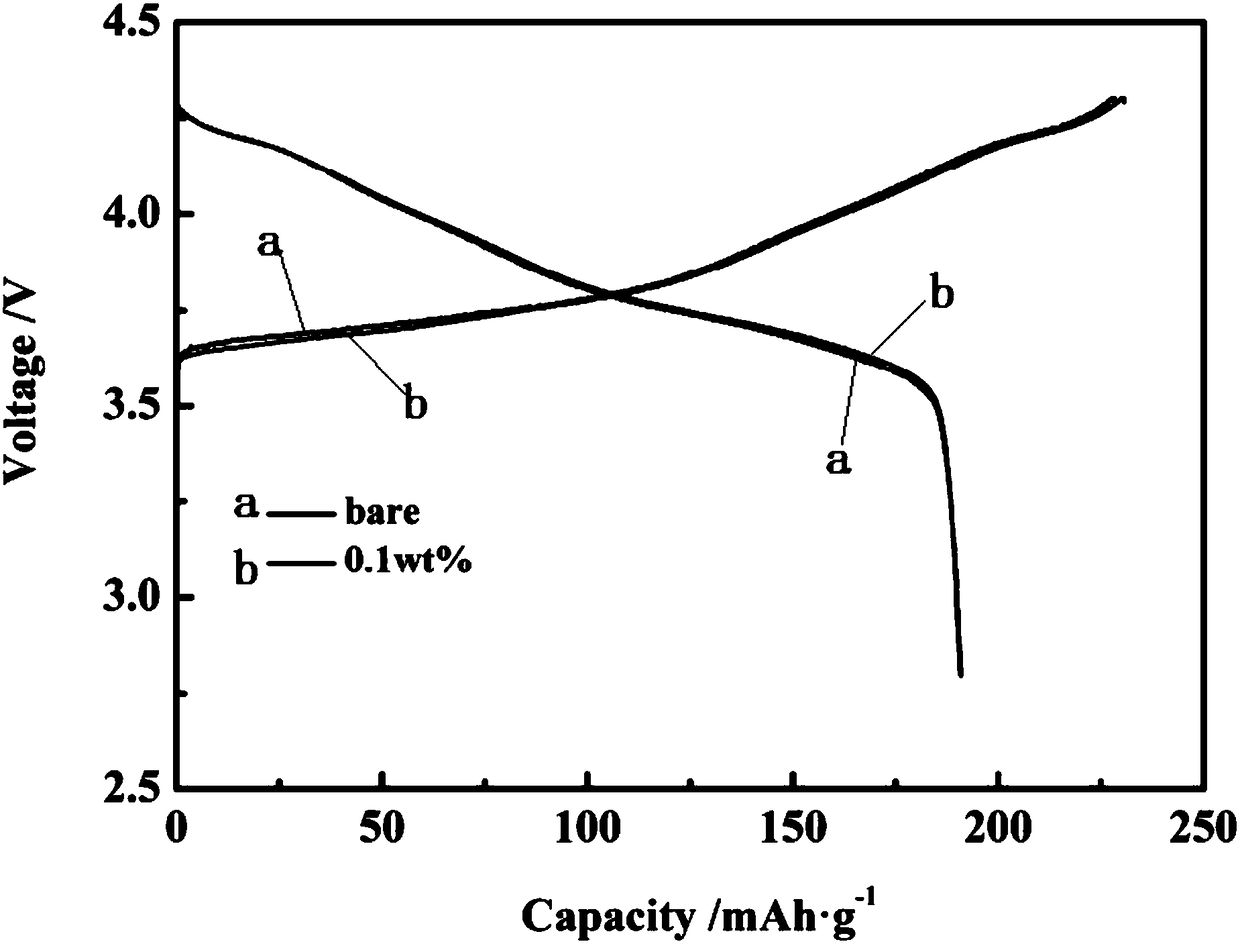

The invention provides a ternary positive pole material with a surface layer coated with lithium tungstate and doped with W and a preparation method. A precursor is prepared by a current industrial hydroxide co-precipitation method, the method is simple and convenient, the production cost is low, and the technological condition is moderate. The preparation of the ternary positive pole material with the surface layer coated with lithium tungstate and doped with W is realized by a one-step method, that is, a tungstate source is added in the mixing process of the precursor and lithium salt, thenhigh-temperature calcination is performed and the ternary positive pole material is obtained, and the preparation method is simple. The ternary positive pole material with the surface layer coated with lithium tungstate and doped with W can solve the problems that the integral circulating property of a material is poor and the like due to the fact that the surface layer structure is unstable in the circulating process of a high-nickel ternary positive pole material; according to the ternary positive pole material with the surface layer coated with lithium tungstate and doped with W, the cooperative action of coating and doping is used for improving the electromechanical property and the structure stability of the ternary positive pole material, and the high-nickel ternary positive pole material with high properties is obtained.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

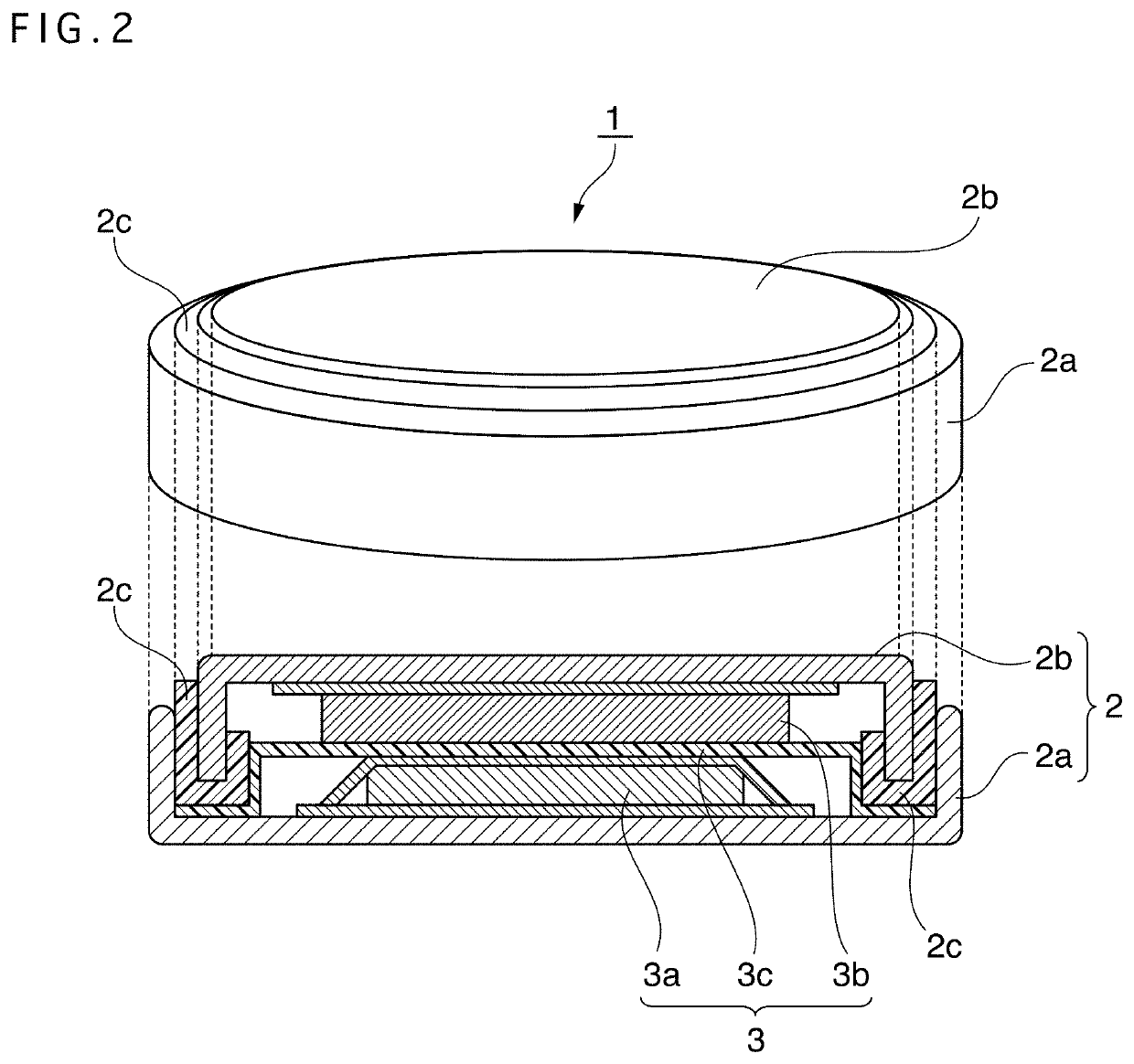

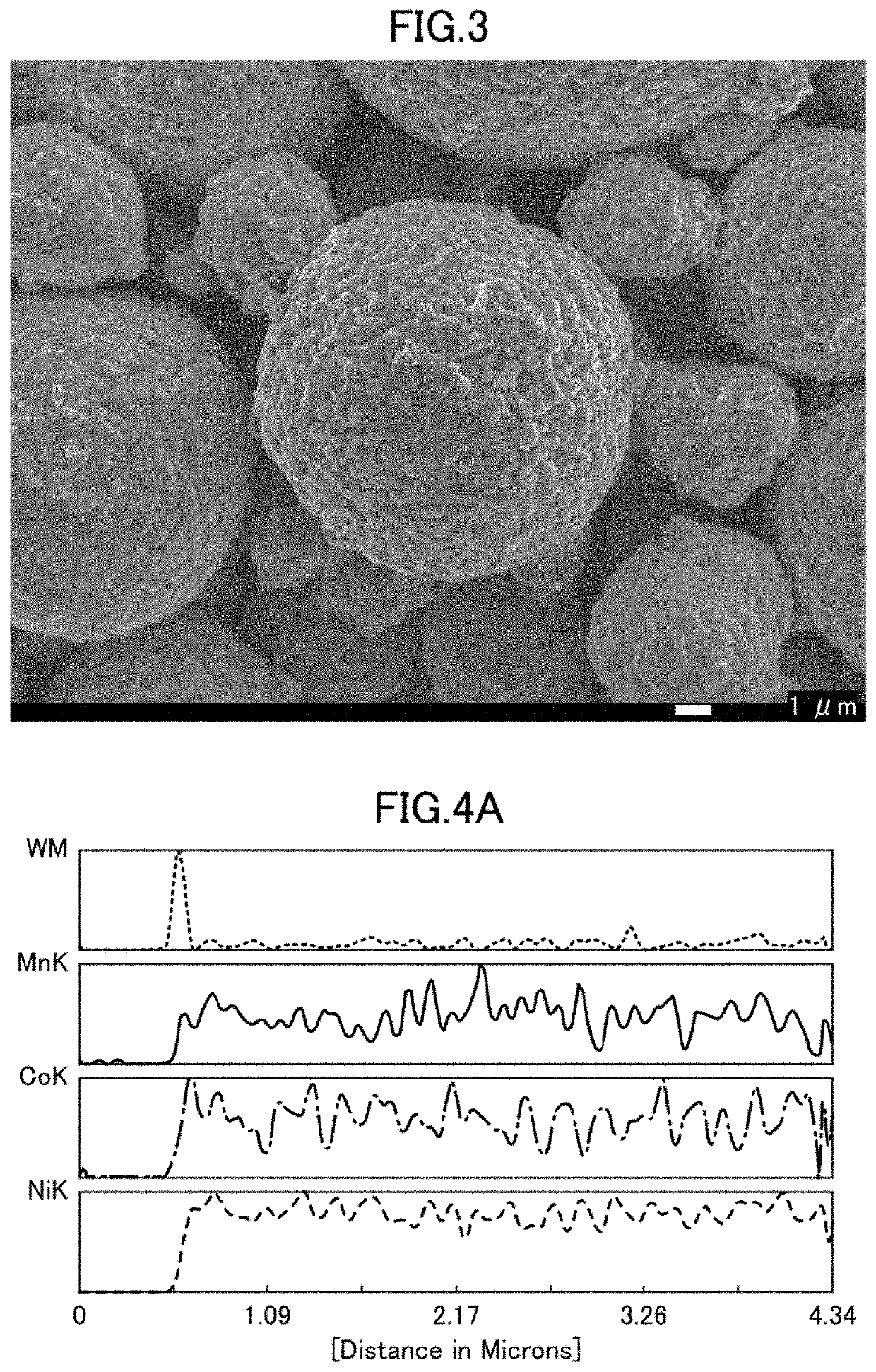

Positive electrode active material for nonaqueous electrolyte secondary battery, method for producing same, and nonaqueous electrolyte secondary battery using said positive electrode active material

ActiveUS20170352885A1Increase powerExcellent cycle characteristicsPositive electrodesLi-accumulatorsPhysical chemistryLithium tungstate

Provided is a method for producing a positive electrode active material for nonaqueous electrolyte secondary batteries, including: a water-washing step of mixing, with water, Li—Ni composite oxide particles represented by the formula: LizNi1-x-yCoxMyO2 and composed of primary particles and secondary particles formed by aggregation of the primary particles to water-wash it, and performing solid-liquid separation to obtain a washed cake; a mixing step of mixing a W compound powder free from Li with the washed cake to obtain a W-containing mixture; and a heat treatment step of heating the W-containing mixture, the heat treatment step including: a first heat treatment step of heating the W-containing mixture to disperse W on the surface of the primary particles; and subsequently, a second heat treatment step of heating it at a higher temperature than in the first heat treatment step to form a lithium tungstate compound on the surface of the primary particles.

Owner:SUMITOMO METAL MINING CO LTD

Positive-electrode material for nonaqueous-electrolyte secondary battery, method for manufacturing the same, and nonaqueous-electrolyte secondary battery using said positive-electrode material

ActiveUS20150021518A1Increase productionGood industrial valuePositive electrodesLi-accumulatorsLithium metalLithium tungstate

Provided is a positive-electrode material for nonaqueous-electrolyte secondary batteries, the positive-electrode material being capable of achieving both high capacity and high output when used for a positive electrode for nonaqueous-electrolyte secondary batteries. Also, provided is a method for manufacturing the positive-electrode material for nonaqueous-electrolyte secondary batteries, wherein a lithium metal composite oxide powder is mixed with lithium tungstate, the lithium metal composite oxide powder being represented by a general formula LizNi1-x-yCoxMyO2 (wherein 0.10≦x≦0.35, 0≦y≦0.35, 0.97≦z≦1.20, and M is an addition element and at least one element selected from Mn, V, Mg, Mo, Nb, Ti, and Al) and comprising primary particles and secondary particles composed of aggregation of the primary particles.

Owner:SUMITOMO METAL MINING CO LTD

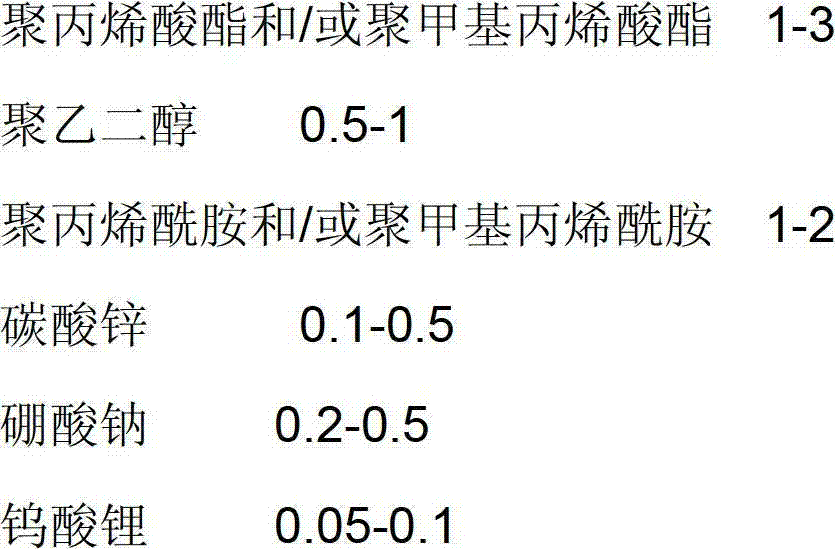

Preparation method of electrolyte of alkaline zinc battery

InactiveCN102832419AReduce corrosionHigh activityAlkaline accumulatorsPhysical chemistryPolyethylene glycol

The invention relates to a preparation method of an electrolyte of an alkaline zinc battery, a basic solution comprises the following components: KOH, LiOH, NaOH, ZnO, Na2Zn(OH)4 and plasma water; an addictive comprises the following components: polyacrylate, polyethylene glycol, polyacrylamide, zinc carbonate, sodium borate and lithium tungstate. The method comprises the following steps: adding the above components which accounts for 1-3% of mass of the basic solution in the basic solution, heating and fully stirring to obtain the electrolyte of alkaline zinc battery. The alkaline zinc battery by using the electrolyte has the advantages of good performance and long usage life.

