Lithium tungstate modified lithium-rich manganese-based layered lithium-ion battery cathode material and preparation method thereof

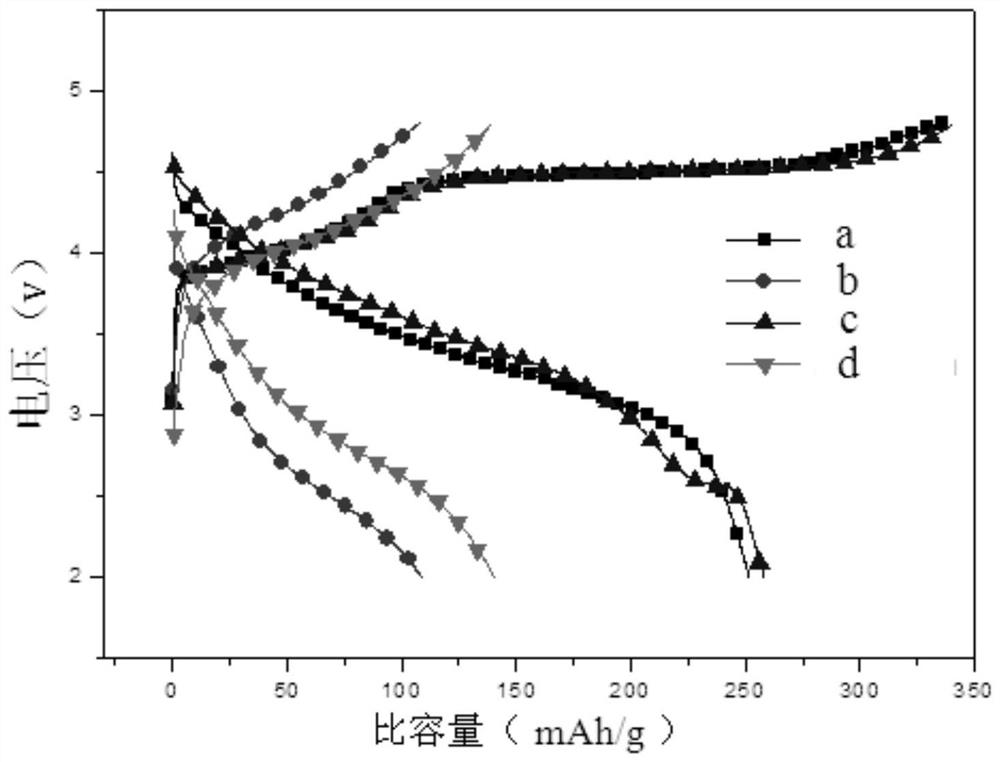

A lithium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited commercialization, poor rate performance and cycle stability, low initial cycle efficiency, etc., and achieve discharge platform and capacity decay Effects of slowing down, rate performance improvement, and electrochemical stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

