Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243results about How to "Shorten the production period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abrasion-resistant steel sheet having excellent processability, and method for production thereof

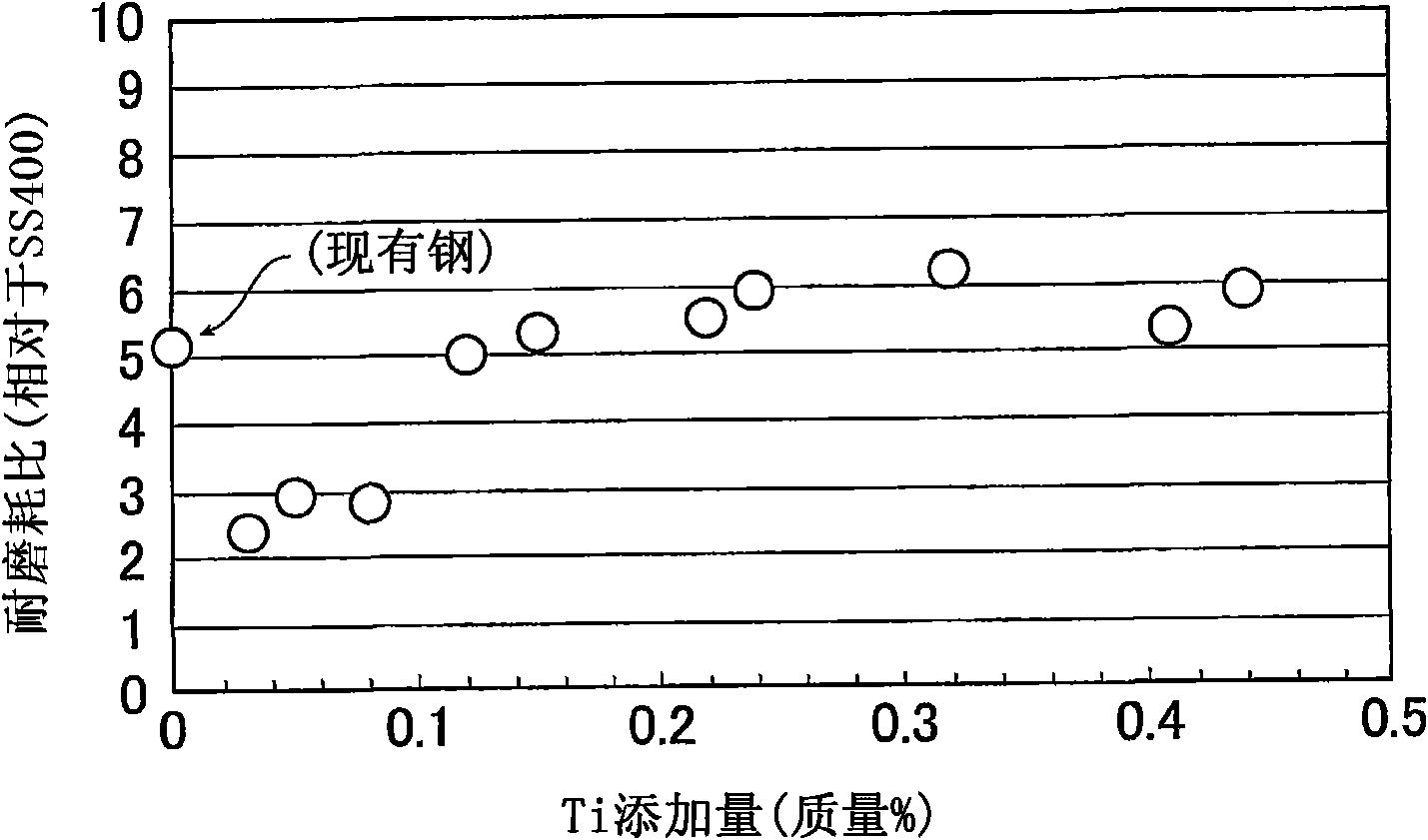

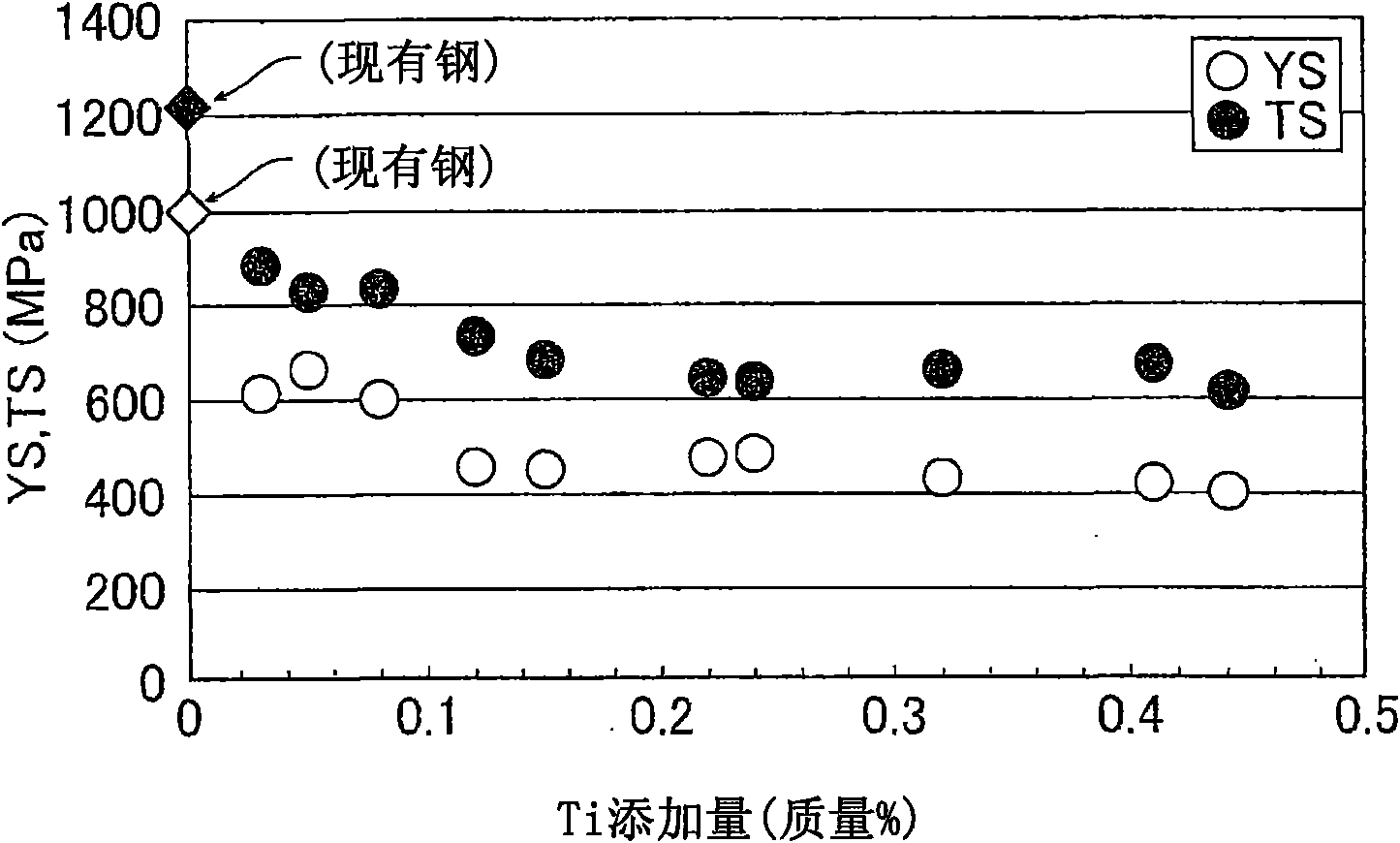

An abrasion resistant steel excellent in bending formability and suitable for members, e.g., power shovels, which come into contact with earth and sand, and a production method thereof are provided. Specifically, the steel contains, on a percent by mass basis, 0.05% to 0.35% of C, 0.05% to 1.0% of Si, 0.1% to 2.0% of Mn, 0.1% to 1.2% of Ti, 0.1% or less of Al, at least one element of 0.1% to 1.0%of Cu, 0.1% to 2.0% of Ni, 0.1% to 1.0% of Cr, 0.05% to 1.0% of Mo, 0.05% to 1.0% of W, and 0.0003% to 0.0030% of B, if necessary at least one element of 0.005% to 1.0% of Nb and 0.005% to 1.0% of V,and the remainder including Fe and incidental impurities, where DI* represented by the following formula is less than 60. DI * = 33.85 0.1 C * 0.5 0.7 Si + 1 3.33 Mn + 1 0.35 Cu + 1 0.36 Ni + 1 2.16 Cr + 1 3 Mo * + 1 1.5 W * + 1 where C* = C - 1 / 4 (Ti - 48 / 14N), Mo* =; Mo (1 - 0.5 (Ti - 48 / 14N)), and W* = W (1 - 0.5 (Ti - 48 / 14N)).

Owner:JFE STEEL CORP

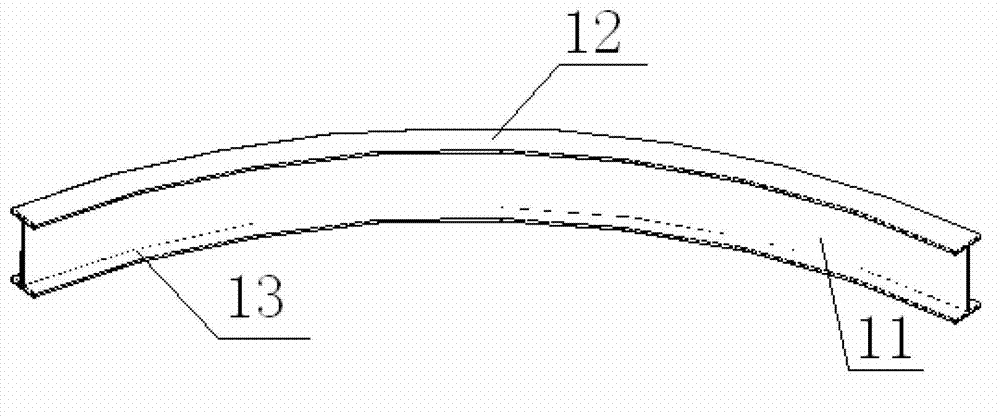

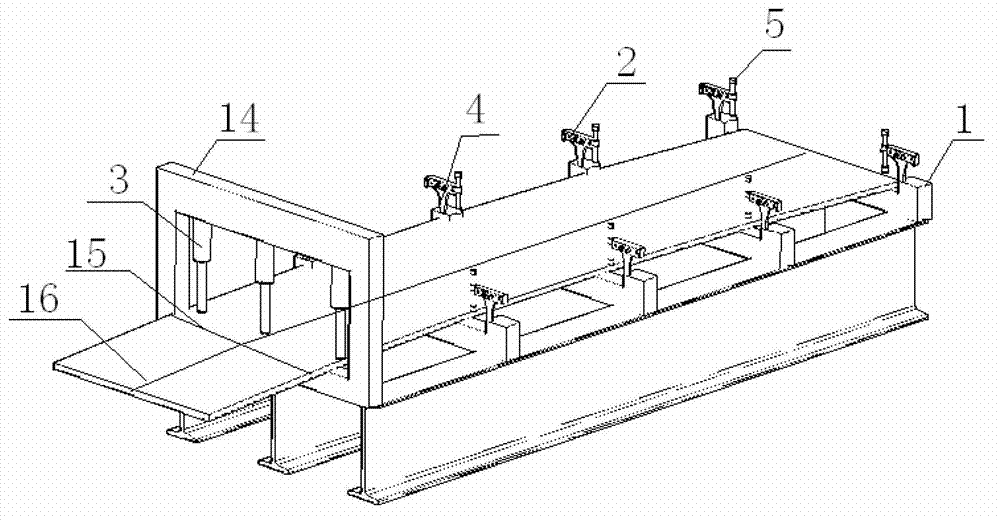

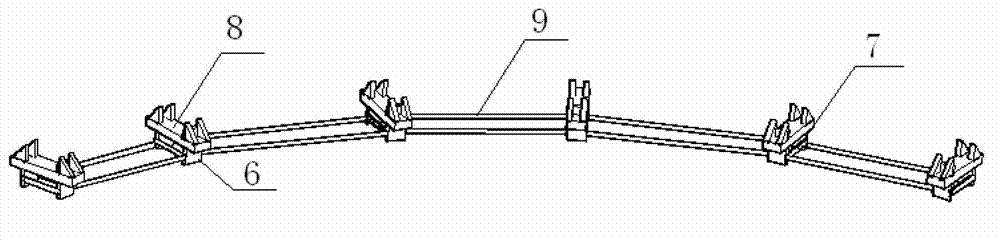

Manufacture method for double-curve H-shaped steel

The invention discloses a manufacture method for double-curve H-shaped steel. The manufacture method comprises the following steps of: 1) reviewing the material quality of a supplied horizontal plate, flattening the horizontal plate, and pre-processing; 2) three-dimensional lofting by a computer, and spreading in a plane; 3) cutting and blanking on a numeric control cutting machine; 4) opening a groove on an H-shaped steel web, and carrying out the butt welding; 5) marking a bending line and an assembly line on the web and a flange plate; 6) manufacturing a bending jig frame according to three-dimensional coordinates; 7) bending the web and the flange plate via the method of flame rectification assisting cold bending formation; 8) manufacturing a assembly jig frame; 9) combining position welding and spot-welding on an upper flange plate and a lower flange plate respectively assembled on an assembly jig frame group; 10) welding the soldering seam between the web and the lower flange plate; 11) lifting the component from the jig frame, and turning over the component to weld the soldering seam between the web and the upper flange plate; and 12) returning the jig for a repeated inspection, and carrying out the three-dimensional coordinates detection through a total-station instrument. According to the manufacture method, used equipment is simple, and efficiencies on manufacture and production are improved.

Owner:YINGDU BRIDGE STEEL STRUCTURE ENG

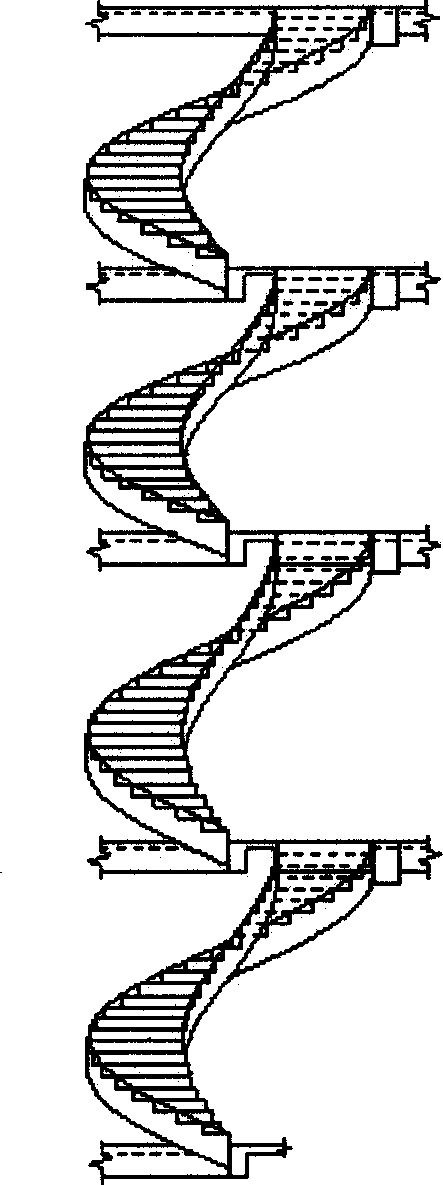

Integrally assembling staircase and method for fabricating same

The invention discloses an installation entire stair and the manufacturing method, especially an installation entire helix stair. The process is that: making every step to box structure and joining the steps into an entire stair by the method of bolt or joint. The shape of the stair could be straight stair or helix stair. The invention sharply decreases the time limit for a project and the cost. Moreover, it has advantages of simple structure, low cost and easy to realize mass production.

Owner:GUIZHOU UNIV

Method used for planning production line and apparatus thereof

ActiveCN102436236AMeet the process requirementsReduced commissioning timeTotal factory controlProgramme total factory controlProduction lineComputer module

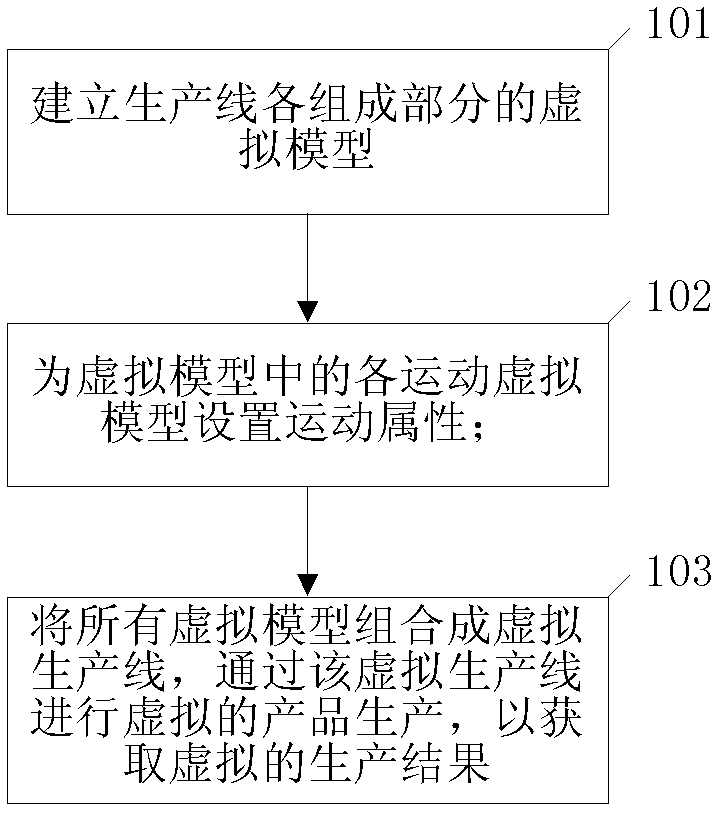

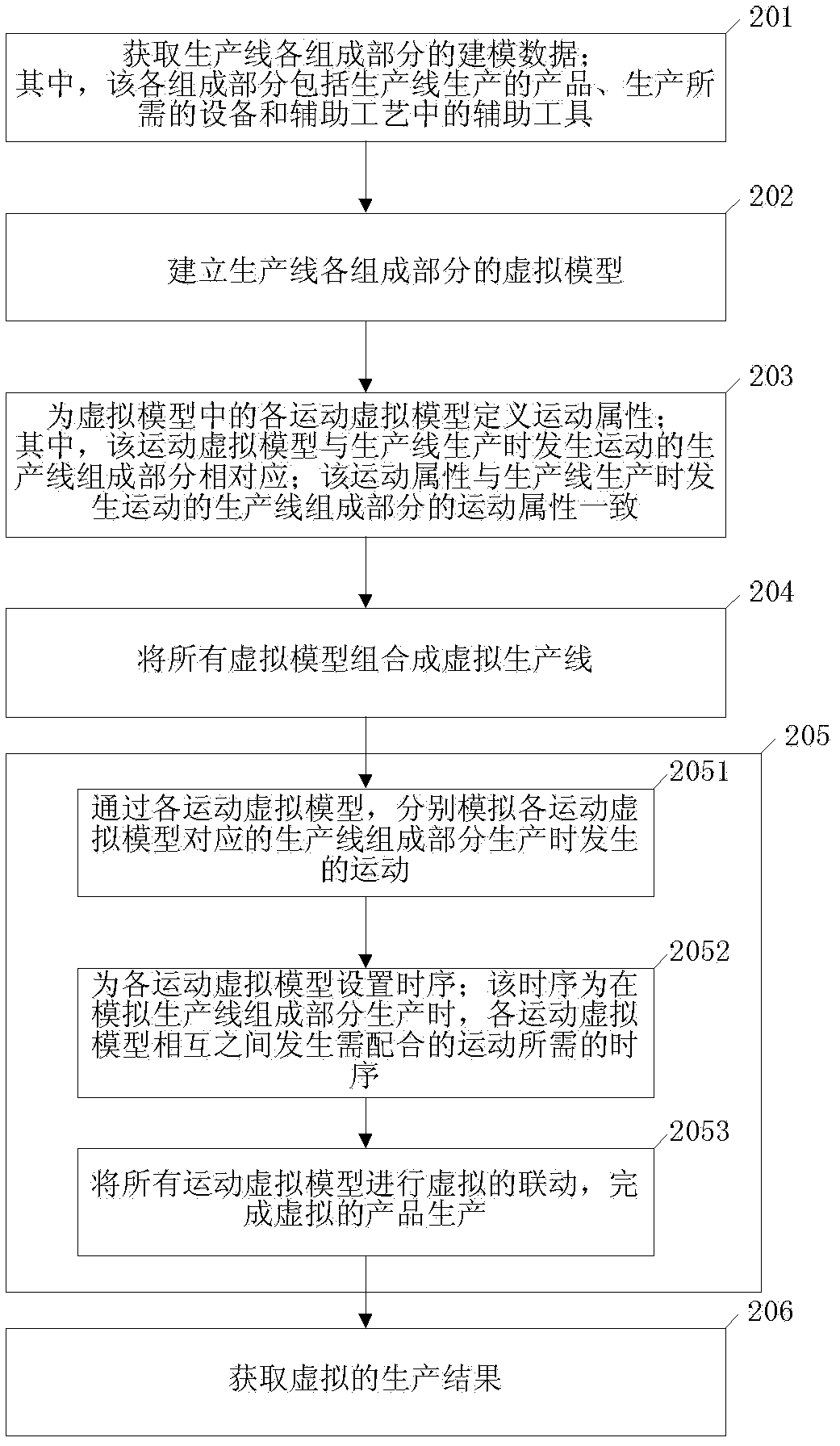

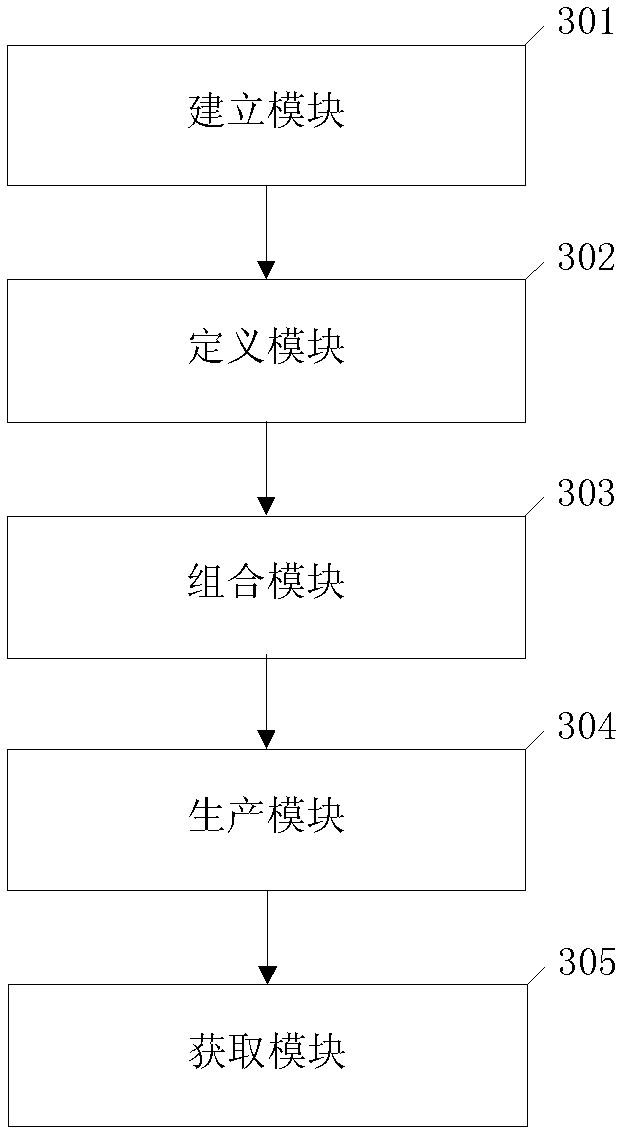

The invention, which belongs to the automation manufacturing field, discloses a method used for planning a production line and an apparatus thereof. The method comprises the following steps: establishing a virtual model of each component in the production line; defining a motion attribute for each moving virtual model in the virtual models, wherein the moving virtual model corresponds with the production line component which moves during production on the production line and the motion attribute corresponds with the motion attribute of the production line component which moves during production on the production line; combining all the virtual models into a virtual production line; carrying out virtual product production through the virtual production line so as to acquire a virtual production result. The apparatus comprises: an establishment module, a definition module, a combination module, a production module and an obtaining module. By using the method and the apparatus of the invention, a motion which is consistent with the motion in on-site production on the production line can be output in a virtual environment. A technology requirement of the on-site production on the production line can be satisfied and a scheme which is suitable for the production site and is used to plan the production line can be acquired.

