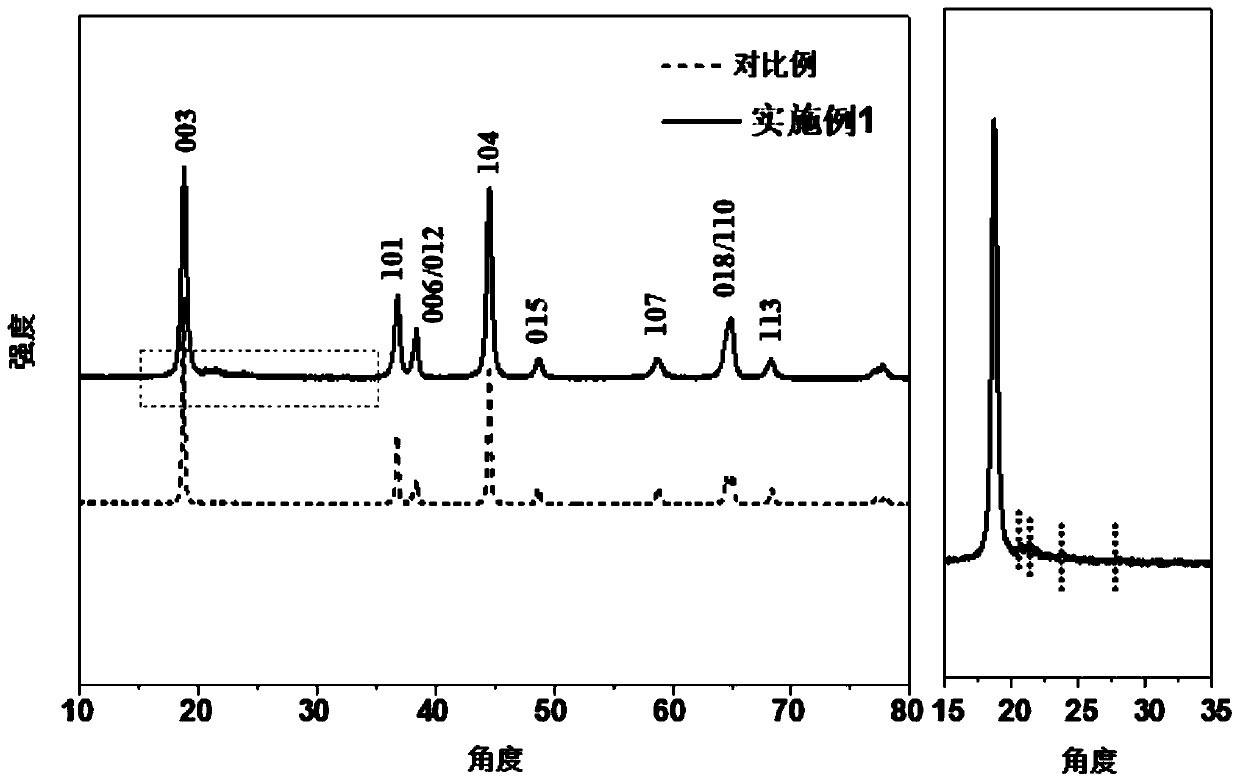

Ternary positive pole material with surface layer coated with lithium tungstate and doped with W and preparation method

A technology for coating lithium tungstate and positive electrode materials, which is applied to electrical components, battery electrodes, electrochemical generators, etc., can solve the problems of unstable surface structure, poor material cycle performance, etc., and achieves low production cost, simple method, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