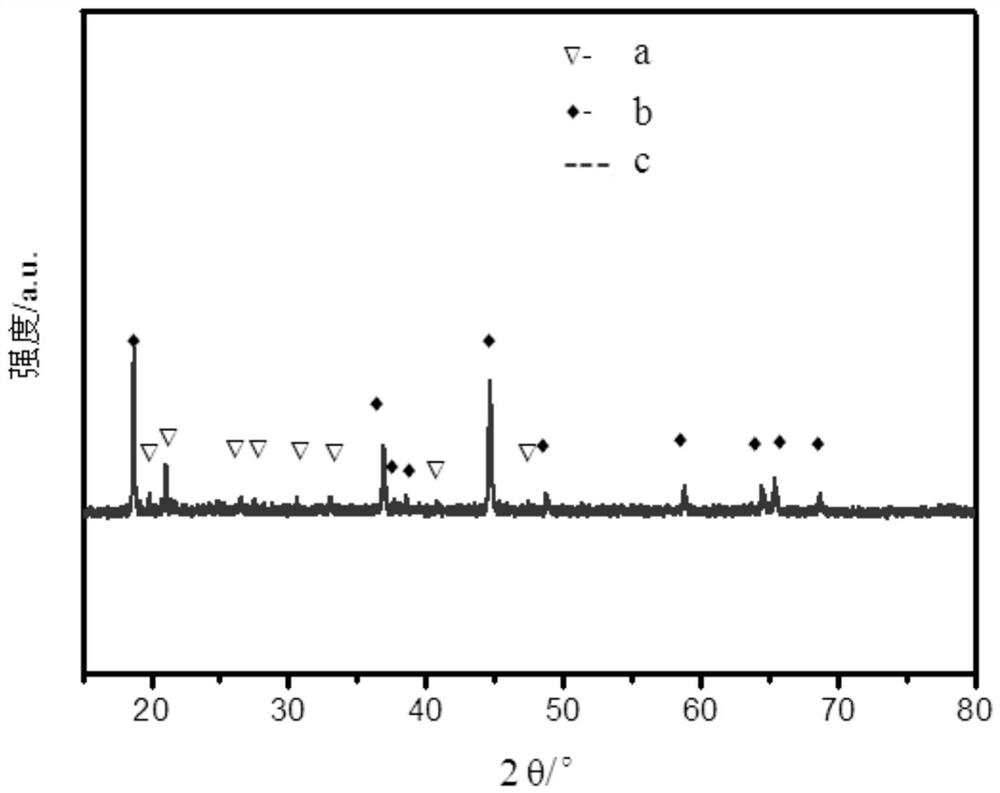

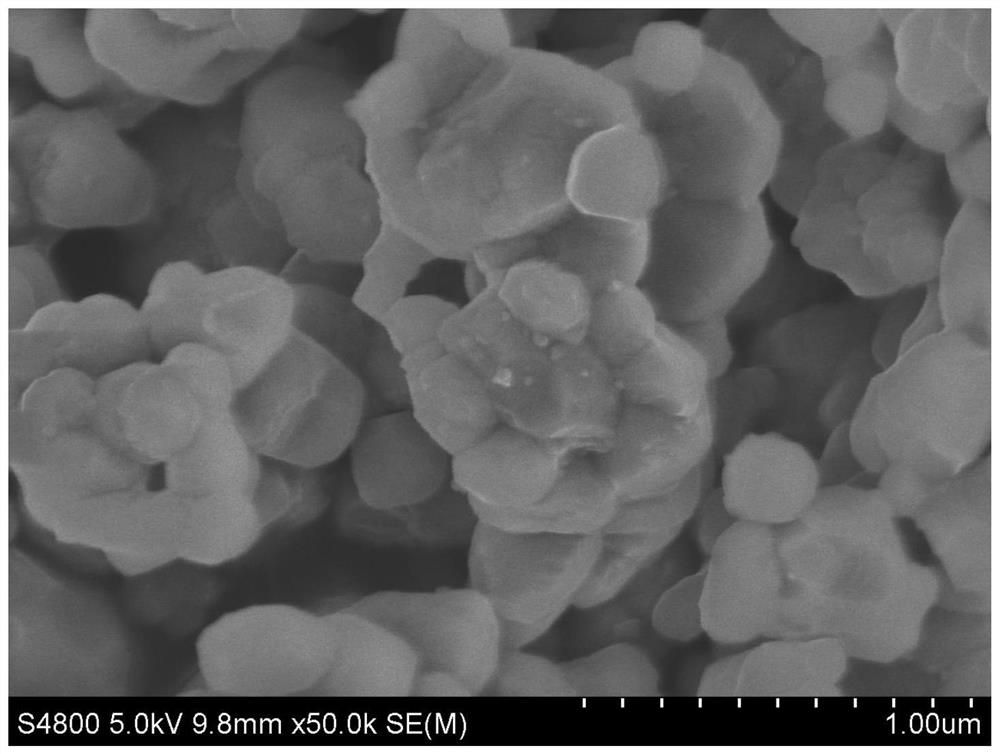

[0085] A lithium tungstate modified lithium-rich manganese-based layered lithium-ion battery positive electrode material, the preparation method comprising the following steps:

[0086] (1) Dissolve 0.067 mol of manganese formate, 0.0167 mol of cobalt formate, 0.0167 mol of nickel formate, and 0.15 mol of lithium formate in 30 mL of ethanol in sequence, and then add 0.1 mol of acetylacetone after fully dissolving, and stir for 3 hours in a water bath at 80°C. The precursor sol was obtained, and kept at 100°C for 24 hours in the air; then calcined in a muffle furnace, specifically at 450°C for 5 hours, and then at 900°C for 12 hours, to obtain a powdery lithium-rich manganese-based layered lithium-ion battery cathode material , its chemical formula is: 0.5Li 2 MnO 3 0.5LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 .

[0087] (2) Weigh 0.00046mol of citric acid and dissolve it in 20mL of deionized water, add 0.0000255mol of ammonium metatungstate, stir for 2 hours in a water bath at 70°C, th...

Embodiment 2

[0090] A lithium tungstate modified lithium-rich manganese-based layered lithium-ion battery positive electrode material, the preparation method comprising the following steps:

[0091] (1) Dissolve 0.333moL of manganese acetate, 0.083moL of cobalt nitrate, 0.083moL of nickel nitrate, and 0.75mol of lithium nitrate in 20mL of deionized water in sequence, then add 0.5mol of citric acid, adjust the pH value to 7 with ammonia water, and place in a water bath at 50°C Stir for 5 hours under the same conditions to form a precursor sol, keep warm at 100°C for 24 hours in the air; then calcinate in a muffle furnace, specifically: first calcinate at 450°C for 5 hours, then calcinate at 900°C for 12 hours; obtain powder Lithium-rich manganese-based layered lithium-ion battery cathode material, its chemical formula is: 0.5Li 2 MnO 3 0.5LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 .

[0092] (2) Weigh 0.0000573mol of citric acid and dissolve it in 20mL of deionized water, add 0.00000318mol of ammoniu...

Embodiment 3

[0095] A lithium tungstate modified lithium-rich manganese-based layered lithium-ion battery positive electrode material, the preparation method comprising the following steps:

[0096] (1) Weigh 1.2moL of lithium nitrate, 0.533moL of manganese sulfate, 0.133moL of nickel sulfate, and 0.133moL of cobalt sulfate and dissolve them in 30ml of ethylene glycol ether, and then add 0.1moL of ethylenediaminetetraacetic acid for complexation after fully dissolving. Stir in a water bath at 70°C for 3 hours to obtain a precursor sol, which is kept at 100°C in air for 24 hours; then calcined in a muffle furnace, specifically at 450°C for 5 hours, and then calcined at 900°C for 12 hours to obtain lithium-rich manganese Grass-layer lithium-ion battery cathode material, its chemical formula is: 0.5Li 2 MnO 3 0.5LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 .

[0097] (2) Weigh 0.00138mol of citric acid and dissolve it in 20mL of deionized water, add 0.0000764mol of ammonium metatungstate, stir for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com