Owner:SHANGHAI JINZHONG INFORMATION TECH

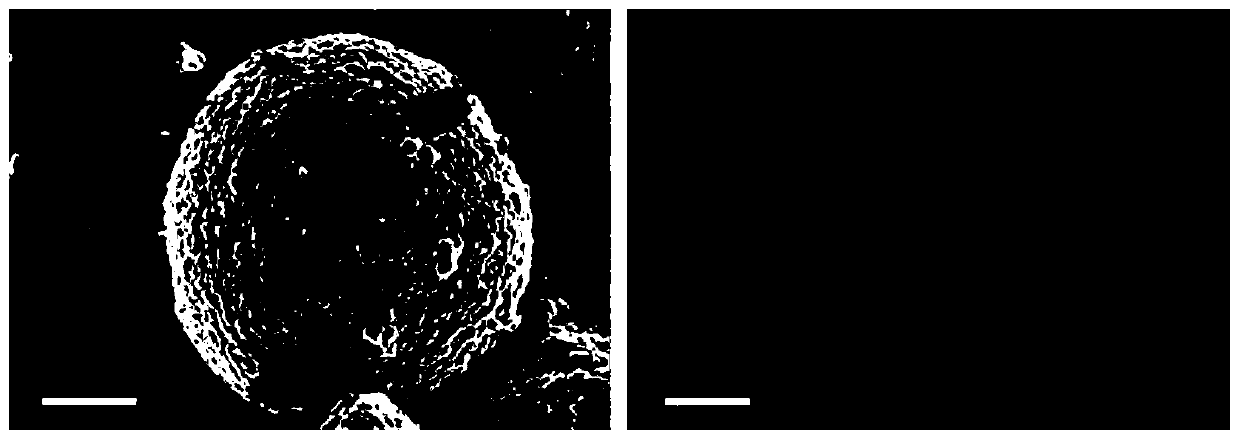

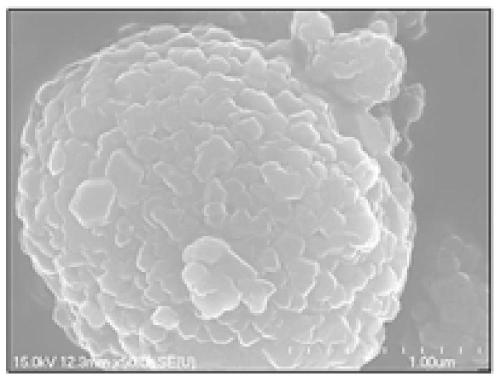

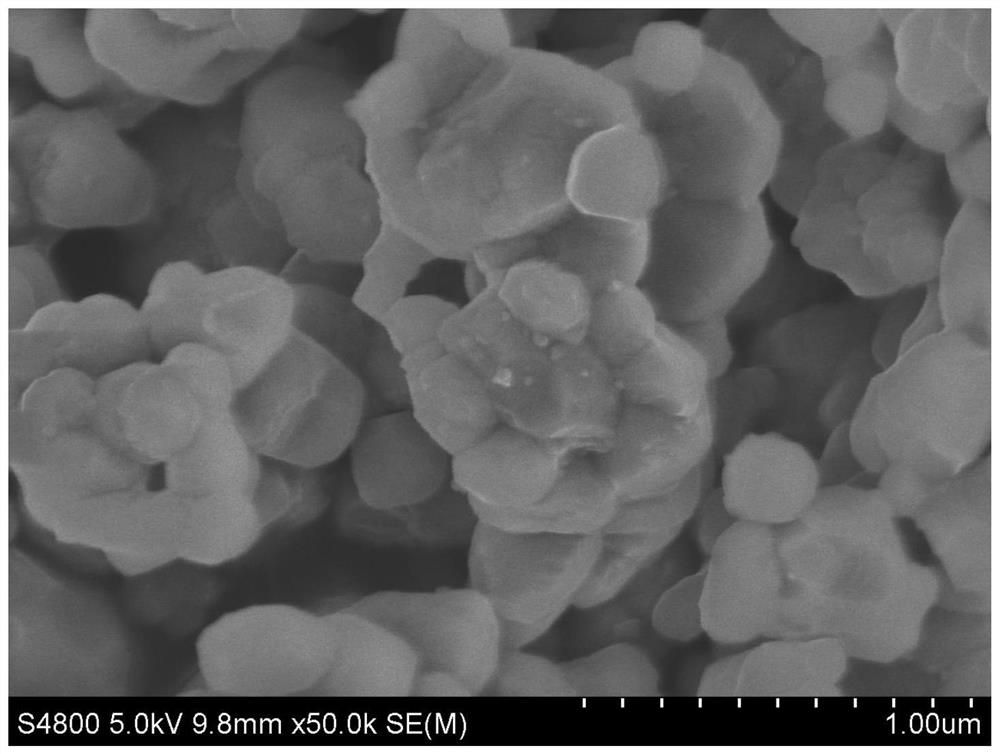

Ternary cathode material coated with lithium tungstate and preparation method of ternary cathode material

InactiveCN111082026AHigh capacity retentionImprove cycle performanceSecondary cellsPositive electrodesManganatePhysical chemistry

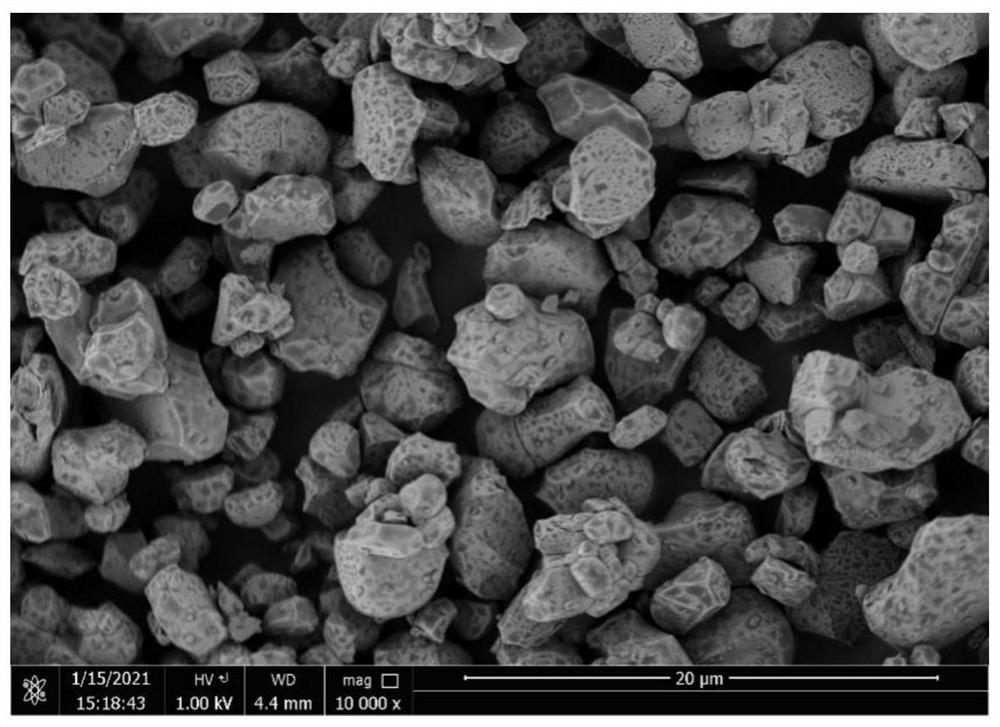

The invention provides a ternary positive electrode material coated with lithium tungstate and a preparation method of the material, and the preparation method comprises the following steps: calcininga nickel-cobalt-manganese hydroxide precursor to obtain a porous nickel-cobalt-manganese oxide precursor; dissolving a tungsten source in a solvent to form a tungsten source solution; dispersing theporous nickel-cobalt-manganese oxide precursor in the tungsten source solution, and then carrying out stirring, dipping and evaporating to dryness to obtain a powder product; and mixing the powder product with a lithium source according to a molar ratio of 1: 1.03-1.05, and sintering a mixture to obtain the ternary positive electrode material coated with lithium tungstate. The obtained positive electrode material is porous nickel cobalt lithium manganate, the surface of the porous nickel cobalt lithium manganate is coated with lithium tungstate, and the inner walls of pores are coated with lithium tungstate, so that the capacity retention ratio and the cycle performance of the positive electrode material are effectively improved.

Owner:CENT SOUTH UNIV +1

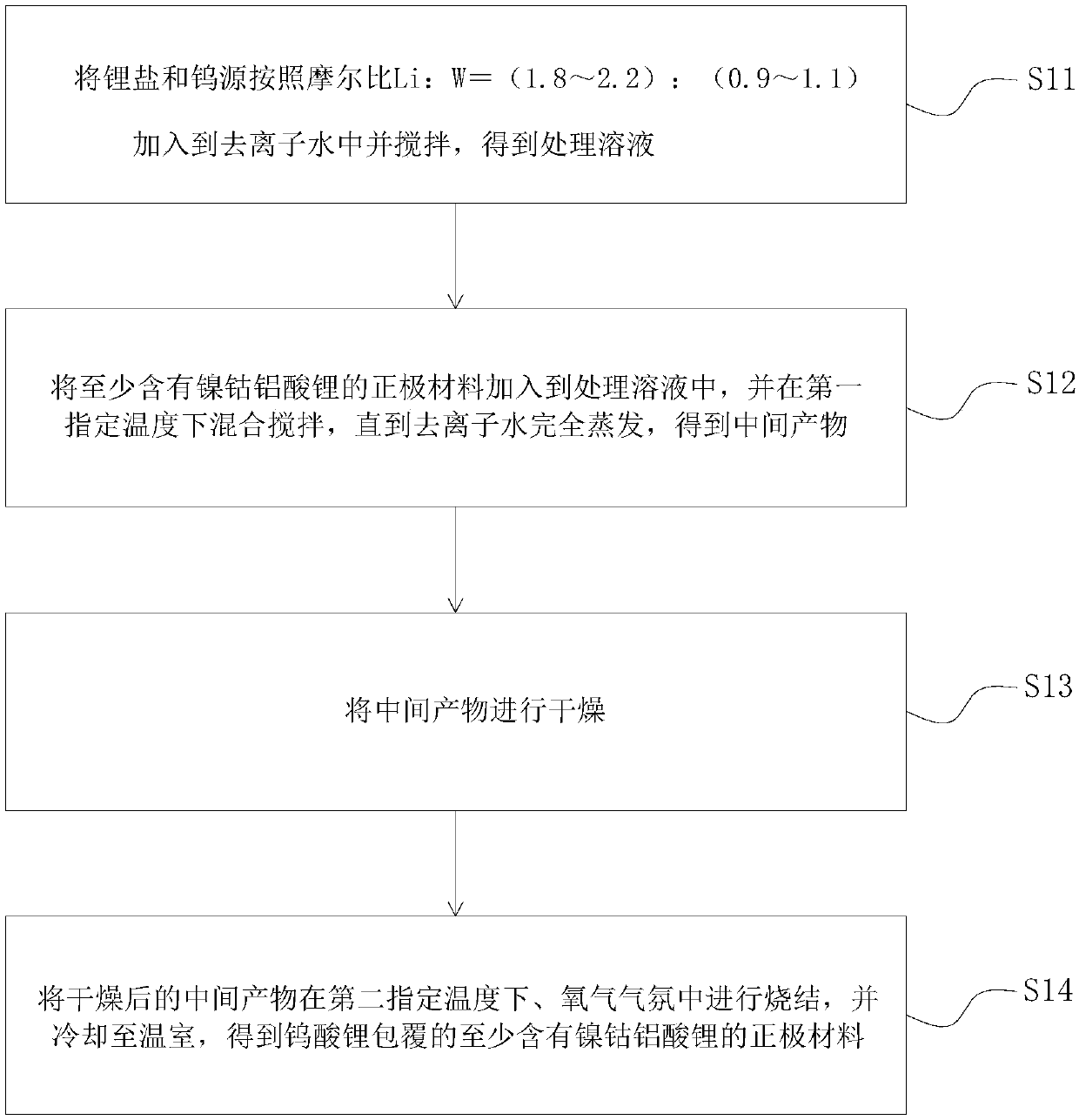

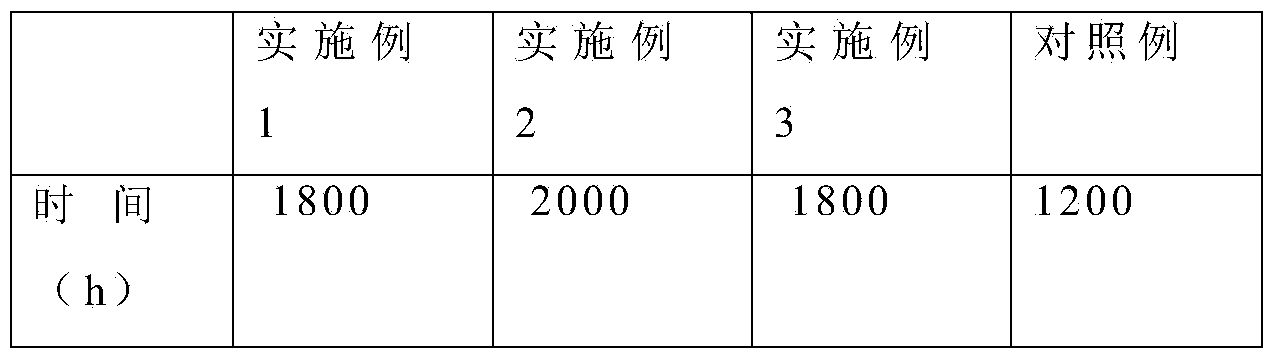

Preparation method of nickel cobalt lithium aluminate cathode material and lithium ion battery

InactiveCN109546101AImproved magnification performanceDoes not hinder migrationCell electrodesSecondary cellsLithium tungstateLithium aluminate

The invention discloses a preparation method of a nickel cobalt lithium aluminate cathode material and a lithium ion battery. The method comprises steps that a lithium salt and a tungsten source are added to the deionized water according to the molar ratio of Li:W=(1.8-2.2):(0.9-1.1) and stirred to obtain a treatment solution; a positive electrode material containing at least nickel cobalt lithiumaluminate is added to the treatment solution, mixed and stirred at the first specified temperature till the deionized water is completely evaporated to obtain an intermediate product; the intermediate product is dried; the dried intermediate product is sintered at the second specified temperature in the oxygen atmosphere and then cooled to the indoor temperature to obtain the positive electrode material containing the at least nickel cobalt lithium aluminate coated with lithium tungstate. The method is advantaged in that the rate, cycle and safety of the nickel cobalt lithium aluminate cathode material can be improved.

Owner:SUNWODA ELECTRONICS

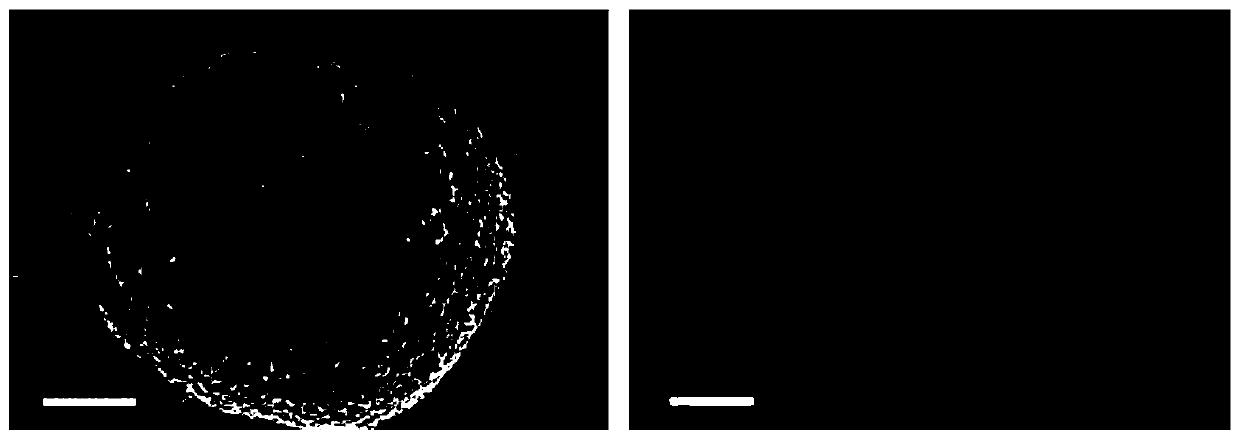

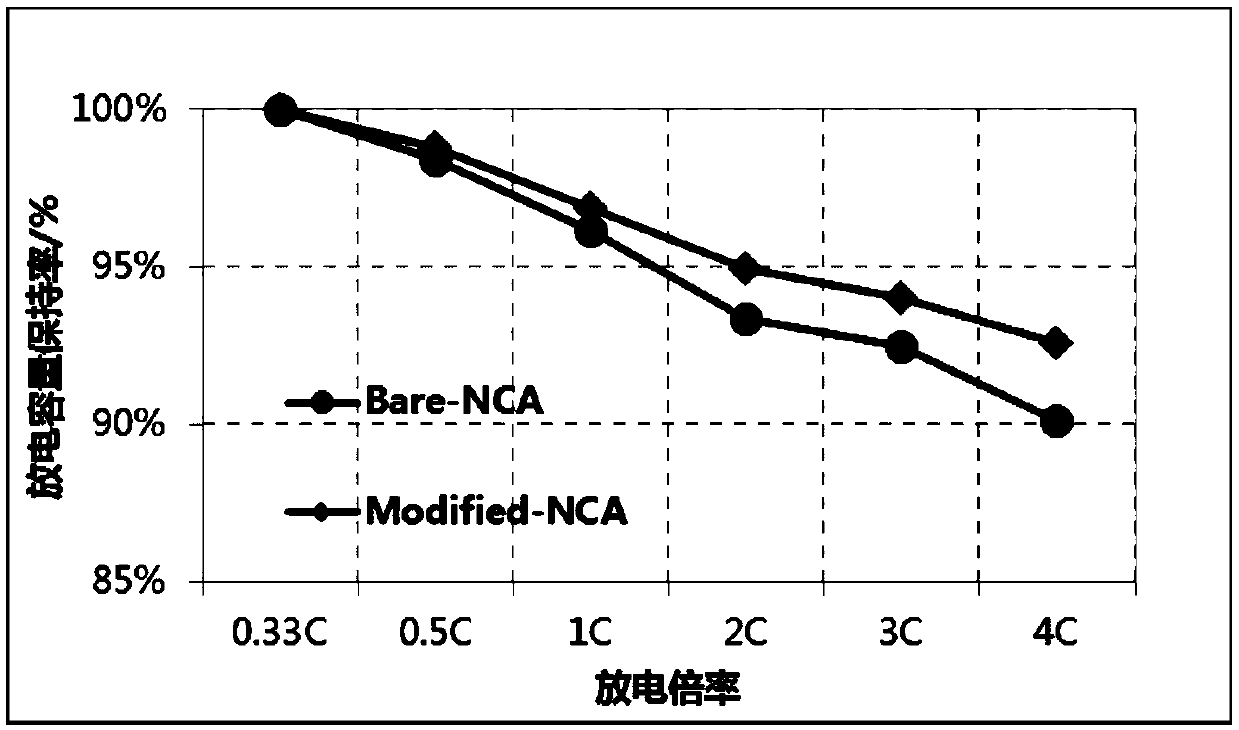

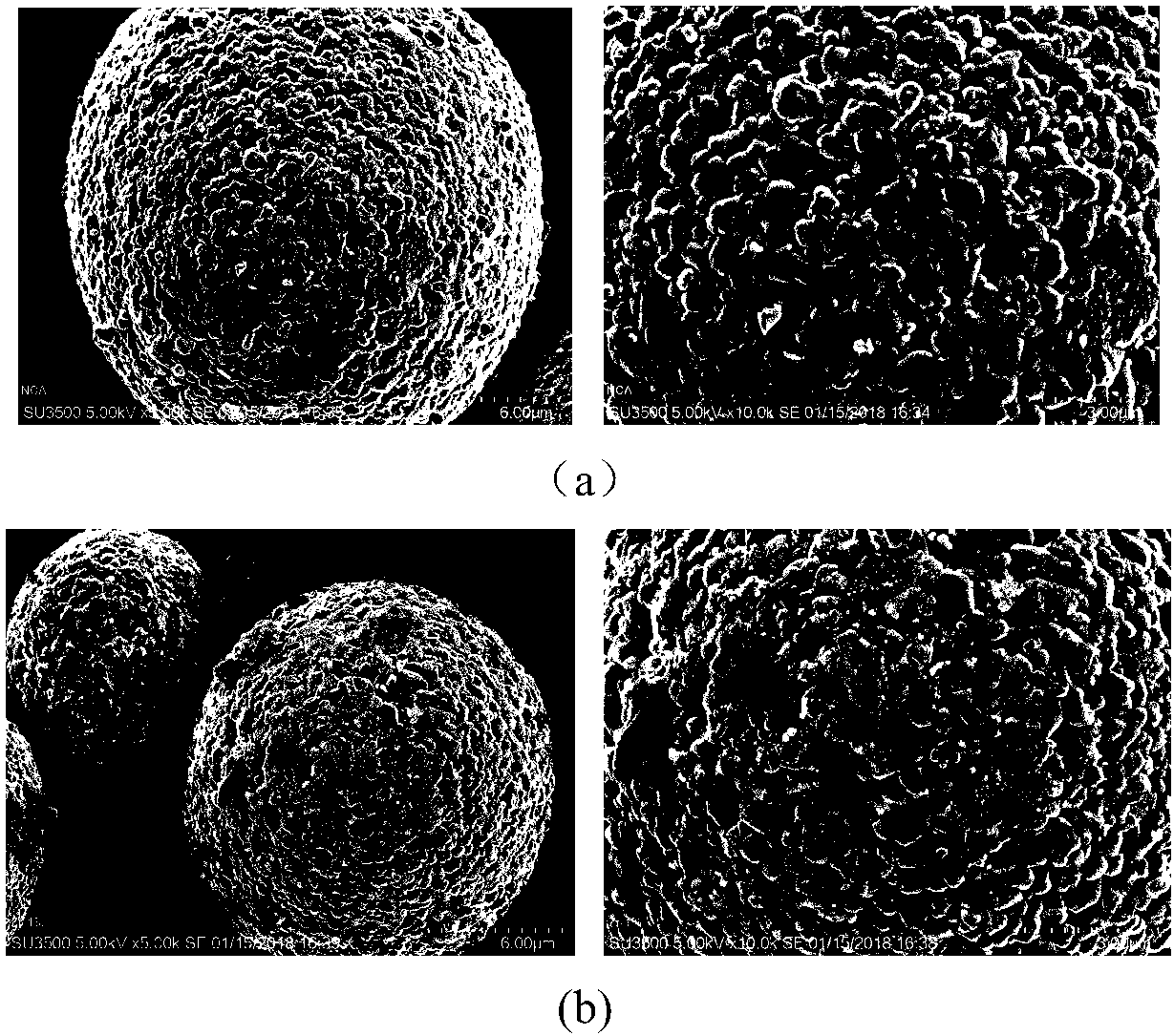

Lithium tungstate-coated Ni-Co lithium aluminate composite material and preparation method and application thereof

InactiveCN108598379AHigh crystallinityUniform compositionCell electrodesSecondary cellsLithium aluminateCrystallinity

The invention discloses a lithium tungstate-coated Ni-Co lithium aluminate composite material and a preparation method and an application thereof. According to the invention, a nickel-cobalt-aluminumprecursor is dispersed in a lithium-containing solution, cobalt trioxide is added, the lithium-containing solution and cobalt trioxide are subjected to a reaction to generate Li2WO4, during an evaporative crystallization process, Li2WO4 is subjected to direct deposition coating on the nickel-cobalt-aluminum precursor, and lithium-mixing sintering is carried out to obtain LiNi0.8Co0.15Al0.05O2 coated Li2WO4, and through the in-situ reaction, the formed deposited coating can form an uniform coating layer. through crystallization and deposited coating, the obtained coating layer has the advantages of good crystallinity and uniform component, and can be used in a lithium ion battery as a ternary cathode material, the circularity of the obtained lithium ion battery is stable, and the multiplying power performance is excellent.