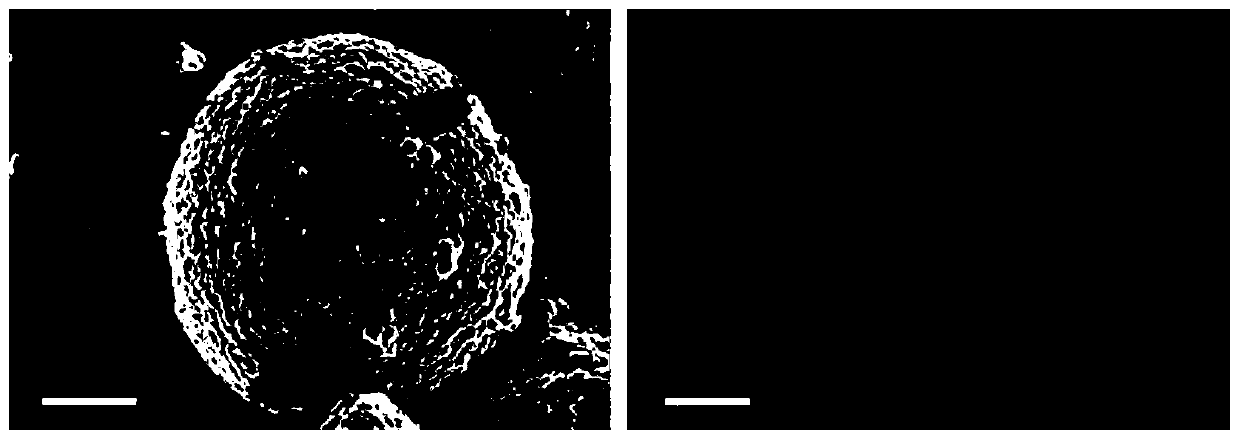

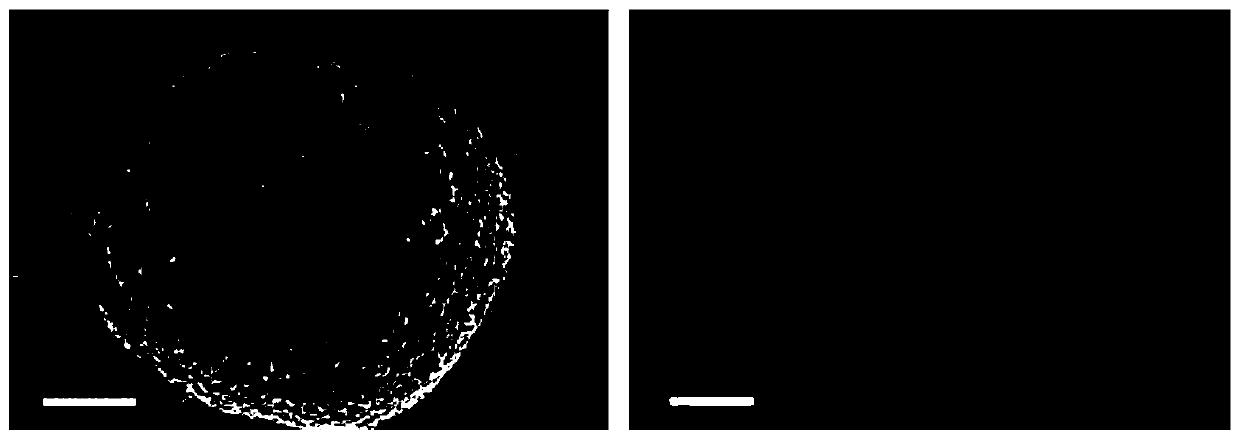

Embodiment 1

[0059] Weigh NiSO according to the molar ratio Ni:Co:Mn=8:1:1 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O, use deionized water to prepare a mixed salt solution with a total concentration of Ni, Co, and Mn ions of 2mol / L, and then use deionized water to prepare NaOH and ammonia water with the same concentration.

[0060] Add 50 mL of deionized water into the reaction kettle as the reaction base solution, and add ammonia water to adjust the pH to 11±0.2. The stirring speed was controlled at 600 r / min, and the reaction temperature was controlled at 55°C. Pump the mixed salt solution and ammonia water into the reaction kettle at a speed of 0.4ml / min, and at the same time adjust the feeding speed of the sodium hydroxide solution to stabilize the pH at 11±0.2, the feeding time is 4h, and continue to feed argon after the feeding is completed Stir with air for 4h. After the reaction is completed, the precipitate is filtered, washed and dried with deionized water to prepare the ...

Embodiment 2

[0064] Weigh NiSO according to the molar ratio Ni:Co:Mn=8:1:1 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O, use deionized water to prepare a mixed salt solution with a total concentration of Ni, Co, and Mn ions of 2mol / L, and then use deionized water to prepare NaOH and ammonia water with the same concentration.

[0065] Add 50 mL of deionized water into the reaction kettle as the reaction base solution, and add ammonia water to adjust the pH to 11±0.2. The stirring speed was controlled at 600 r / min, and the reaction temperature was controlled at 55°C. Pump the mixed salt solution and ammonia water into the reaction kettle at a speed of 0.4ml / min, and at the same time adjust the feeding speed of the sodium hydroxide solution to stabilize the pH at 11±0.2, the feeding time is 4h, and continue to feed argon after the feeding is completed Stir with air for 4h. After the reaction is completed, the precipitate is filtered, washed and dried with deionized water to prepare the ...

Embodiment 3

[0069] Weigh NiSO according to the molar ratio Ni:Co:Mn=8:1:1 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O, use deionized water to make the total concentration of Ni, Co, Mn ions is 2mol L -1 The mixed salt solution, and then prepare the same concentration of NaOH and ammonia with deionized water.

[0070] Add 50 mL of deionized water into the reaction kettle as the reaction base solution, and add ammonia water to adjust the pH to 11±0.2. The stirring speed was controlled at 600 r / min, and the reaction temperature was controlled at 55°C. Pump the mixed salt solution and ammonia water into the reaction kettle at a speed of 0.4ml / min, and at the same time adjust the feeding speed of the sodium hydroxide solution to stabilize the pH at 11±0.2, the feeding time is 4h, and continue to feed argon after the feeding is completed Stir with air for 4h. After the reaction was completed, the precipitate was filtered, washed and dried with deionized water to obtain the precursor of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com