Preparation method of electrolyte of alkaline zinc battery

A technology of electrolyte and zinc batteries, which is applied in the direction of alkaline storage batteries, etc., and can solve the problems of battery electrical performance and insulation resistance decline, battery failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] base solution

[0027] The parts by mass of each component of the base solution are:

[0028]

[0029] The balance is deionized water

[0030] After the above components are dissolved and stirred sufficiently, a basic solution with a total alkali concentration of 5 mol / L is formed. Electrolyte additives are added to the base solution to form the final alkaline zinc battery electrolyte

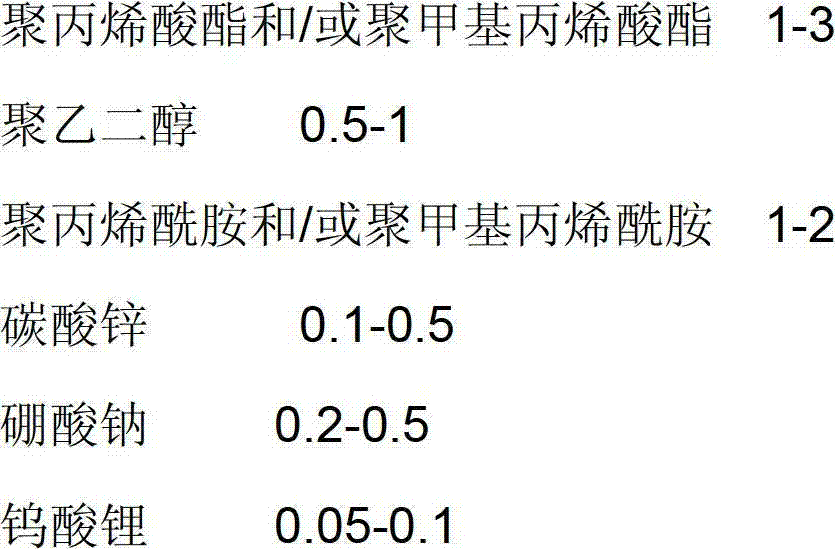

[0031] Wherein the component of additive is by mass ratio:

[0032]

[0033] The additives of the above components accounting for 1% of the mass of the basic solution are added to the basic solution, heated and fully stirred to obtain an alkaline battery electrolyte.

Embodiment 2

[0035] base solution

[0036] The parts by mass of each component of the base solution are:

[0037]

[0038]

[0039] The balance is deionized water

[0040] After the above components are dissolved and fully stirred, a basic solution with a total alkali concentration of 8mol / L is formed; electrolyte additives are added to the basic solution to form the final alkaline zinc battery electrolyte

[0041] Wherein the component of additive is by mass parts:

[0042]

[0043] The additives of the above components accounting for 3% of the mass of the basic solution are added to the basic solution, heated and fully stirred to obtain an alkaline battery electrolyte.

[0044] The electrolytic solution that embodiment 1 and 2 prepares and existing electrolytic solution (comparative example) are used for the performance detection of alkaline zinc-nickel battery as follows:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com