Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

580results about "Ingredients weighing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

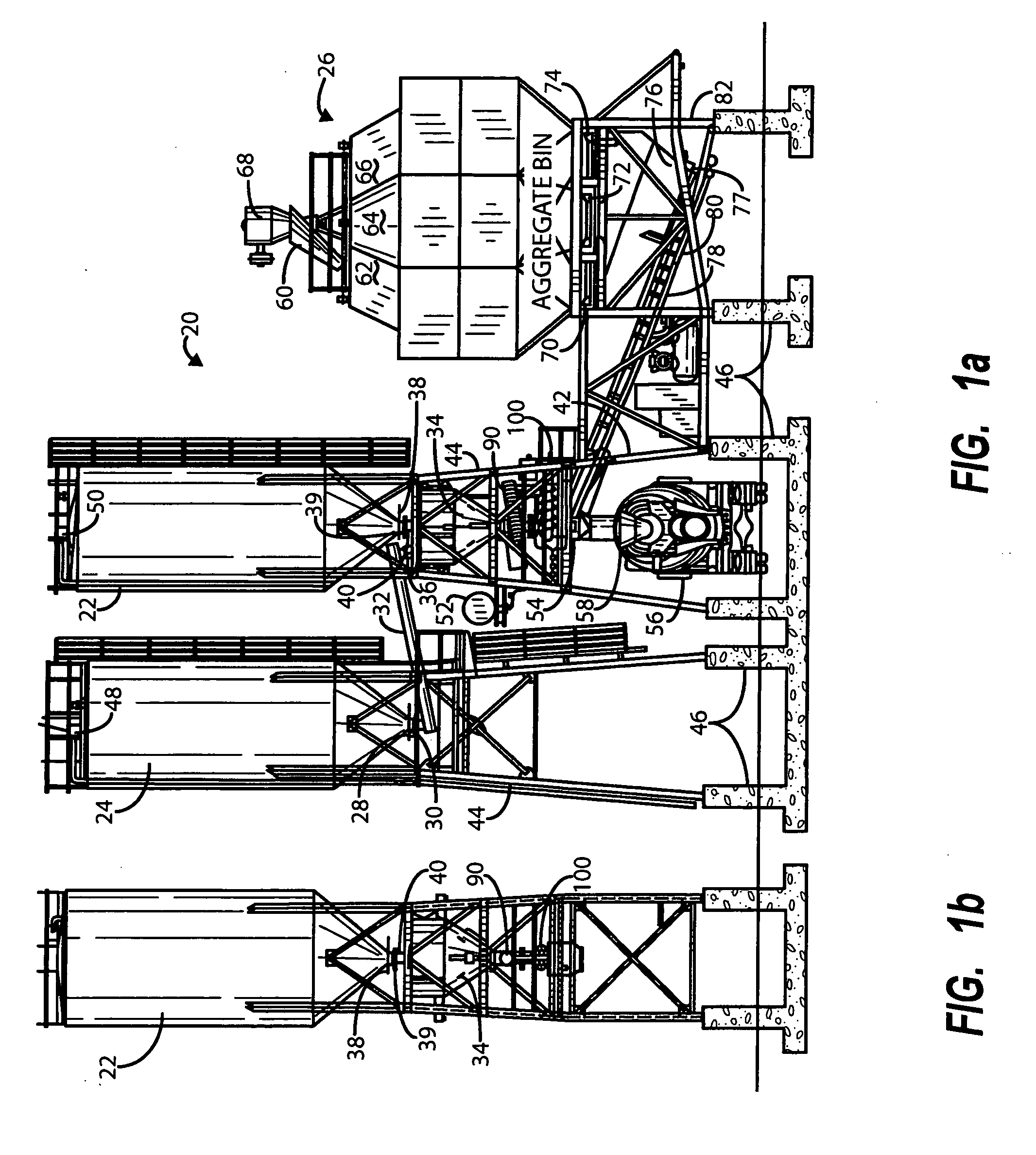

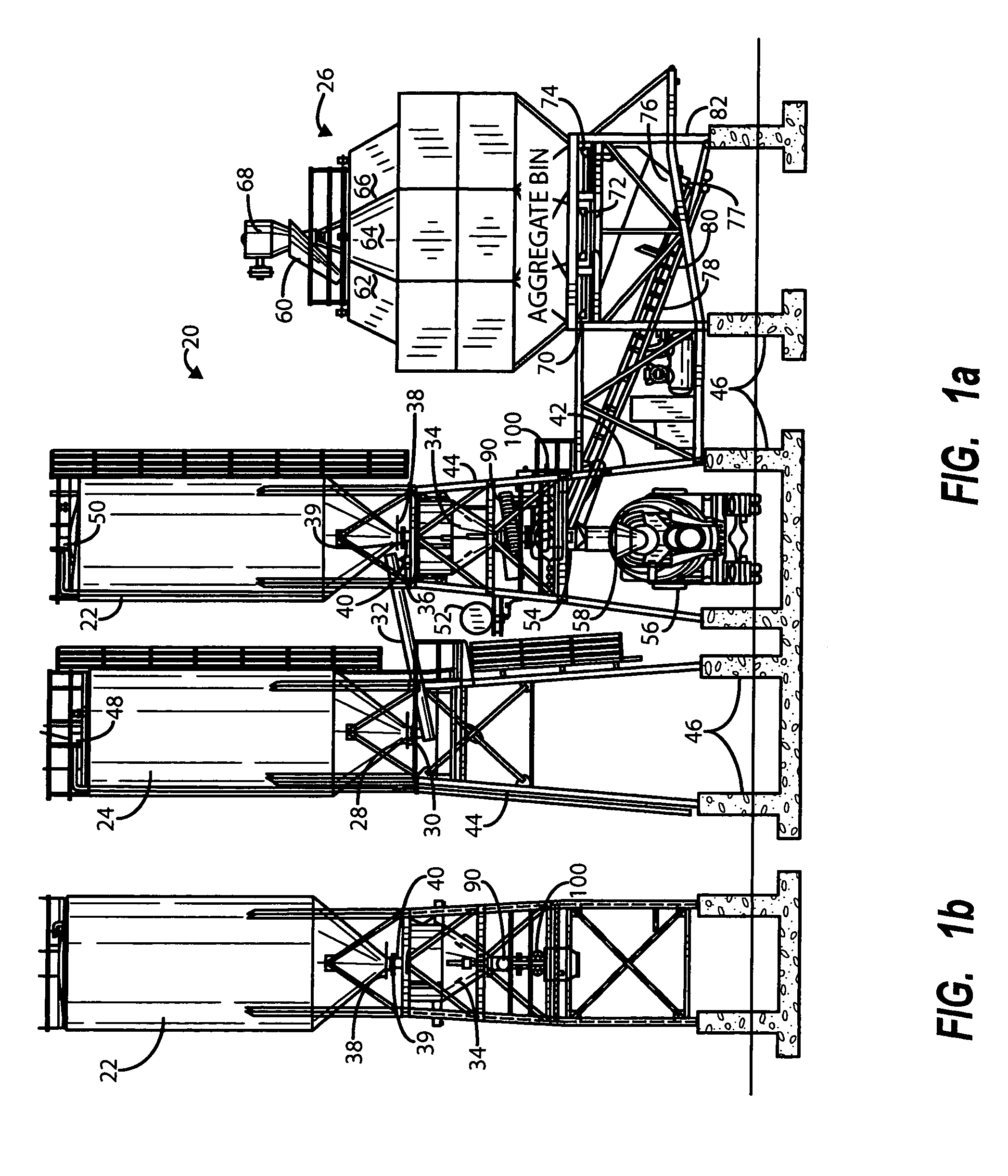

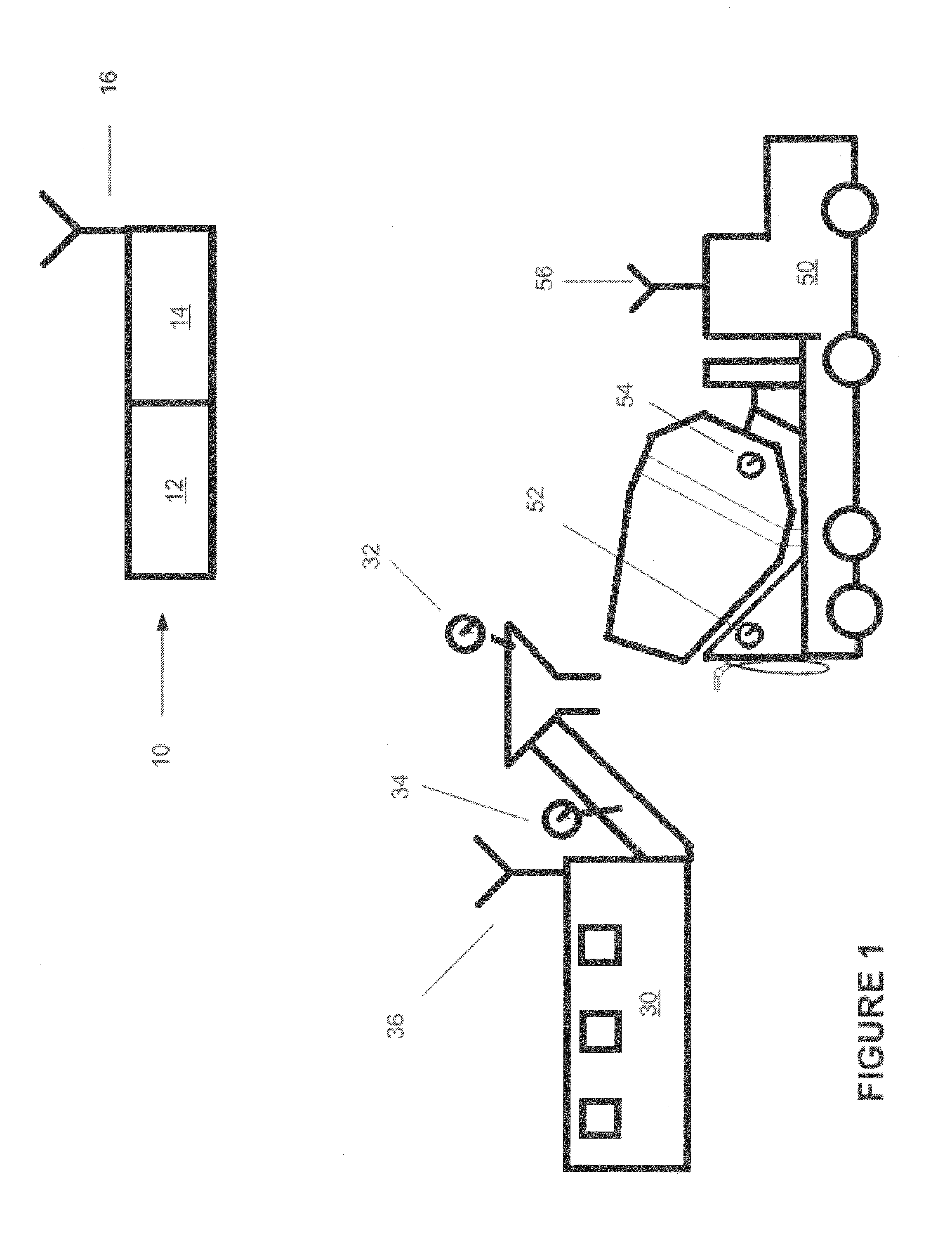