Owner:CHERY AUTOMOBILE CO LTD

Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

The invention discloses a manufacturing process of a spheroidal graphite cast iron casting of a wind power yaw variable-pitch device. The process comprises the following processes of mould making, foaming and moulding, paint brushing, boxing and shaping, electric furnace smelting, tundish-covering nodulizing treatment, vacuum-assist pouring and three-time inoculation treatment, wherein the boxing and shaping process is a layered assembling process, so that the production efficiency can be improved and the process yield can be increased; cold iron is vibrated and reasonably arranged, so that the compactness of tissues in the casting can be improved and the defect of shrinkage porosity can be avoided; by virtue of the processes of electric furnace smelting and tundish-covering nodulizing treatment, the nodulizing rate of the casting can be stabilized and increased and the mechanical properties of the casting can meet the technical quality requirements of wind power castings; the spheroidal graphite cast iron casting manufactured by the process is compact and uniform in tissue, hardly has defects, has good surface quality and high size precision; the casting forming of multiple layers of castings can be realized; and the production efficiency and the process product yield are improved.

Owner:CHTC HEAVY IND

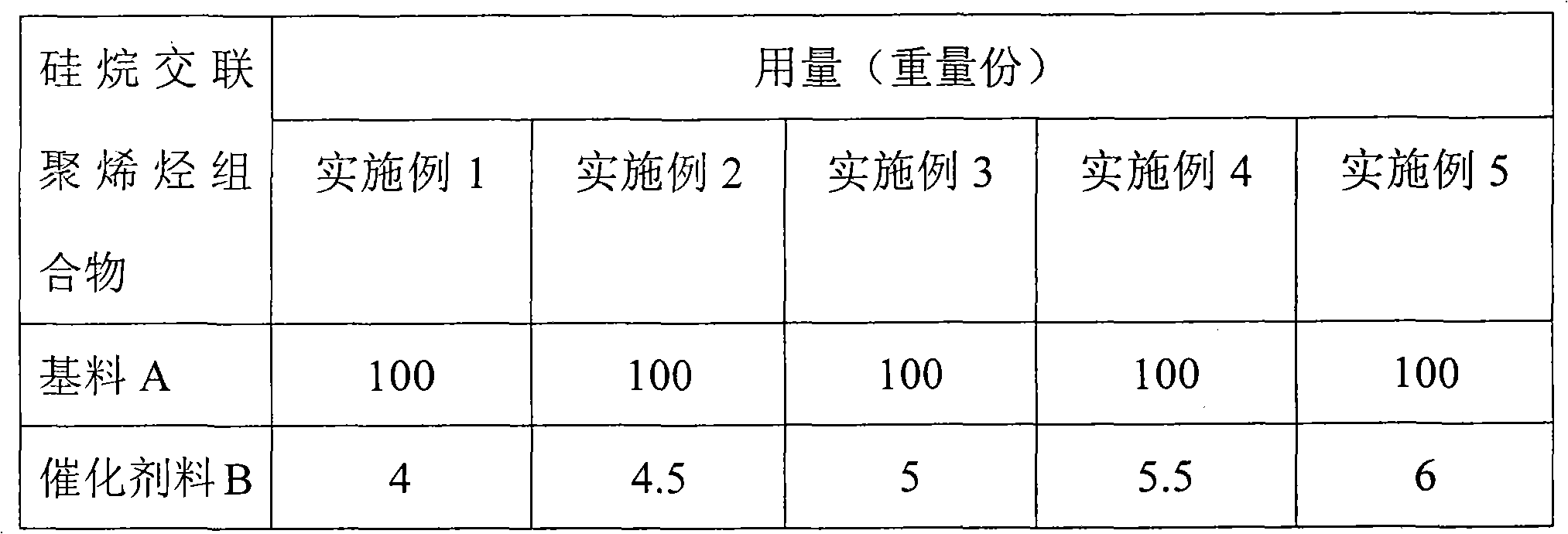

Boiling-free silicane cross-linking polyolefin composition

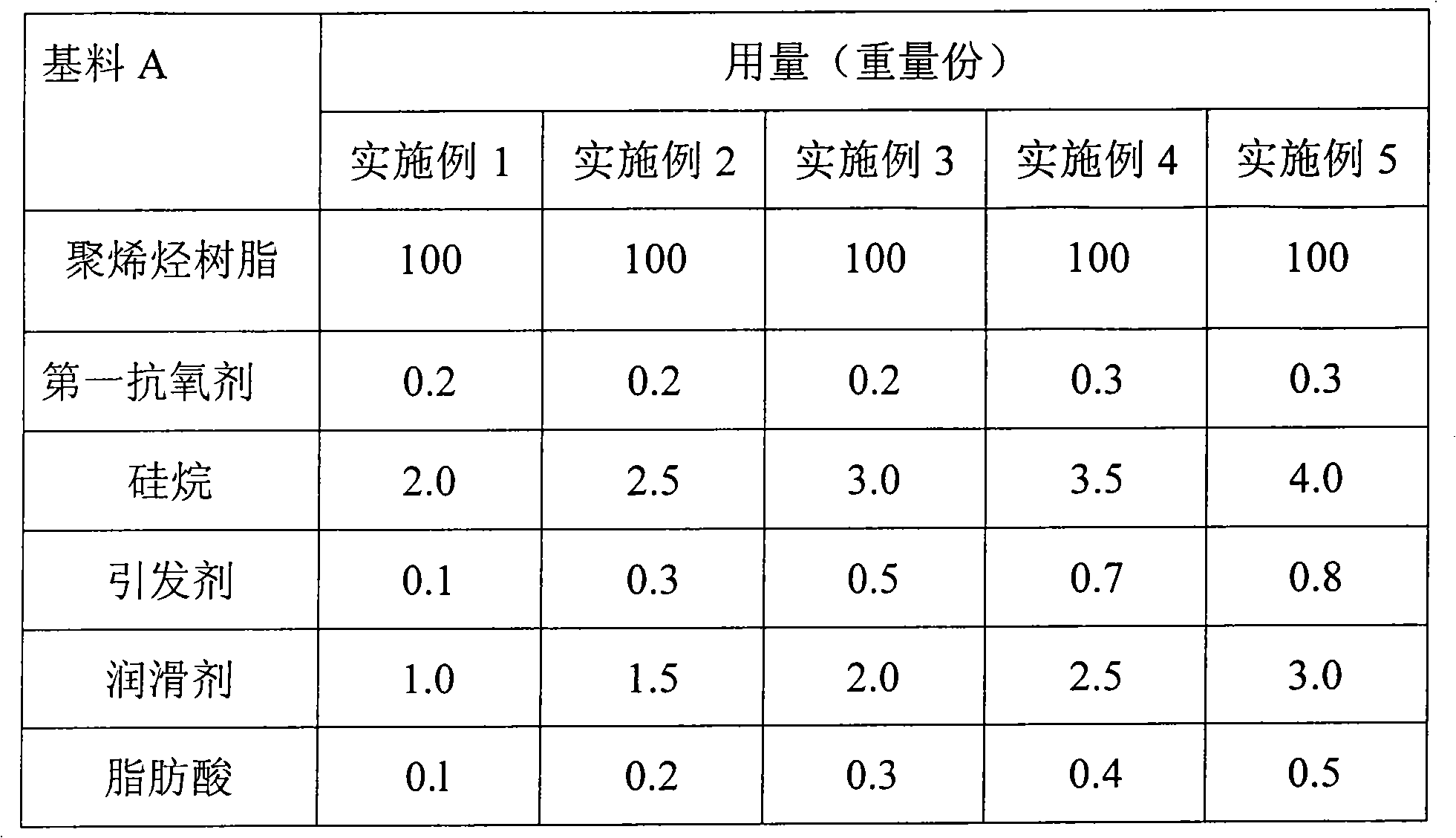

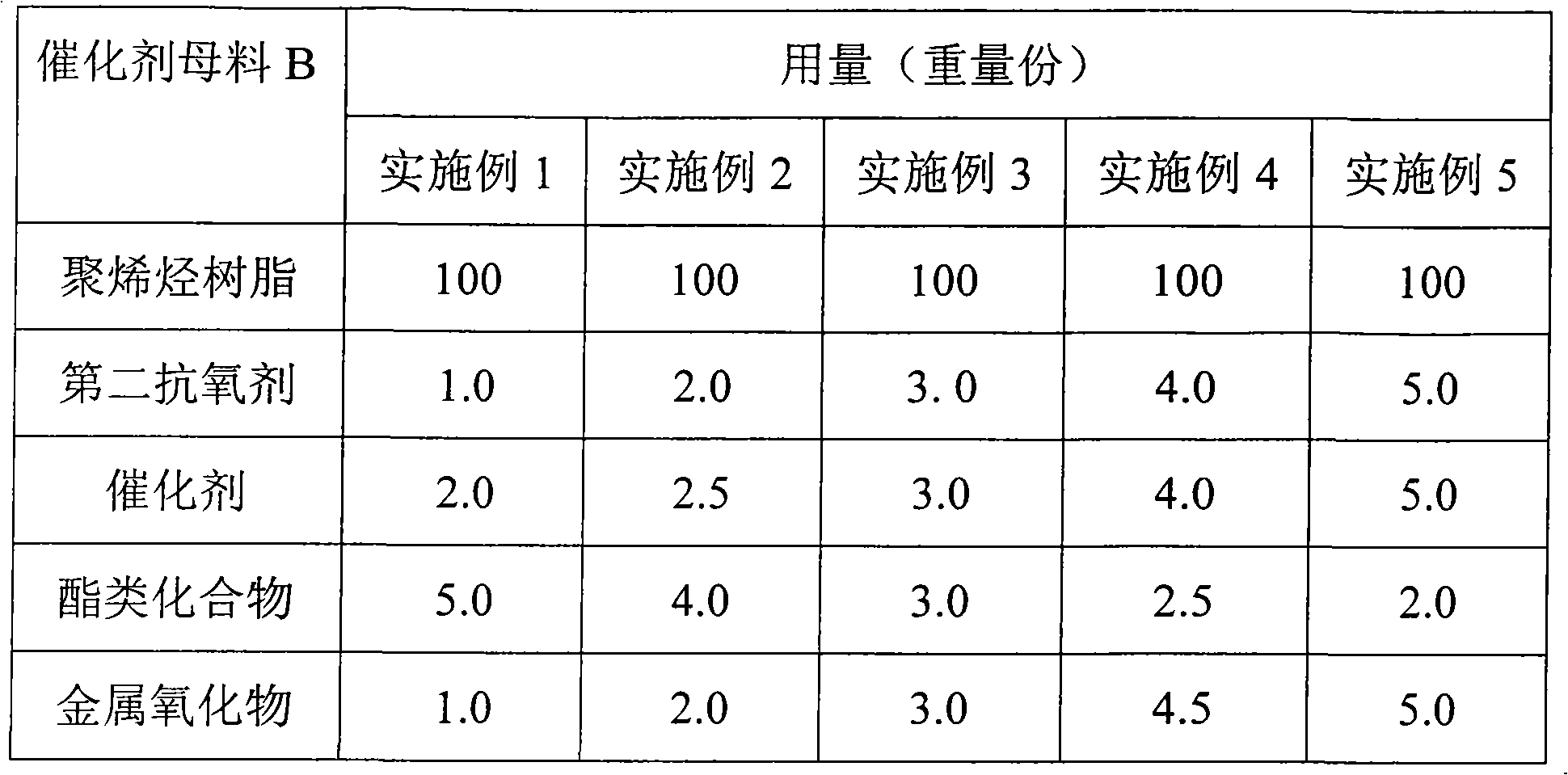

The invention provides a warm-water-free silane crosslinking polyolefines composition, comprising base material A and catalyst parent material B, the weight ratio thereof being :100:4-6, wherein the base material A is composed of (by weight parts): polyolefine rsin 100 parts, first antioxidant 0.2-0.3 parts, silicane 2.0-4.0 parts, initiator 0.1-1.0 parts, lubricant 1.0-3.0 parts, fatty acid 0.1-0.5 parts, the catalyst parent material B is composed of (by weight parts): polyolefine resin 100 parts, second antioxidant 1.0-5.0 parts, catalyst 2.0-5.0 parts, ester compound 2.0-5.0 parts, metal oxide 2.0-5.0 parts. The preparation method is uniformly mixing the above material. The silane crosslinking polyolefines composition can be linkable under natural conditions not through boiling or vapor bathing, with property corresponding the operational requirement, especially silane crosslinking polyolefines cable material .