Owner:CENT SOUTH UNIV +1

Cobalt-free nickel-manganese positive electrode material and preparation method and application thereof

ActiveCN113161548AExtended service lifeImprove cycle performanceSecondary cellsPositive electrodesLithium tungstateManganese

The invention belongs to the technical field of battery materials, and discloses a cobalt-free layered nickel-manganese positive electrode material and a preparation method and application thereof. The chemical formula of the cobalt-free layered nickel-manganese positive electrode material is LiaNixMnyMezO2@Mb, wherein Me is at least one of Zr, Al, W, Sr, Ti or Mg; and M is at least one of Al2O3, CeO2, TiO2, Yb2O3, Nb2O5, La2O3, WO3, titanium sol, aluminum sol, titanium aluminum sol, aluminum isopropoxide, butyl titanate, dialuminum hydrogen phosphate or lithium tungstate. Shallow layer coating is achieved through high-temperature sintering after metal oxide coating, and the shallow layer coating of the material is beneficial for preventing microcrack expansion caused by material structure change and internal stress change in the charging and discharging process in the circulation process of the material.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Preparation method of lithium ion battery positive electrode composite material

The invention provides a preparation method of lithium ion battery positive electrode composite material, which comprises the following steps of: 1) dissolving tungsten source in a solvent, and addingPVP to disperse to form a mixed solution; 2) adding high nickel anode material into the mixed solution, and heating and evaporating the solvent after constant temperature stirring; 3) drying the material obtained in the step 2) and then performing dry mixing with the lithium salt; 4) sintering the dry-mixed material under the aerobic condition to obtain the lithium tungstate-coated high-nickel anode material. The coated layer of the obtained material is good in uniformity, and the coated lithium tungstate helps to improve the electrochemical performance of the high-nickel anode material, in particular to the cycling stability in the high-temperature environment.