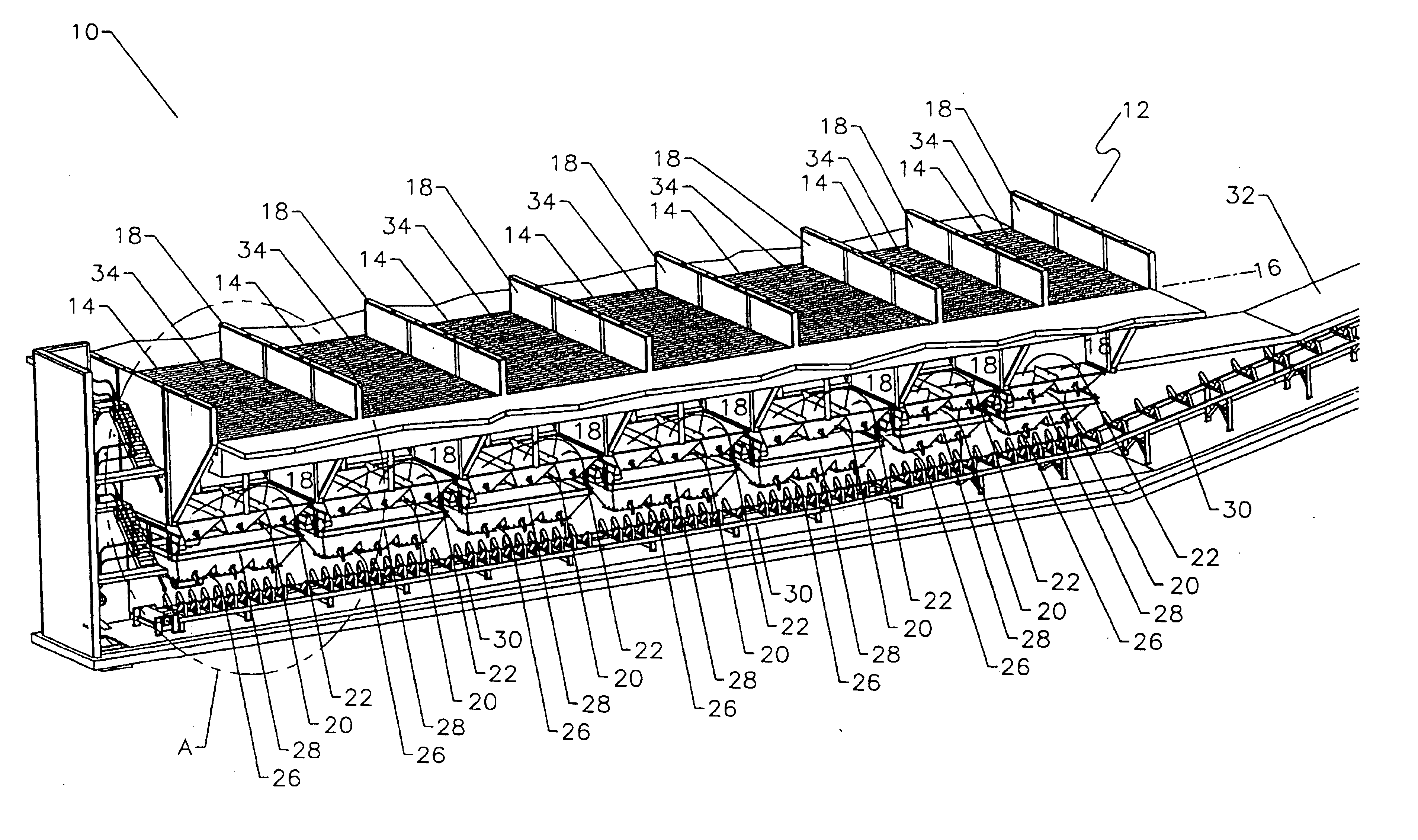

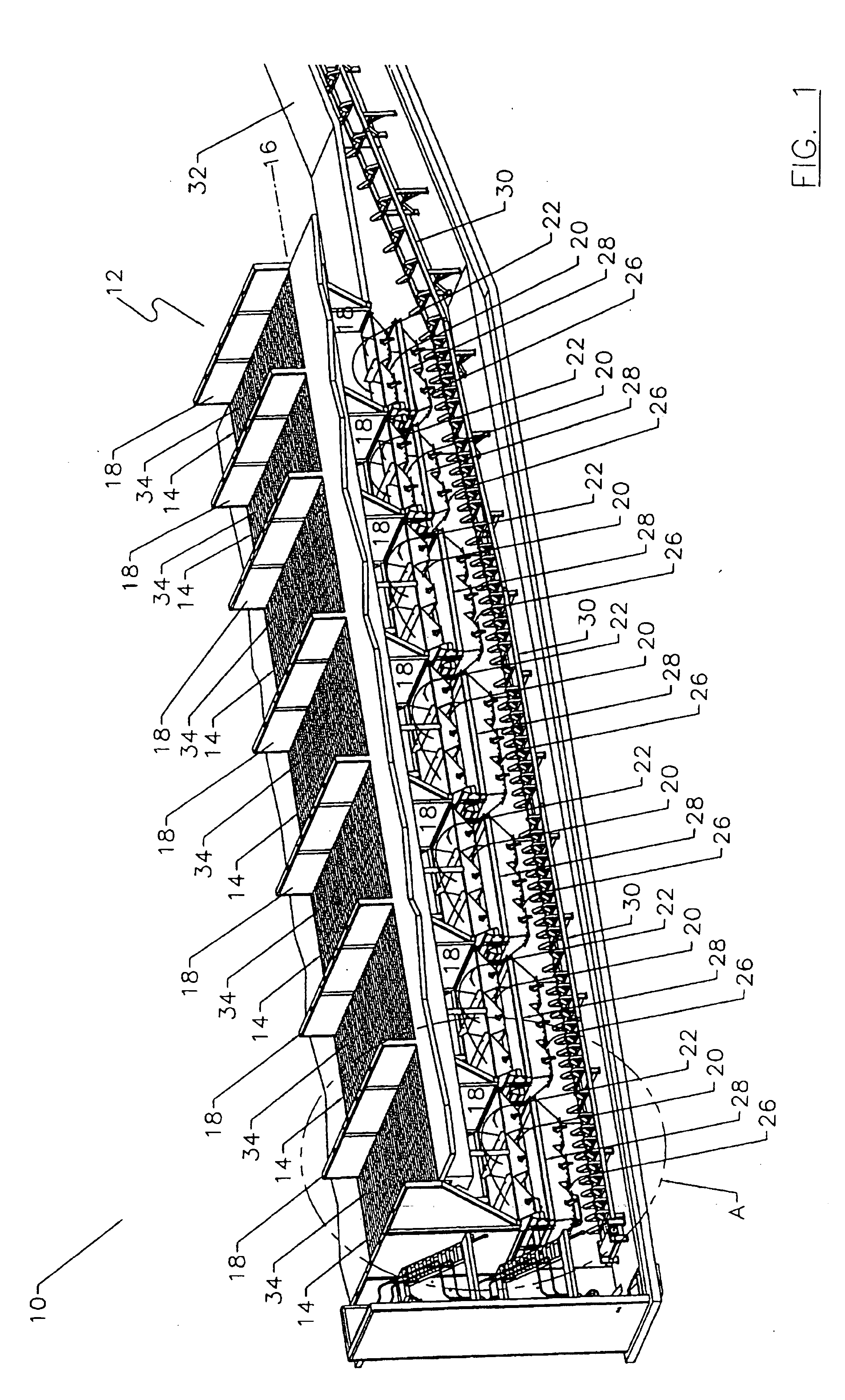

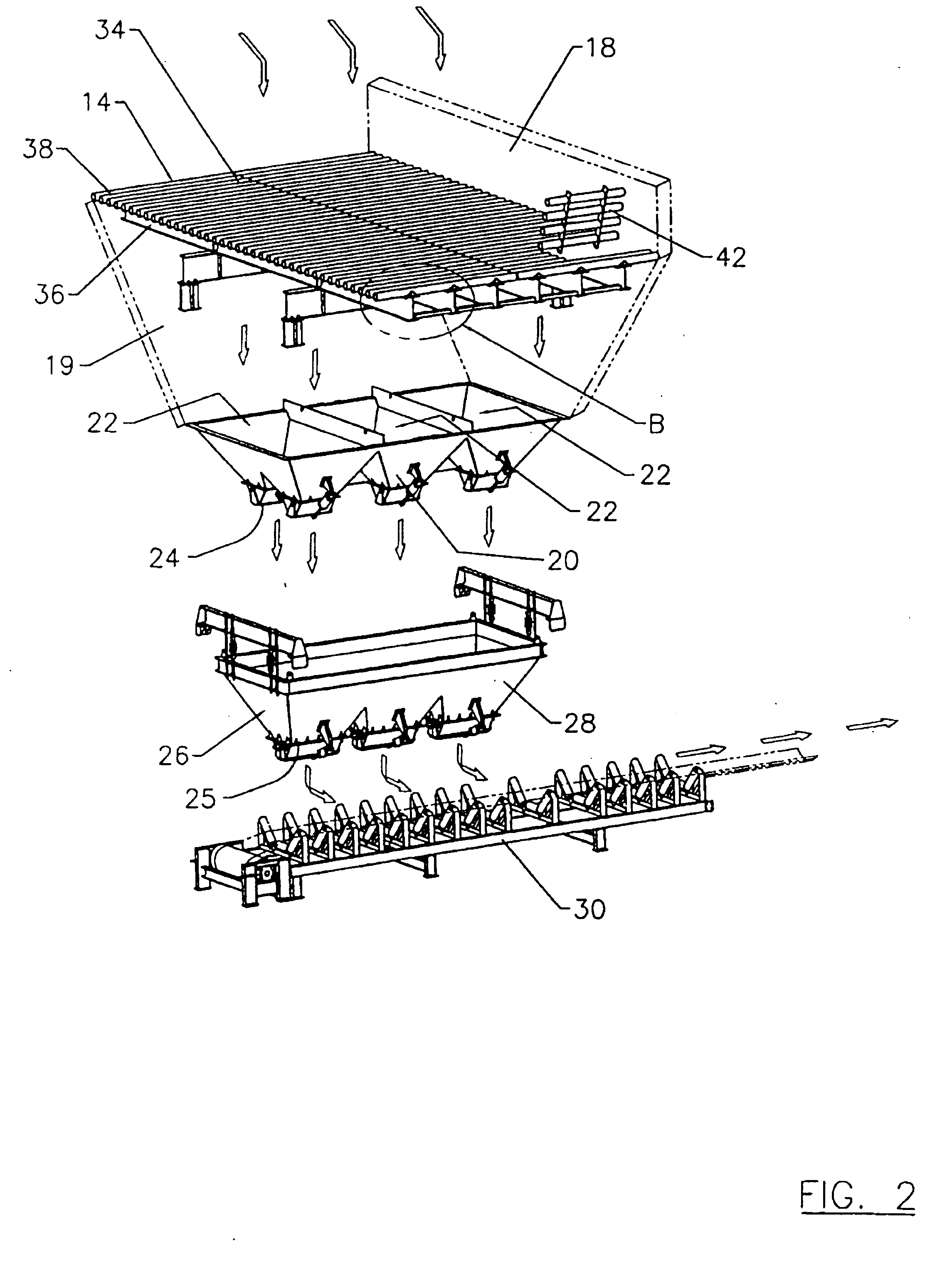

Low profile mixing plant for particulate materials

InactiveUS20050219942A1Mixing methodsMixing operation control apparatusParticulatesProcess engineering

A low profile particulate mixing plant is described. The plant is suitable for discharging the components of a particulate mixture. The plant includes a pair of storage receptacles located side-by-side. Each of the receptacles has a discharge adjacent an underside thereof to transfer a component of the particulate material mix within each receptacle to a respective conveyor at a height adjacent to ground level. The conveyor elevates the components from the discharges to a mixing station spaced from the receptacles. The plant is suitable for use as a concrete mixing plant.

