Cobalt-free nickel-manganese positive electrode material and preparation method and application thereof

A positive electrode material, nickel-manganese technology, applied in the field of cobalt-free nickel-manganese positive electrode material and its preparation, can solve the problems of less layered nickel-manganese positive electrode material, price fluctuation and high cost, and achieves inhibition of cation dissolution, reduction of preparation cost, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

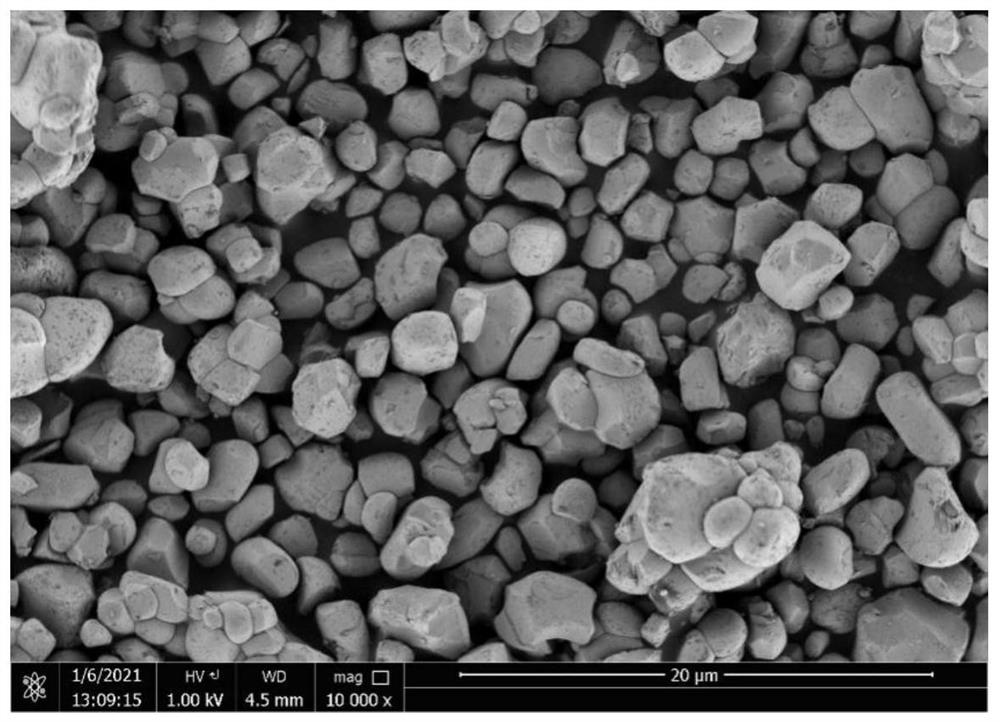

[0040] The cobalt-free layered nickel-manganese positive electrode material (Li 1.06 Ni 0.6 mn 0.3974 Me 0.0026 o 2 @(Al 2 o 3 ) 0.001 ·(TiO 2 ) 0.0015 ) preparation method, the concrete steps are as follows:

[0041] (1) NiSO 4 with MnSO 4 According to the molar ratio of Ni: Mn = 6:4, it was configured as a solution A of 2.5mol / L, placed in a reaction stirred tank and stirred at a stirring speed of 25rpm / min, and then sodium hydroxide and ammonia water were mixed at a pressure of 5m 3 / h flow rate into the prepared A solution, the reaction temperature is 55 ° C ~ 60 ° C, the reaction time is 2 h, after the reaction is completed, use deionized water to wash, place in a centrifuge for filtration, and the centrifugal speed is 600 rpm / min. The centrifugation time is 90min, and then dried at 150°C for 4h, and finally the cobalt-free nickel manganese hydroxide precursor Ni 0.6 mn 0.4 (OH) 2 ;

[0042] (2) The above-mentioned cobalt-free nickel-manganese hydroxide pre...

Embodiment 2

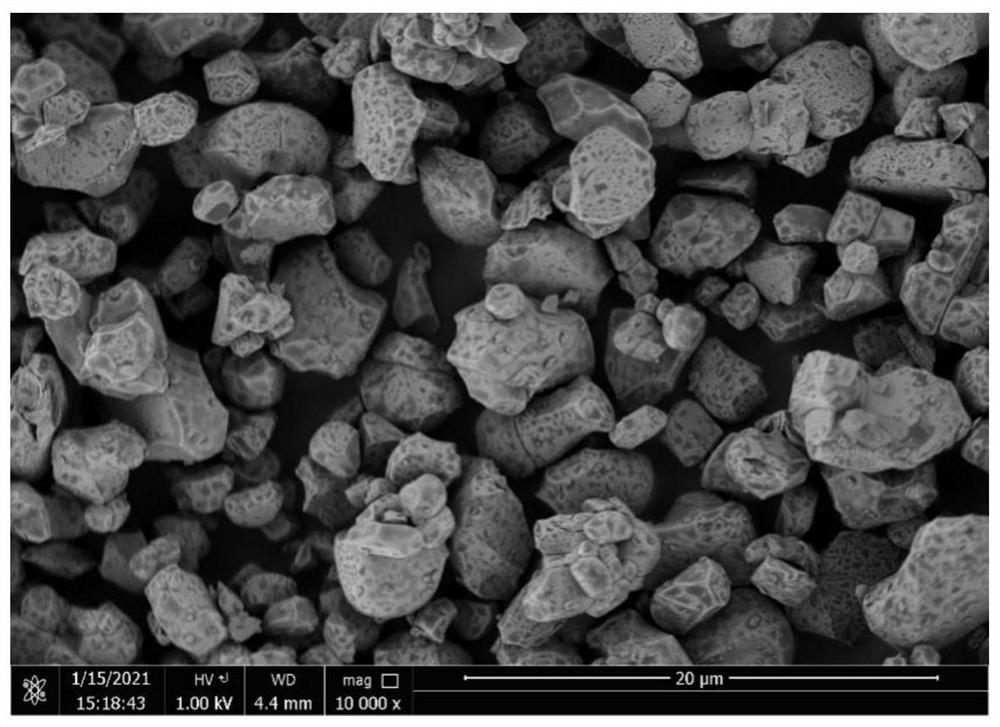

[0052] The cobalt-free layered nickel-manganese positive electrode material (Li 1.04 Ni 0.6 mn 0.3969 Me 0.0031 o 2 @(Al 2 o 3 ·TiO 2 ) 0.001 ·(Li 2 WO 4 ) 0.0015 ) preparation method, the concrete steps are as follows:

[0053] (1) NiSO 4 with MnSO 4 According to the molar ratio of Ni:Mn=6:4, it is configured into 2.3mol / L solution A, placed in a reaction stirred tank and stirred, the stirring speed is preferably 30rpm / min, and then sodium hydroxide and ammonia water are mixed at a pressure of 6.3m 3 / h flow rate into the prepared A solution, the reaction temperature is 50 ° C ~ 55 ° C, the reaction time is 2.5 h, after the reaction is completed, it is washed with deionized water, placed in a centrifuge for filtration, and the centrifugal speed is 600 rpm / min. The centrifugation time is 90min, and then dried at 150°C for 4h, and finally the cobalt-free nickel manganese hydroxide precursor Ni 0.6 mn 0.4 (OH) 2 ;

[0054] (2) The above-mentioned cobalt-free nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com