Owner:CENT SOUTH UNIV

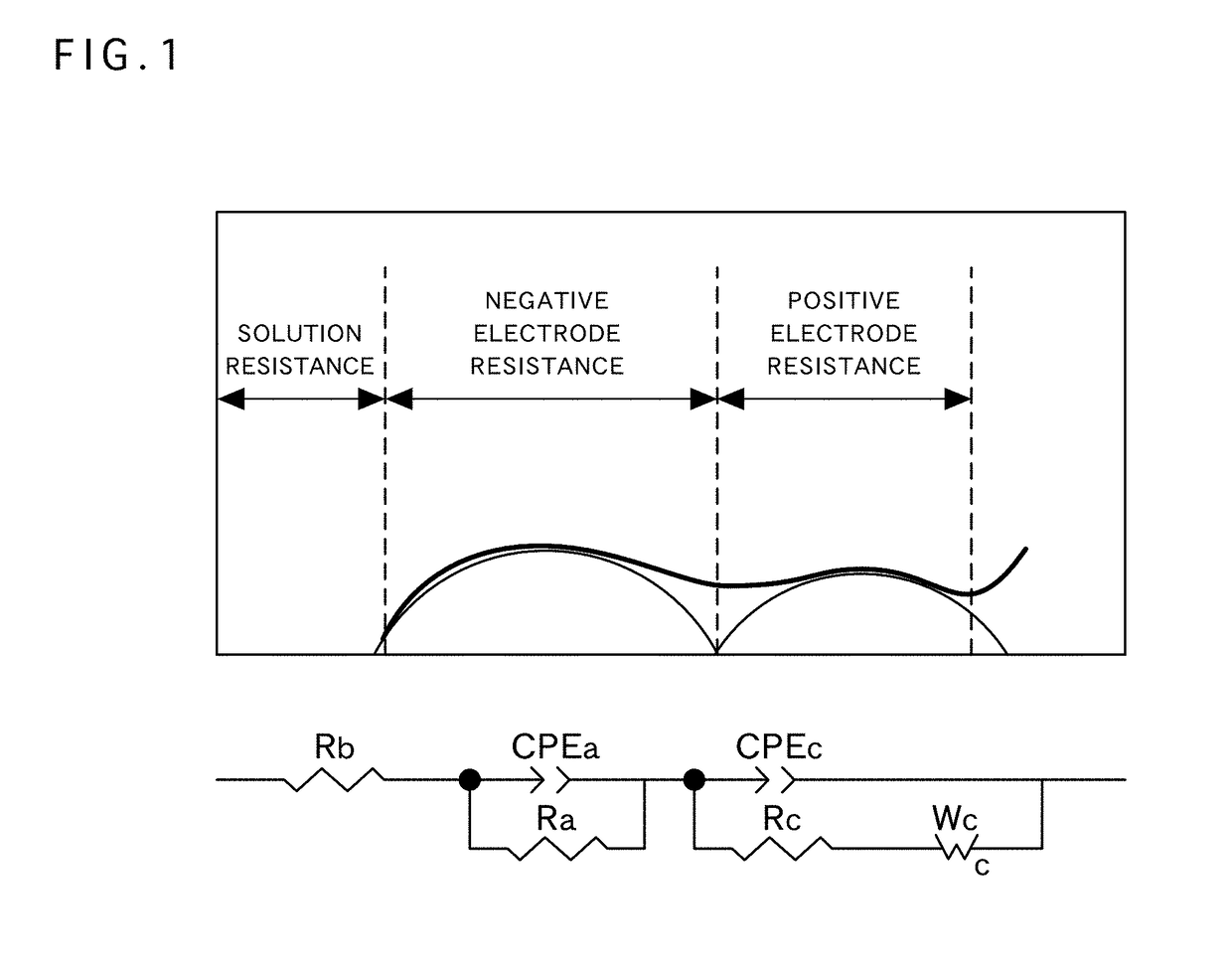

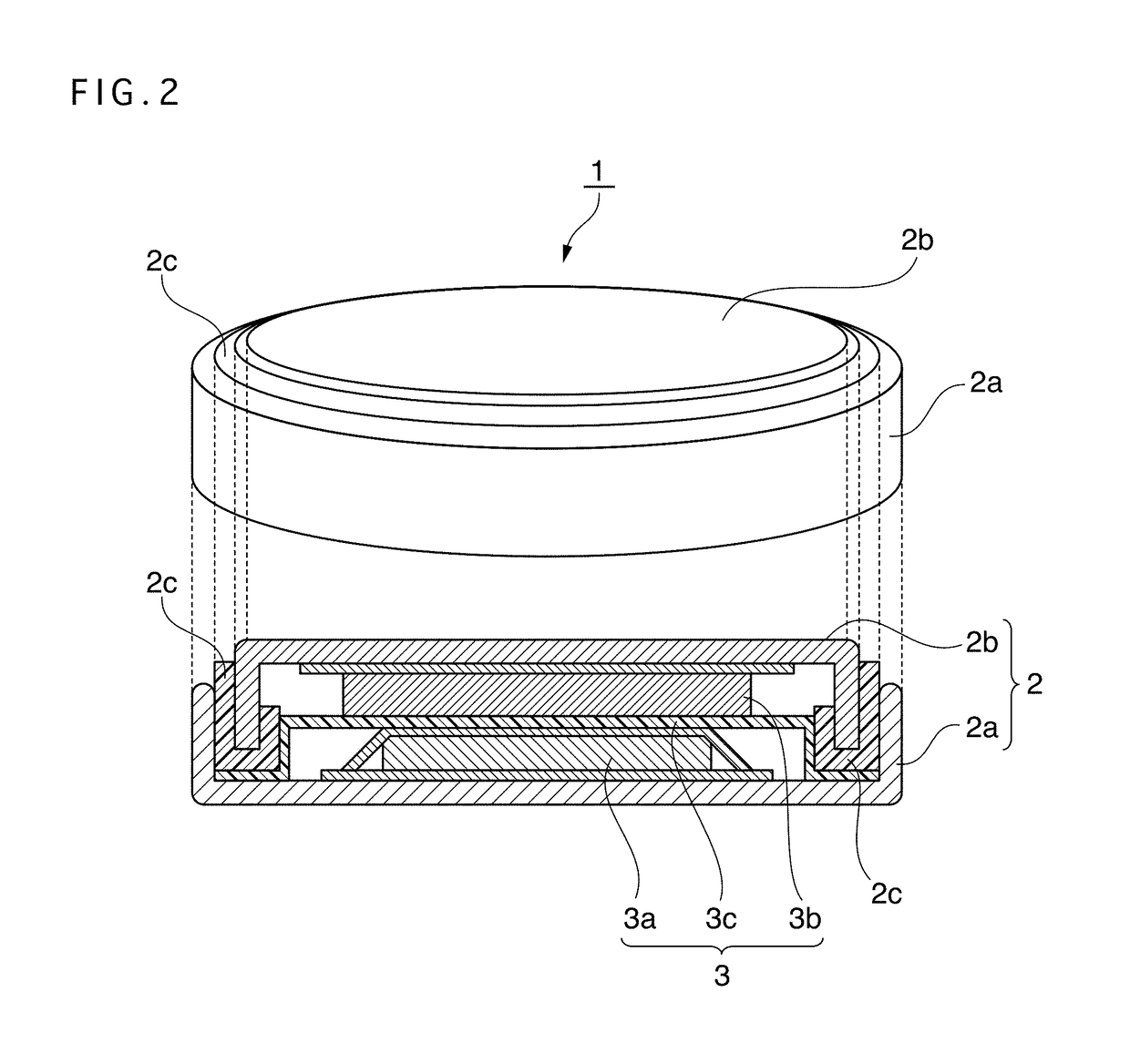

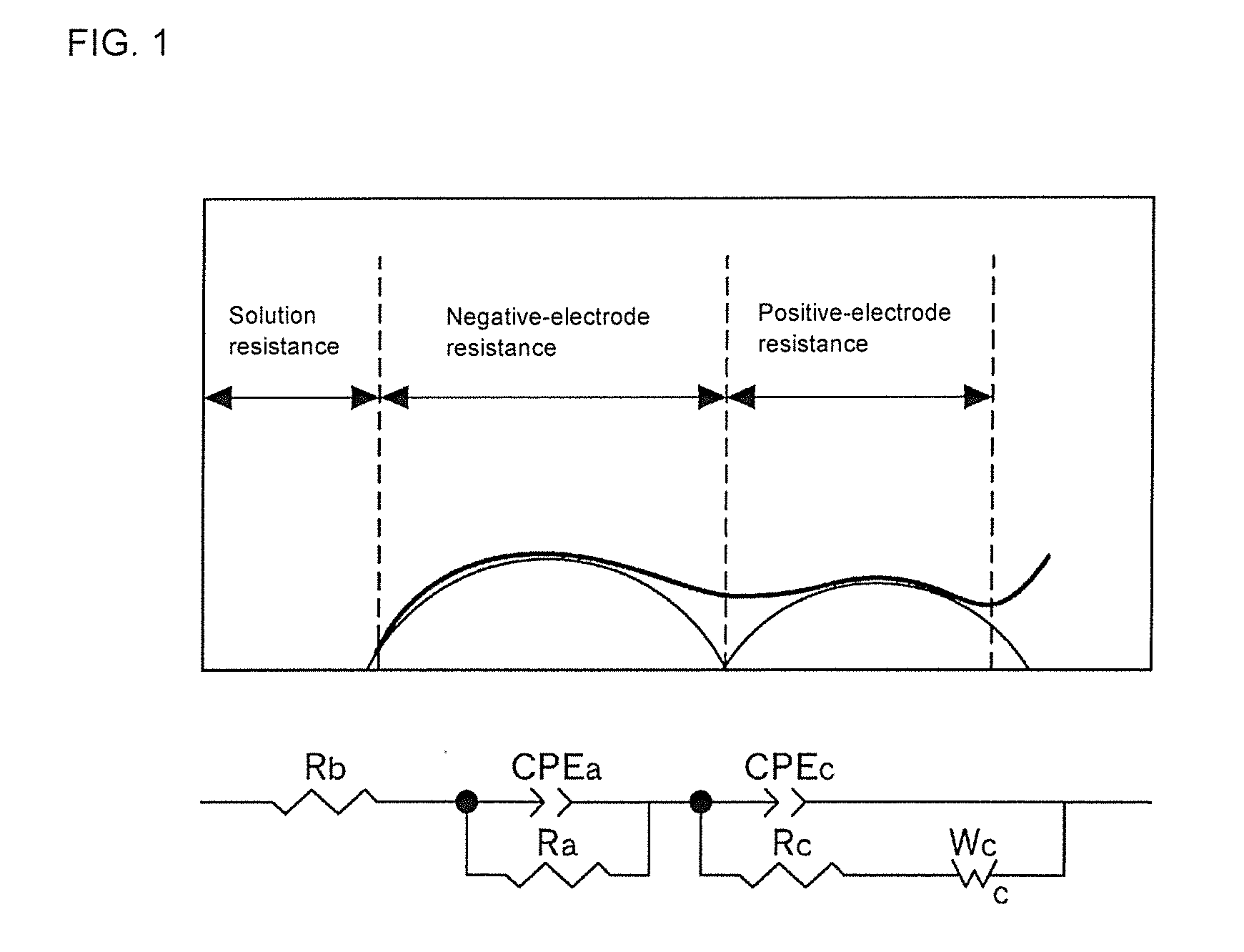

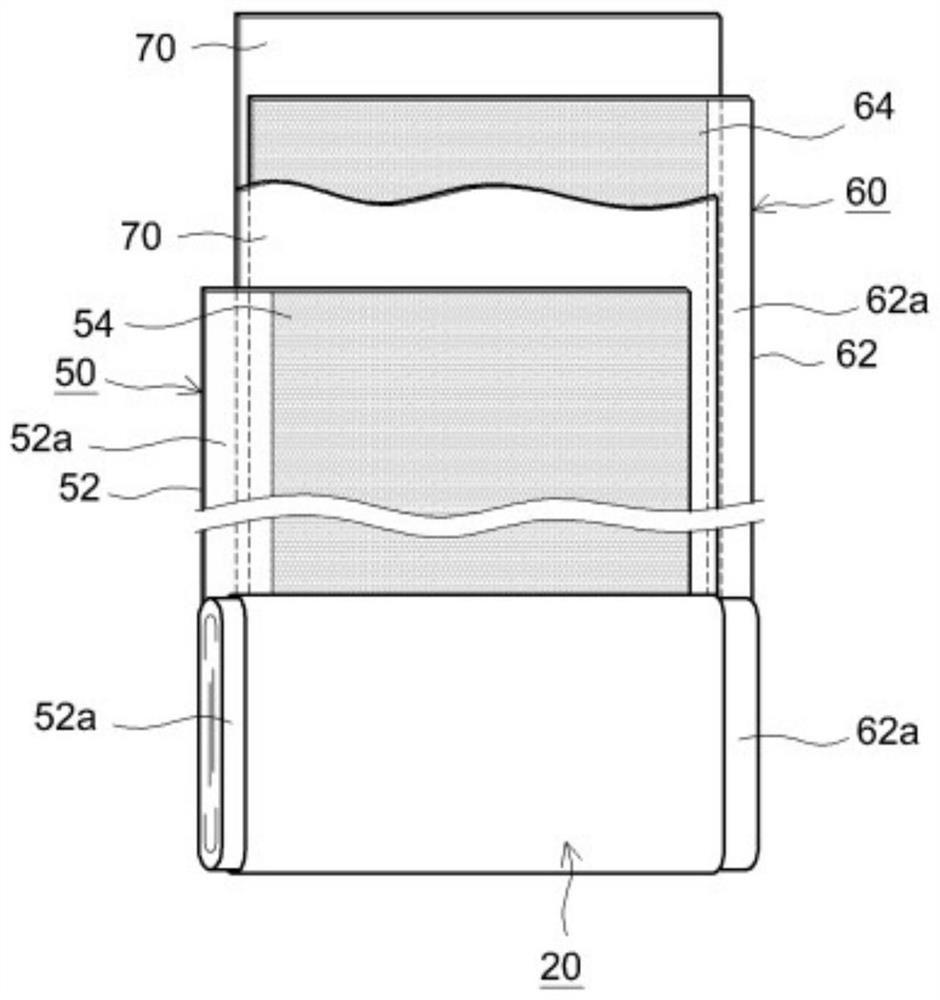

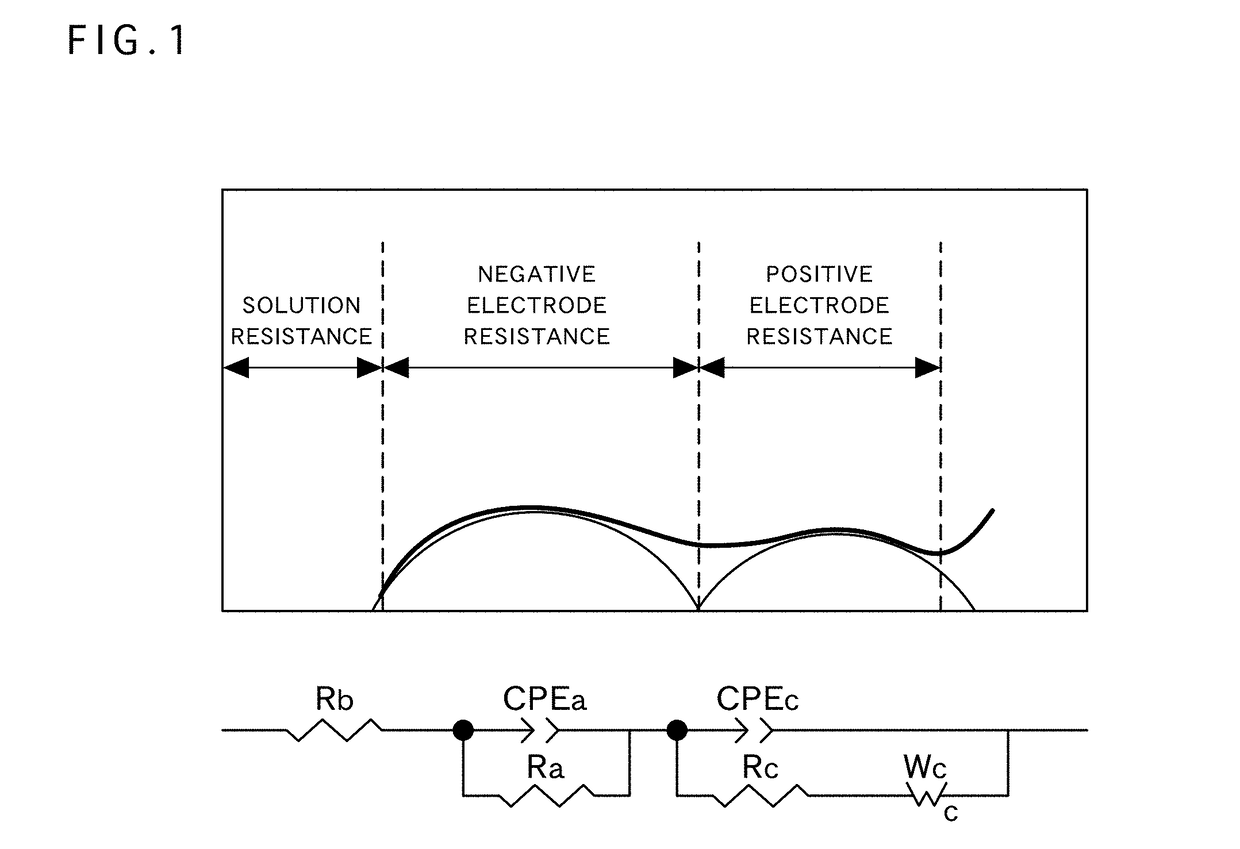

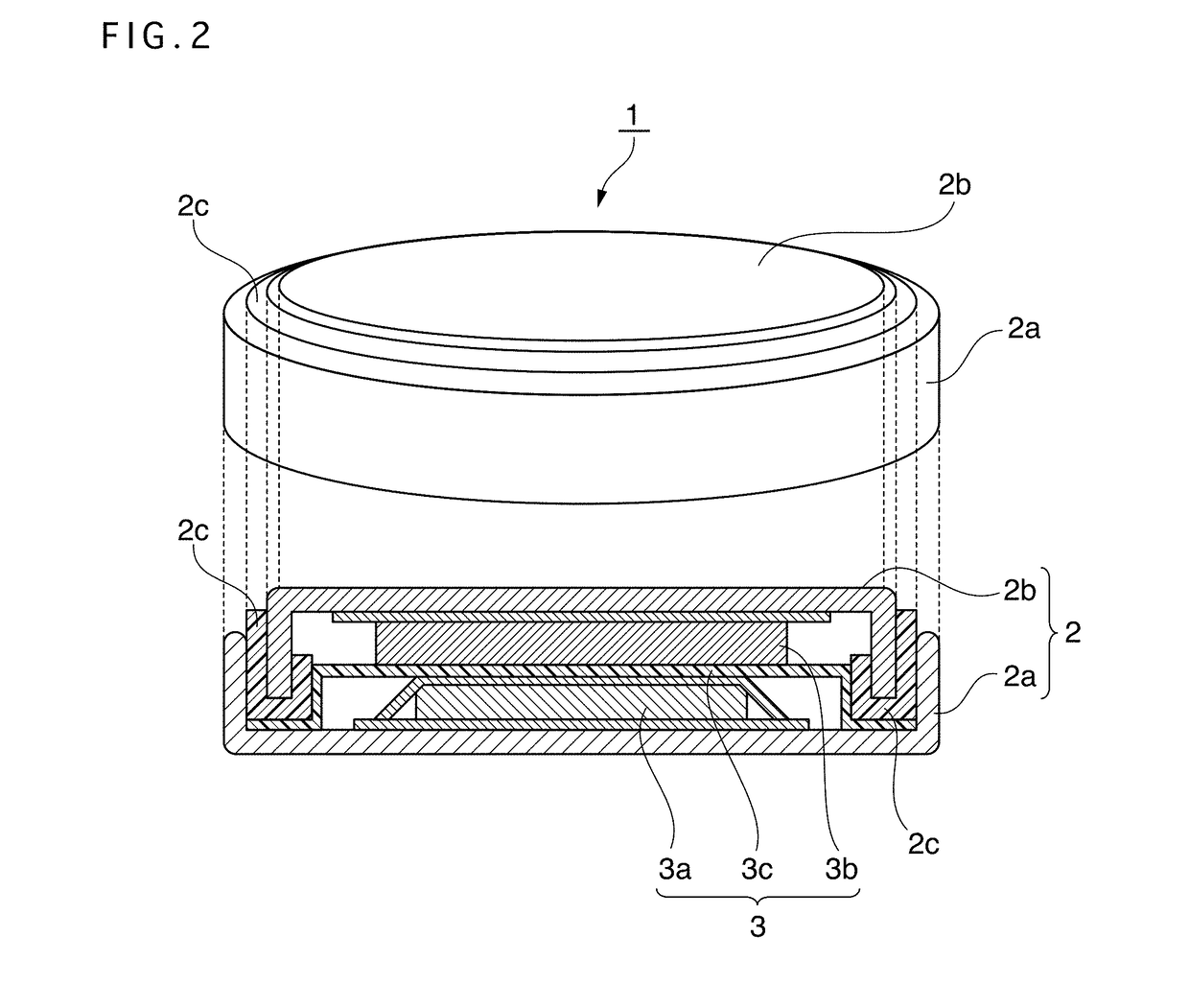

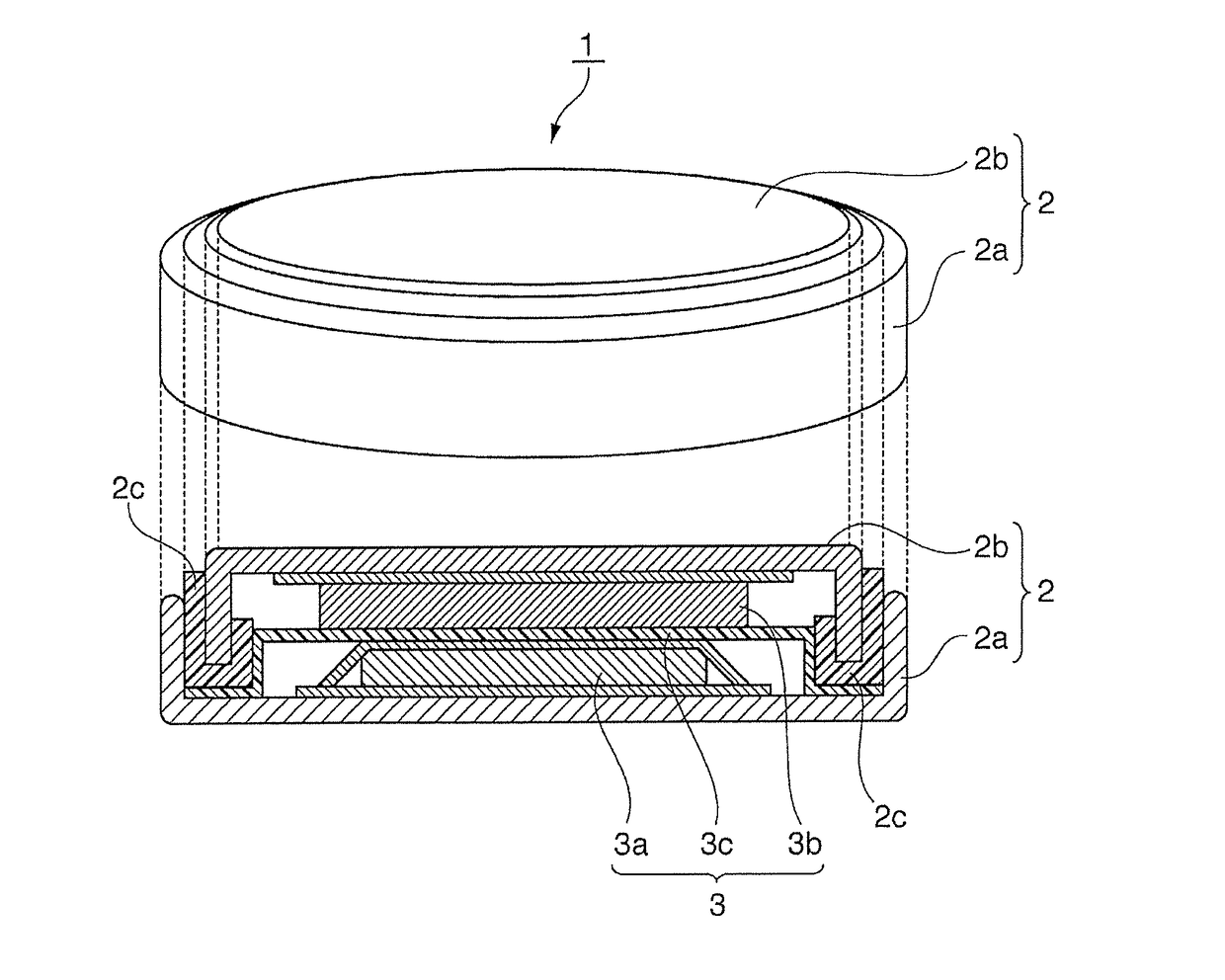

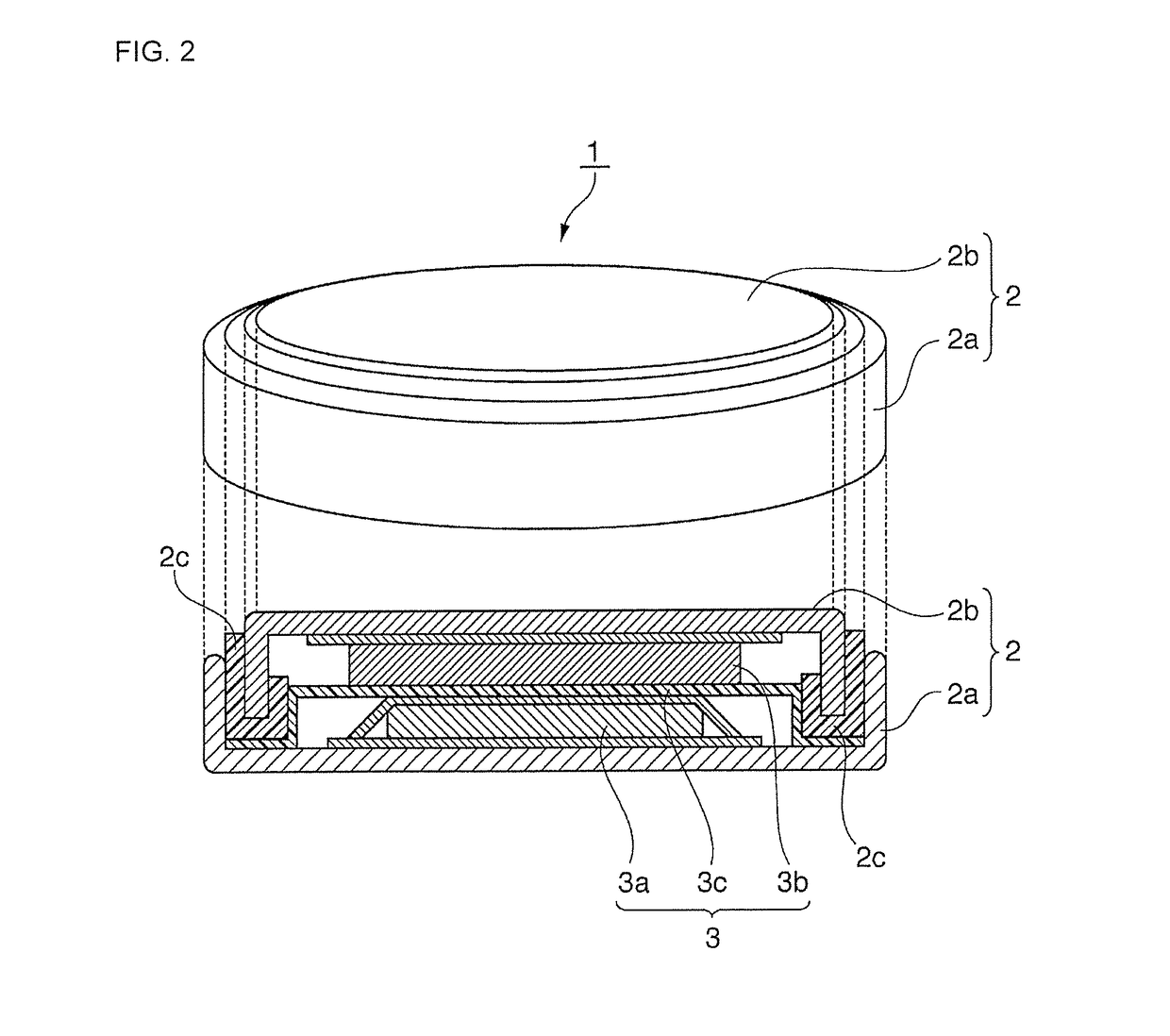

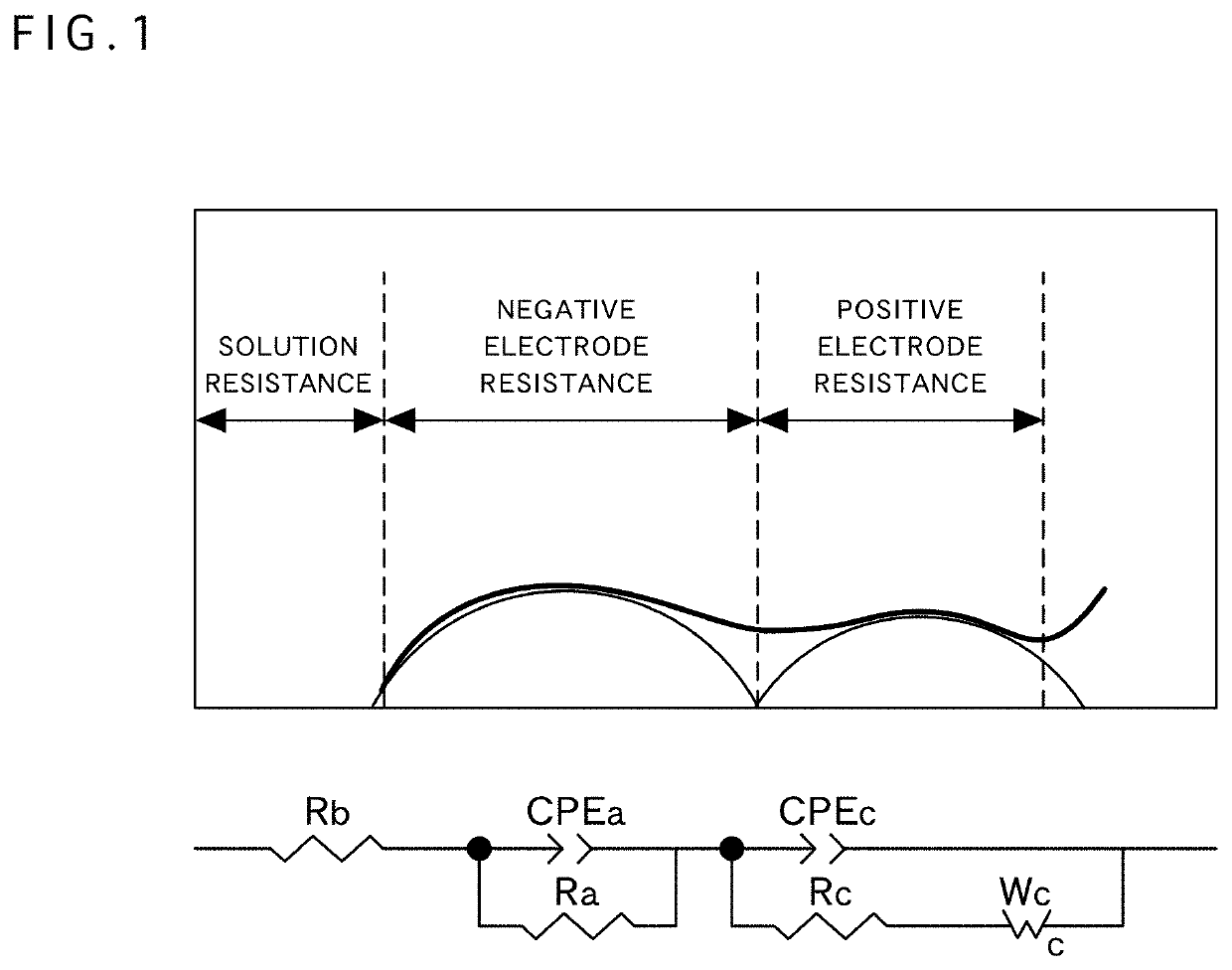

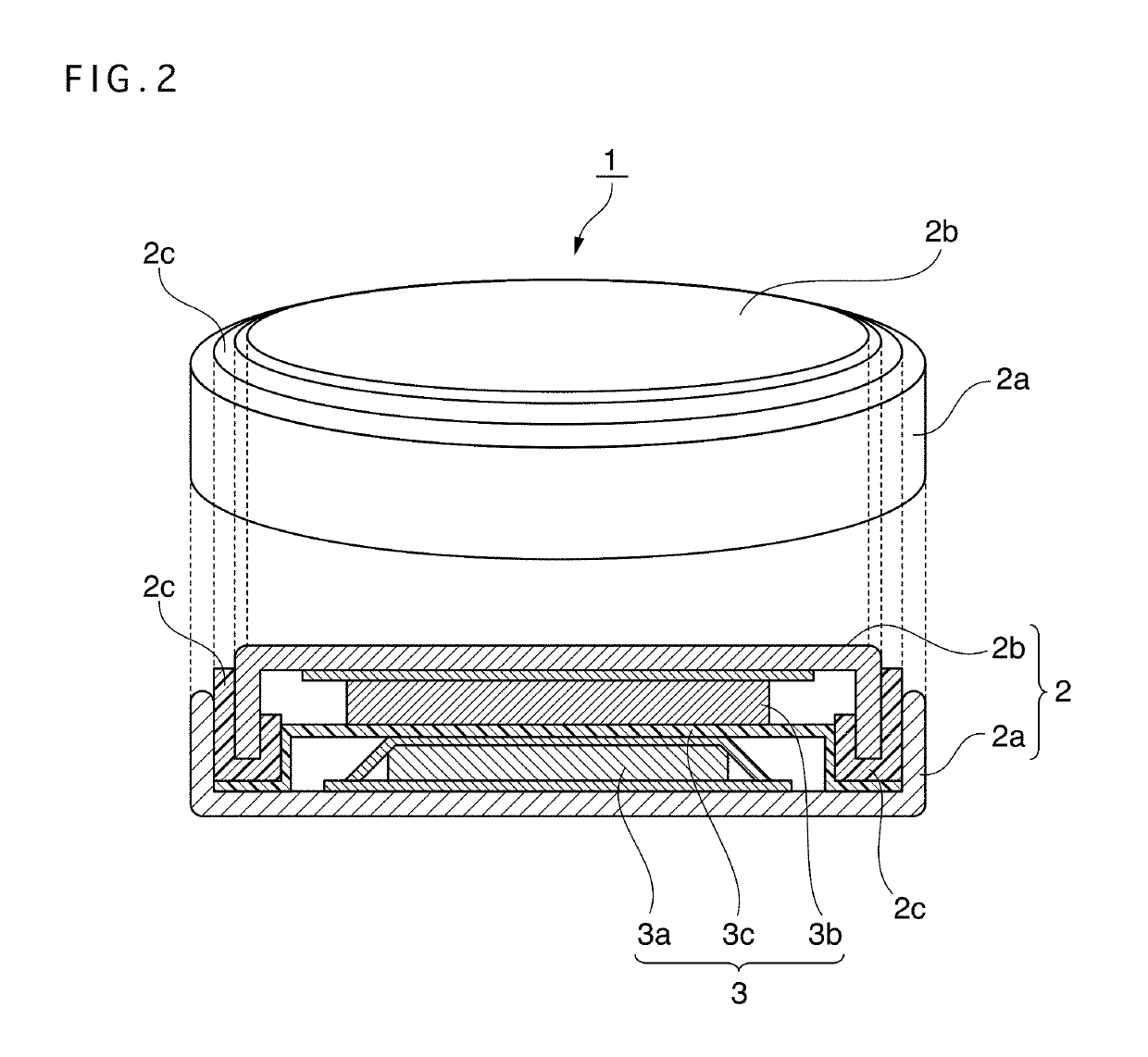

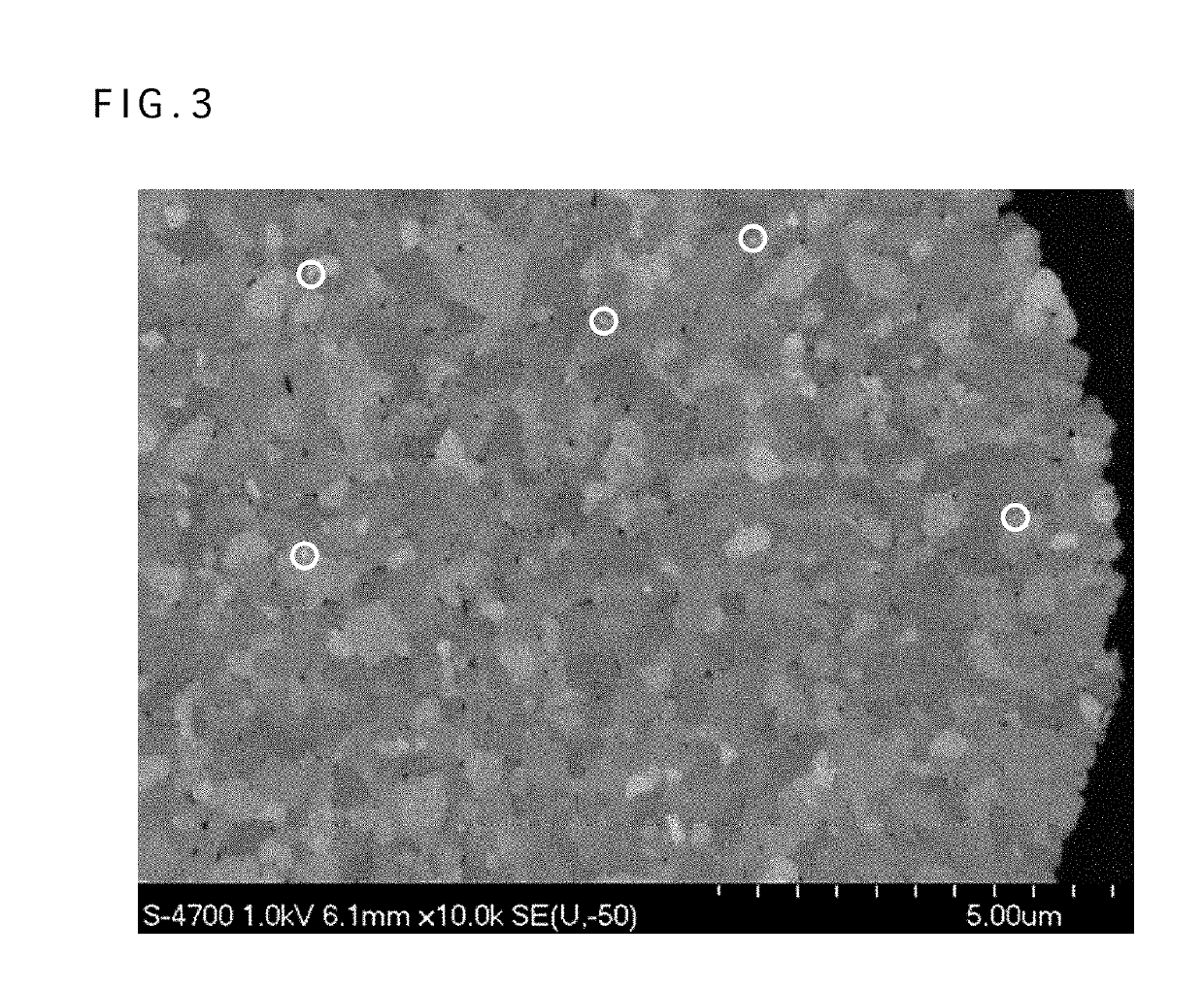

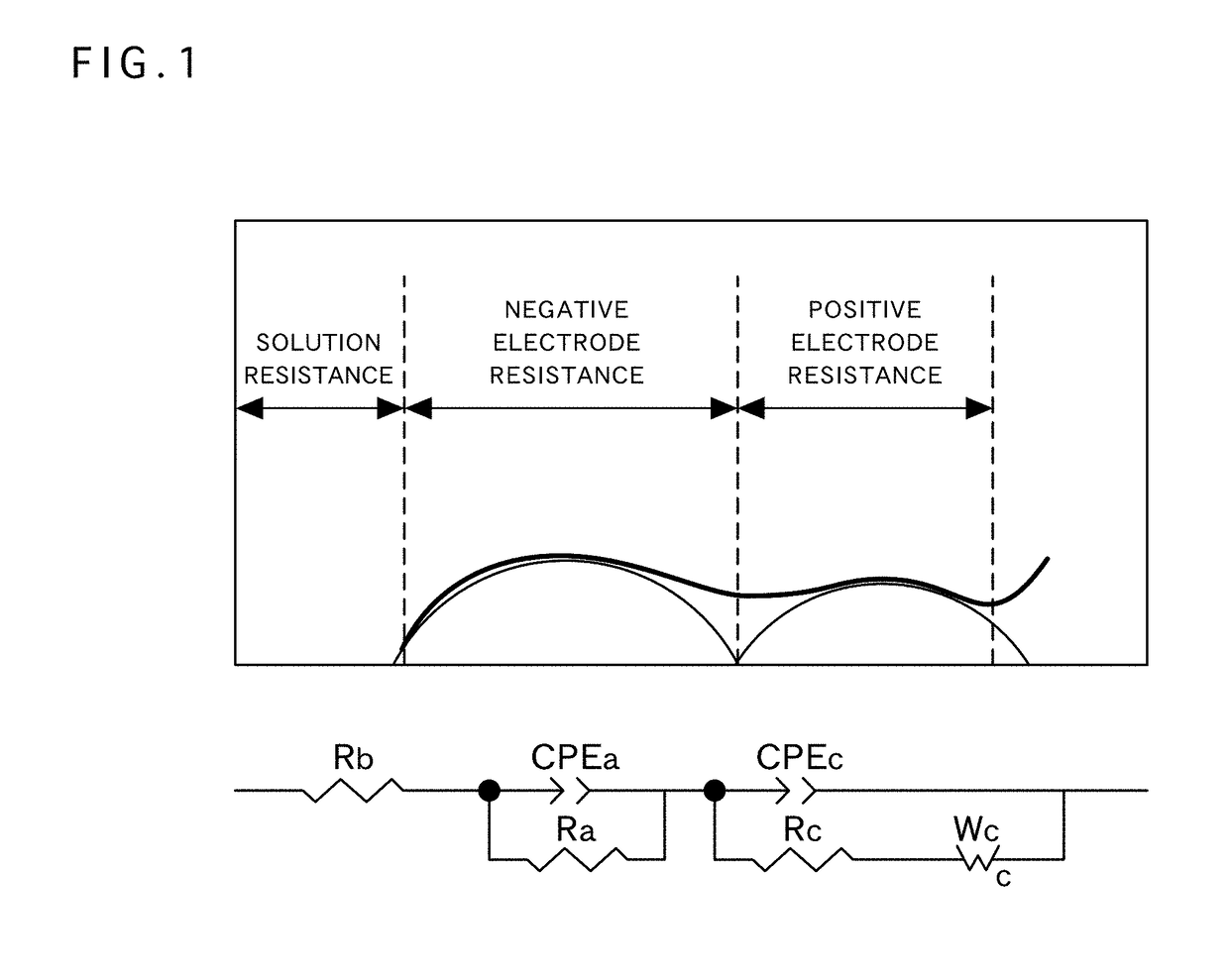

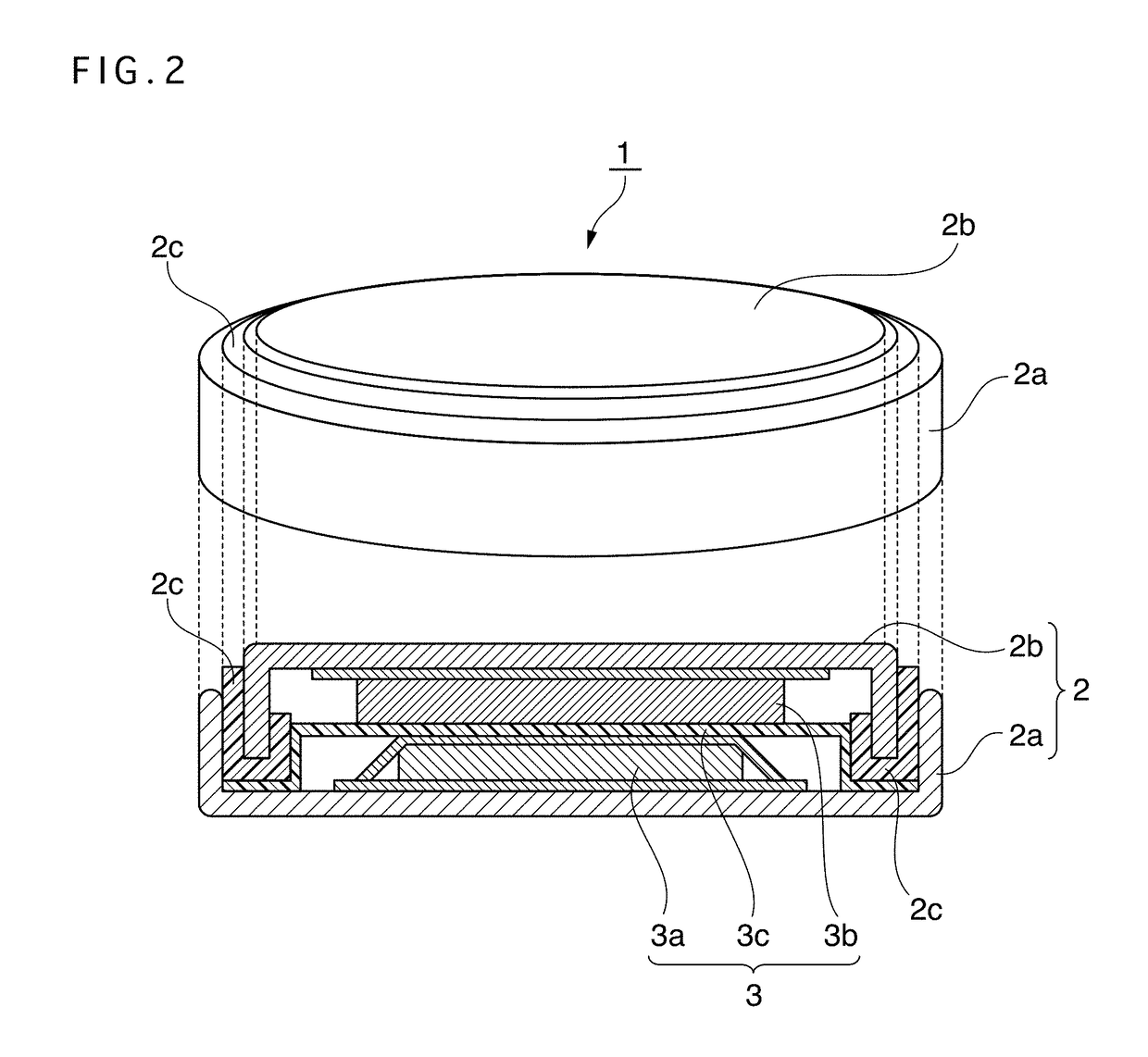

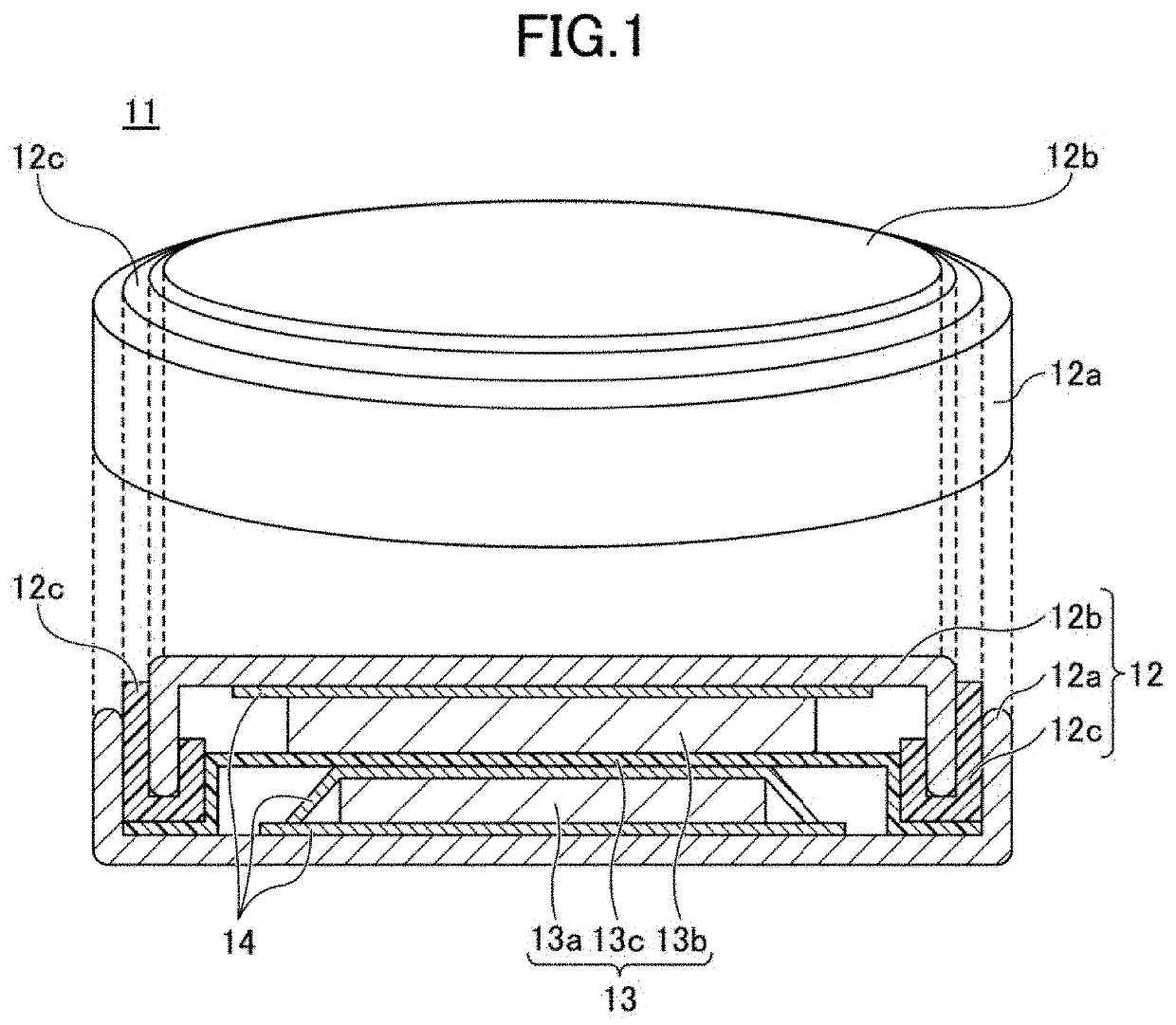

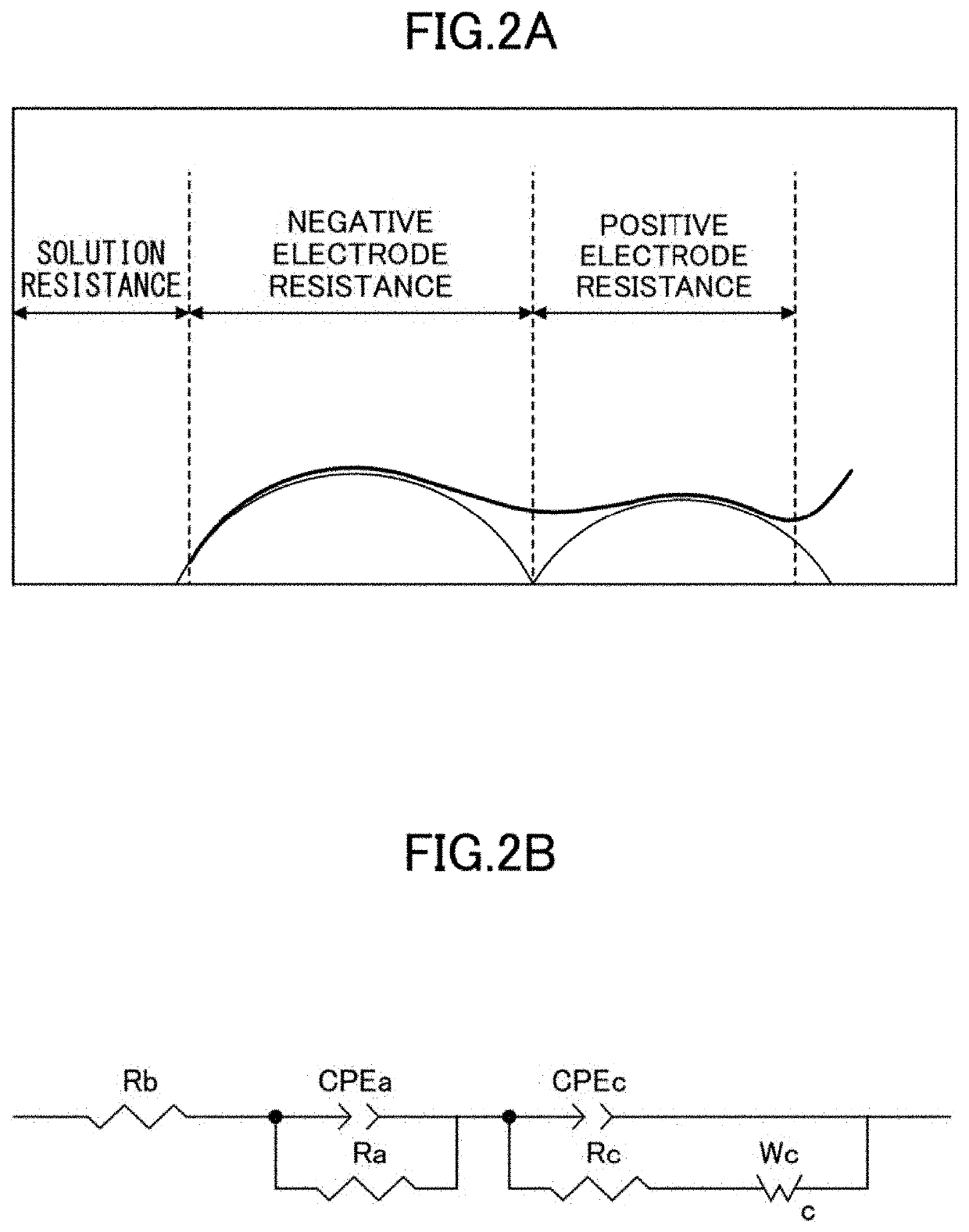

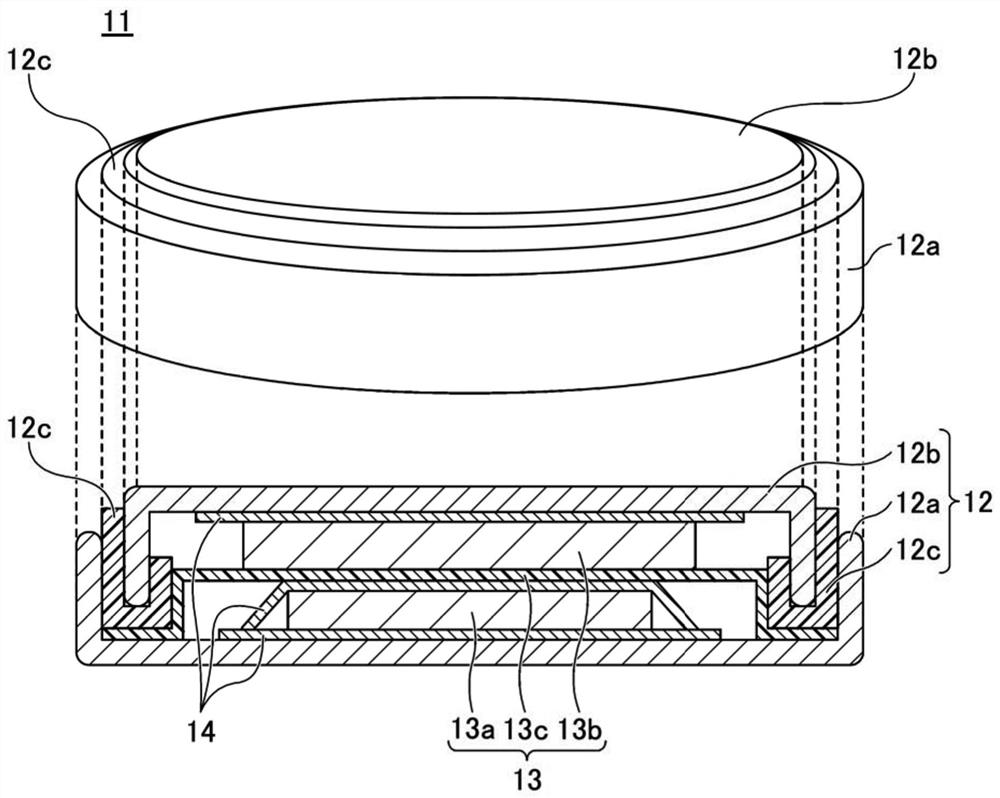

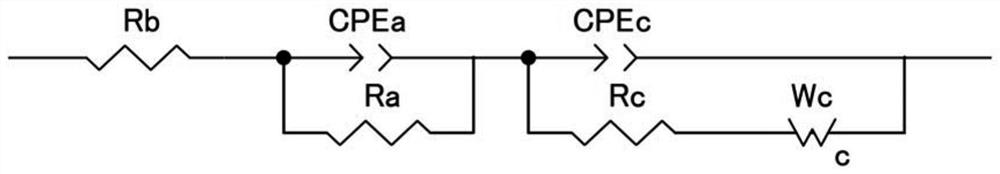

Non-aqueous electrolyte secondary battery

PendingCN112242505AReduce initial resistanceFinal product manufactureNegative electrodesLithium tungstateAqueous electrolyte

A non-aqueous electrolyte secondary battery that is obtained using a lithium composite oxide having a layered structure as a positive electrode active material and has a low initial resistance and anincrease in resistance after repeated charging and discharging is suppressed. The non-aqueous electrolyte secondary battery includes a positive electrode, a negative electrode, and a non-aqueous electrolyte. The positive electrode includes a positive electrode active substance layer, which contains a lithium composite oxide having a layered structure. The lithium composite oxide is a porous particle. A surface of the porous particle includes a layer having a rock salt type structure. A thickness of the layer is not less than 5 nm and not more than 80 nm. A void ratio of the porous particle isnot less than 15% and not more than 48%. The porous particle contains two or more voids having diameters that are at least 10% of the particle diameter of the porous particle. The surface of the porous particle includes a coating of lithium tungstate.

Owner:TOYOTA JIDOSHA KK +1

Positive electrode active material for nonaqueous electrolyte secondary battery, method for producing same, and nonaqueous electrolyte secondary battery using said positive electrode active material

ActiveUS20180287144A1Reaction resistance of the positive electrode active material can be reducedImprove output characteristicsPositive electrodesLi-accumulatorsLithium tungstateComposite oxide

Provided is a method for producing a positive electrode active material for nonaqueous electrolyte secondary batteries, the method including: a mixing step of obtaining a W-containing mixture of Li-metal composite oxide particles represented by the formula: LizNi1-x-yCoxMyO2 and composed of primary particles and secondary particles formed by aggregation of the primary particles, 2 mass % or more of water with respect to the oxide particles, and a W compound or a W compound and a Li compound, the W-containing mixture having a molar ratio of the total amount of Li contained in the water and the solid W compound, or the W compound and the Li compound of 1.5 or more and less than 3.0 with respect to the amount of W contained therein; and a heat treatment step of heating the W-containing mixture to form lithium tungstate on the surface of the primary particles.

Owner:SUMITOMO METAL MINING CO LTD

Ytterbium doped yttrium lithium tungstate of femtosecond pulsed laser crystal and method of producing the same