Owner:JIANGSU DEWEI ADVANCED MATERIALS +1

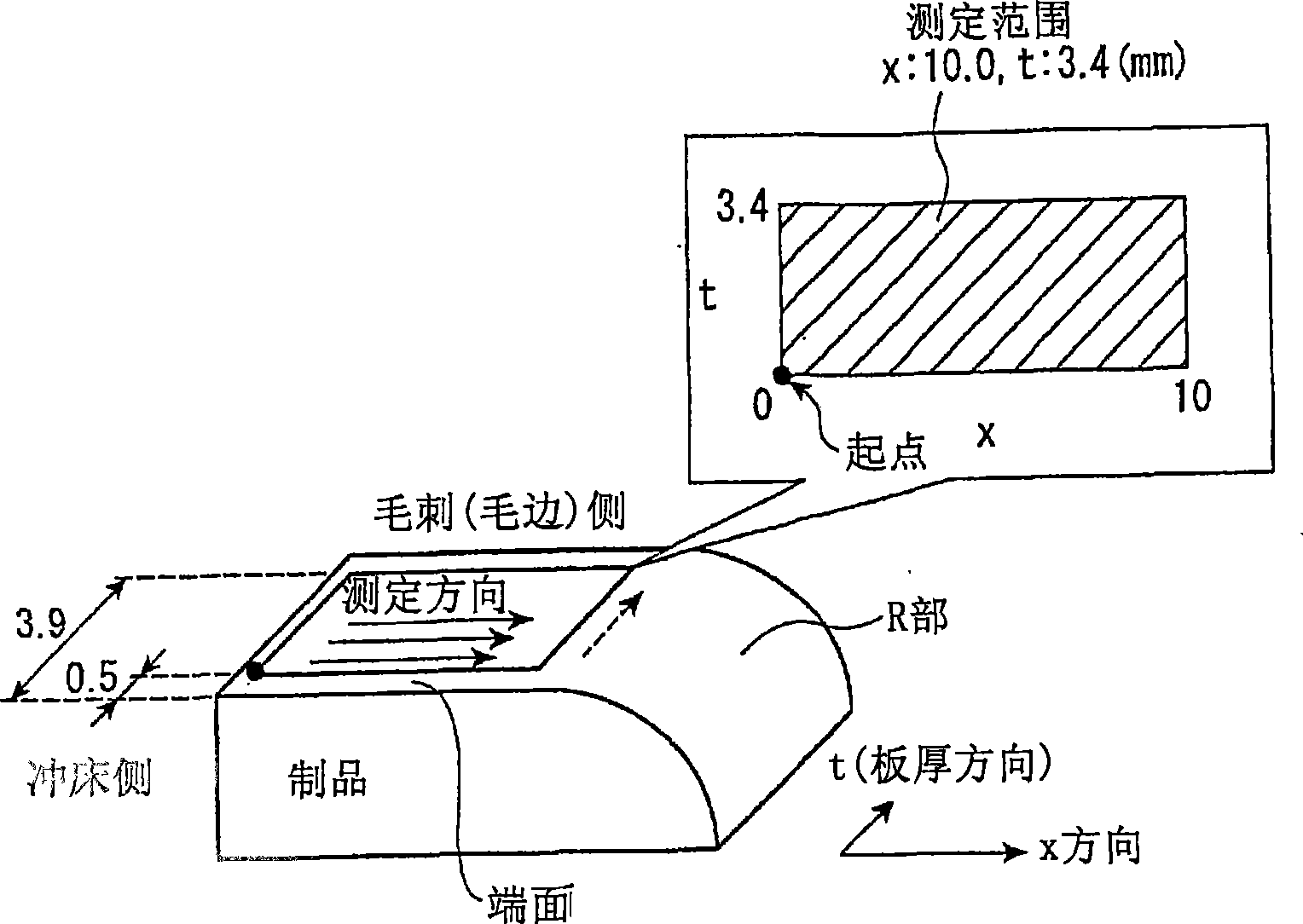

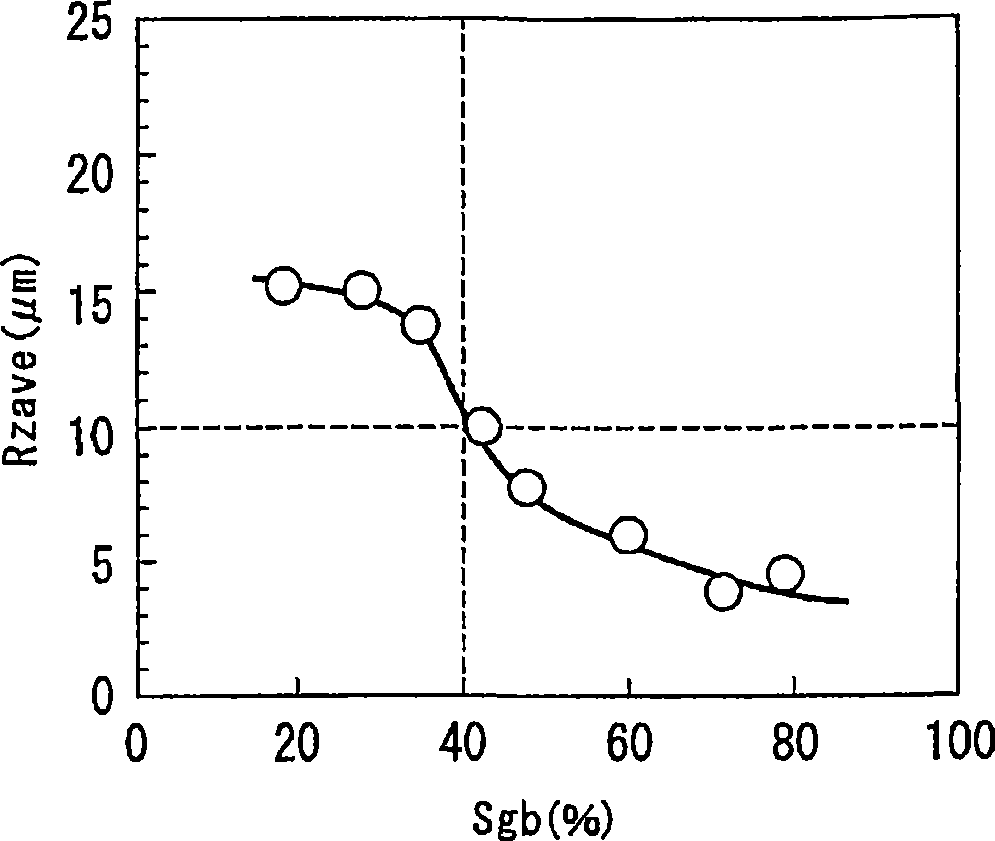

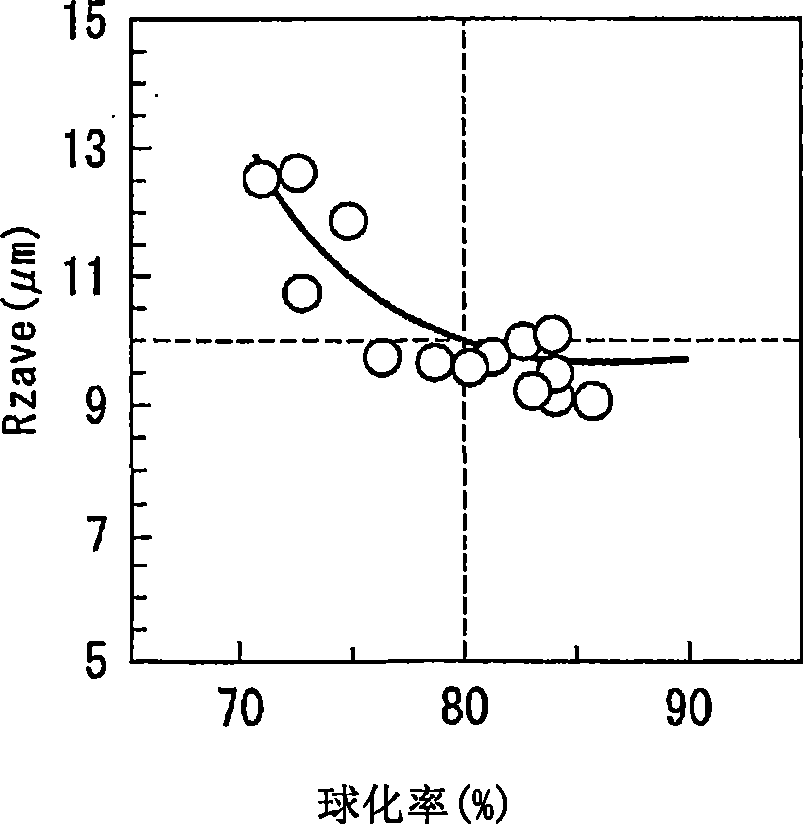

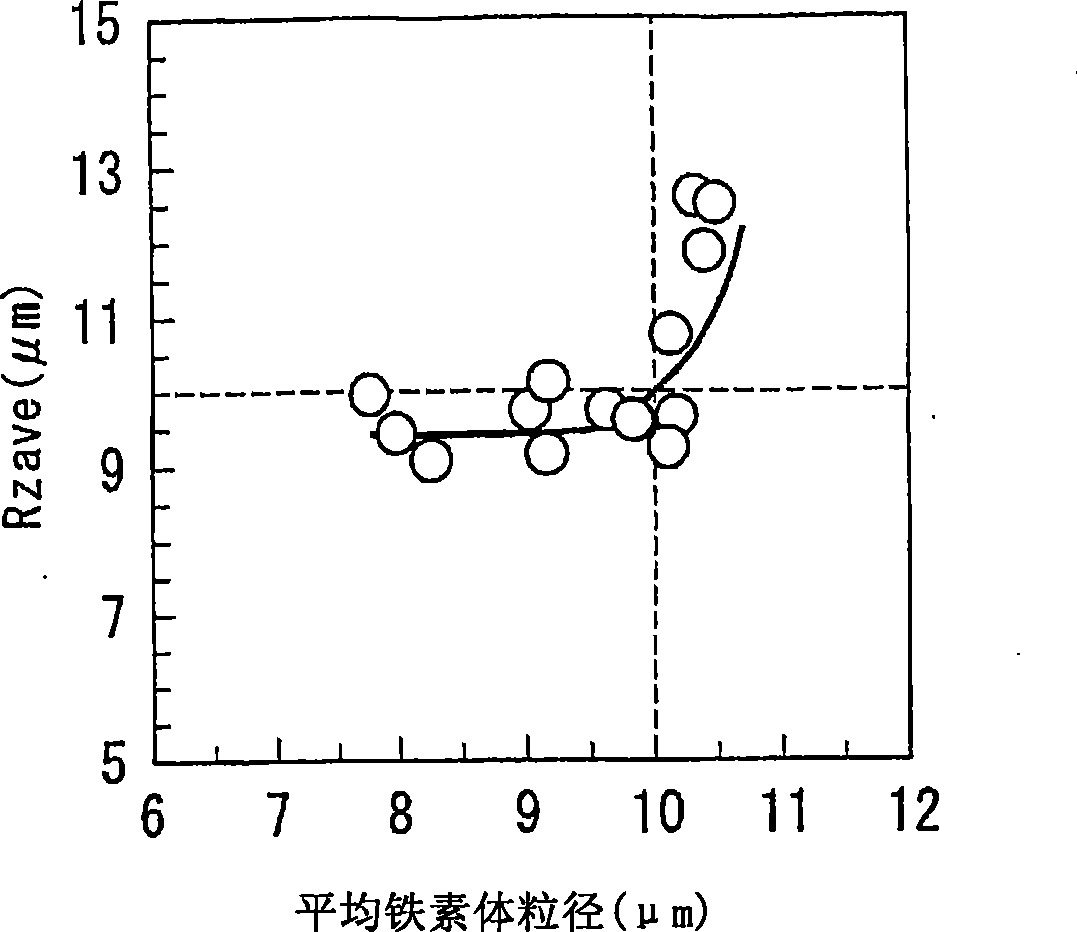

Steel plate having excellent fine blanking processability and method for manufacture thereof

ActiveCN101379207ASimple and cheap to manufactureEasy to processFurnace typesHeat treatment furnacesChemical compositionSheet steel

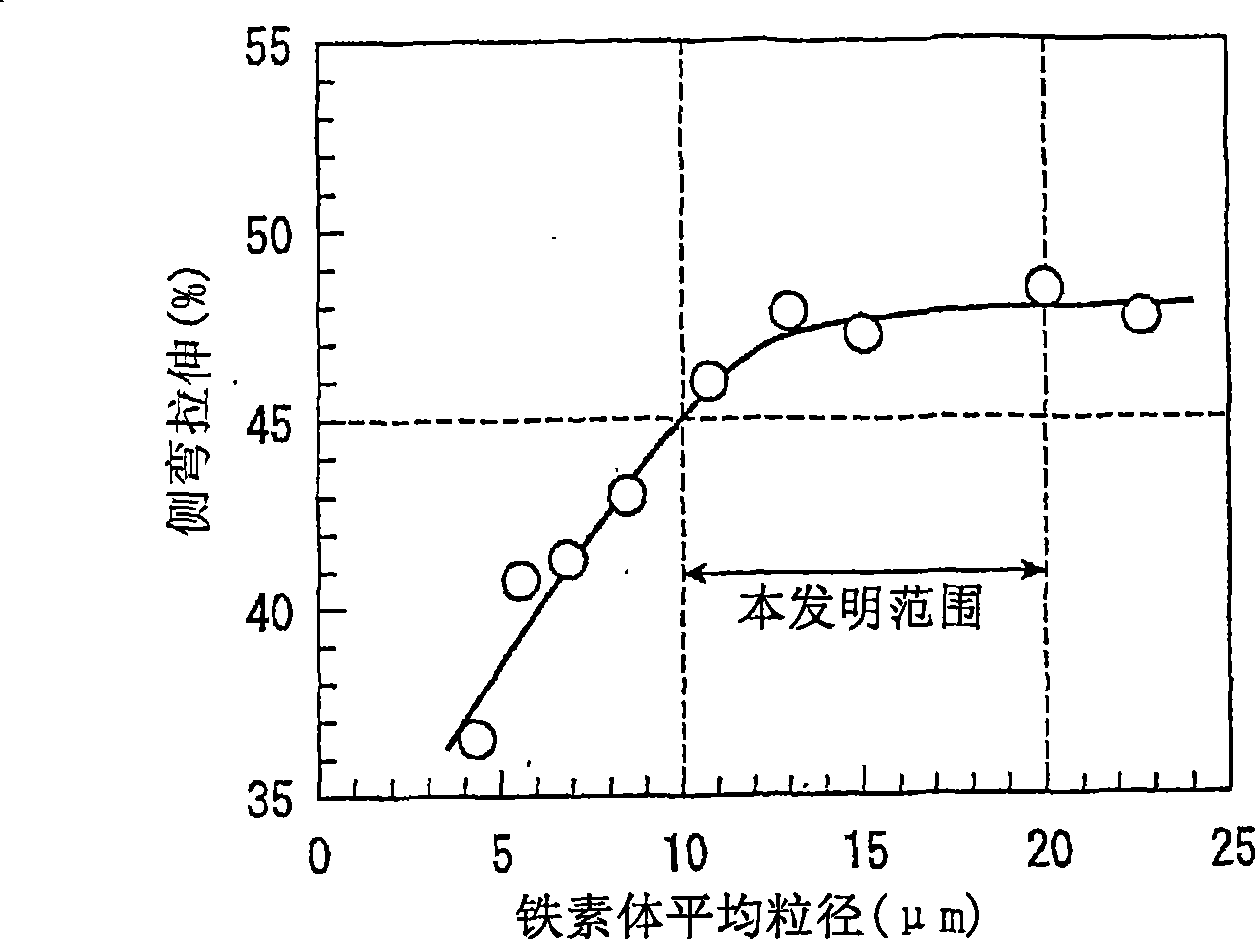

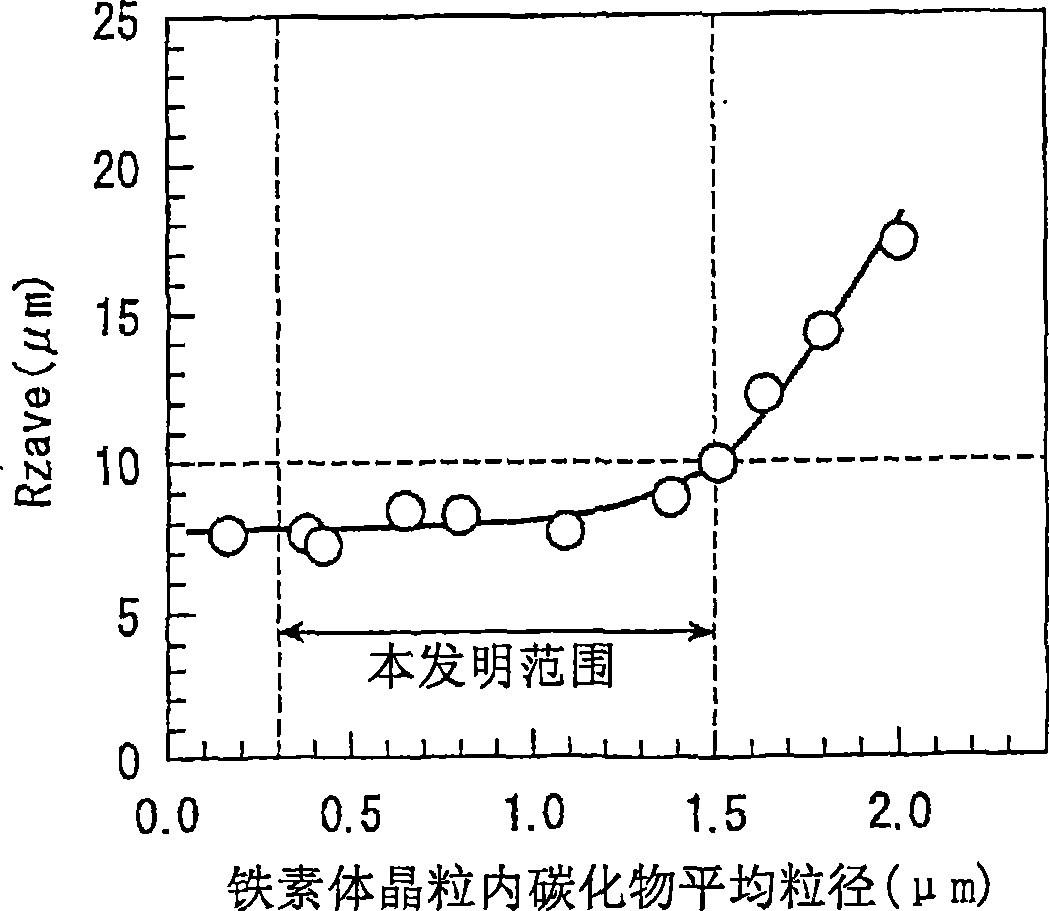

Disclosed are: a steel plate excellent in FB processability as well as molding processability after the FB processing; and a method for manufacture of the steel plate. The steel plate is characterized by having the following chemical composition (by mass): C: 0.1-0.5%; Si: 0.5% or less; and Mn: 0.2-1.5%; with the contents of P and S being adjusted within proper ranges, and has a tissue composed of ferrite having an average particle diameter of 10 to 20 [mu]m (exclusive) and a carbide contained in the ferrite particle and having an average particle diameter of 0.3 to 1.5 [mu]m. The steel plate is excellent in FB processability, die life, and processability after the FB processing (a side bend elongation property).

Owner:JFE STEEL CORP

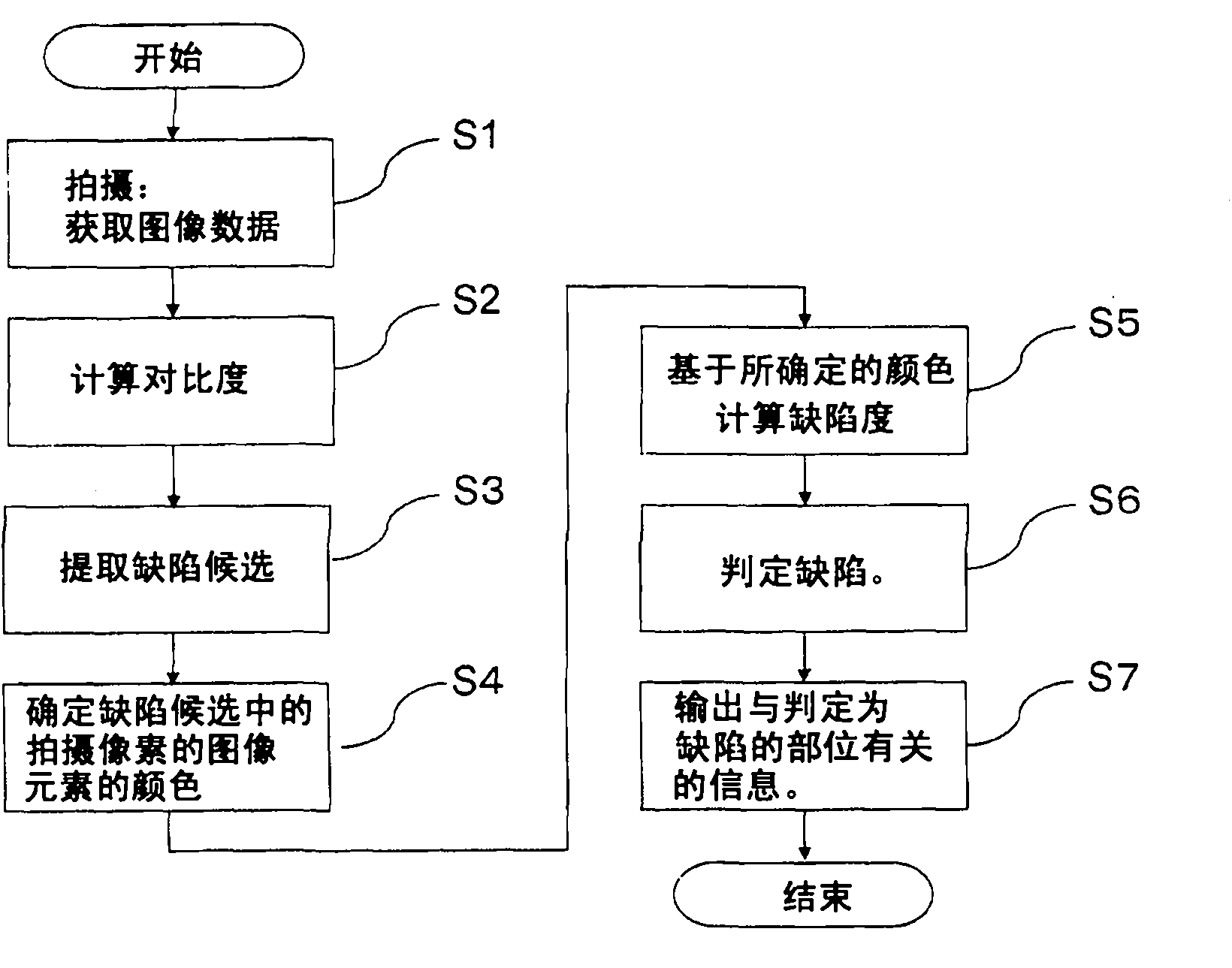

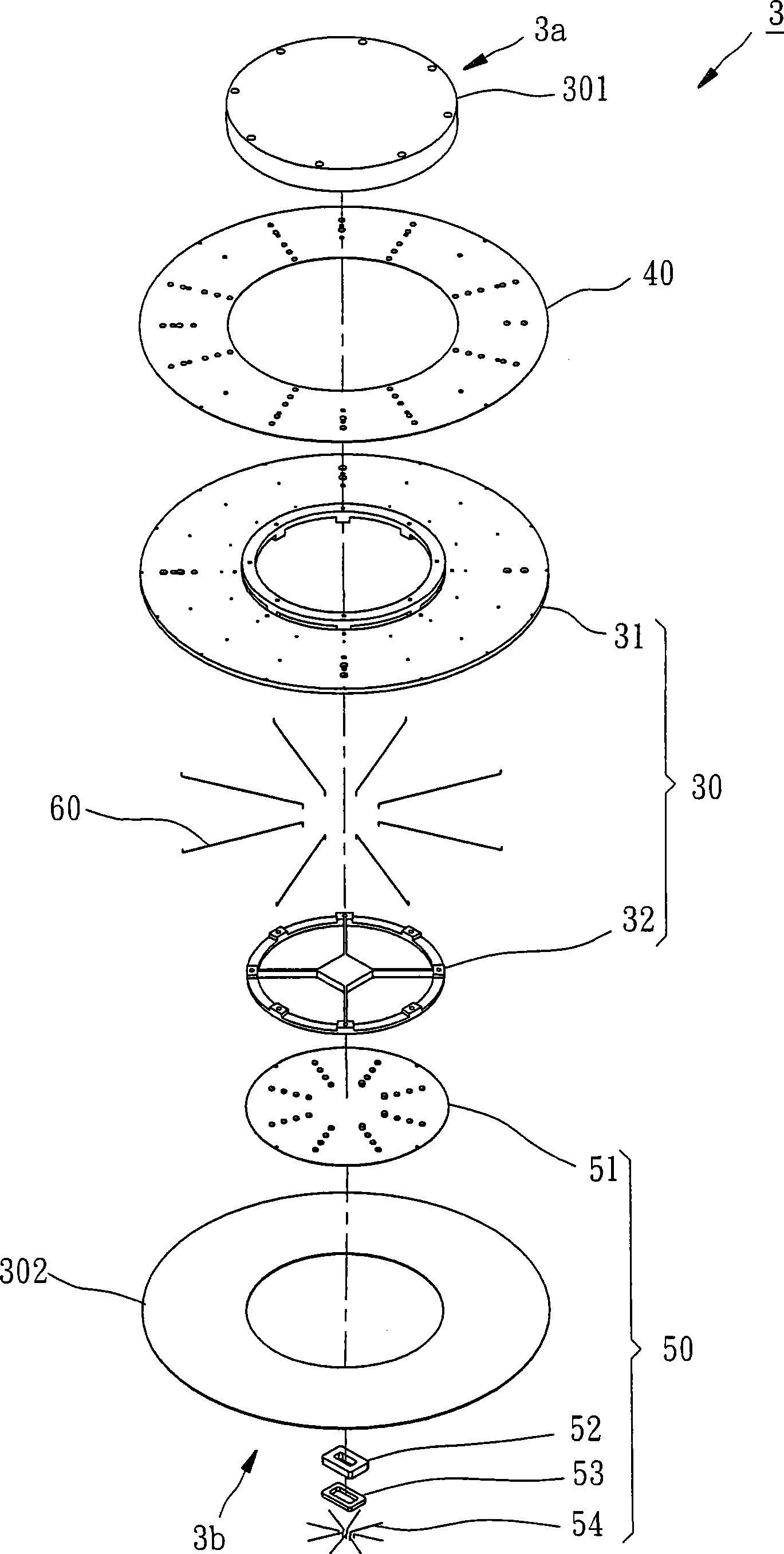

Defect detection device, defect repair device, defect detection method

InactiveCN102279189APrevent false detectionDefect correctOptically investigating flaws/contaminationNon-linear opticsColor imageDefect repair

The invention discloses a defect detecting device, a defect restoring device and a defect detecting method. The invention provides a defect detecting device which is capable of judging defects in a proper standard according to the color proportion even when the defects contain multiple-color image elements. The defect detecting device comprises a shooting part for shooting a display panel and obtaining image data; a defective part detecting part for selecting defective part candidates from the image data; a color determining part for determining the image element color of the defective part candidates; and a judging part for calculating the defective rate by multiplying a contrast degree with a correction coefficient varying with different colors, and then judging the defects by comparing the defective rate with a judging value. The judging part concludes after the contrast degree and a corresponding correction coefficient of each color are multiplied to calculate the defective rates when a defective part candidate comprises multi-color image elements.

