Lithium tungstate-coated Ni-Co lithium aluminate composite material and preparation method and application thereof

A nickel-cobalt lithium aluminate and composite material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as obstacles, reduced material capacity and cycle performance, and unfavorable lithium ion transmission, achieving continuous and simple process , uniform composition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

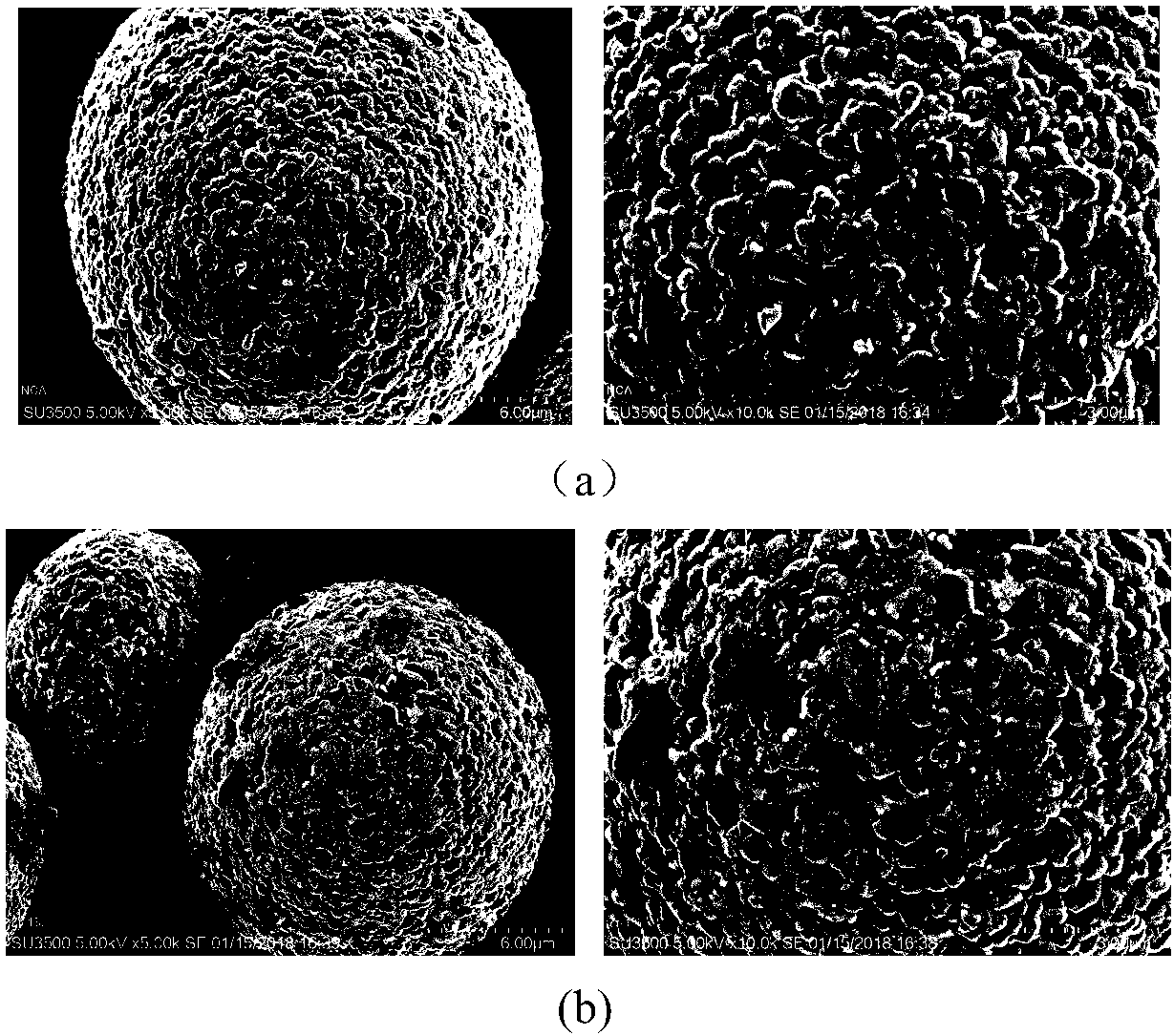

[0044] Add 100 g of nickel-cobalt-aluminum precursor to 1 L of lithium hydroxide solution with a concentration of 1 mol / L, stir and mix at a low speed to obtain liquid A, and then add tungsten trioxide with 1% of the mass of the nickel-cobalt-aluminum precursor to obtain slurry B; Evaporate and crystallize the slurry B at 90°C until the slurry is dry, then mix the obtained crystallized product with lithium, and mix it with lithium hydroxide. In the lithium mixed material, the molar ratio of Li:(Ni+Co+Al) is 1.05, Then sinter the lithium-mixed material in oxygen at 750°C for 15 hours to obtain LiNi 0.8 co 0.15 al 0.05 o 2 @Li 2 WO 4 composite material.

[0045] Li in this example 2 WO 4 clad in LiNi 0.8 co 0.15 al 0.05 o 2 @Li 2 WO 4 The mass fraction of composite material is 1%.

[0046] Adopt the LiNi that present embodiment obtains 0.8 co 0.15 al 0.05 o 2 @Li 2 WO 4 The cycle performance at 0.2C (1C=180mAh / g) current density is as follows figure 1 , the ...

Embodiment 2

[0050] Add 200 g of nickel-cobalt-aluminum precursor to 1 L of lithium hydroxide solution with a concentration of 1 mol / L, stir and mix at a low speed to obtain liquid A, and then add tungsten trioxide with 2% of the mass of the nickel-cobalt-aluminum precursor to obtain slurry B; Evaporate and crystallize the slurry B at 100°C until the slurry is dry, then