InactiveCN101319396APromote growthQuality improvementPolycrystalline material growthFrom melt solutionsTungstateMicrochip laser

The invention provides a femtosecond pulse laser crystal ytterbium-doped lithium ytterbium tungstate and a preparation method thereof. The invention is characterized in that: the method adopts a molten salt method and uses Li2W2O7 with a mol ratio of between 70 and 90 percent as a slagging medium to grow a Yb<3+>: beta-LiY(WO4)2 crystal with high quality and large dimension at a temperature of between 750 and 800 DEG C at a cooling rate of between 0.1 and 1 DEG C / day for about 30 days. The crystal is particularly applicable to a microchip laser crystal and a micro-laser. A solid laser produced by the crystal can be used in spectroscopy, biomedicine, military and other fields.

Owner:黄新阳

Positive-electrode material for nonaqueous-electrolyte secondary battery, method for manufacturing the same, and nonaqueous-electrolyte secondary battery using said positive-electrode material

ActiveUS20170098821A1Reduce resistanceImprove output characteristicsElectrode manufacturing processesPositive electrodesLithium metalLithium tungstate

Provided is a positive-electrode material for nonaqueous-electrolyte secondary batteries, the positive-electrode material being capable of achieving both high capacity and high output when used for a positive electrode for nonaqueous-electrolyte secondary batteries. Also, provided is a method for manufacturing the positive-electrode material for nonaqueous-electrolyte secondary batteries, wherein a lithium metal composite oxide powder is mixed with lithium tungstate, the lithium metal composite oxide powder being represented by a general formula LizNi1-x-yCoxMyO2 (wherein 0.10≦x≦0.35, 0≦y≦0.35, 0.97≦z≦1.20, and M is an addition element and at least one element selected from Mn, V, Mg, Mo, Nb, Ti, and Al) and comprising primary particles and secondary particles composed of aggregation of the primary particles.

Owner:SUMITOMO METAL MINING CO LTD

Positive electrode active material for nonaqueous electrolyte secondary battery, method for producing same, and nonaqueous electrolyte secondary battery using said positive electrode active material

ActiveUS10784507B2Reaction resistance of the positive electrode active material can be reducedImprove output characteristicsPositive electrodesLi-accumulatorsElectrical batteryLithium metal

Provided is a method for producing a positive electrode active material for nonaqueous electrolyte secondary batteries, the method including: a mixing step of obtaining a W-containing mixture of Li-metal composite oxide particles represented by the formula: LizNi1-x-yCoxMyO2 and composed of primary particles and secondary particles formed by aggregation of the primary particles, 2 mass % or more of water with respect to the oxide particles, and a W compound or a W compound and a Li compound, the W-containing mixture having a molar ratio of the total amount of Li contained in the water and the solid W compound, or the W compound and the Li compound of 1.5 or more and less than 3.0 with respect to the amount of W contained therein; and a heat treatment step of heating the W-containing mixture to form lithium tungstate on the surface of the primary particles.