Owner:SHARP KK

Steel plate having excellent fine blanking processability and method for manufacture thereof

ActiveCN101379208ASimple and cheap to manufactureEasy to processFurnace typesHeat treatment furnacesSheet steelCarbide

Owner:JFE STEEL CORP

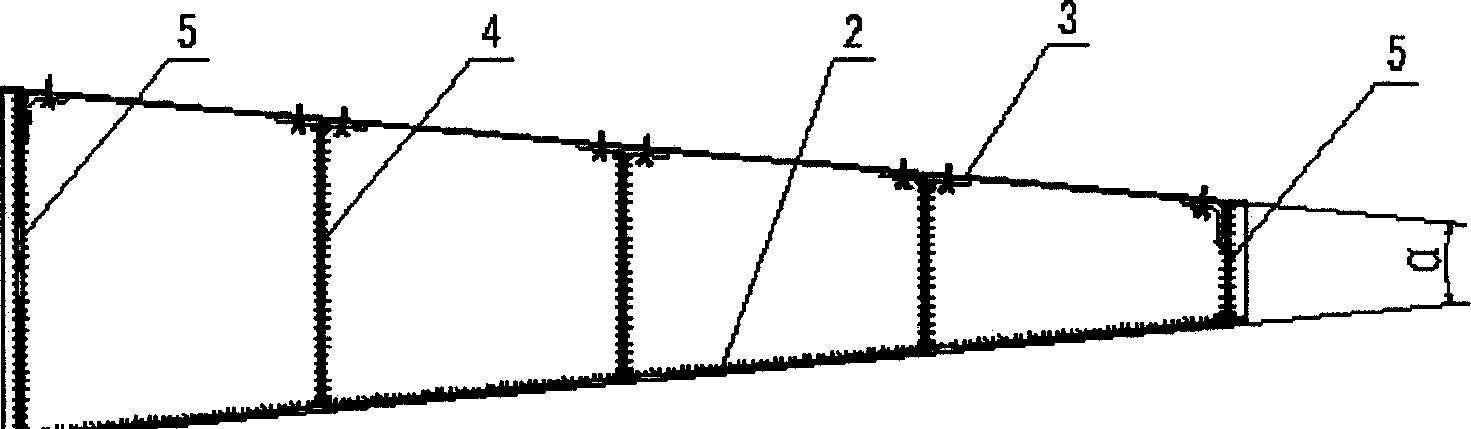

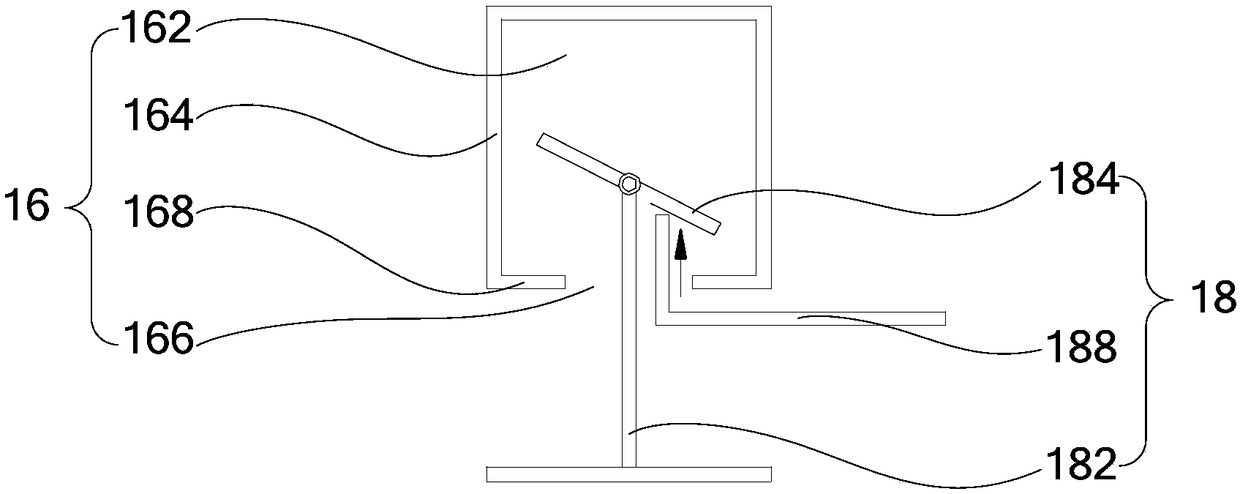

Straddle type single rail traffic rail flexible turnout beam

ActiveCN102787536AEasy accessGuaranteed comfortRailway tracksManufacturing cost reductionWork period

The invention discloses a straddle type single rail traffic rail flexible turnout beam, which comprises a flexible beam section and a flexibility driving assembly, wherein the flexible beam section is used for forming the flexible turnout beam, the flexibility driving assembly is used for driving the flexible turnout beam to generate the flexibility deformation, and the flexible beam section comprises a flexible beam main body and a walking supporter. The flexible turnout beam structure formed by the flexible beam section with forced flexible deformation is adopted, when the rail conversion joint is needed, the flexibility deformation is generated through external force driving, the stabilizing surface and the guide surface of the flexible beam section are respectively in smooth transition, broken lines are eliminated, the passing of light rail trains is favorably realized, in addition, the structure is greatly simplified through being compared with that of the existing turnout structure, the manufacture cost is reduced, the manufacture work period is shortened, the service life is longer, the use and maintenance cost is saved, the comfort and the safety of the light rail running can be ensured, the vehicle running noise is reduced, and better environment protection performance is realized.

Owner:重庆川东船舶重工有限责任公司

Method for welding 16MnDR low-temperature pressure container pot body closing end splicing welding line

ActiveCN101462195AHigh tensile strengthImprove impact toughnessArc welding apparatusWorkpiece edge portionsWeld seamEngineering

The invention provides a method for welding a joint welding seam of a sealing head of a tank body of a 16MnDR low-temperature pressure vessel and relates to a method for welding the joint welding seam of the sealing head of the tank body of the pressure vessel. The method solves the problem that indexes of tensile strength and impact toughness at the joint of the sealing head of the tank body are reduced in the normalizing temperature state in the prior welding process. The method comprises the following steps: 1, opening a Y-type groove on a joint end face of two joint plates of a 16MnDR sealing head; 2, welding one side of the Y-type groove; 3, gouging and chipping back; 4, welding the welding seam on the back; 5, carrying out normalizing temperature treatment at a charging temperature of between 200 and 400 DEG C and a heat preserving temperature of between 900 and 930 DEG C, and keeping the temperature for 10 to 75 minutes; and 6, carrying out annealing treatment at a charging temperature of between 20 and 390 DEG C and a heat preserving temperature of between 600 and 640 DEG C, and keeping the temperature for 40 to 50 minutes and the temperature dropping speed of between 1.0 and 6.7 DEG C / min. Step 2 and step 4 adopt automatic submerged arc welding, wherein the welding wire brand is H09MnDR, the welding wire diameter is Phi 4 millimeters and the flux brand is SJ305, and the drying is performed for 1 to 2 hours at a drying temperature of between 340 and 360 DEG C. The welding current is 650 to 710A, the electric arc voltage is 34 to 36 V, and the welding speed is 48 to 50 cm / min. The method can improve the tensile strength and the low-temperature impact toughness of the welding seam at the joint of the sealing head after the normalizing temperature treatment.

Owner:哈尔滨建成北方专用车有限公司

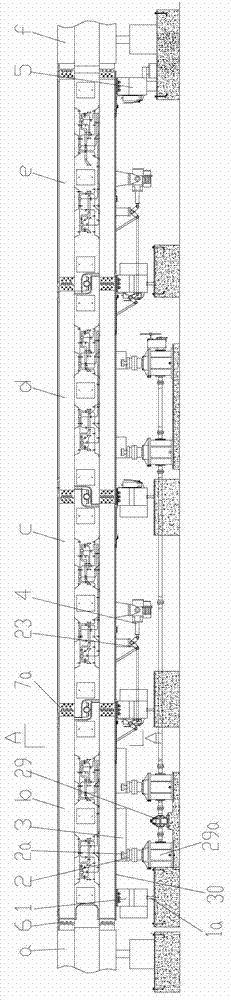

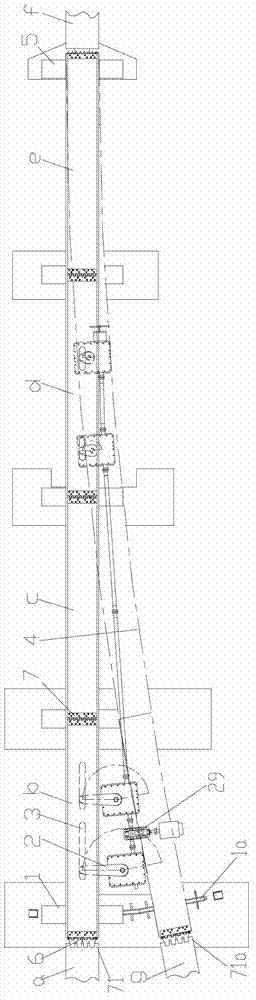

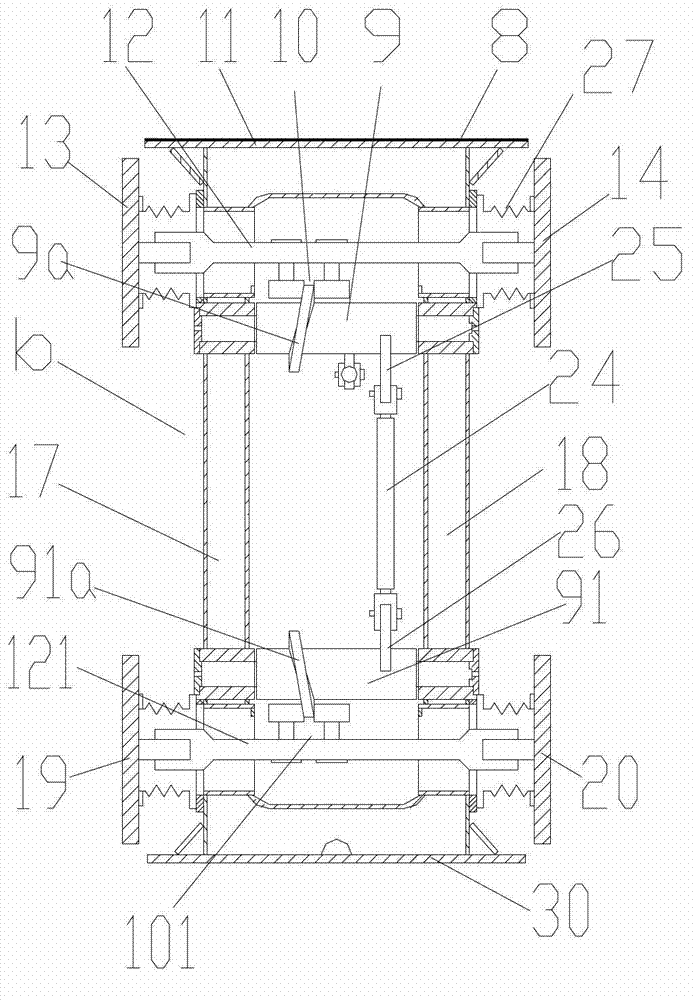

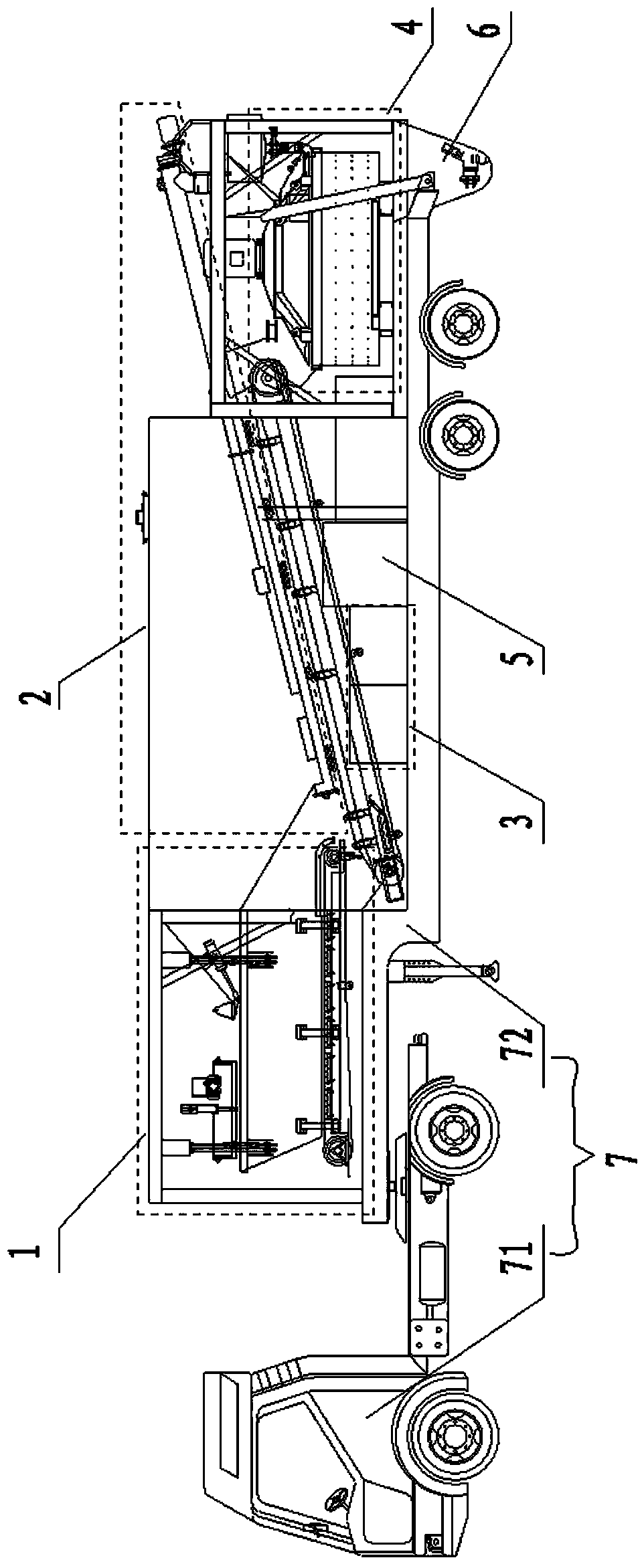

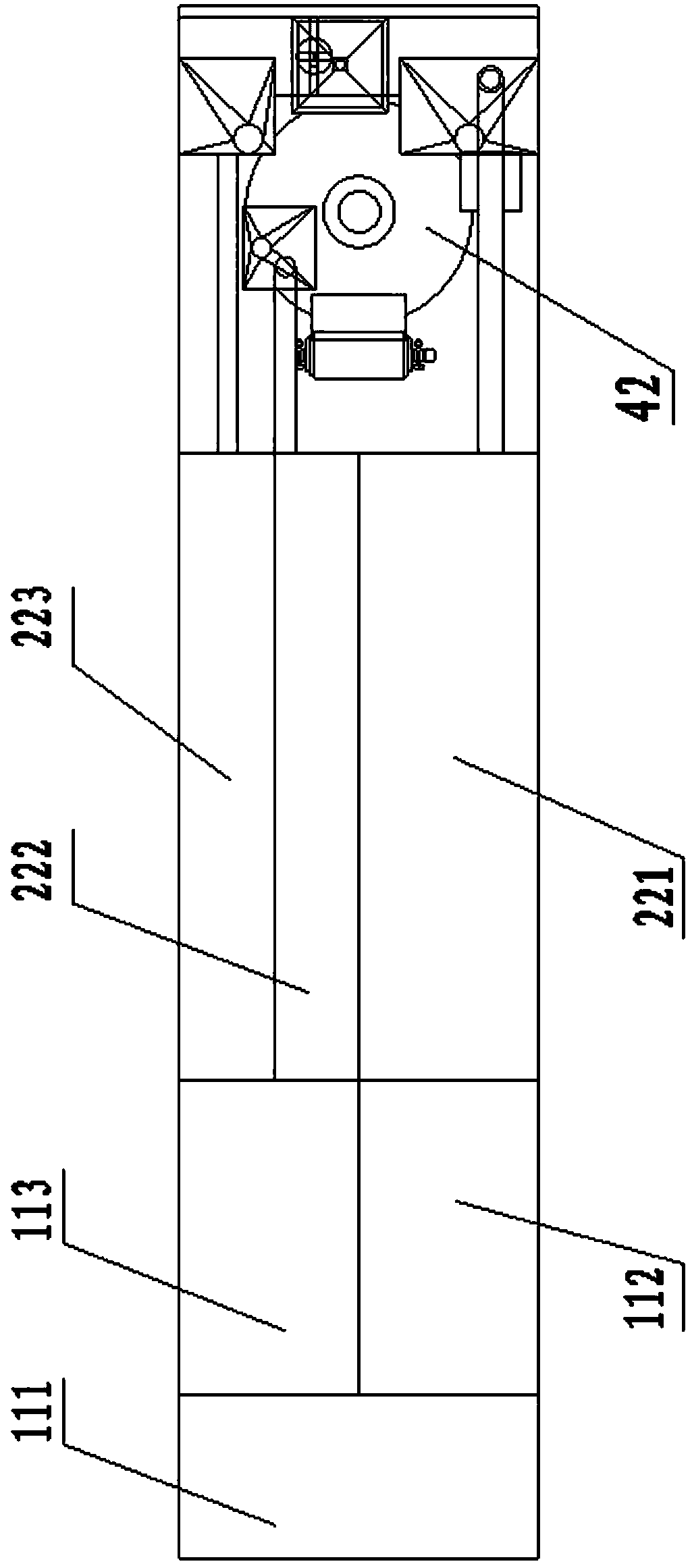

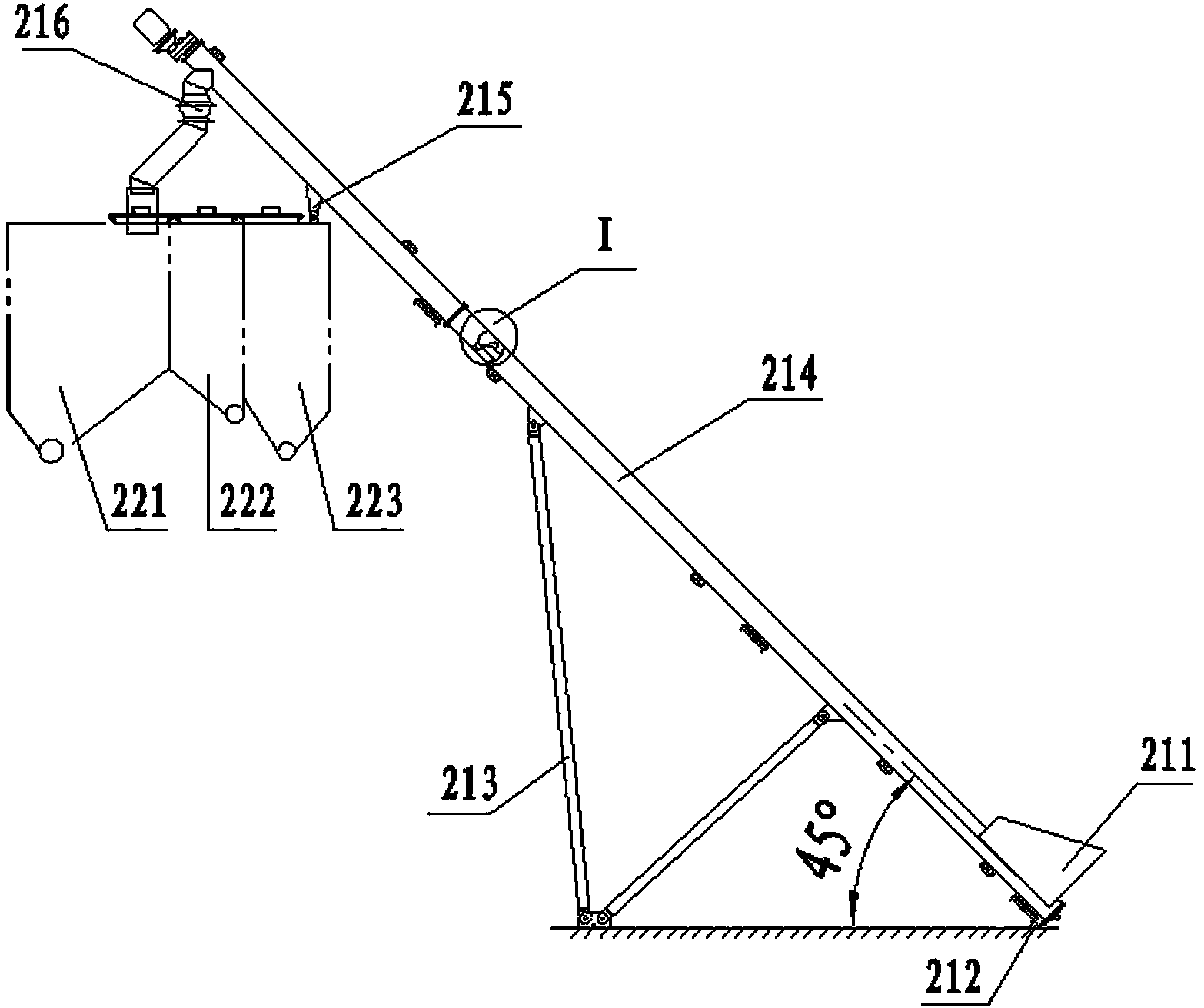

Quickly-moving type concrete mixing station

ActiveCN103660040AShorten the production periodIncrease productivityDischarging apparatusIngredients weighing apparatusMaterial supplyDelivery system

The invention discloses a quickly-moving type concrete mixing station, and relates to the technical field of concrete production equipment. The station comprises an aggregate supplying system, a powdered auxiliary material supplying system, a liquid auxiliary material supplying system, a stirring system, a control panel, a pump delivery system, and a transportation system; wherein the transportation system comprises traction equipment and a trailer plate, the aggregate supplying system, the powdered auxiliary material supplying system, the liquid auxiliary material supply system, the stirring system, the control panel, and the pump delivery system are all arranged on the trailer plate; the aggregate supplying system, the powdered auxiliary material supplying system, and the liquid auxiliary material supplying system all communicate with the stirring system, the stirring system comprises a frame and a stirrer, the stirrer is arranged on the frame; and the pump delivery system is arranged below the material unloading door of the stirrer. The quickly-moving type concrete station has the advantages of compact structure, user-friendliness, and rapid movement, can shorten the construction time and guarantee the concrete quality, satisfies the using requirement of small-batch concrete, improves the construction efficiency, and saves the construction cost.