mix the obtained crystallized product with lithium, and mix it with lithium hydroxide. In the lithium mixed material, the molar ratio of Li:(Ni+Co+Al) is 1.01, and then Sinter the lithium-mixed material in oxygen at 700°C for 15 hours to obtain LiNi 0.8 co 0.15 al 0.05 o 2 @Li 2 WO 4 composite material.

[0051] Li in this example 2 WO 4 clad in LiNi 0.8 co 0.15 al 0.05 o 2 @Li 2 WO 4 The mass fraction of composite material is 2%.

[0052] Adopt the LiNi that present embodiment obtains 0.8 co 0.15 al 0.05 o 2 @Li 2 WO 4 The cycle performance at 0.2C (1C=180mAh / g) current density is as follows figure 1 ,...

Embodiment 3

[0056] Add 100 g of nickel-cobalt-aluminum precursor to 1 L of lithium carbonate solution with a concentration of 0.2 mol / L, stir and mix at a low speed to obtain liquid A, and then add tungsten trioxide with 1% of the mass of the nickel-cobalt-aluminum precursor to obtain slurry B; Evaporate and crystallize the slurry B at 80°C until the slurry is dry, then mix the obtained crystallized product with lithium, and mix it with lithium hydroxide. In the lithium mixed material, the molar ratio of Li:(Ni+Co+Al) is 1.03, and then Sinter the lithium-mixed material in oxygen at 800°C for 15 hours to obtain LiNi 0.8 co 0.15 al 0.05 o 2 @Li 2 WO 4 composite material.

[0057] Li in this example 2 WO 4 clad in LiNi 0.8 co 0.15 al 0.05 o 2 @Li 2 WO 4 The mass fraction of composite material is 1%.

[0058] Adopt the LiNi that present embodiment obtains 0.8 co 0.15 al 0.05 o 2 The cycle performance at 0.2C (1C=180mAh / g) current density is as follows figure 1 , the rate pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial discharge specific capacity | aaaaa | aaaaa |

| Initial discharge specific capacity | aaaaa | aaaaa |

| Initial discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com