Owner:SUMITOMO METAL MINING CO LTD

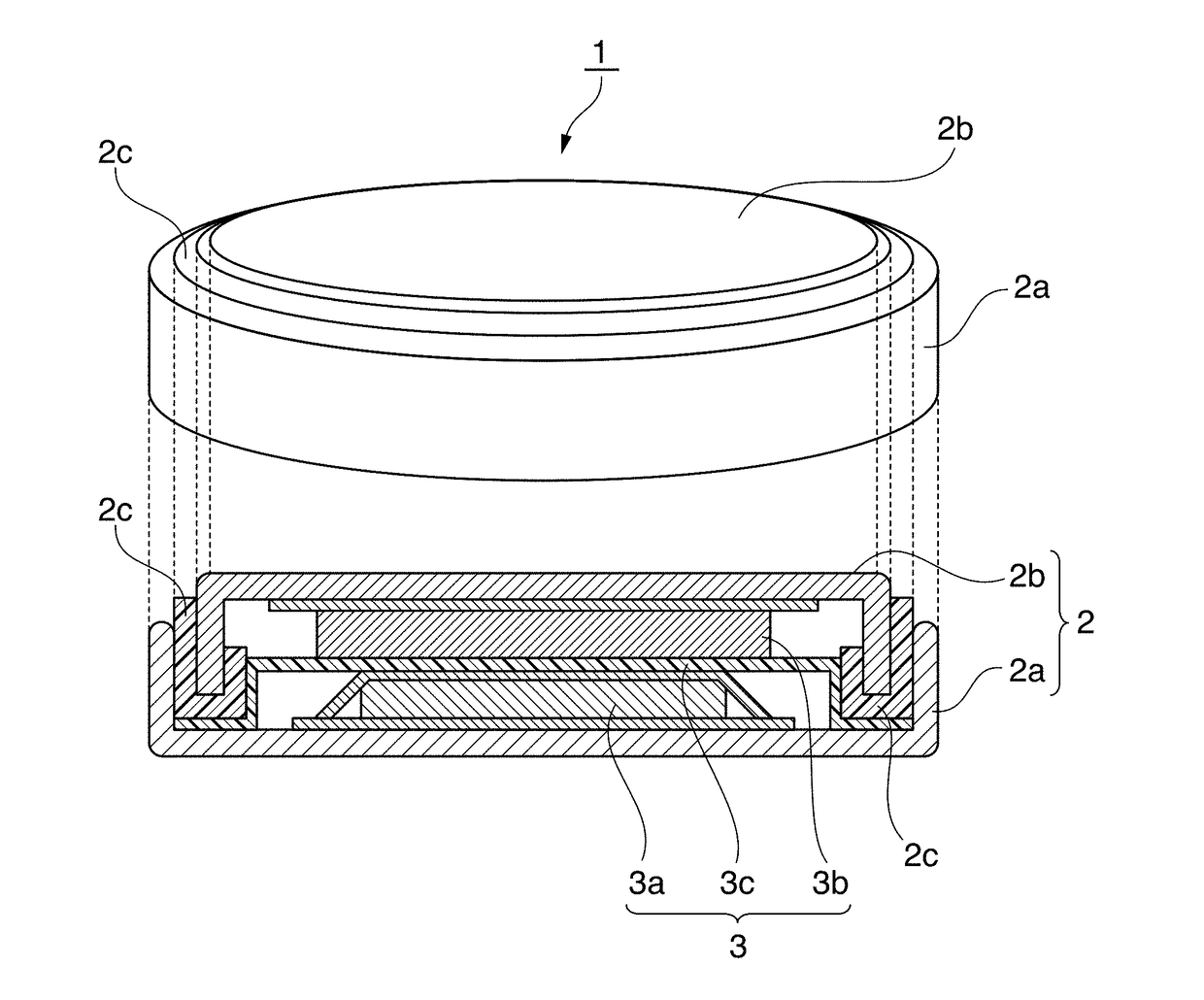

A solid-state electrolyte, a method for making the same, and an all-solid-state lithium battery

ActiveCN103904360BSmall resistanceCan undergo plastic deformationSolid electrolytesSecondary cellsSolid state electrolyteElectrical conductor

The invention relates to a solid electrolyte. The solid electrode comprises a substrate, and the substrate is a garnet type fast ion conductor Li7M3Zr2O12 or Li5Ta3M2O12, wherein the M can be one or more components selected from La, Al, Sr, Sc, Cr, Ba, Fe, Mo, and Y. The surface of the substrate is covered by a surface modification layer which can carry out plastic deformation, and the surface modification layer is made of non-crystal lithium silicate, lithium sulfate, or lithium tungstate. The invention also relates to a preparation method of the solid electrolyte. The solid electrolyte is covered by a surface modification layer made of non-crystal lithium silicate, lithium sulfate or lithium tungstate, and the non-crystal lithium silicate, lithium sulfate, and lithium tungstate are all flexible, can carry out plastic deformation, and all have a high ionic conductivity; so the surface modification layer can fully carry out surface contact with the garnet type fast ion conductor, thus the interfaces between the crystals in the solid electrolyte and the interfaces between the electrodes and the solid electrolyte are all improved, the interface impedance and grain resistance are low, and the durability and circulation performance are both prominently improved.

Owner:HUAWEI TECH CO LTD

Lithium bromide absorption refrigerator high-efficiency corrosion inhibitor and preparation method thereof

The invention provides a lithium bromide absorption refrigerator high-efficiency corrosion inhibitor and a preparation method thereof and in particular relates to a polyoxometalate composite inorganic high polymer material. The lithium bromide absorption refrigerator high-efficiency corrosion inhibitor provided by the invention is prepared from the following raw materials in parts by weight: 15-35 parts of lithium molybdate, 10-50 parts of lithium tungstate, 1-5 parts of lithium dihydrogen phosphate, 50-75 parts of deionized water, 4-15 parts of hydrobromic acid and 0.5-2 parts of zinc dihydrogen phosphate. The preparation method comprises the following steps of: firstly preparing hydrobromic acid solution, dissolving lithium molybdate, lithium tungstate and lithium dihydrogen phosphate, heating lithium tungstate solution and lithium dihydrogen phosphate solution in a reaction kettle, regulating the pH value, then dropwise adding lithium molybdate solution, and finally regulating the pH value and adding zinc dihydrogen phosphate, so that the lithium bromide absorption refrigerator high-efficiency corrosion inhibitor is obtained. Compared with the prior art, the lithium bromide absorption refrigerator high-efficiency corrosion inhibitor provided by the invention has the characteristics that inner cavity material of the lithium bromide refrigerator is obviously passivated, a passivated film is excellently bonded with the inner cavity material and has high corrosion resistance, and the corrosion inhibitor has good temperature resistance and stability and is low in additive amount.