Owner:SHIJIAZHUANG TIEDAO UNIV +2

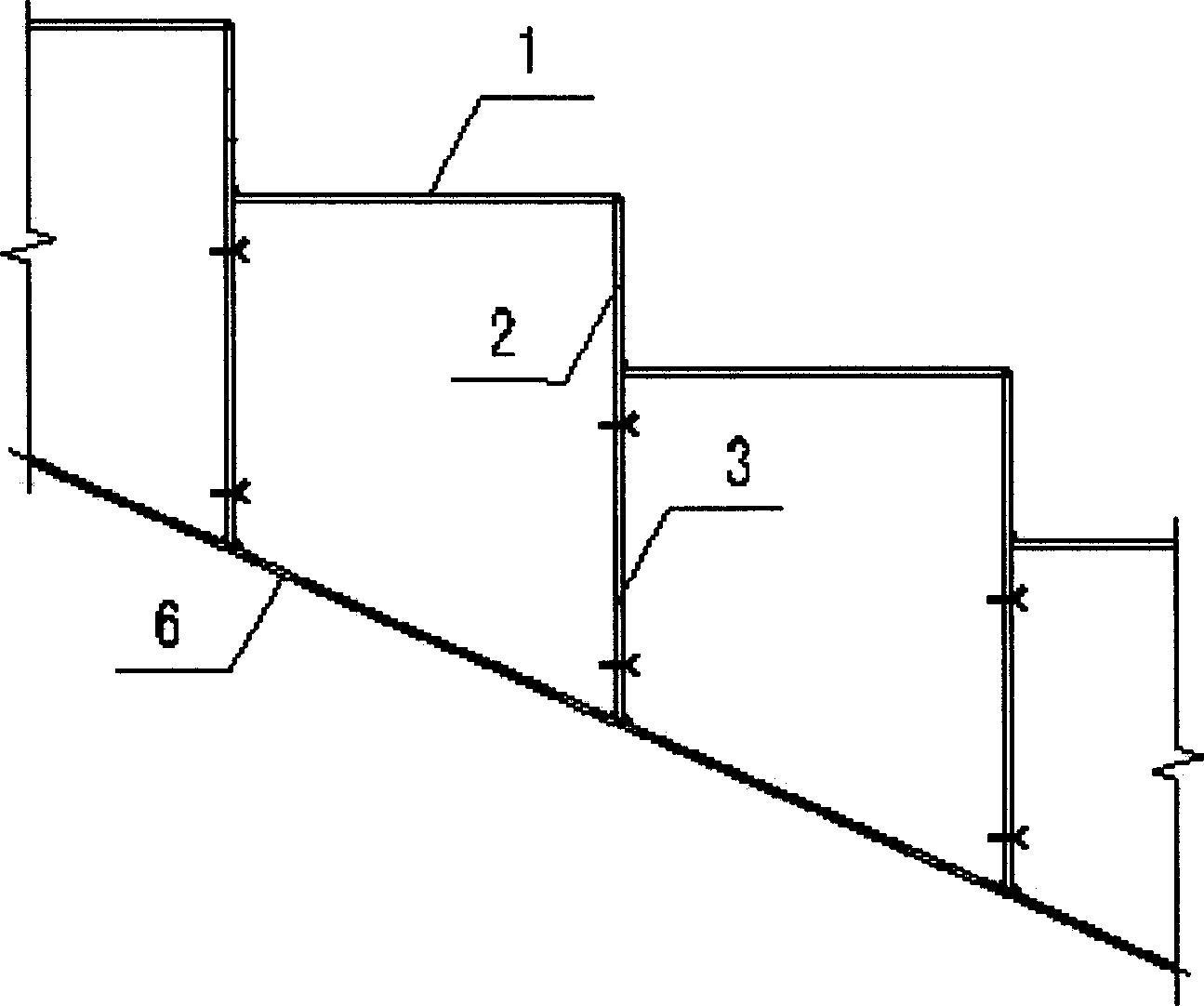

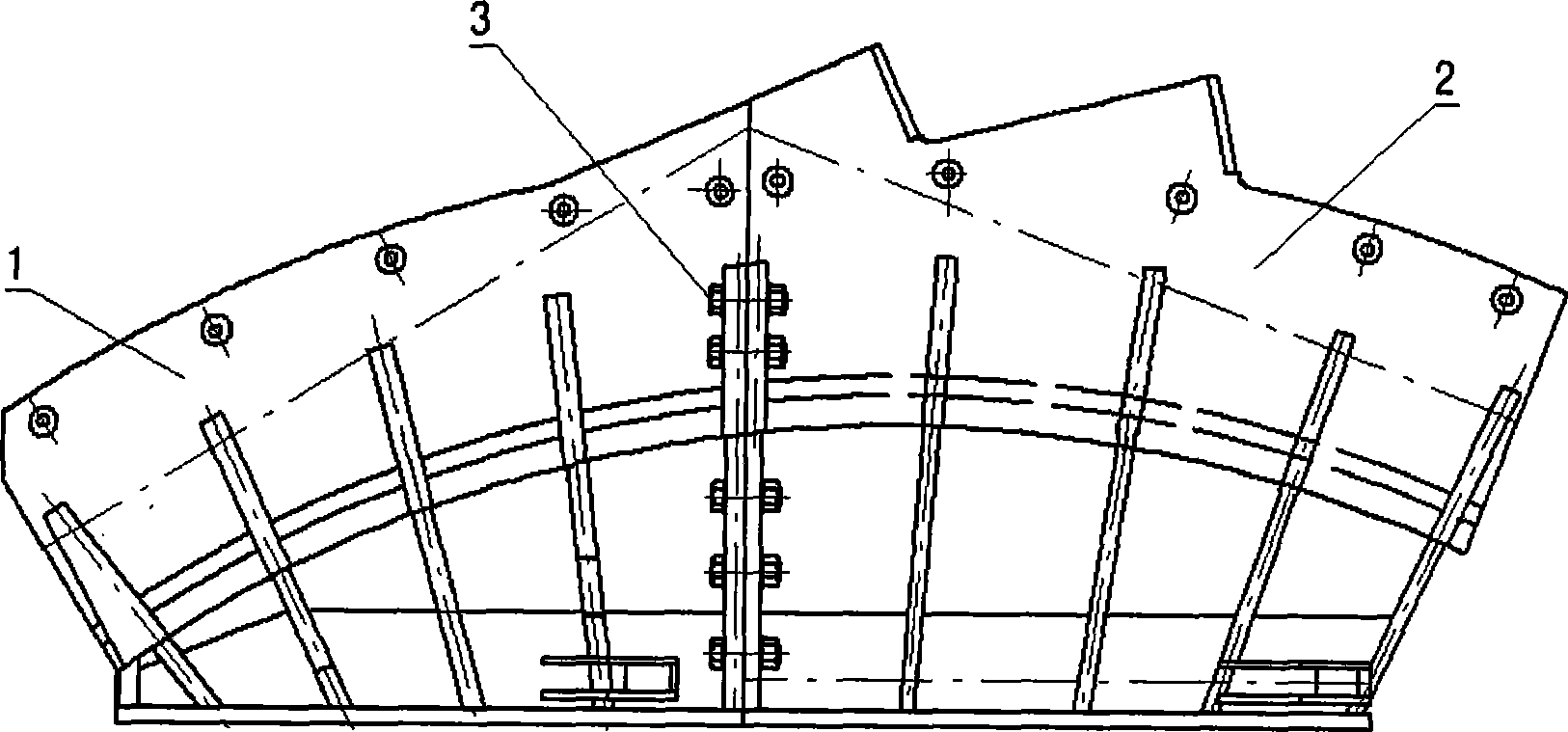

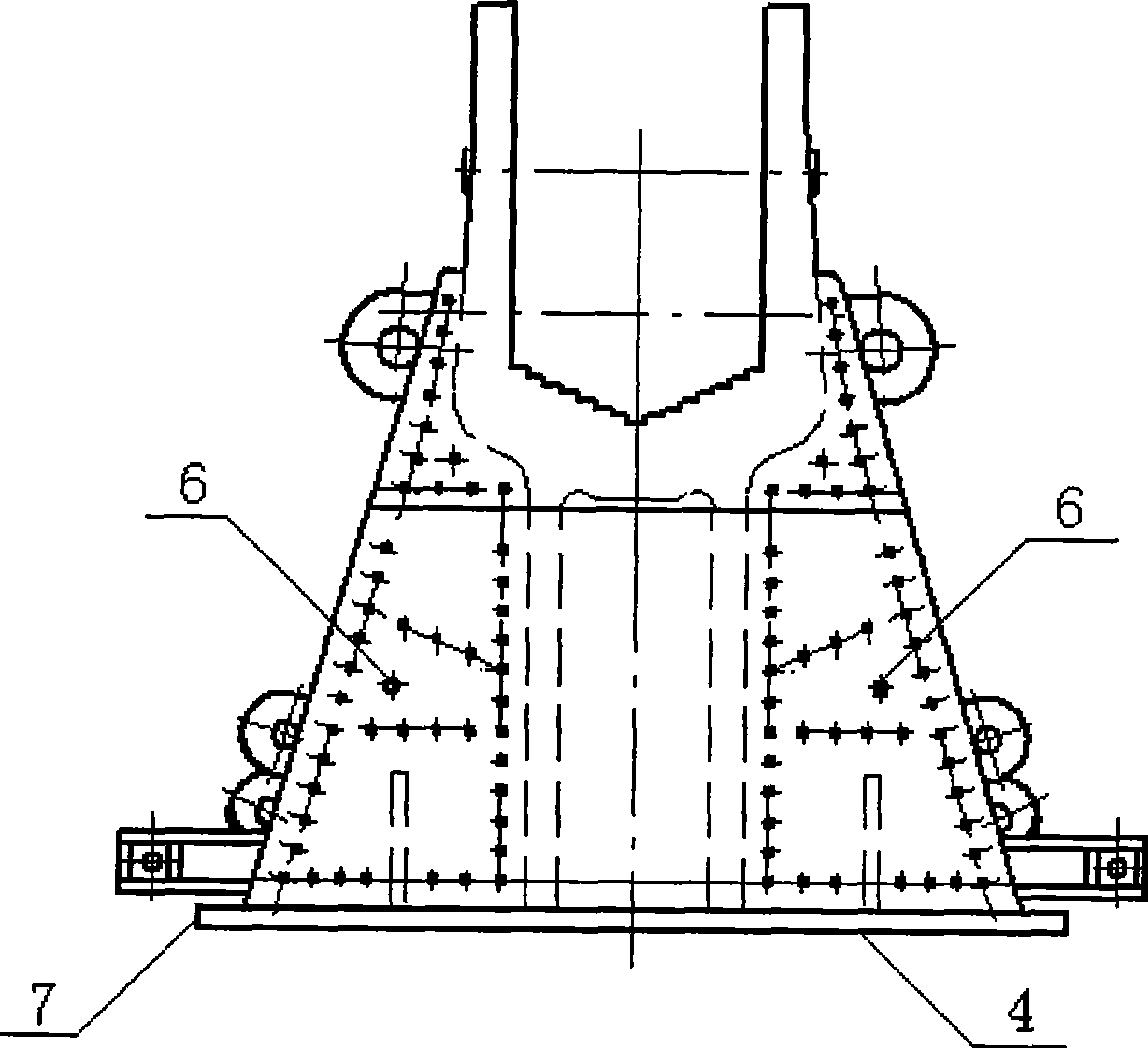

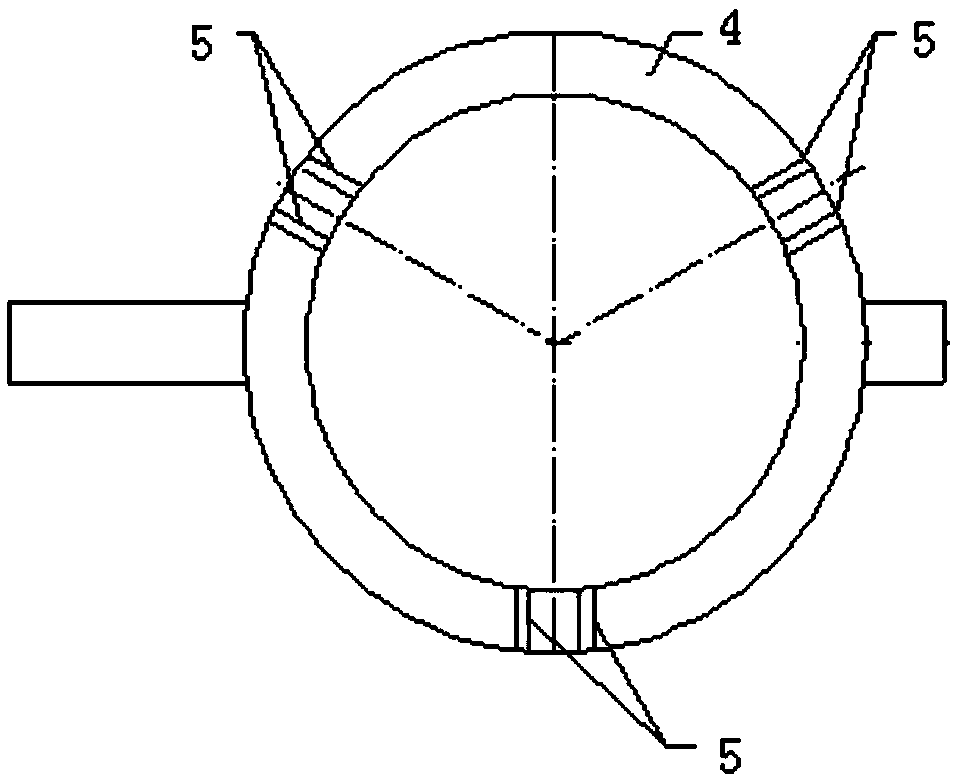

Method for processing main cable saddle of suspension bridge

The invention discloses a method for processing a main cable saddle of a suspension bridge. A side span (1) and a midspan (2) of the main cable saddle are respectively processed, then a bolt (3) is used to connect the side span and the midspan, and a joint surface of the side span (1) and the midspan (2) is provided with a positioning pin hole (6). The method guarantees the consistency of the size of a rope groove after the side span (1) and the midspan (2) are butted, has no alternate edges, high butting accuracy and small error, unifies processing reference, has low requirement on processing equipment, is more convenient for clamping and calibration of workpieces, is easy to guarantee processing accuracy, and improves processing efficiency.

Owner:WUHAN MARINE MACHINERY PLANT

Hippocampus japonicus liquor and method for preparing same

InactiveCN101307282AShorten the production periodPure tasteDigestive systemAntinoxious agentsCaramel FlavorCistanche salsa

The present invention discloses hippocampi wine and a method for preparing the same. The formula comprises the following raw materials of: fresh alive hippocampi, radix codonopsitis, astragalus, black date, Chinese wolfberry, eucommia, prepared radix rehmanniae, topaz, polygonatum sibiricum red, cistanche salsa, radix morindae, ganoderma lucidum, black bean, American ginseng, Korean Ginseng, pericarpium citri reticulataw, honey, caramel, and rice wine, etc. By adopting a unique process, the wine is made from natural compositions of the fresh alive hippocampi and a traditional Chinese medicine formula of 'medicine and food are from the same source'. The wine has the advantages of Qi invigorating, blood enriching, kidney tonifying, Yang strengthening, senescence postponing and good taste, etc.

Owner:李秉记

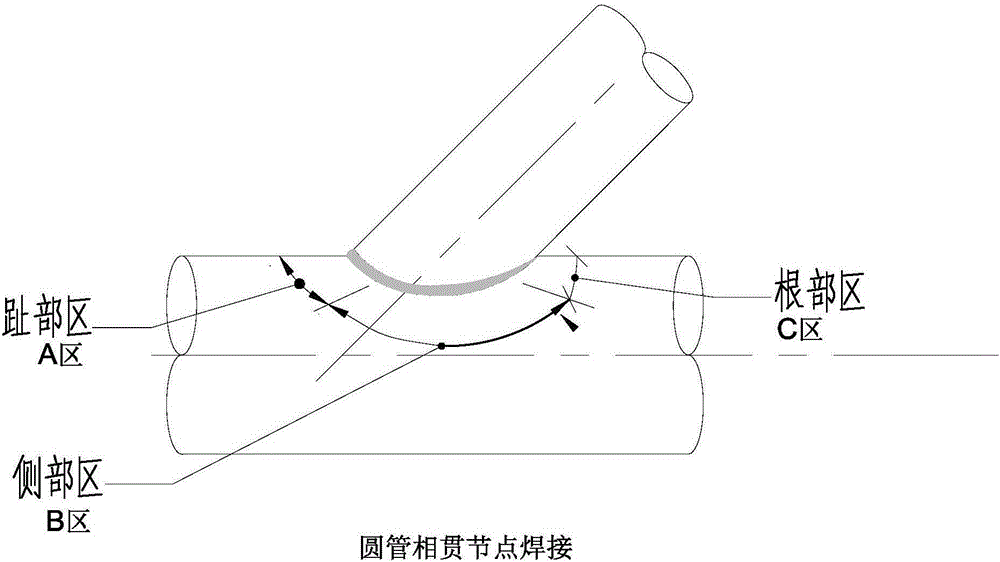

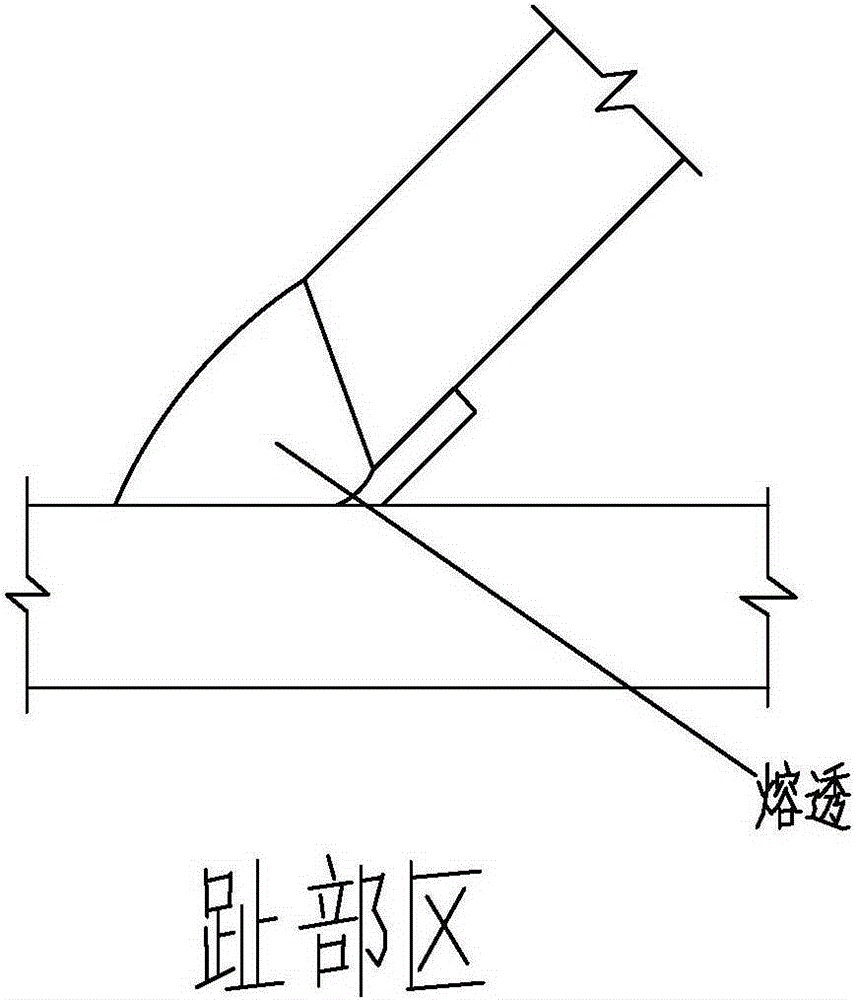

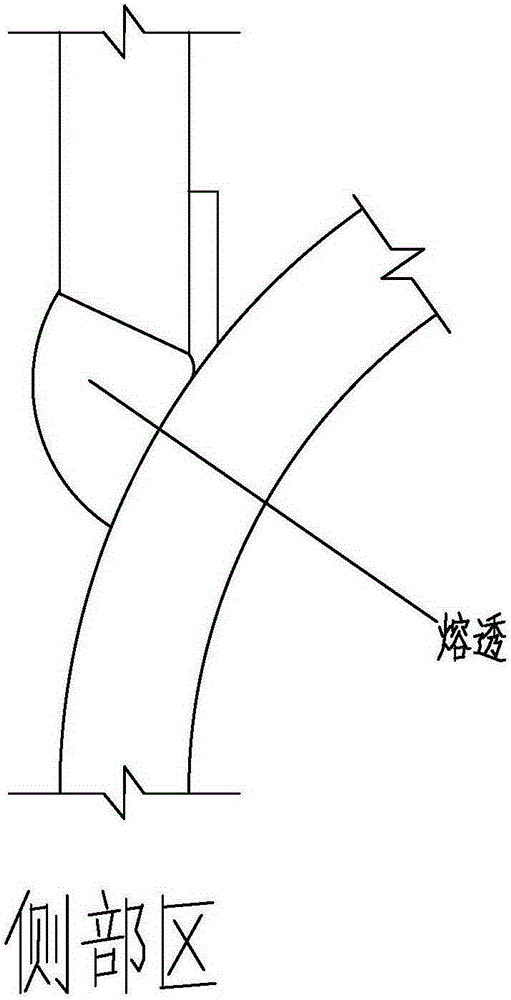

Whole plate thick penetration welding method for intersection joint of circular tube

ActiveCN105234568ASolve the problem of not being able to weld through the full thickness of the plateMeet the design requirementsWelding apparatusMachiningSteel tube

The invention belongs to the technical field of steel tube welding and specifically relates to a whole plate thick penetration welding method for an intersection joint of a circular tube. The method comprises the following specific steps that a, the intersection circular tube is cut through a intersection line, and the position of a cutting starting point is marked; b, a starting point of a base plate is identical to the cutting starting point of the intersection circular tube, and an installation datum line is drawn on the outer side of the base plate with the cutting starting point as a datum; c, the intersection circular tube is assembled, and the precision of the installation dimensions of the circular tube is ensured; d, the special-shaped intersection base plate is assembled and stuffed in form the tail portion of the circular tube, and the installation datum line of the base plate is made coincide with the datum line of the inner wall of the circular tube; e, secondary groove machining is conducted, and a groove is polished through a polisher to make the groove face smooth after groove machining is finished; and f, groove machining is conducted, and the intersection joint can meet the requirement of a whole plate thick penetration welding line. According to the method, the conditions that the side portion and the root portion of the circular tube can not achieve full penetration are avoided.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Travelling support for flexible turnout beam section of straddle-type monorail traffic track

ActiveCN102787535AEasy accessGuaranteed comfortRailway tracksManufacturing cost reductionPolygonal line

The invention discloses a travelling support for a flexible turnout beam section of a straddle-type monorail traffic track, which comprises a travelling side and a flexible side support board, wherein the flexible side support board comprises two guide boards which are positioned at the upper part and two stabilization boards which are positioned at the lower part. The travelling support which can be forcefully deformed flexibly is adopted to form the flexible turnout beam section and a flexible turnout beam structure, when a track is needed to be transferred and joined, flexible deformation is generated due to the drive of the external force, both the guide side and the stabilization side of the flexible turnout beam section are in smooth transition, fold lines are eliminated, the travelling of light rails is benefited; and moreover, compared with the existing turnout structure, the travelling support is more greatly simplified, the manufacturing cost is lowered, the manufacturing period is shortened, the service life is longer, the use and maintenance costs are saved, the comfortability and safety of the light rail can be ensured, the vehicle travelling noise is lowered, and travelling support has better environmental protection property.

Owner:重庆川东船舶重工有限责任公司

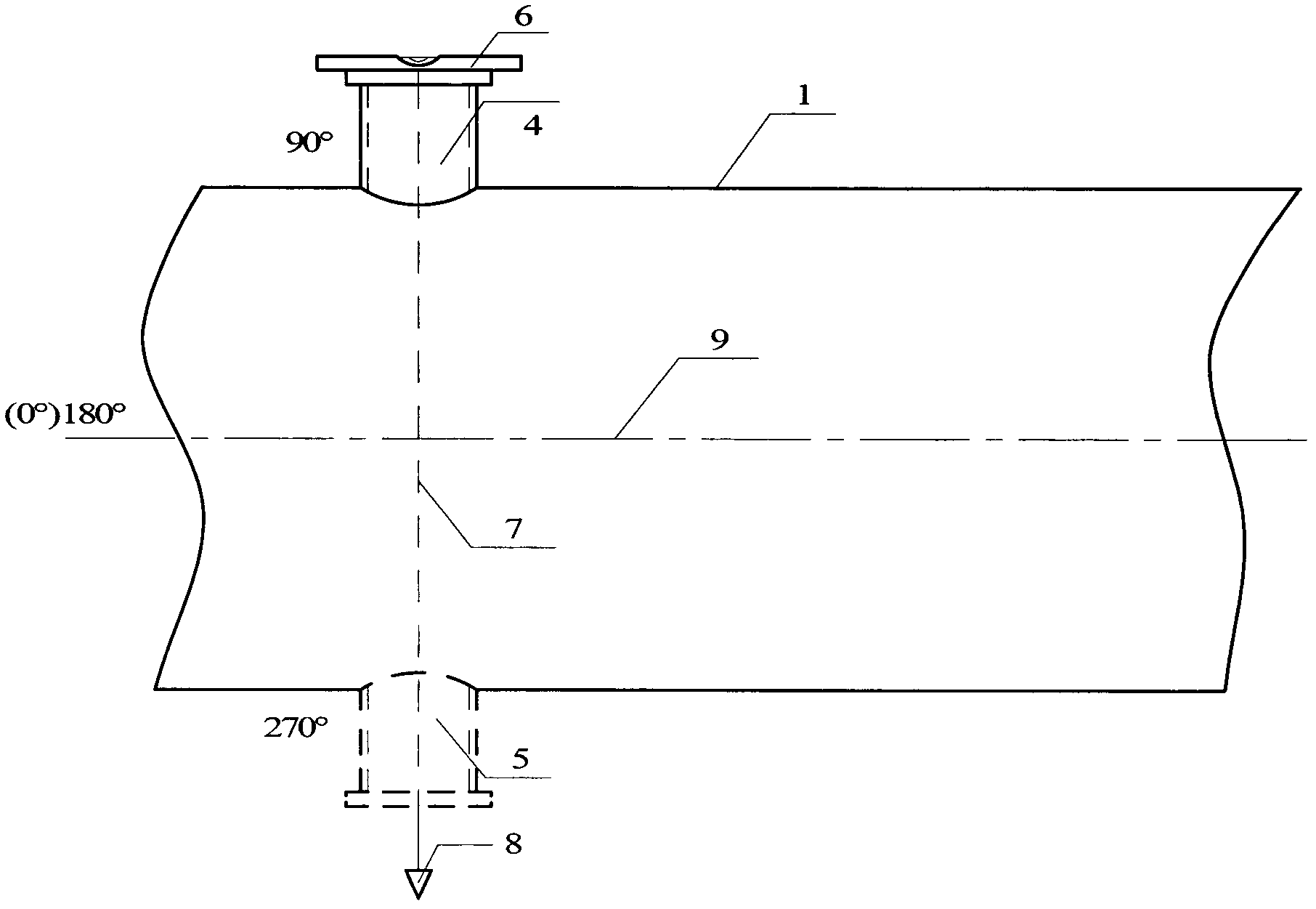

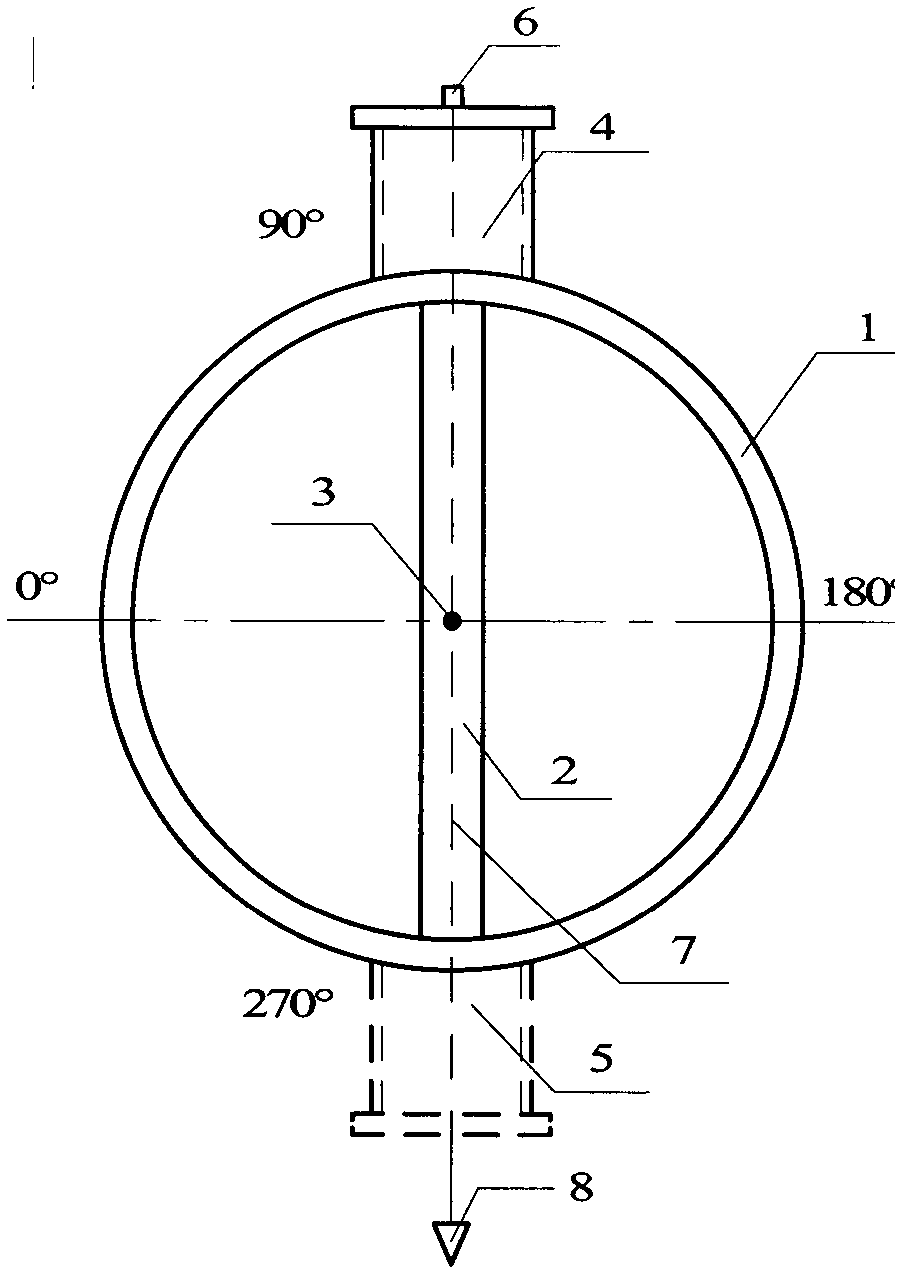

Method for assembling and detecting barrel connecting pipe

ActiveCN102430917AEasy to operateImprove accuracyMetal working apparatusMechanical measuring arrangementsEngineeringElectrical and Electronics engineering

The invention discloses a method for assembling and detecting a barrel connecting pipe. The method is used for connecting a connecting pipe to a barrel and enabling the central axis of the connecting pipe to be vertically intersected with the central axis of the barrel body. The method comprises the following steps of: calibrating the central axis of the barrel, adjusting the level of the barrel,and arranging the connecting pipe to the upper side of the barrel. According to the method disclosed by the invention, aiming at a measured object of a product, assembling and measuring procedures are optimized and simplified by utilizing advanced detection equipment and combining the traditional measuring method to reach the purpose of controlling assembling quality.

Owner:SHANGHAI BOILER WORKS

High-speed test device

InactiveCN101487874AShorten the production periodReduce complicated production processElectronic circuit testingElectrical measurement instrument detailsSpeed testEngineering

The invention discloses a high-speed test device, which is used for transmitting a test signal sent out by a test machine to electrically test an integrated circuit chip. A circuit layer and a probe set are arranged on and below a support frame respectively. When a lower pressure point of the test machine is contacted with the circuit layer and a corresponding point of the probe set is contacted with an electronic component on the chip, the support frame bears stress on upside and underside.

Owner:MICROELECTRONICS TECH INC

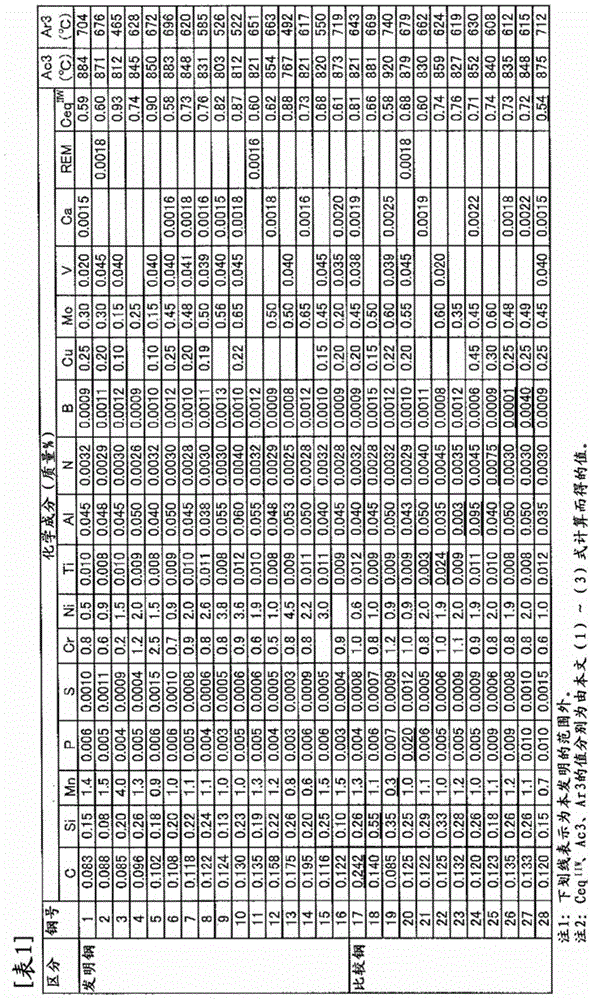

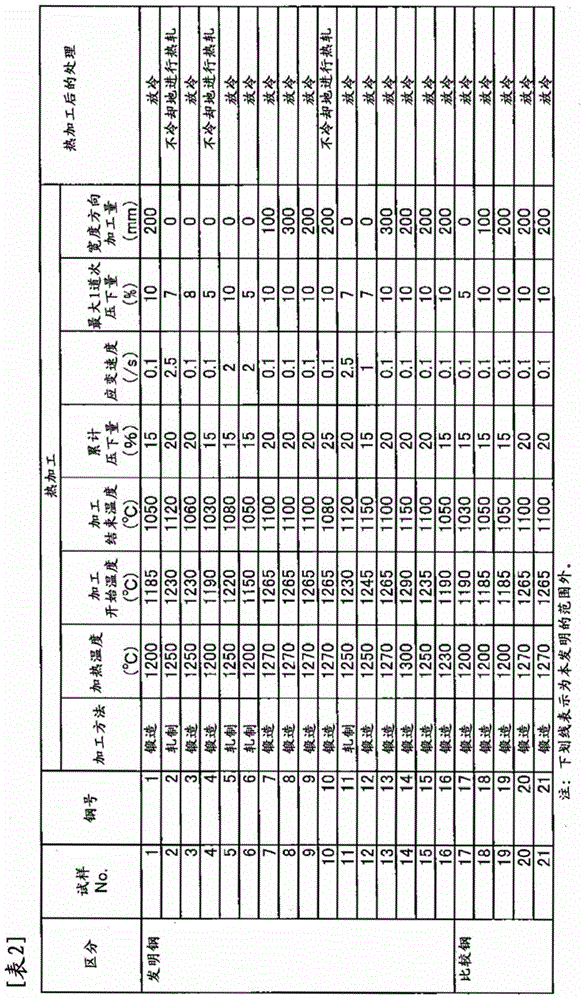

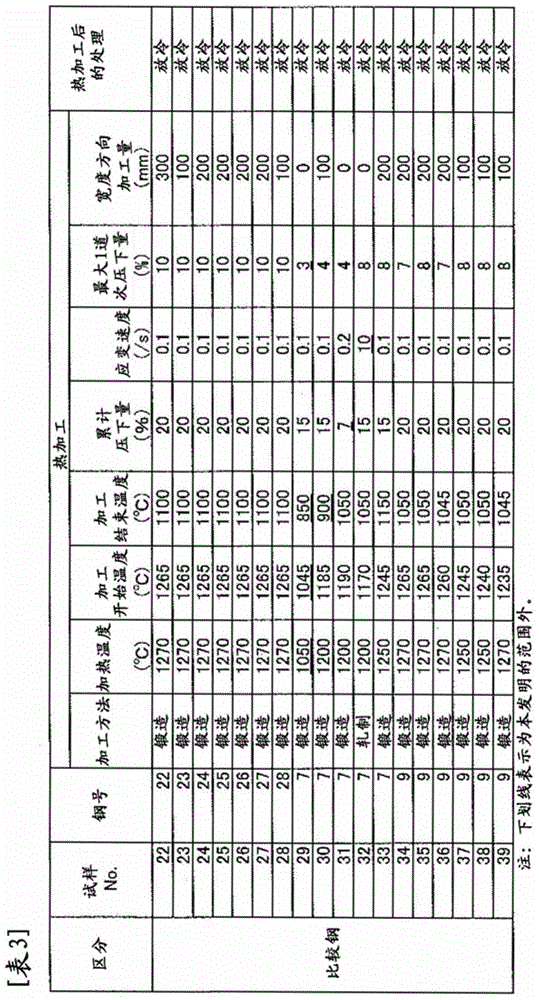

Thick, tough, high tensile strength steel plate and production method therefor

The invention provides thick high-toughness high-strength steel plates having excellent strength and toughness in the central area through the plate thickness, and methods for manufacturing such steel plates. The thick steel plate has a specific chemical composition and includes a microstructure having, throughout an entire region in the plate thickness direction, an average prior austenite grain size of not more than 50 µm and a martensite and / or bainite phase area fraction of not less than 80%. A continuously cast slab having the specific chemical composition is heated to 1200°C to 1350°C, hot worked with a strain rate of not more than 3 / s and a cumulative working reduction of not less than 15%, and thereafter hot rolled and heat treated.

Owner:JFE STEEL CORP

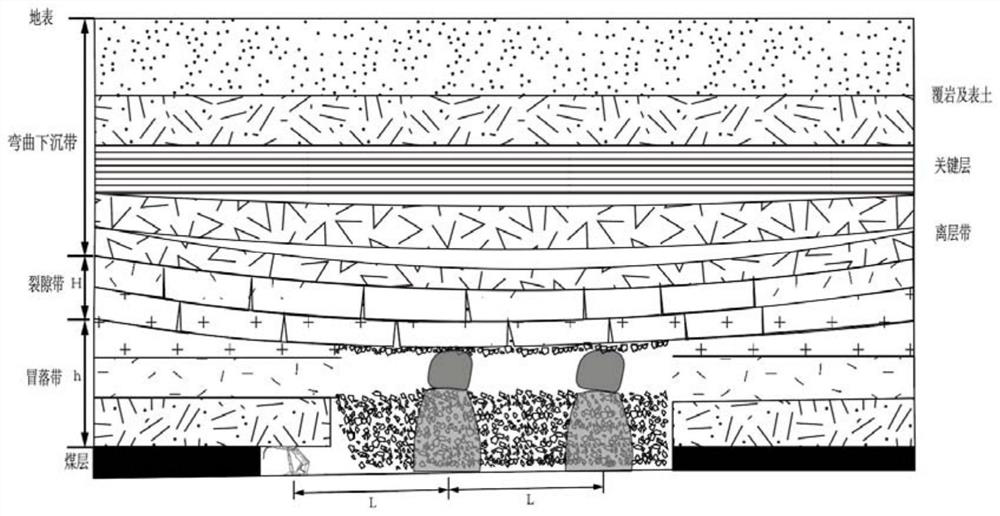

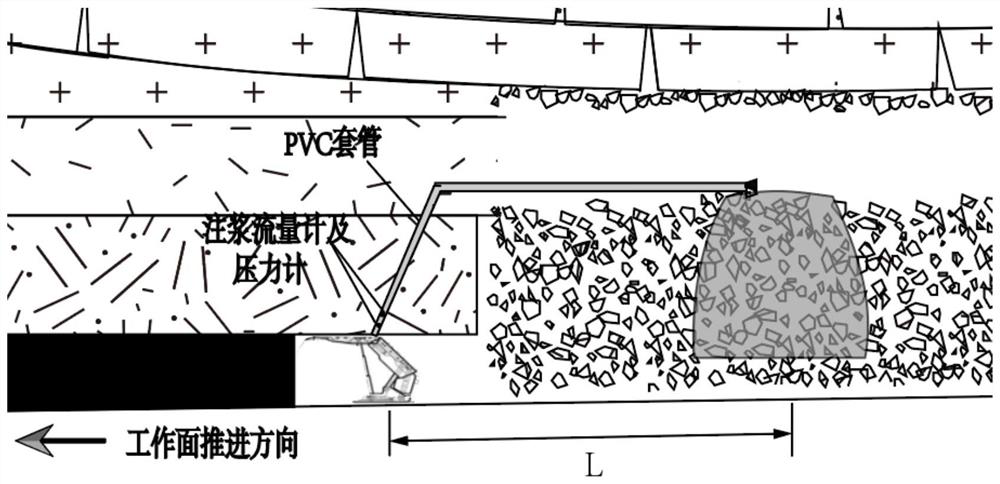

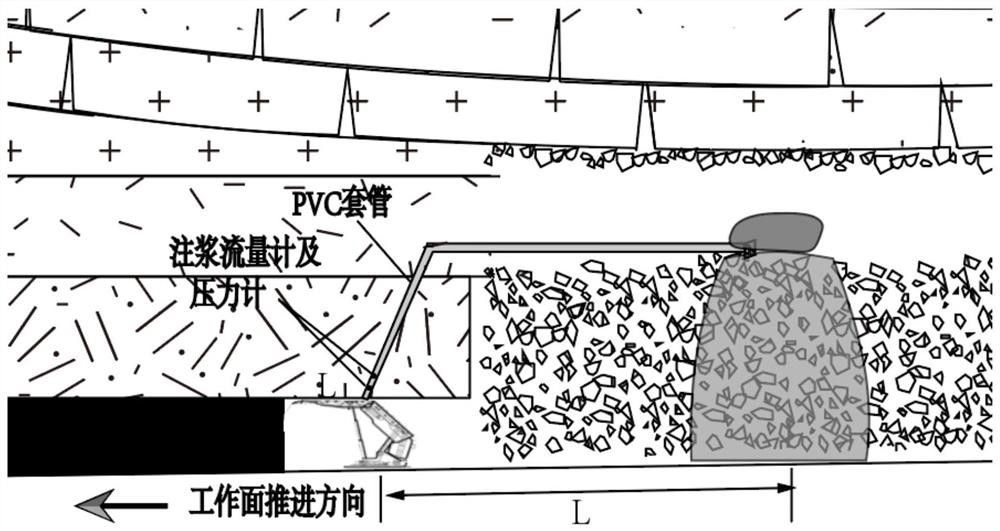

Method using gangue cementation combined with bag grouting to support and reduce loss

InactiveCN111734482AReduce transportationReduce the use effectMaterial fill-upMining engineeringCrushed stone

The invention discloses a method using gangue cementation combined with bag grouting to support and reduce loss. The method using the gangue cementation combined with bag grouting to support and reduce the loss is suitable for a goaf with natural roof collapse and incomplete filling of a broken body after mining a thin and medium thick coal seam. Firstly, downhole oblique upward directional drilling is adopted to the upper part of a caving belt, and then a PVC casing pipe and a grouting pipe are arranged; local jet grouting is carried out on caved and broken overlying strata with a spherical nozzle, and the grouting quantity and pressure are separately controlled according to a grouting flowmeter and a pressure gauge to achieve the goal of controlling the shape and size of a crushed rock cement body; and then a bag is placed on the upper part of a gangue cement body and grouting and filling are carried out to make the gangue cement body contact a roof plate, and the accurate and real-time monitoring of the expansion volume of the bag is realized through the grouting pressure gauge and the flowmeter to ensure that the effective support is formed between the bag grouting and the cemented gangue broken body.