Owner:镇江市富来尔制冷工程技术有限公司

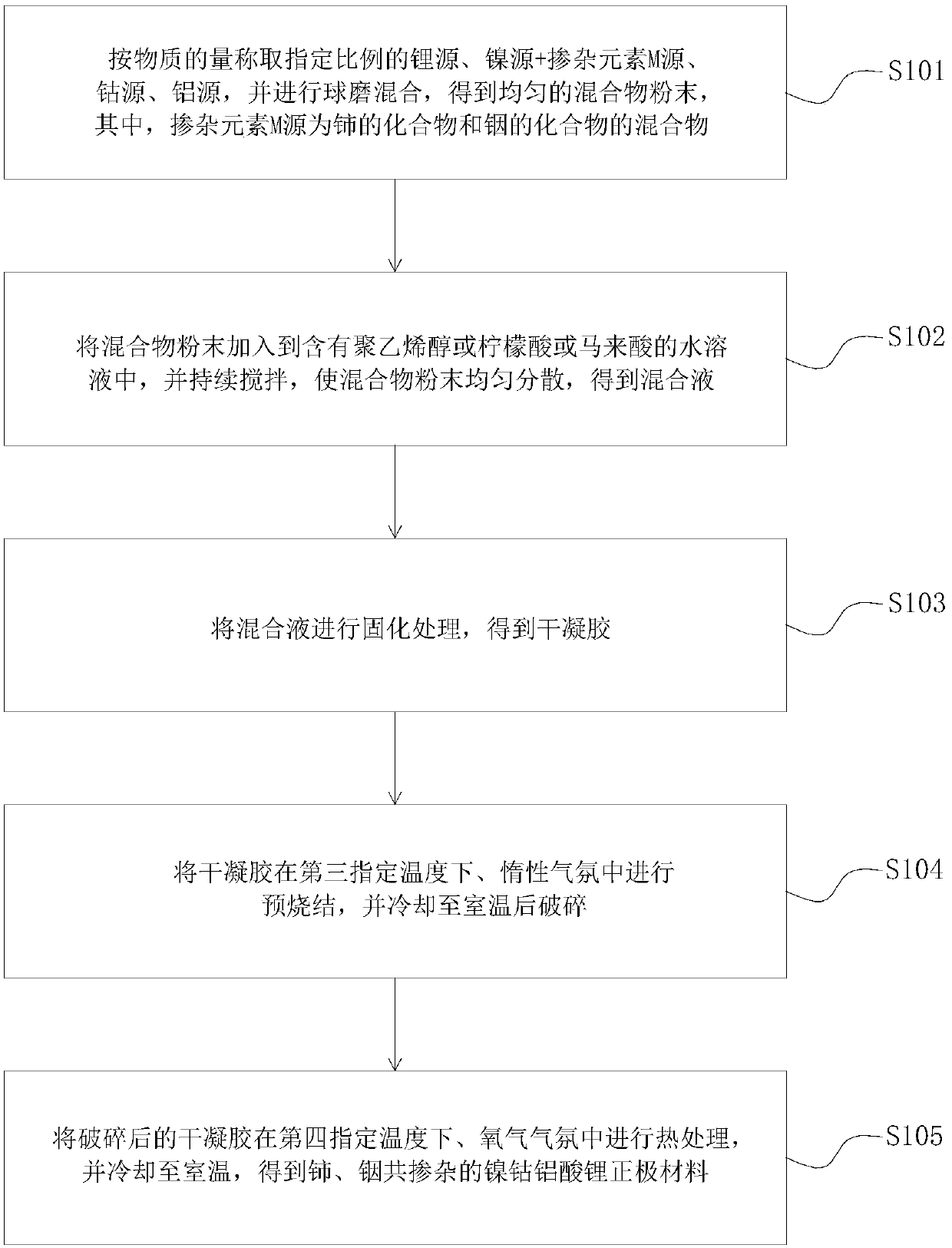

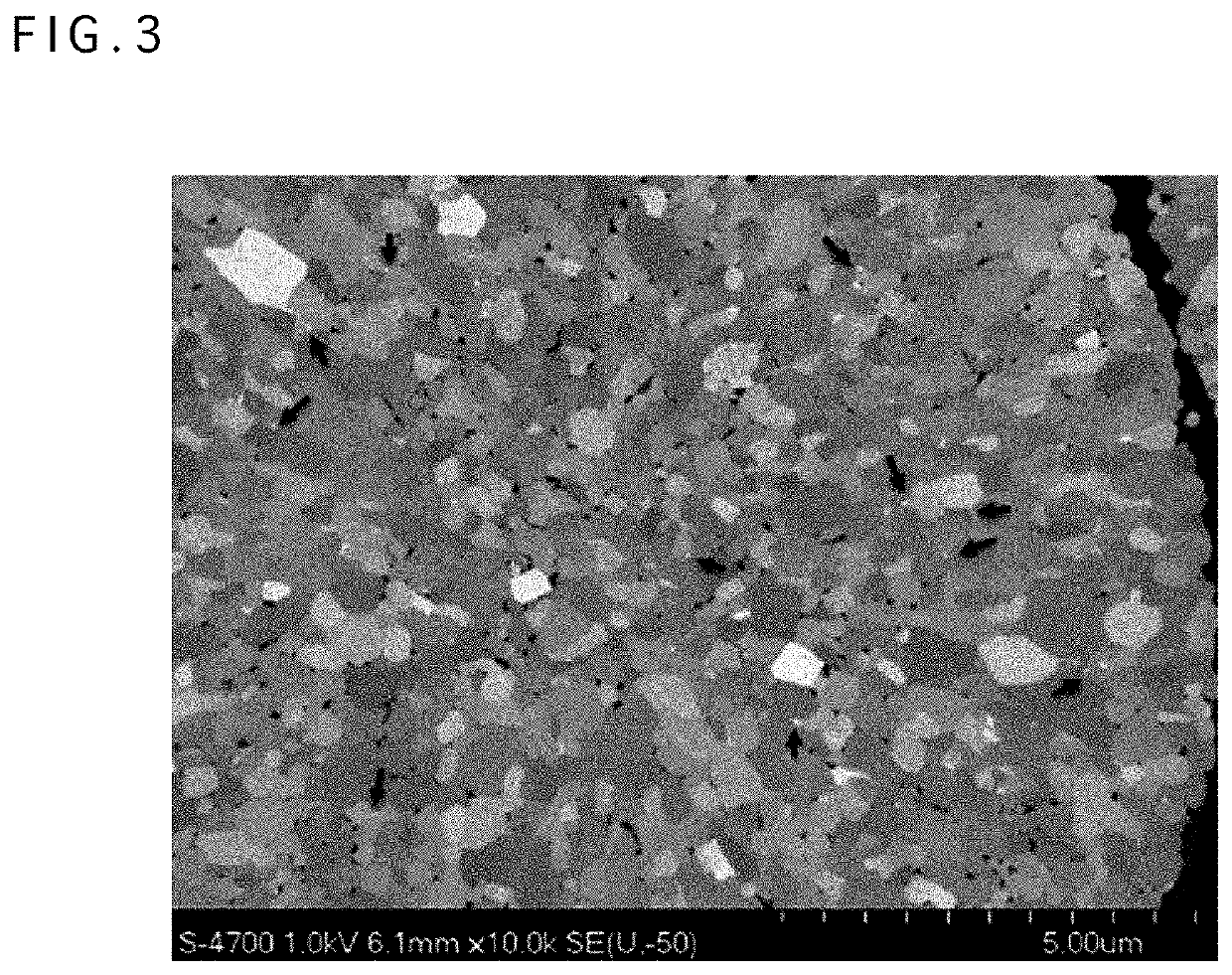

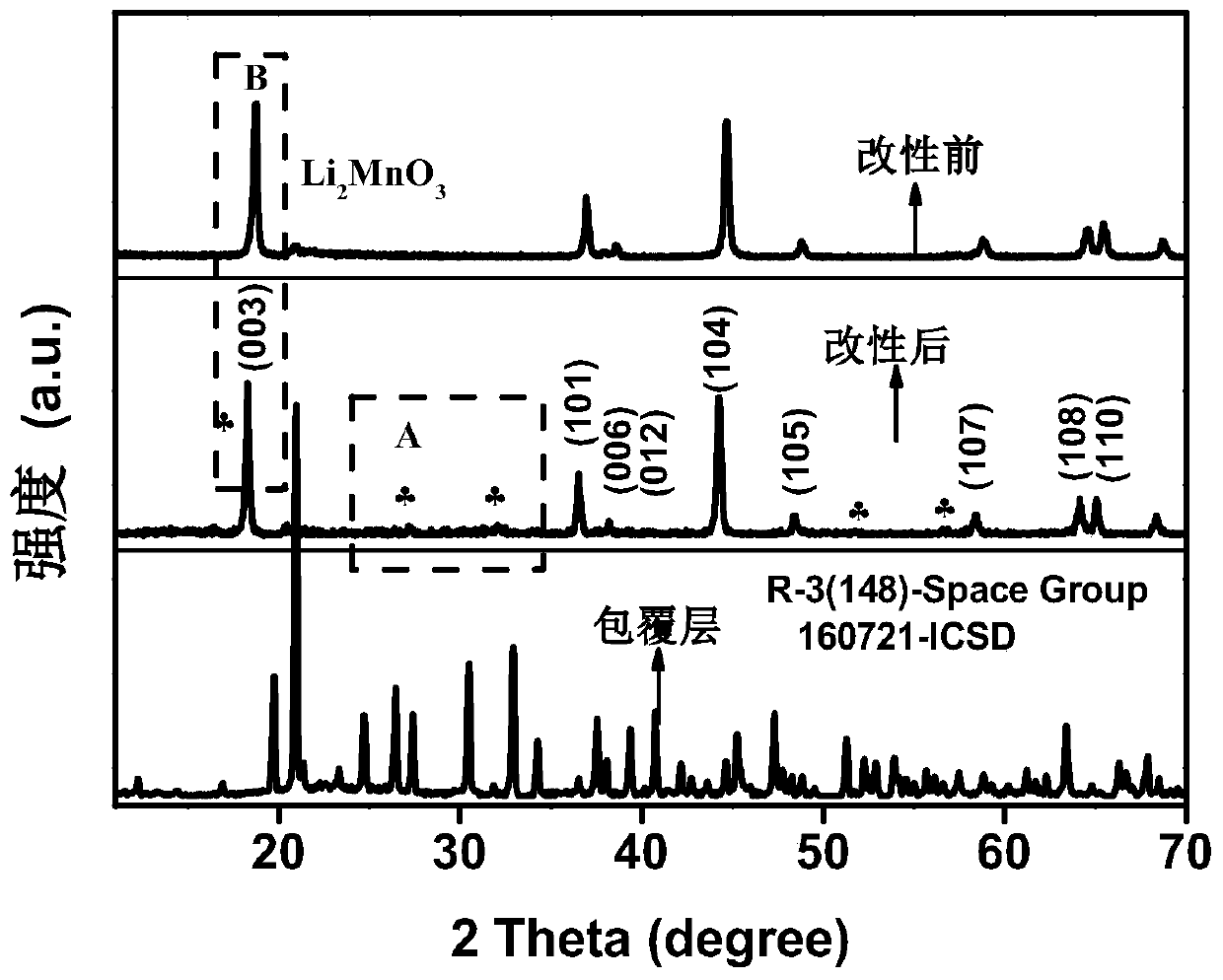

Lithium ion battery cathode material, and preparation method thereof

InactiveCN109879330AExcellent rate performanceImprove cycle performanceMaterial nanotechnologyCell electrodesSpace groupManganese

The invention discloses a lithium ion battery cathode material, and a preparation method thereof. The preparation method comprises following steps: S1, a granular lithium-enriched manganese-based material, and preferable with a spherical morphology, is dispersed and dissolved in a mixed solution containing a lithium salt and a tungsten oxide; S2, a solution obtained in step S1 is dried up; and S3,a mixture obtained after drying in step S2 is grinded and dispersed, and is subjected to sintering so as to obtain the lithium-enriched manganese-based ternary cathode material, wherein the surface of the lithium-enriched manganese-based ternary cathode material is provided with a R-3 space group lithium tungstate coating layer. Operation of the preparation method is simple; only a small amount of a modifying material is capable of improving the circulation conservation rate and electrochemical performance of the lithium-enriched manganese-based material obviously, and obtaining the lithium ion battery cathode material with excellent rate capability.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Special lithium bromide solution for adsorption refrigerator and preparation method thereof

InactiveCN103509521AGood passivation propertiesImprove the shortcoming of easily generating hydrogenHeat-exchange elementsPhosphateLithium bromide

The invention belongs to the technical field of air conditioning refrigeration and particularly relates to a special lithium bromide solution for an adsorption refrigerator and a preparation method thereof. The special lithium bromide solution for the adsorption refrigerator comprises a corrosion inhibitor which accounts for 1 to 3.5 percent of the total mass of the lithium bromide solution. The corrosion inhibitor comprises the following raw material components in parts by mass: 15 to 35 parts of lithium molybdate, 10 to 50 parts of lithium tungstate, 1 to 5 parts of lithium dihydrogen phosphate, 4 to 15 parts of hydrobromic acid, 0.5 to 2 parts of zinc dihydrogen phosphate and 0.5 to 2 parts of manganous nitrate. The special lithium bromide solution for the adsorption refrigerator is excellent in combination of a passive film layer and an inner cavity material, has more excellent corrosion resistance and good temperature resistance and stability.

Owner:昆山市周市溴化锂溶液厂

Positive electrode active material for nonaqueous electrolyte secondary battery, method for producing same, and nonaqueous electrolyte secondary battery using said positive electrode active material

ActiveUS10497936B2Increase powerExcellent cycle characteristicsPositive electrodesLi-accumulatorsLithium tungstateComposite oxide

Provided is a method for producing a positive electrode active material for nonaqueous electrolyte secondary batteries, including: a water-washing step of mixing, with water, Li—Ni composite oxide particles represented by the formula: LizNi1-x-yCoxMyO2 and composed of primary particles and secondary particles formed by aggregation of the primary particles to water-wash it, and performing solid-liquid separation to obtain a washed cake; a mixing step of mixing a W compound powder free from Li with the washed cake to obtain a W-containing mixture; and a heat treatment step of heating the W-containing mixture, the heat treatment step including: a first heat treatment step of heating the W-containing mixture to disperse W on the surface of the primary particles; and subsequently, a second heat treatment step of heating it at a higher temperature than in the first heat treatment step to form a lithium tungstate compound on the surface of the primary particles.

Owner:SUMITOMO METAL MINING CO LTD

Neodymium-doped gadolinium barium lithium tungstate laser crystal and preparation method and application thereof

InactiveCN101676445AExcellent optical propertiesStable growth processPolycrystalline material growthFrom melt solutionsFluorescenceChemistry

The invention relates to a neodymium-doped gadolinium barium lithium tungstate laser crystal and a preparation method and application thereof. The high-quality crystal with large size is grown by using 30-60at% Li2WO4 as a fluxing agent under the conditions that the cooling rate is 0.5-2 DEG C / day and the rotating speed is 5-30r / min. The crystal belongs to the monoclinic system and has C2 / c spacegroup structure. The main absorption peak of the Nd<3+>:Li3Ba2Gd3(WO4)8 crystal is 804nm, the half-peak width is 19nm and the absorption transition cross section is 5.37*10<-20>cm<2>, and the crystalis suitable for being pumped by the AsGaAl semiconductor laser. A quite wide emission band exists in the range from 850nm-1400nm. The emission transition cross section at the emission peak of 1064nm is 12.08*10<-20>cm<2>, the fluorescence lifetime is 0.153ms, and the crystal is easy to generate and output lasers with wavelength being 1064nm.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

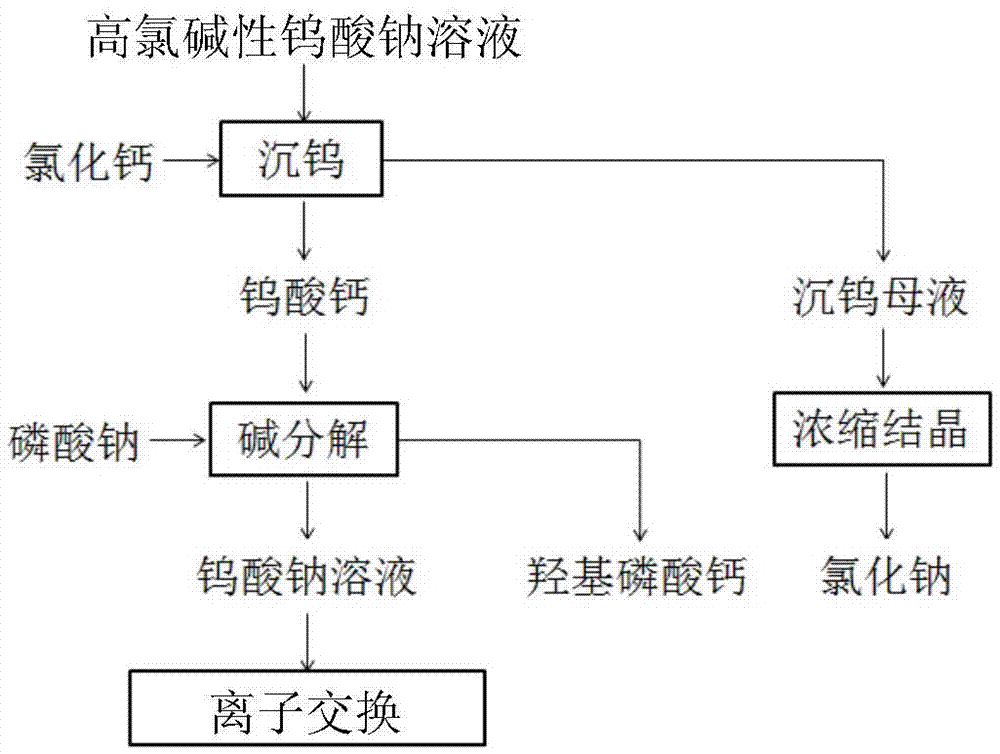

Method for separating and recycling tungsten in alkaline sodium tungstate solution with high chlorine content

ActiveCN105439204AHigh purityHigh recovery rateAlkali metal chloridesTungsten compoundsAmmonium paratungstateDecomposition

The invention discloses a method for separating and recycling tungsten in an alkaline sodium tungstate solution with a high chlorine content. The method comprises the following steps: (1) precipitating tungsten: adjusting the pH value of an alkaline sodium tungstate solution with high chlorine content to 9-13 by hydrochloric acid, then adding enough saturated calcium chloride solution to fully carry out reactions so as to precipitate tungsten, washing the precipitate, and filtering to obtain precipitate (calcium tungstate) and a tungsten precipitation mother liquor; (2) alkali decomposition: using sodium phosphate as a leaching agent to fully decompose calcium tungstate in a sodium hydroxide solution to obtain a sodium tungstate solution; (3) ion exchange: subjecting the obtained sodium tungstate solution in the alkali decomposition step to ion exchange according to a convention ion exchange method, and after desorption, performing evaporation and crystallization to obtain high purity secondary ammonium tungstate. According to the method, in the tungsten precipitation step, the tungstate groups in the alkaline sodium tungstate solution with a high chlorine content are precipitated so as to separate the tungstate groups from the chlorine ions; and then obtained calcium tungstate is decomposed by a leaching agent (sodium phosphate) under an alkaline condition so as to obtain a sodium tungstate solution, which can be applied to ion exchange, so that the alkaline sodium tungstate solution with a high chlorine content can be processed by an ion exchanged method to recycle tungsten to obtain a high purity secondary ammonium tungstate product.

Owner:湖北绿钨资源循环有限公司

Chromium-doped lithium tungstate magnesium crystal as well as preparation and application thereof

ActiveCN103668459AModerate mechanical properties and thermal propertiesWide tunable laser bandPolycrystalline material growthFrom frozen solutionsChromium dopingSpace group

The invention discloses a chromium-doped lithium tungstate magnesium crystal as well as a preparation method and an application thereof. The molecular formula of the crystal is Cr3+:Li2Mg2(WO4)3, the crystal belongs to an orthorhombic crystal system and a Pnma space group, and the cell parameter is as follows: Z=4. The crystal grows in a top seeded solvent growth method, the mixture of 75% Li2WO4 and 25% WO3 is used as a fluxing agent, the concentration ratio of the fluxing agent in the growth raw material is 55 to 80 percent, and the growth parameters are as follows: the cooling rate is 0.5 to 5 DEG C / day, the growth temperature is 800 to 880 DEG C, and the rotation speed is 5 to 30 turns / min. The crystal has the characteristics such as moderate mechanical performance, large transmission cross section and the like, the tunable range is 750nm to 1050nm, and the crystal is expected to become a novel tunable laser crystal and can be actually used.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Positive electrode active material for nonaqueous electrolyte secondary battery, method for producing same, and nonaqueous electrolyte secondary battery using said positive electrode active material

ActiveUS20180287143A1Increase powerLarge capacityPositive electrodesLi-accumulatorsLithium tungstateComposite oxide

Provided is a method for producing a positive electrode active material for nonaqueous electrolyte secondary batteries, the method including: a mixing step of obtaining a W-containing mixture of Li metal composite oxide particles represented by the formula: LizNi1-x-yCOxMyO2 and composed of primary particles and secondary particles formed by aggregation of the primary particles, 2 mass % or more of water with respect to the oxide particles, and a W compound or a W compound and a Li compound, the W-containing mixture having a molar ratio of the total amount of Li contained in water and the solid W compound or the W compound and the Li compound of 3 to 5 with respect to the amount of W contained therein; and a heat treatment step of heating the W-containing mixture to form lithium tungstate on the surface of the primary particles of the Li metal composite oxide particles.

Owner:SUMITOMO METAL MINING CO LTD

Positive electrode active material for non-aqueous electrolyte secondary battery, and non-aqueous electrolyte secondary battery

PendingUS20210167378A1Improve short circuit resistanceImprove output characteristicsPositive electrodesLi-accumulatorsLithium tungstateAqueous electrolyte

The present invention relates to a positive electrode active material for non-aqueous electrolyte secondary battery, including lithium-nickel composite oxide particles having a layer structure of hexagonal system; and a lithium tungstate coating film disposed on a surface of secondary particles of the lithium-nickel composite oxide particles, wherein the positive electrode active material for non-aqueous electrolyte secondary battery includes, as metallic elements, lithium (Li), nickel (Ni), cobalt (Co), element M (M) which is at least one element selected from Mn, V, Mg, Mo, Nb, Ti, Ca, Cr, Zr, Ta, and Al, and tungsten (W), wherein a ratio of amount of substance in the metallic elements contained is Li:Ni:Co:M:W=a:1-x-y:x:y:z, wherein 0.97≤a≤1.25, 0≤x≤0.35, 0≤y≤0.35, and 0.005≤z≤0.030.