Owner:XIAN UNIV OF SCI & TECH

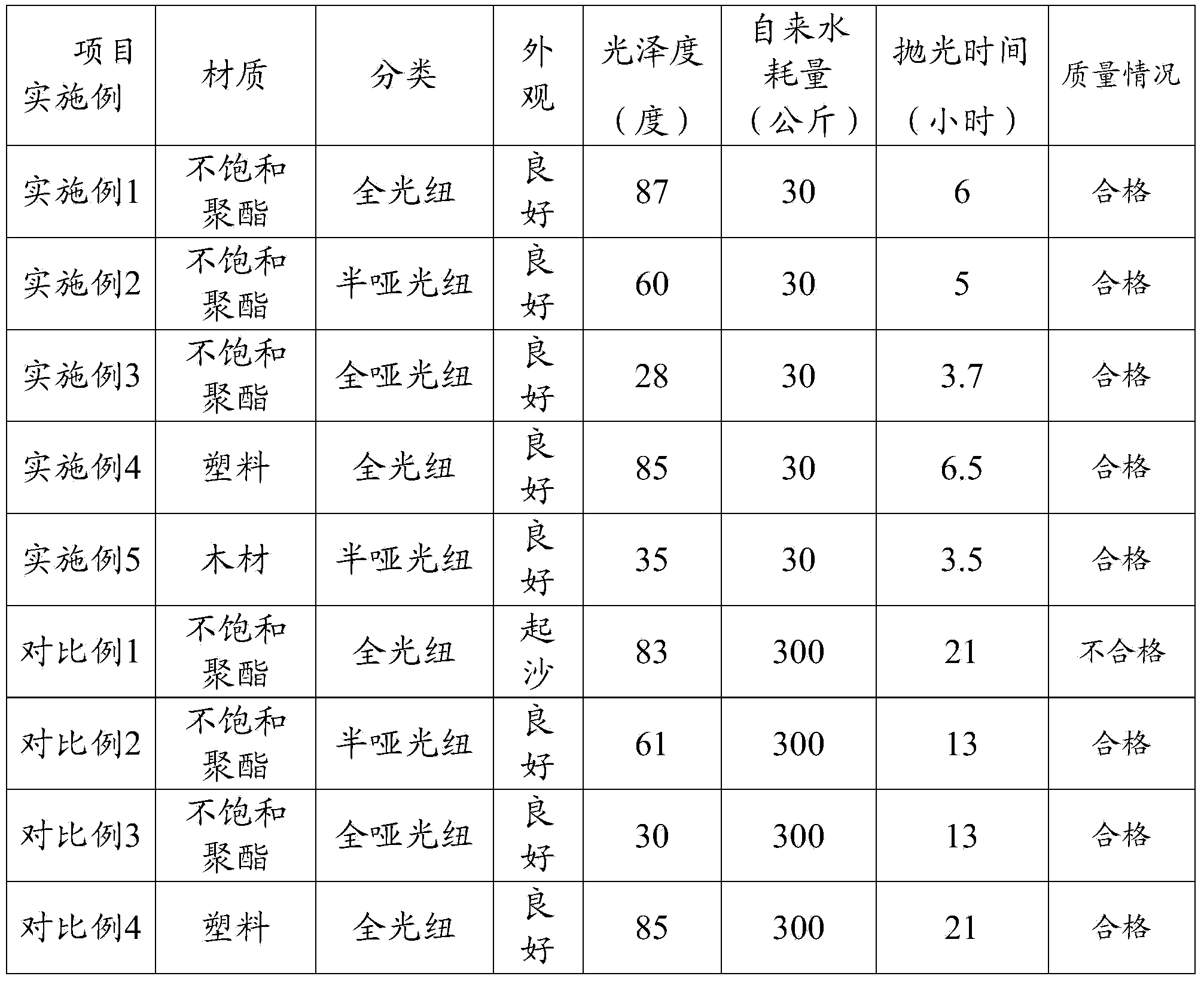

Button polishing method

ActiveCN103639884AGood lookingReduce labor intensityPolishing machinesLapping machinesMass ratioUltimate tensile strength

The invention discloses a button polishing method. High-frequency porcelain particles, buttons to be polished, silica sand powder, chemical polishing agents are put in a duplex vortex polishing machine, and water is added to immerse the materials; the mass ratio of the buttons to be polished and the high-frequency porcelain particles is 1:2-1:7, and the adding amount of the silica sand powder and the chemical polishing agents are 2% to 7% and 0.5% to 1.5% of the total mass of the solid materials; the size of the high-frequency porcelain particles is 2.5*8.0mm or 3*3mm; first polishing time is set, and the rotation speed of the vortex polishing machine is 100 revolutions / min-180 revolutions / min; second polishing time is set according to the first polishing effect till the button lustre meets requirements, and the buttons are cleaned. According to the polishing method, comparing with a traditional method, the polishing efficiency is improved by 3 times to 4 times, the polishing effect is stable, the production period is shortened, the labor cost and the worker labor intensity are reduced, and the produced button appearance is outstanding.

Owner:广东康派环创科技有限公司

Method for preparing proppant

ActiveCN101665687AEnhanced interactionImprove stabilityFluid removalDrilling compositionPolymer scienceSolvent

The invention relates to a method for preparing a surface-modified proppant, which comprises the following steps: (a) heating a proppant substrate to 100 to 240 DEG C; (b) adding resin into the heated substrate with stirring to form a mixture to allow the resin to be coated on the surface of the substrate and then adding a curing with stirring to cure the resin coated on the substrate; (c) addinga lubricant and a macromolecular surfactant with string before the mixture of the resin and the substrate begin to cake; (d) obtaining the proppant by cooling, crushing and screening the mixture obtained by the step c; and (e) spraying, impregnating or soaking the proppant by a hydrophobic macromolecular solvent and drying the proppant to obtain the finished proppant. The proppant prepared by themethod has the advantage of stable environment corrosion resistance.

Owner:内蒙古仁创沙产业有限公司

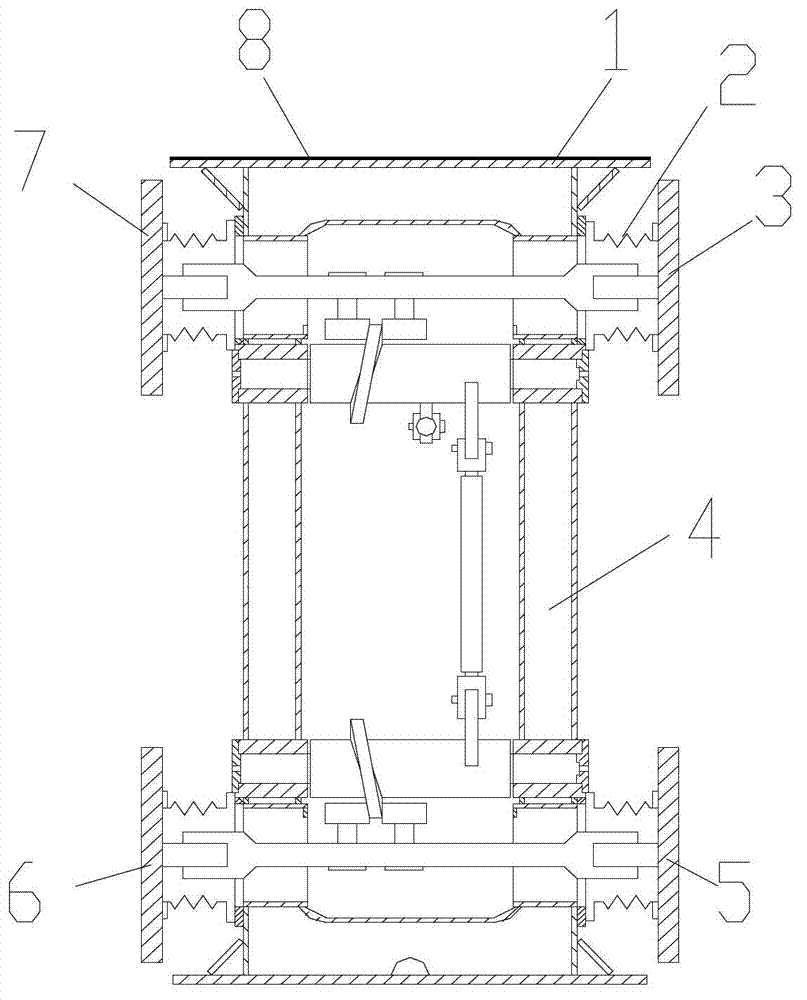

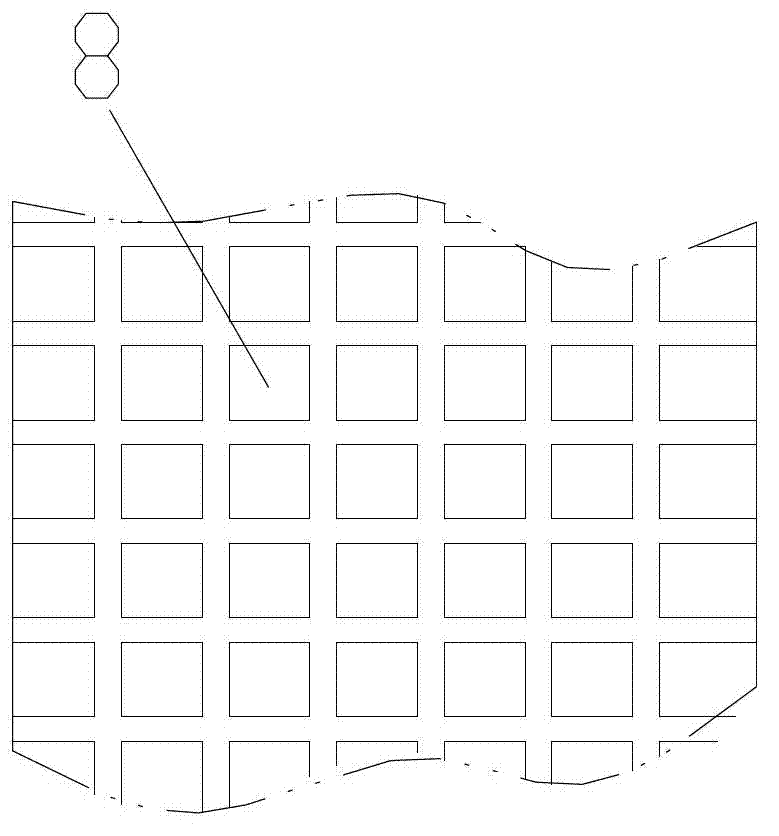

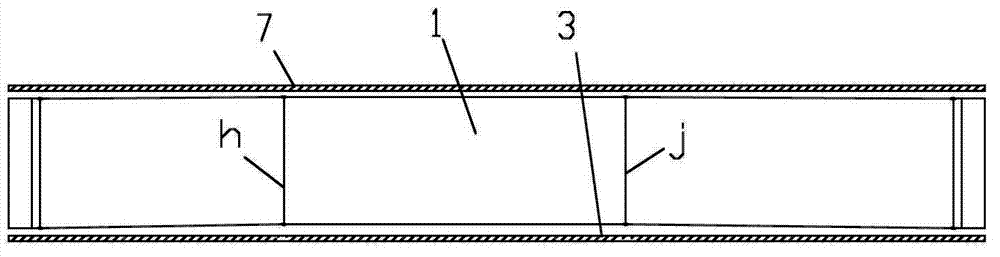

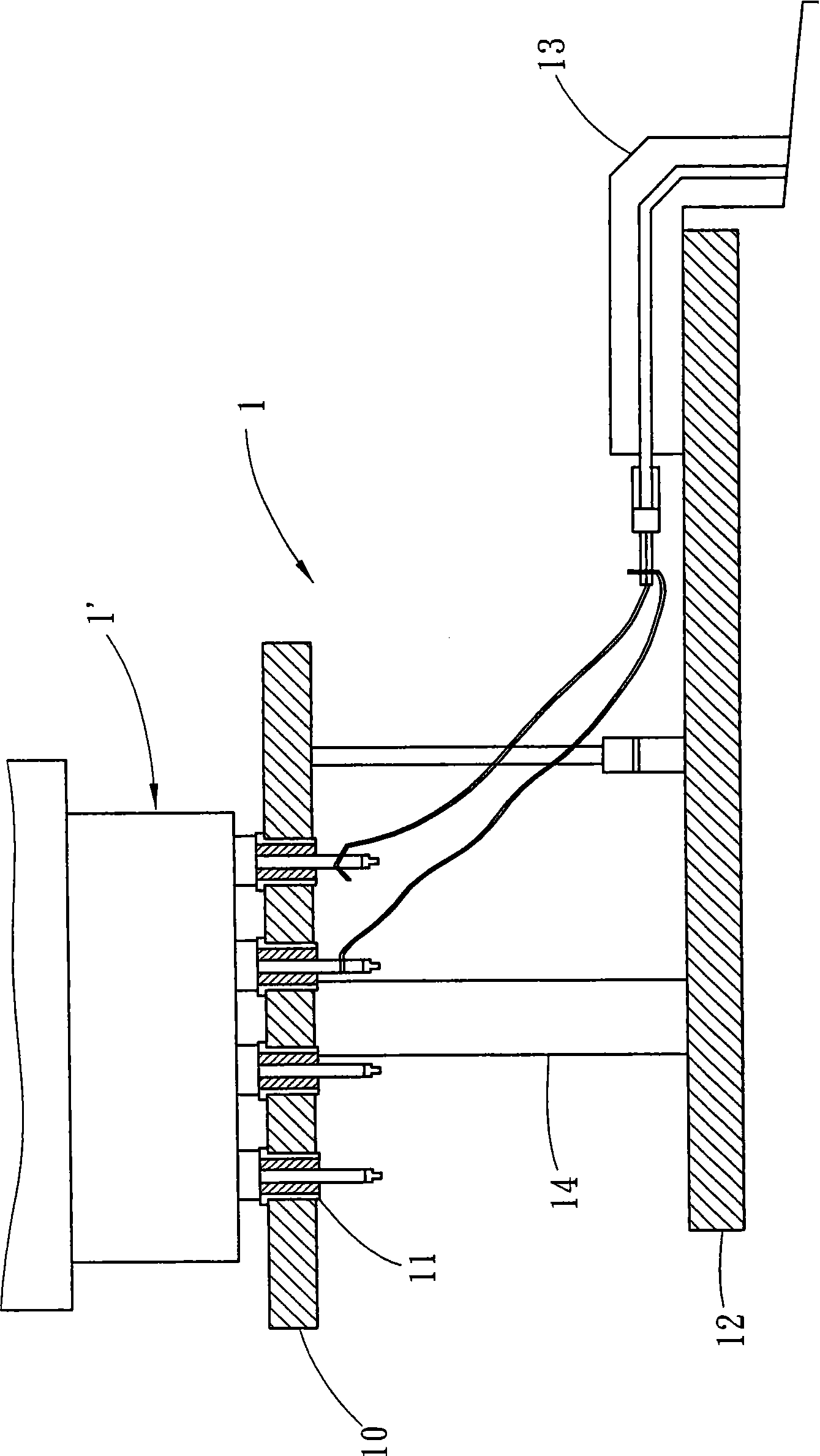

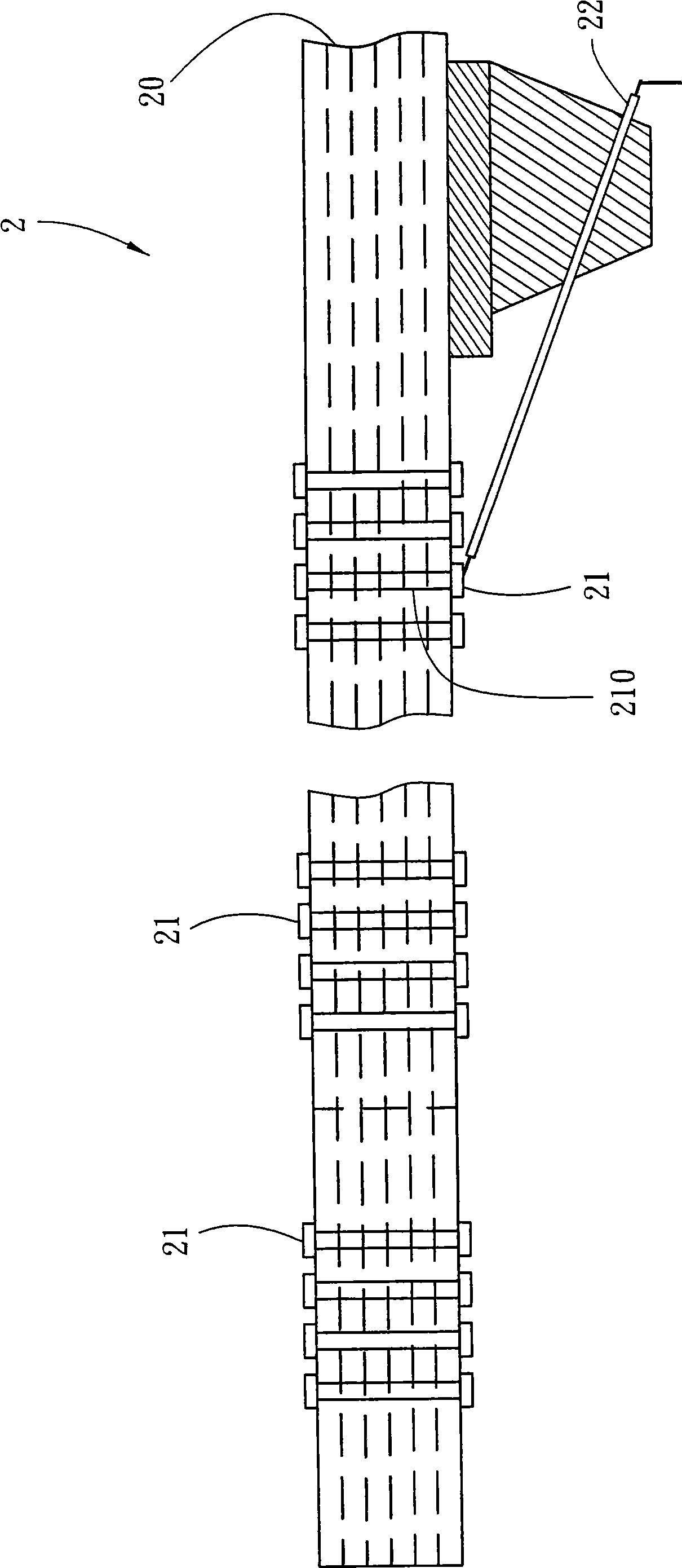

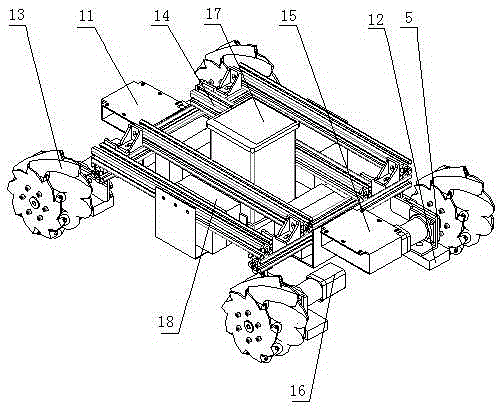

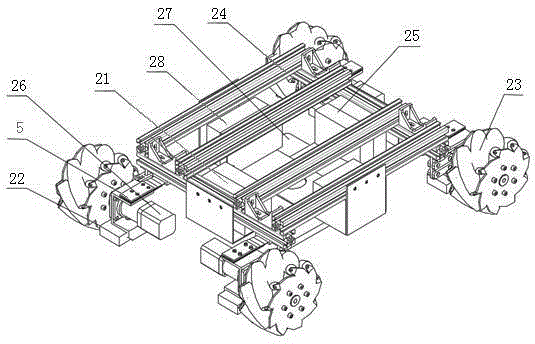

Digital flat panel ray detection ray source end robot based on Mecanum wheels

ActiveCN105301020AFlexible detectionRealize omni-directional movementNon-rotating vibration suppressionResilient suspensionsVehicle frameX-ray

The invention provides a digital flat panel ray detection ray source end robot based on Mecanum wheels. The digital flat panel ray detection ray source end robot based on the Mecanum wheels comprises a frame I, Mecanum wheels I, servo motors I, a front tracking sensor I, a rear tracking sensor I, an X-ray source, permanent magnets I and a motion control box I, the motion control box I is arranged on the frame I, the front tracing sensor I is arranged at the front end of the frame I, the rear tracking sensor I is arranged at the rear end of the frame I, the X-ray source is arranged in the middle of the frame I, the Mecanum wheels I are arranged on the two sides of the frame I respectively, the servo motors I are connected with the motion control box I, and the permanent magnets I are arranged on the two sides of the bottom of the frame I respectively. The detection robot can conduct omni-directional movement, and on one hand, advancing and retreating, lateral moving and turning around own center can be achieved; on the other hand, rotational movement around any point can be further achieved; the flexibility of the robot on weld joint detection on the curved surface of equipment can be greatly improved specially in large-scale in-service bearing special equipment such as power station boilers, spherical tanks and vertical storage tanks.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE +1