Owner:SUMITOMO METAL MINING CO LTD

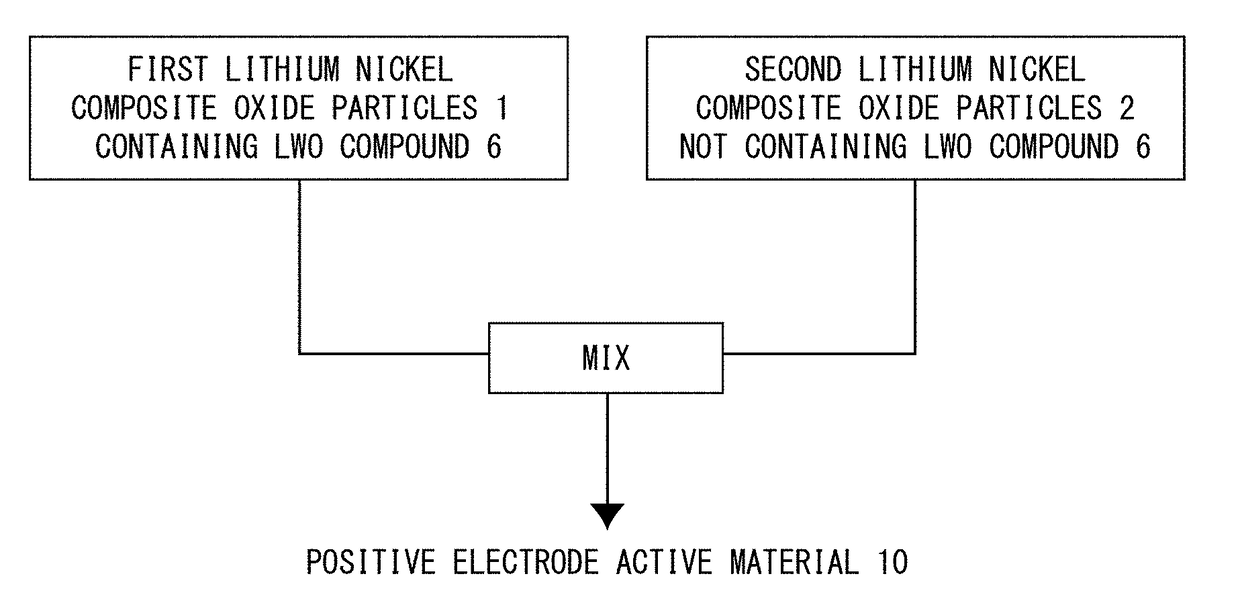

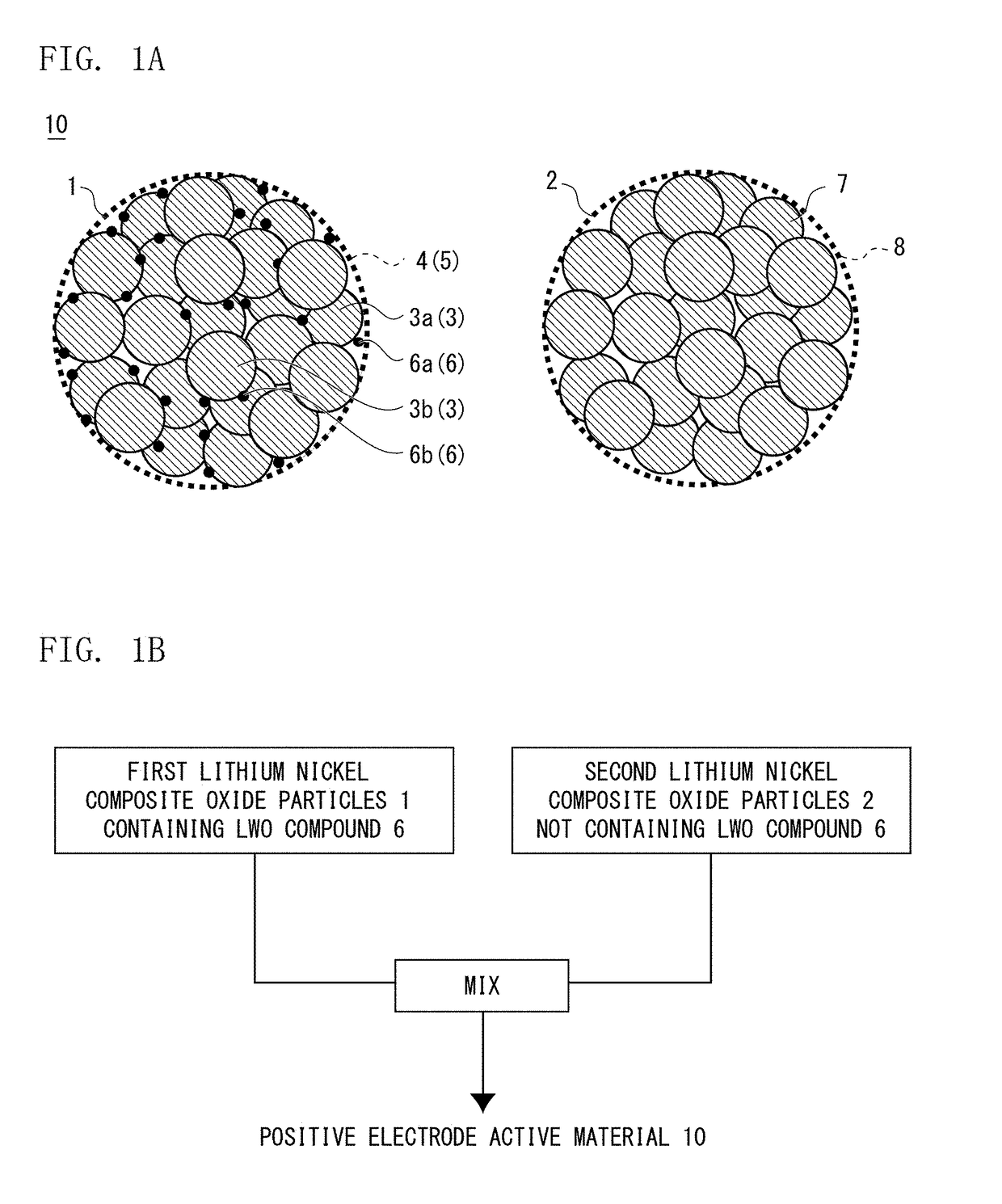

Positive electrode active material for nonaqueous electrolyte secondary battery, method for producing the same, and nonaqueous electrolyte secondary battery

ActiveUS20180315997A1Large capacityReduce the amount requiredElectrode manufacturing processesElectrode carriers/collectorsLithium tungstateComposite oxide

In one aspect, a method for producing a positive electrode active material for a nonaqueous electrolyte secondary battery, includes mixing first lithium nickel composite oxide particles containing lithium tungstate and second lithium nickel composite oxide particles not containing lithium tungstate. The first lithium nickel composite oxide particles have a composition represented by Liz1Ni1-x1-y1Cox1M1y1O2, and include a core material containing secondary particles each corresponding to an aggregation of a plurality of primary particles, and the lithium tungstate existing on at least a part of a surface of the primary particles on a surface of and inside the first lithium nickel composite oxide particles. The second lithium nickel composite oxide particles have a composition represented by Liz2Ni1-x2-y2Cox2M2y2O2, and include secondary particles each corresponding to an aggregation of a plurality of primary particles.

Owner:SUMITOMO METAL MINING CO LTD

Positive electrode active material for non-aqueous electrolyte secondary battery, and non-aqueous electrolyte secondary battery

PendingCN112219298AHigh short-circuit resistanceImprove output characteristicsPositive electrodesLi-accumulatorsPhysical chemistryLithium tungstate

Owner:SUMITOMO METAL MINING CO LTD

Chromium-doped lithium magnesium tungstate crystal and its preparation and application

ActiveCN103668459BModerate mechanical properties and thermal propertiesWide tunable laser bandPolycrystalline material growthFrom frozen solutionsChromium dopingConcentration ratio

The invention discloses a chromium-doped lithium tungstate magnesium crystal as well as a preparation method and an application thereof. The molecular formula of the crystal is Cr3+:Li2Mg2(WO4)3, the crystal belongs to an orthorhombic crystal system and a Pnma space group, and the cell parameter is as follows: Z=4. The crystal grows in a top seeded solvent growth method, the mixture of 75% Li2WO4 and 25% WO3 is used as a fluxing agent, the concentration ratio of the fluxing agent in the growth raw material is 55 to 80 percent, and the growth parameters are as follows: the cooling rate is 0.5 to 5 DEG C / day, the growth temperature is 800 to 880 DEG C, and the rotation speed is 5 to 30 turns / min. The crystal has the characteristics such as moderate mechanical performance, large transmission cross section and the like, the tunable range is 750nm to 1050nm, and the crystal is expected to become a novel tunable laser crystal and can be actually used.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

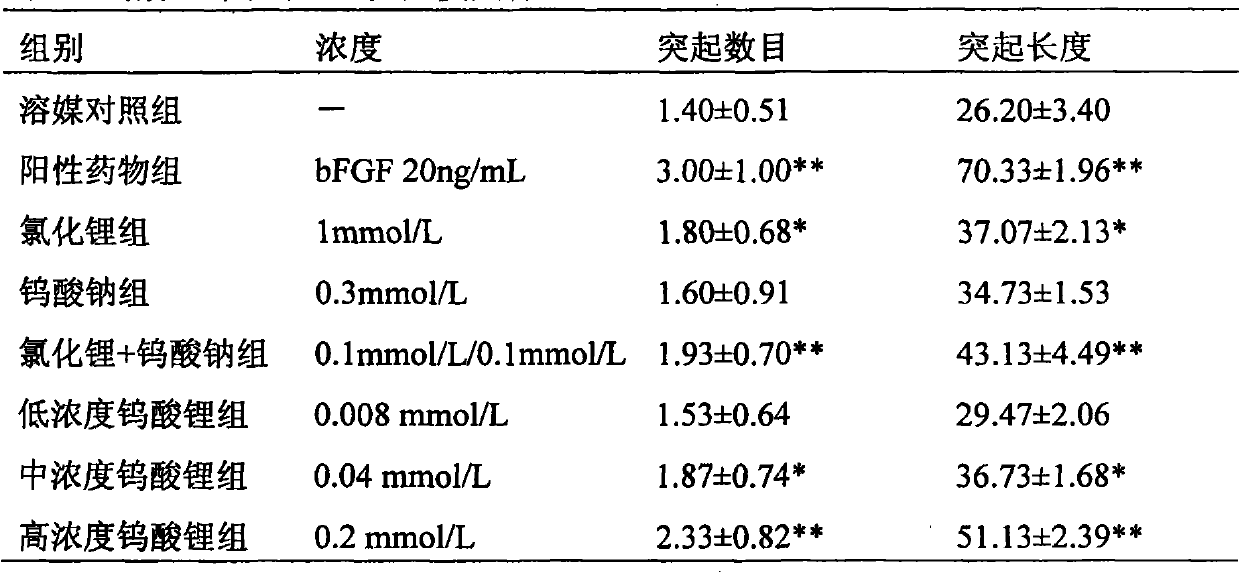

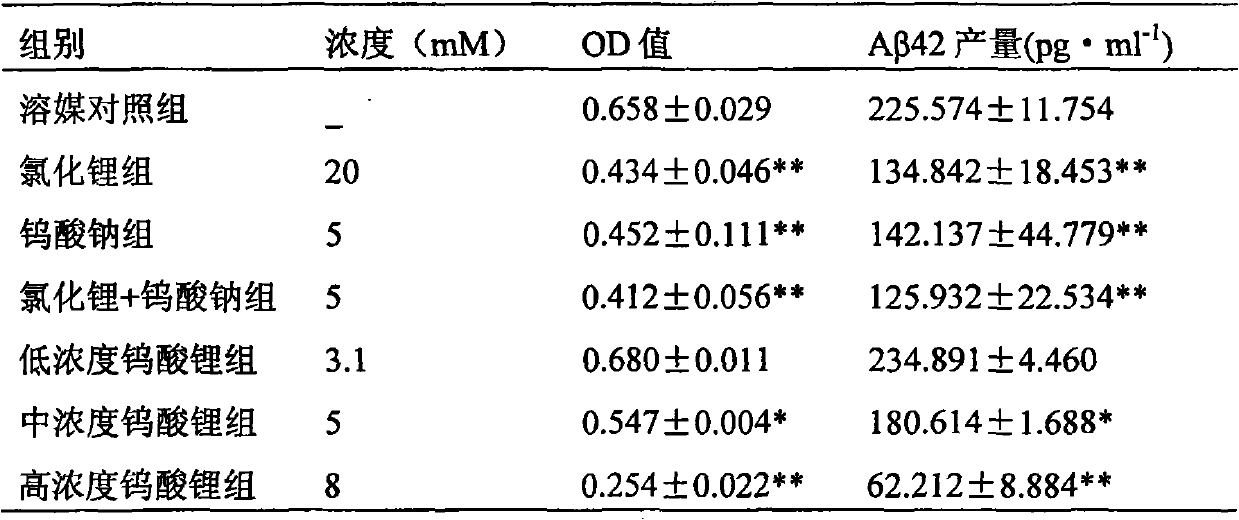

Application of Li2WO4 in preparing medicine

InactiveCN100515428CInhibitory activityInhibit hyperphosphorylationNervous disorderInorganic active ingredientsCortical neuronsNerve cells

The invention discloses the application of lithium tungstate in pharmaceuticals, especially in the preparation of drugs for treating neurodegenerative diseases, neuropathy caused by diabetes, and cerebral ischemia including brain dysfunction. Since lithium tungstate anion and cation are both active, the two play a synergistic effect and can better inhibit the activity of GSK-3. By inhibiting the activity of GSK-3α, reducing the production of Aβ to reduce SP; by inhibiting the activity of GSK-3β, inhibiting the hyperphosphorylation of tau protein to reduce NFT. By increasing the content of BDNF in cortical neurons, it can promote the survival and repair of nerve cells in the state of ischemia and hypoxia, and improve learning and memory dysfunction.

Owner:JINAN UNIVERSITY

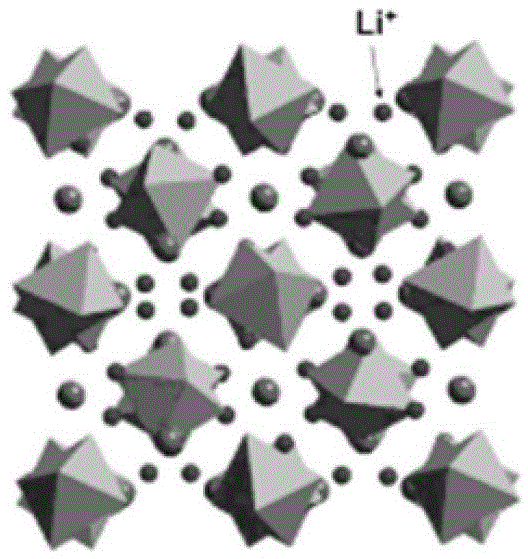

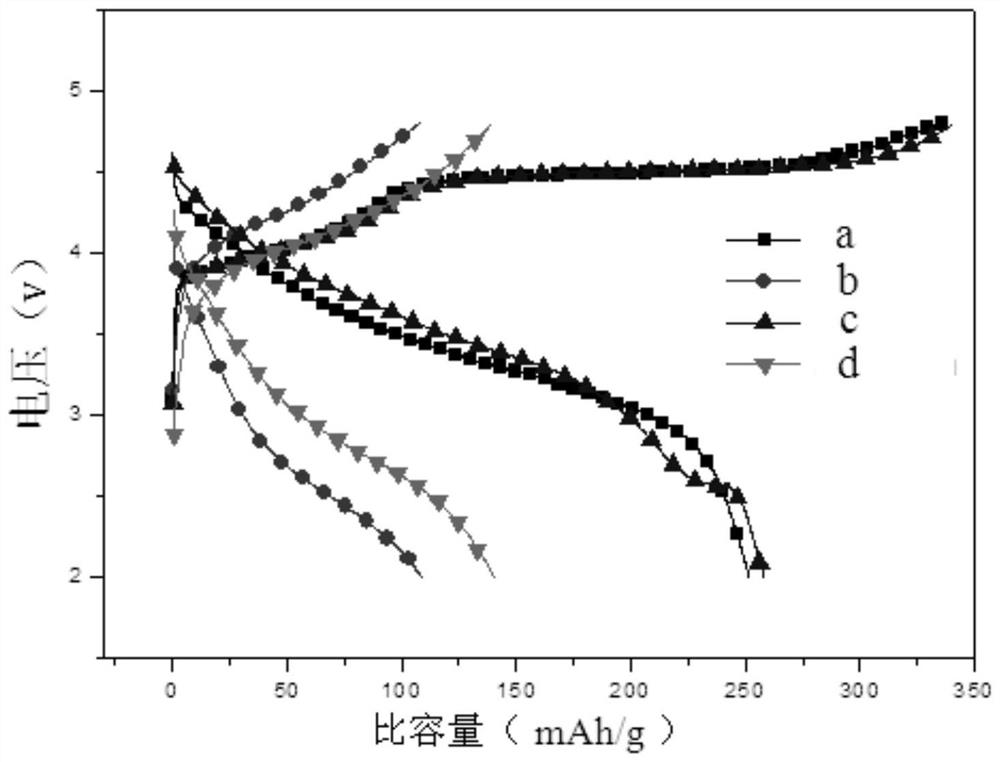

Lithium tungstate modified lithium-rich manganese-based layered lithium-ion battery cathode material and preparation method thereof

ActiveCN107394172BImproved magnification performanceImprove electrochemical stabilityCell electrodesSecondary cellsElectrical batteryManganese

The invention specifically discloses a lithium tungstate modified lithium-rich manganese-based layered lithium-ion battery positive electrode material, the general chemical formula of which is (xLi 2 MnO 3 ·(1-x)LiMO 2 ) / yLi 2 WO 4 ; wherein, 0.1≤x≤0.9, 0.001≤y≤0.4, M is Mn, Co and Ni; it includes the following raw material components: manganese raw material, nickel raw material, cobalt raw material, lithium salt, tungsten salt, complexing agent, reducing agent and liquid solvent; and discloses a preparation method of lithium tungstate modified lithium-rich manganese-based layered lithium-ion battery cathode material. The invention utilizes the good conductivity of lithium tungstate to greatly improve the rate performance of the positive electrode material of the lithium ion battery, improve its electrochemical stability, and significantly improve the cycle stability of the positive electrode material of the lithium ion battery, making the present invention The discharge platform and capacity decay of the invented lithium tungstate-coated lithium-rich manganese-based layered lithium-ion battery cathode material are slowed down.

Owner:CHANGAN UNIV

Molybdenum removal technology for calcium tungstate production process

InactiveCN105271416AGood effect of removing impuritiesReduce manufacturing costTungsten compoundsSimple Organic CompoundsLithium tungstate

The invention discloses a molybdenum removal technology for calcium tungstate production process. The molybdenum removal technology comprises the following steps of S1, vulcanizing a calcium tungstate solution containing impurity element of molybdenum, so as to convert the impurity element of molybdenum into the corresponding thioic acid radical; S2, adding a precipitant into the vulcanized calcium tungstate solution, stirring for 0.5 to 2.5h at the temperature of 20 to 70 DEG C, and forming an organic compound precipitation together with the thioic acid salt containing the impurity element of molybdenum; S3, finally, adding an adsorbate, filtering and separating, wherein the filtering liquid is the impurity-removed calcium tungstate solution, and the filtering residues are the adsorbate and the organic precipitation; S4, increasing the acidity of the calcium tungstate solution to 140 to 160g / L, and adding tungsten powder into the solution; S5, repeating the steps S1 to S4 once. The molybdenum content of the existing calcium tungstate is 2% to 3.5%. The molybdenum removal technology has the advantages that the existing smelting impurity removal procedure is improved, so that the molybdenum content of the calcium tungstate is less than 0.5%; the impurity removal effect is good, the equipment is simple, the production cost is low, the process flow is short, and the operation is easy.

Owner:DAYU DONGHONG TIN PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com