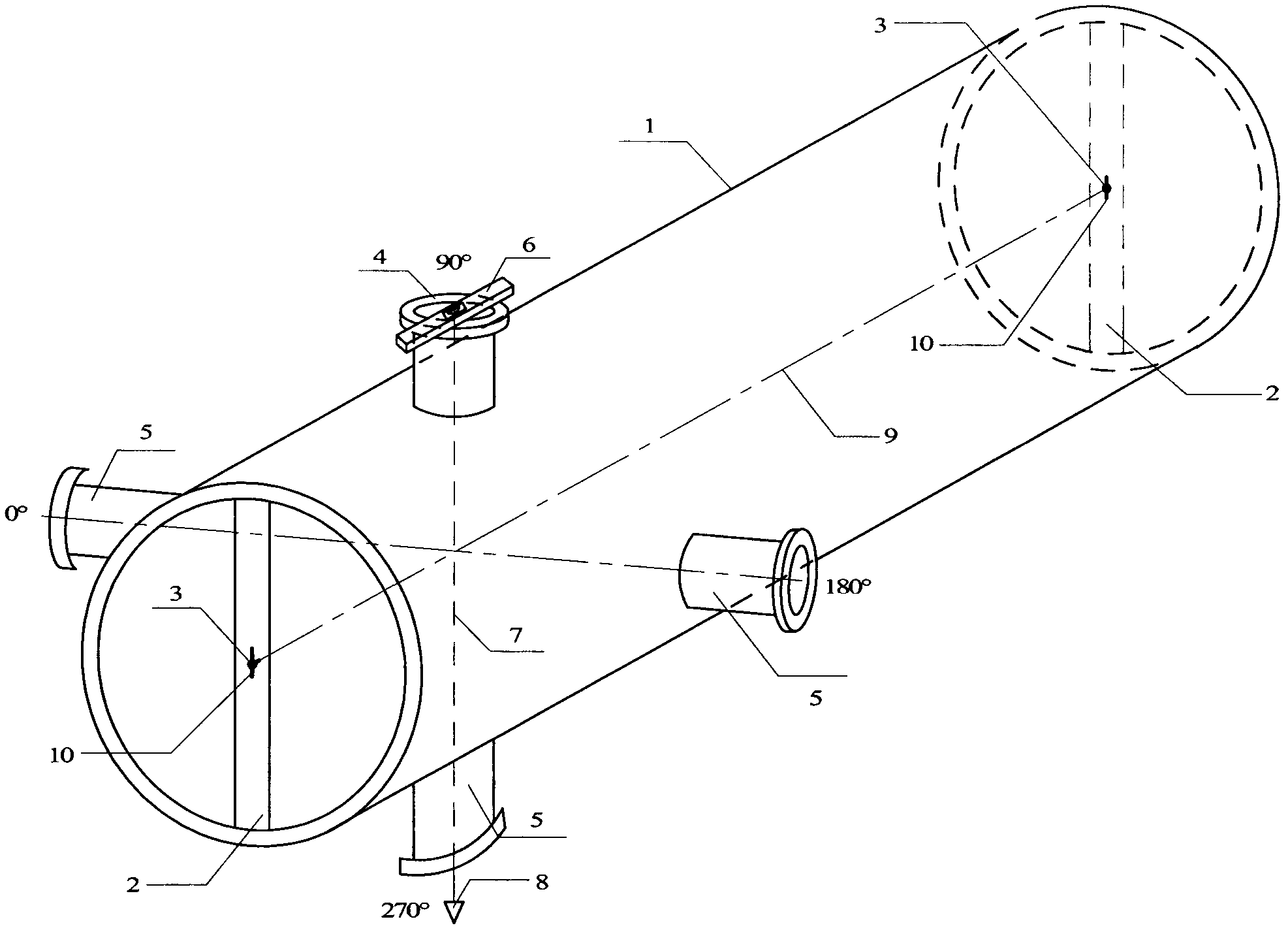

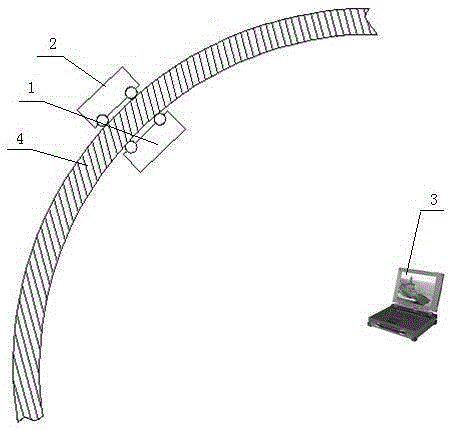

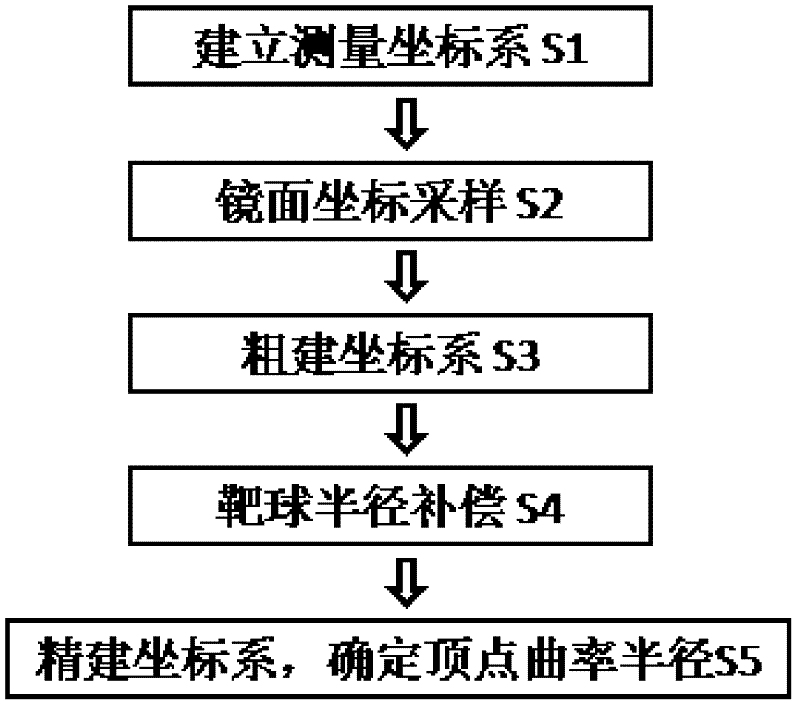

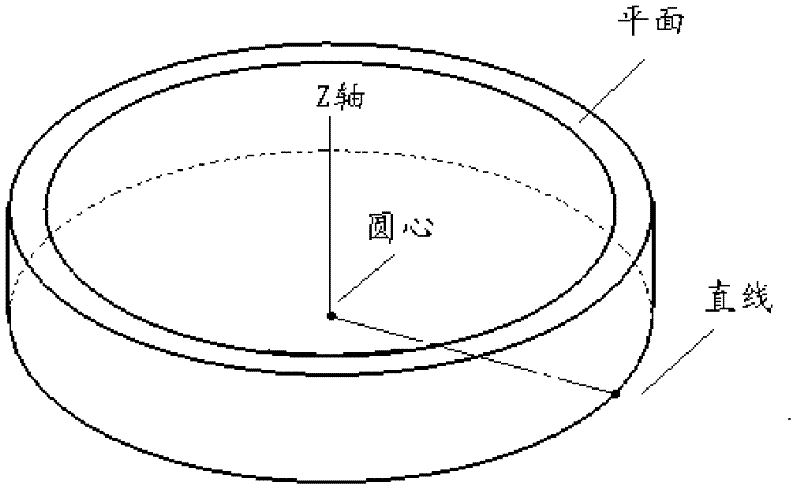

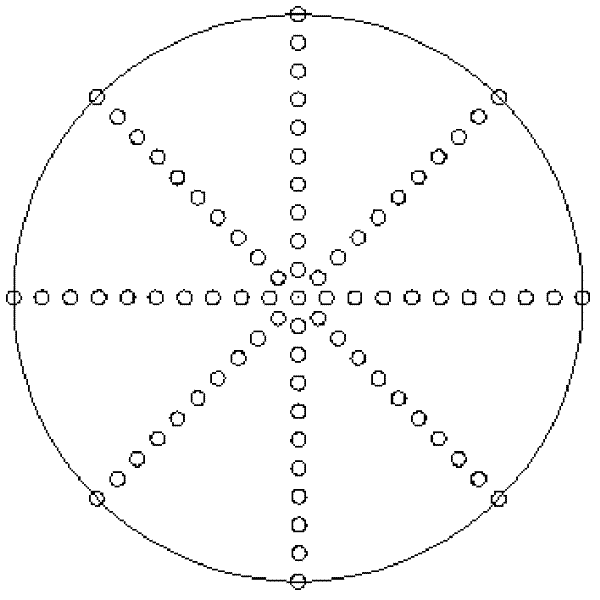

Method using laser tracker to measure aspherical surface peak curvature radius

InactiveCN102506761AImprove measurement efficiencyHigh measurement accuracyUsing optical meansOptical testingLaser tracker

A method using a laser tracker to measure the aspherical surface peak curvature radius belongs to the technical field of optical testing. The laser tracker is used for acquiring aspherical coordinate according to a specific mode, and the aspherical surface peak curvature radius can be obtained through data processing and optimized search algorithm. The method is a novel method for measuring the aspherical surface peak curvature radius, is suitable for in-place measurement of the aspherical surface peak curvature radius in manufacturing and processing aspherical surfaces and in particular has important application values on measurement of the large-bored-diameter aspherical surface peak curvature radius.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Manufacture method of chemicals independent cargo hold in hull

A manufacture method of a chemicals independent cargo hold in a hull is characterized by including the steps of designing drawing stock, and directly manufacturing stainless steel parts to be machined, in a manufacturer; scribing steel material, cutting and blanking; cold-machining the stainless steel parts; assembling and welding the stainless steel parts cold-machined; assembling and welding section by section; assembling an independent cargo hold; launching after pickling-passivation tightness test. The stainless steel parts are directly manufactured by the stainless steel manufacturer, so that expenditure on purchasing machining equipment is greatly saved, management cost is reduced, and construction period is short; in addition, the parts, in contact with liquid cargoes, of both side of the cargo hold are made of double-phase stainless steel, the part, in contact with the liquid cargoes, of one side of the cargo hold is made of stainless steel composite plates, and accordingly the cargo hold has high strength and corrosion resistance and the cost is saved; the process is reasonable, manufacture period is short, the cost is low, the manufactured independent cargo hold is high in strength, high in tightness and resistant to corrosion, and the needs for carrying high-corrosive chemicals are met.

Owner:ZHOUSHAN PENGLAI SHIP REPAIR & BUILDING CO LTD

Health-care preserved eggs and method for preparing same

The invention relates to a method for preparing health-care preserved eggs. The method comprises the following steps of: soaking eggs into vinegar, soaking eggs into filter solution of traditional Chinese medicines, and wrapping eggs with mud to obtain the finished product. The invention also relates to health-care preserved eggs prepared by the method, and the health-care preserved eggs have the effects of preventing calculi, strengthening the kidney, protecting the liver and the like.

Owner:HAIAN TINGTING AGRI & SIDELINE PRODSCO +1

Method for producing organic fertilizer by using rice straws and livestock and poultry manures

InactiveCN102746041AHelps dehydration efficiencyImprove dehydration efficiencyBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAnimal feces

The invention provides a method for producing an organic fertilizer by using rice straws and livestock and poultry manures, and relates to the technical field of an organic fertilizer production process. According to the method, livestock and poultry manures and crushed straws are stirred, and subjected to stacking anaerobic fermentation, crushing, and packaging to prepare the organic fertilizer. According to the present invention, characteristics of water absorption, deterioration, and the like of the waste rice straws are mainly adopted; during the organic fertilizer production process, a large amount of the waste rice straws can be added before the livestock and poultry manures are subjected to dewatering and fermentation so as to increase dewatering efficiency, accelerate deterioration process, and further increase organic matter content after humic improving; and the method of the present invention has characteristics of relatively available raw material, low energy consumption, and low investment, and provides an important means for sustainable agriculture development.

Owner:YANGZHOU ZHANPENG FERTILIZER

Improved manufacturing method of prestressed concrete cylinder pipe

InactiveCN101987477AImprove anti-corrosion performanceHigh strengthShaping reinforcementsEpoxyPre stress

The invention discloses an improved manufacturing method of a prestressed concrete cylinder pipe, which, besides the four processes of making a steel cylinder, forming a concrete cylinder pipe core, winding prestressed steel wire on the pipe core and making a concrete mortar protective layer outside the steel wire, also comprises: spraying a layer of liquid epoxy resin on the prestressed steel wire while winding the annular prestressed steel wire; and roll-jetting concrete mortar outside the epoxy resin which is not solidified, and thus, accomplishing the manufacturing of the protective layer. The method improves the anticorrosion performance of the prestressed steel wire and the strength of the concrete mortar protective layer coated outside, simplifies production process and shortens production period.

Owner:XINJIANG GUOTONG PIPELINE CO LTD

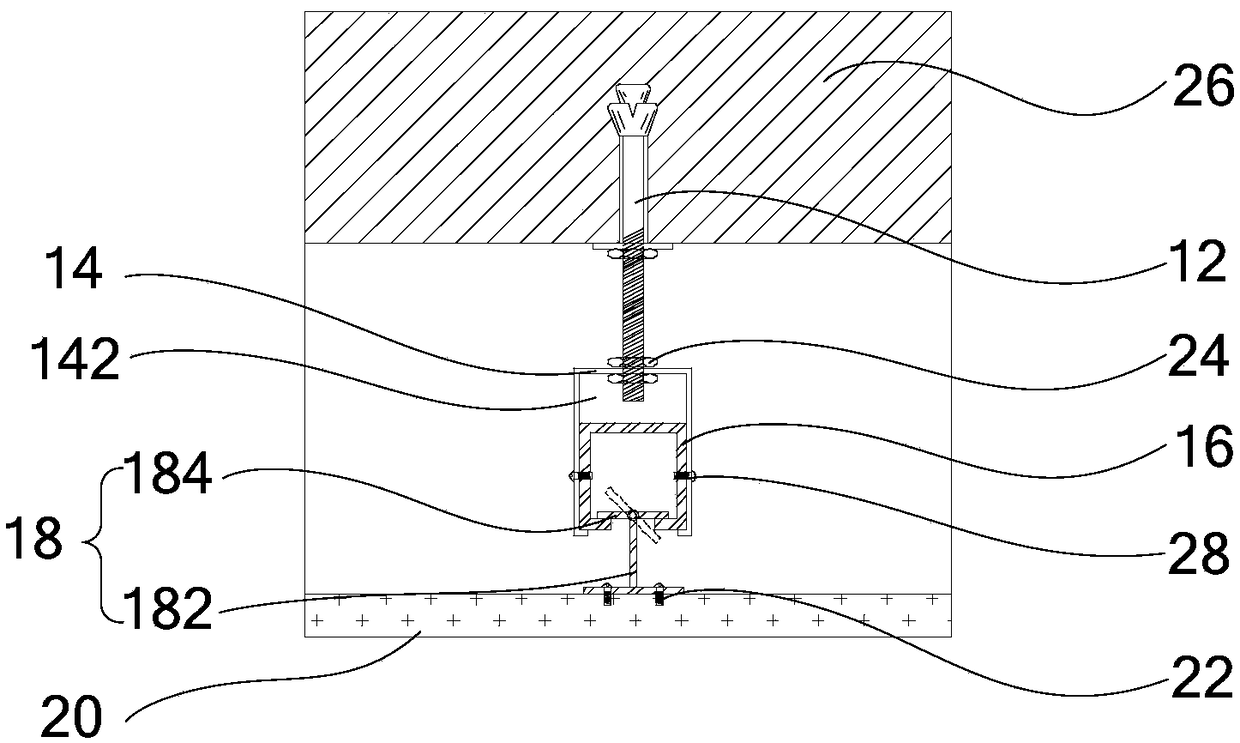

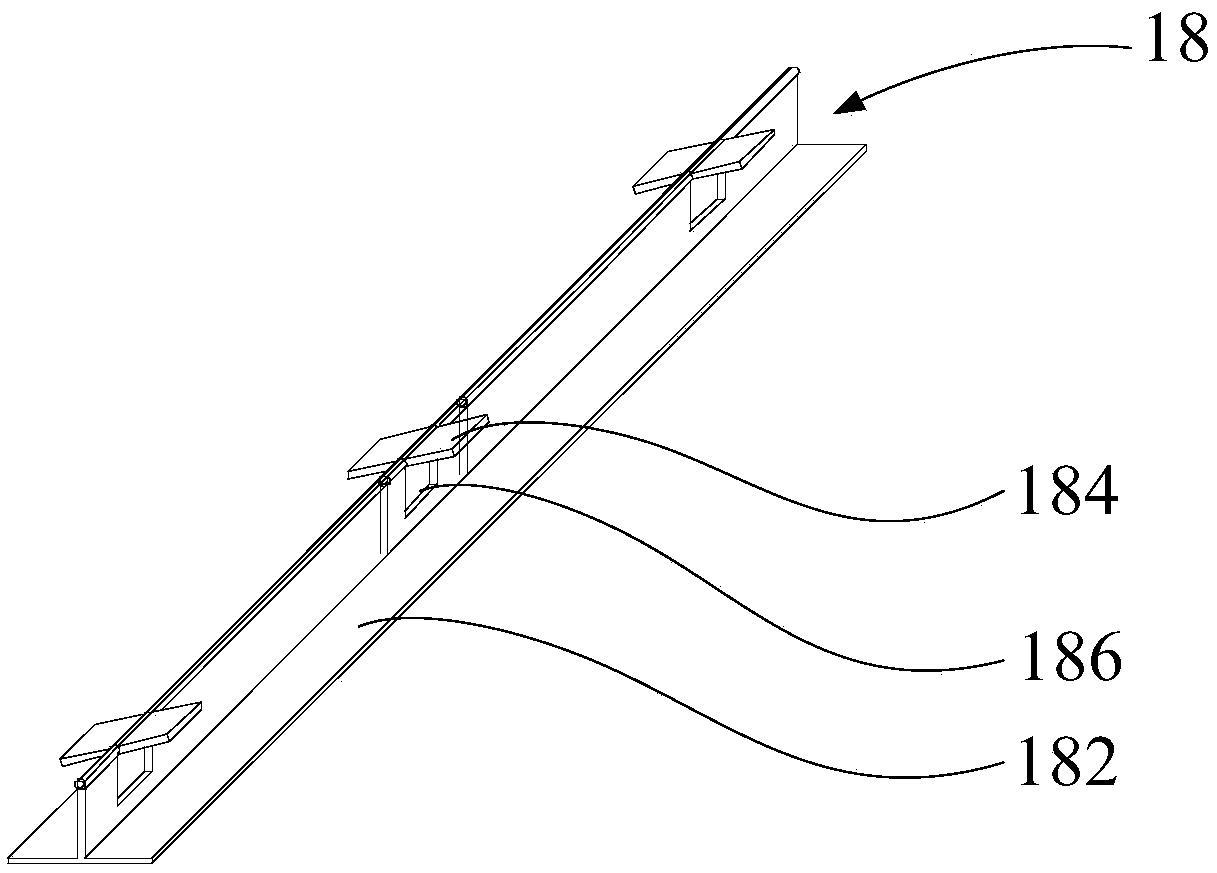

Ceiling keel system and method for installing ceiling keel system

InactiveCN109235737ASimple manufacturing processReduce manufacturing difficultyCeilingsEngineeringBuilding construction

The invention provides a ceiling keel system and a method for installing the ceiling keel system; the ceiling keel system is fixed on the wall surface and comprises a hanging piece, a connecting piece, a main keel, an auxiliary keel, a panel and a screw; one end of the hanging piece is fixed on the wall surface; the connecting piece is provided with a first fixing groove, and one end of the connecting piece is connected with the other end of the hanging piece; the main keel is provided with a second fixing groove, and the main keel is embedded in the first fixing groove; the auxiliary keel comprises a first auxiliary keel body and a connecting part, the connecting part is rotationally connected with the first auxiliary keel body, and the connecting part is embedded in the second fixing groove to make the main keel connected with the auxiliary keel; the panel is fitted to the lower surface of the first auxiliary keel body; at least two screws pass through the first auxiliary keel body and the panel to connect the auxiliary keel to the panel. As the ceiling keel system is of a split type structure, the industrialization and batch installation of all components can be achieved, thereby reducing production cost and shortening construction period.

Owner:周建武

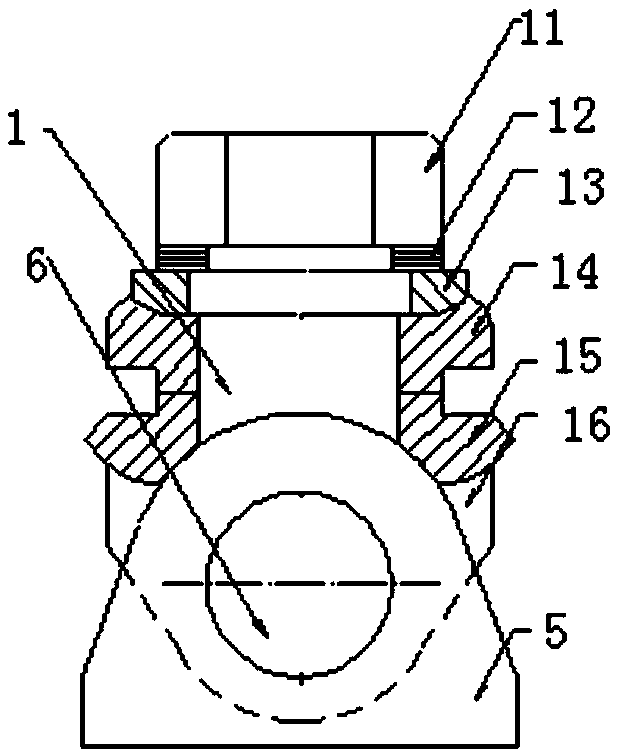

Mounting assisting device for three-point spherical bearing and mounting-welding method of mounting assisting device

ActiveCN105499891AReduce manufacturing costShorten the production periodWelding/cutting auxillary devicesArc welding apparatusSpherical bearingEngineering

The invention discloses a mounting assisting device for a three-point spherical bearing and a mounting-welding method of the mounting assisting device. The mounting assisting device comprises three-point support seats, a dummy shaft pin and temporary rigid supports II, wherein three points are uniformly formed at intervals of 120 degrees along the peripheral direction of a support ring, two three-point support seats are respectively symmetrically arranged on two sides of the center line of the three points, and the dummy shaft pin is located between the inner sides of the two mutually symmetric three-point support seats; and the temporary rigid supports II are symmetrically arranged relative to the center line outside the two mutually symmetric three-point support seats. Two sides of the three-point support seats are supported by the temporary rigid supports II, the dummy shaft pin is arranged between the three-point support seats to maintain the required mounting size, the temporary rigid supports II and the dummy shaft pin act together to enable the axial direction of the three-point support seats to be parallel to the plane on which the support ring is located, so that the side surfaces of the three-point support seats are vertical to the plane on which the support ring is located, the distances from the upper parts to the lower parts of the inner sides of the two three-point support seats are equal, and the mounting and the welding are prepared.

Owner:ANHUI MASTEEL ENG & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com