Owner:WALLGREN KRIS

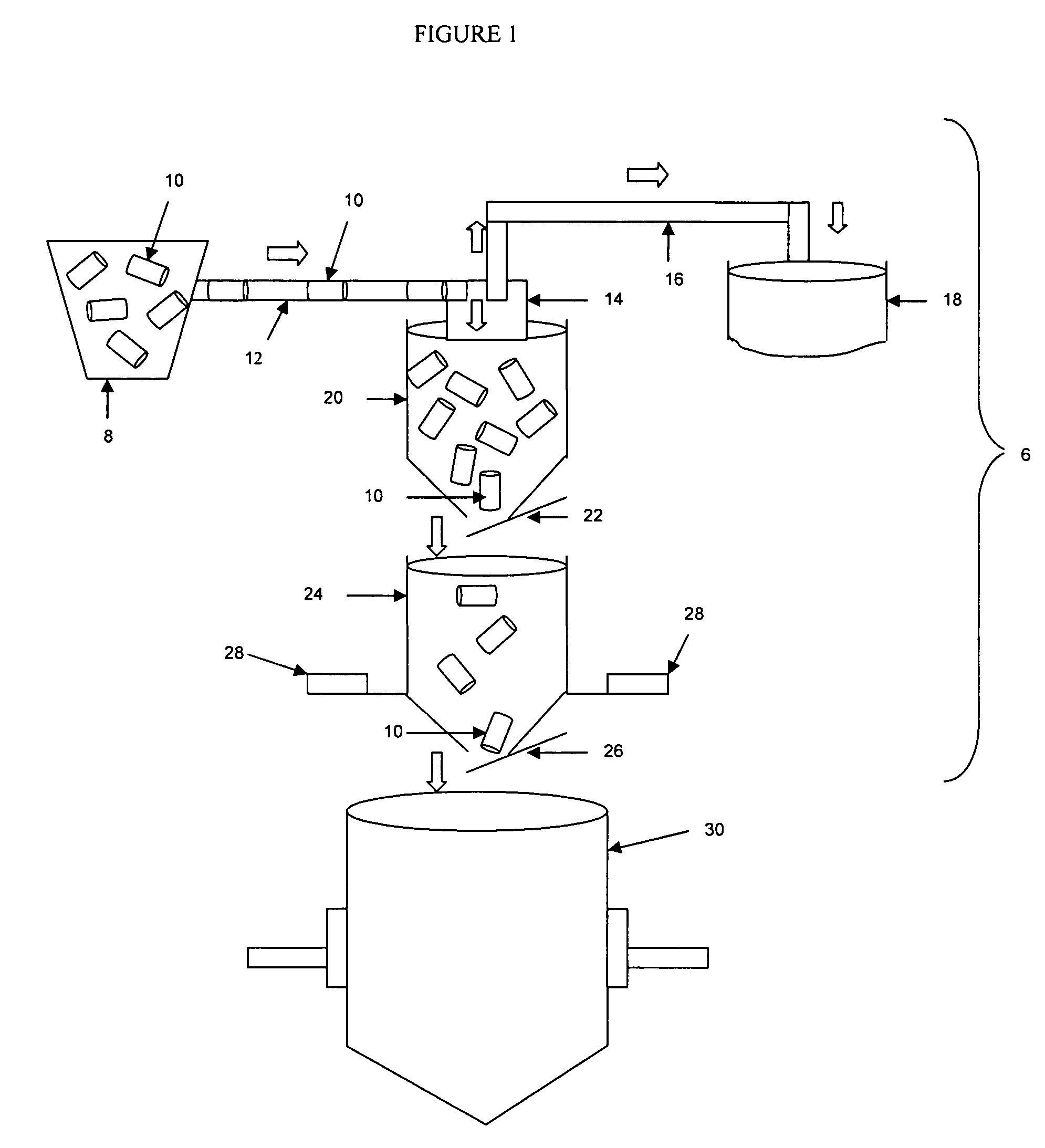

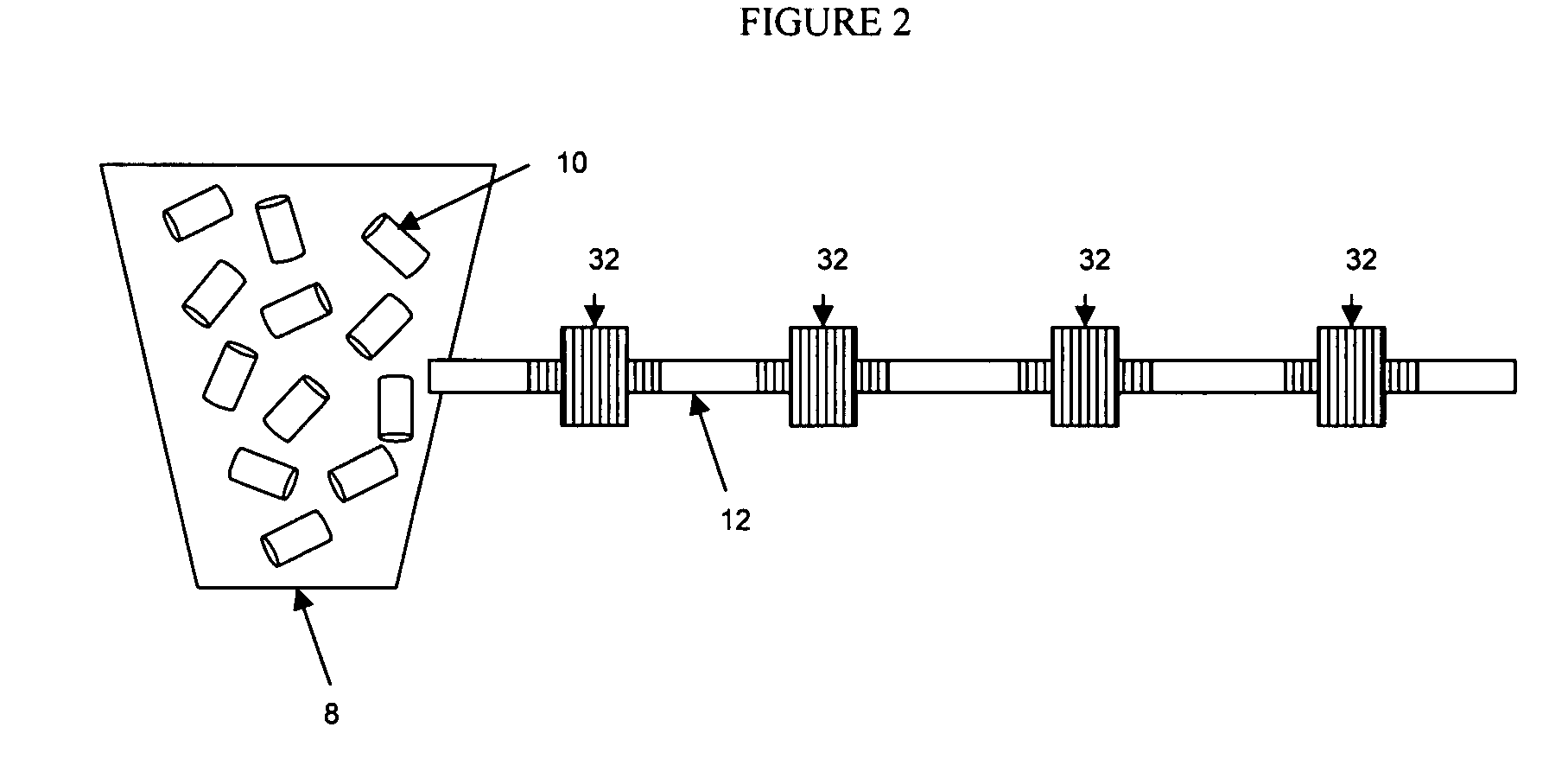

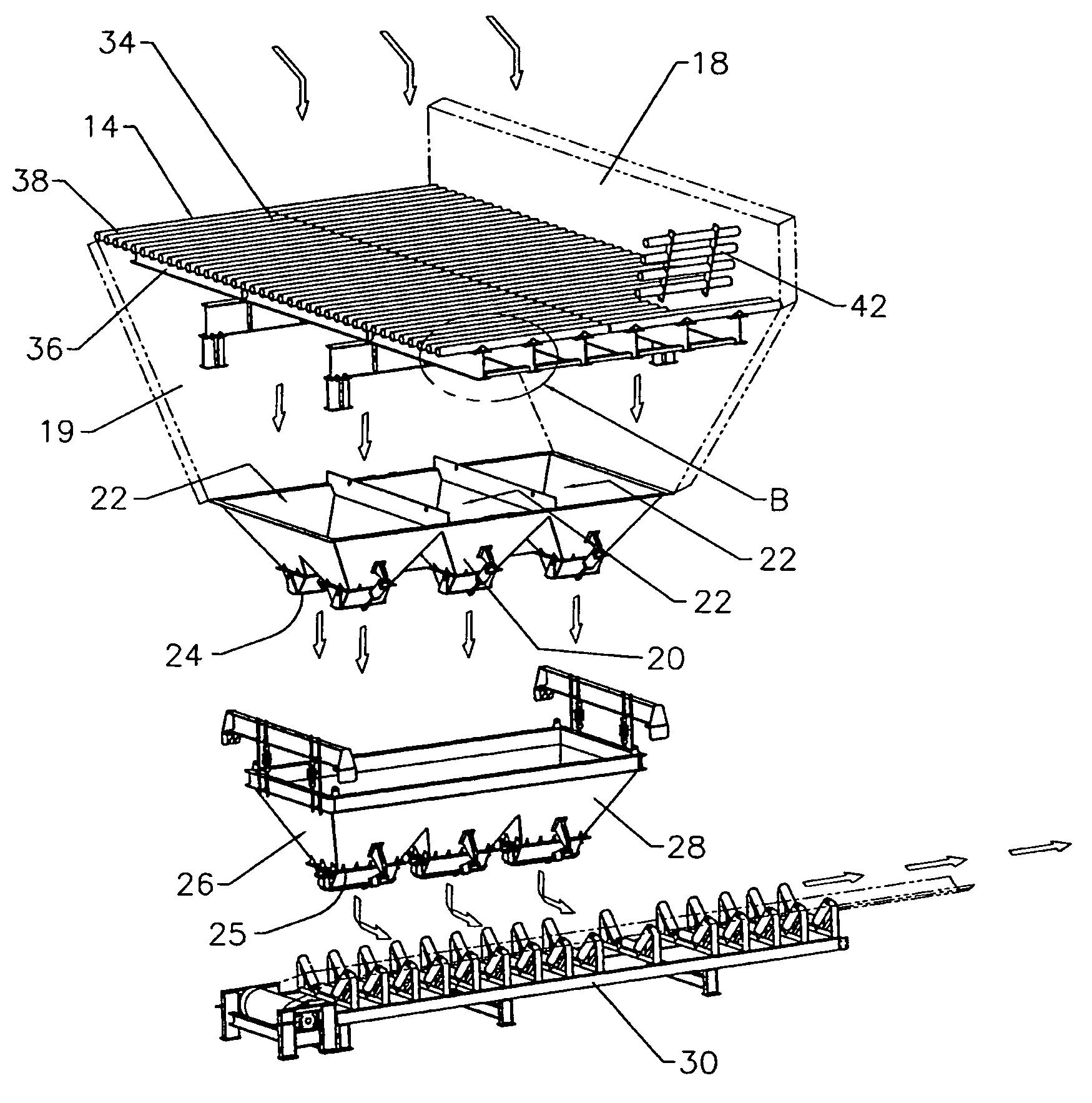

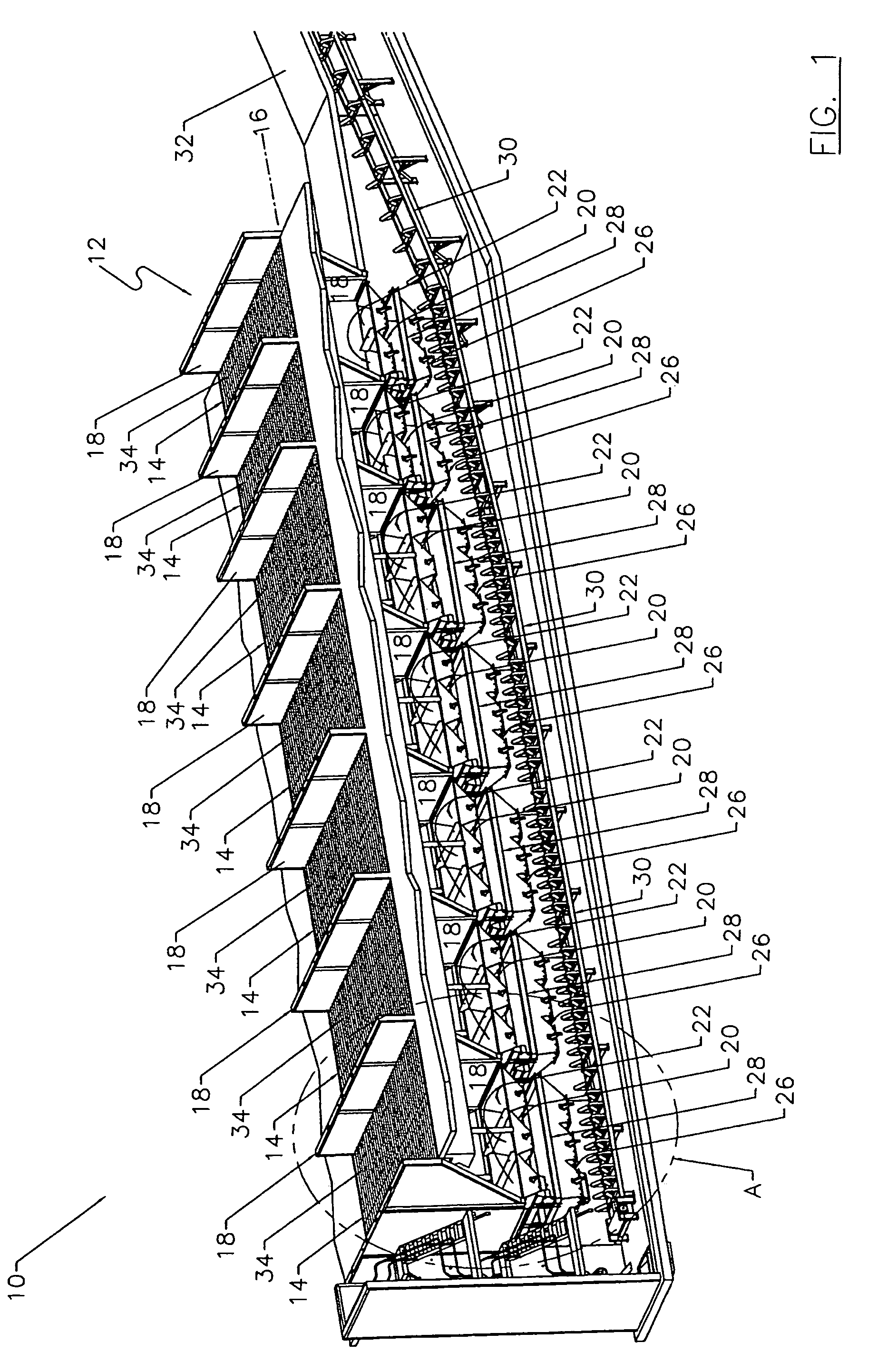

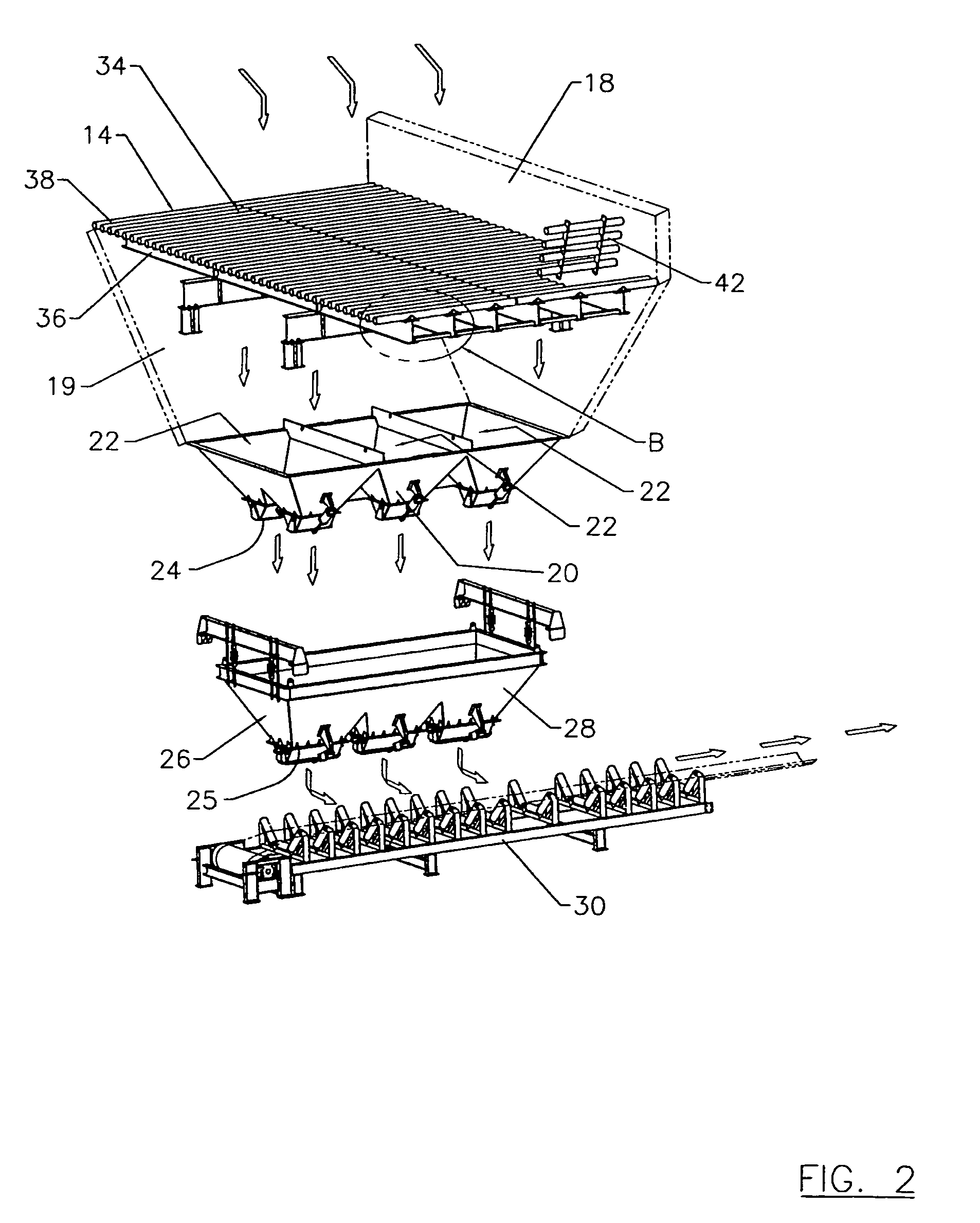

Unitized fibrous construct dispensing system

InactiveUS7228990B2Without affecting structural integrityAssist with stability of systemMixing operation control apparatusLiquid transferring devicesFiberBiomedical engineering

The present invention is directed to a method and system for transporting and dispensing fibers into an aggregate mix, and more specifically, to a method and system for transporting and dispensing unitized fibrous constructs into a mix without affecting the structural integrity of the unitized construct. The dispensing system will transport and dispense unitized fibrous constructs intact into a cementitious mixture.

Owner:FABPRO ORIENTED POLYMERS L L C

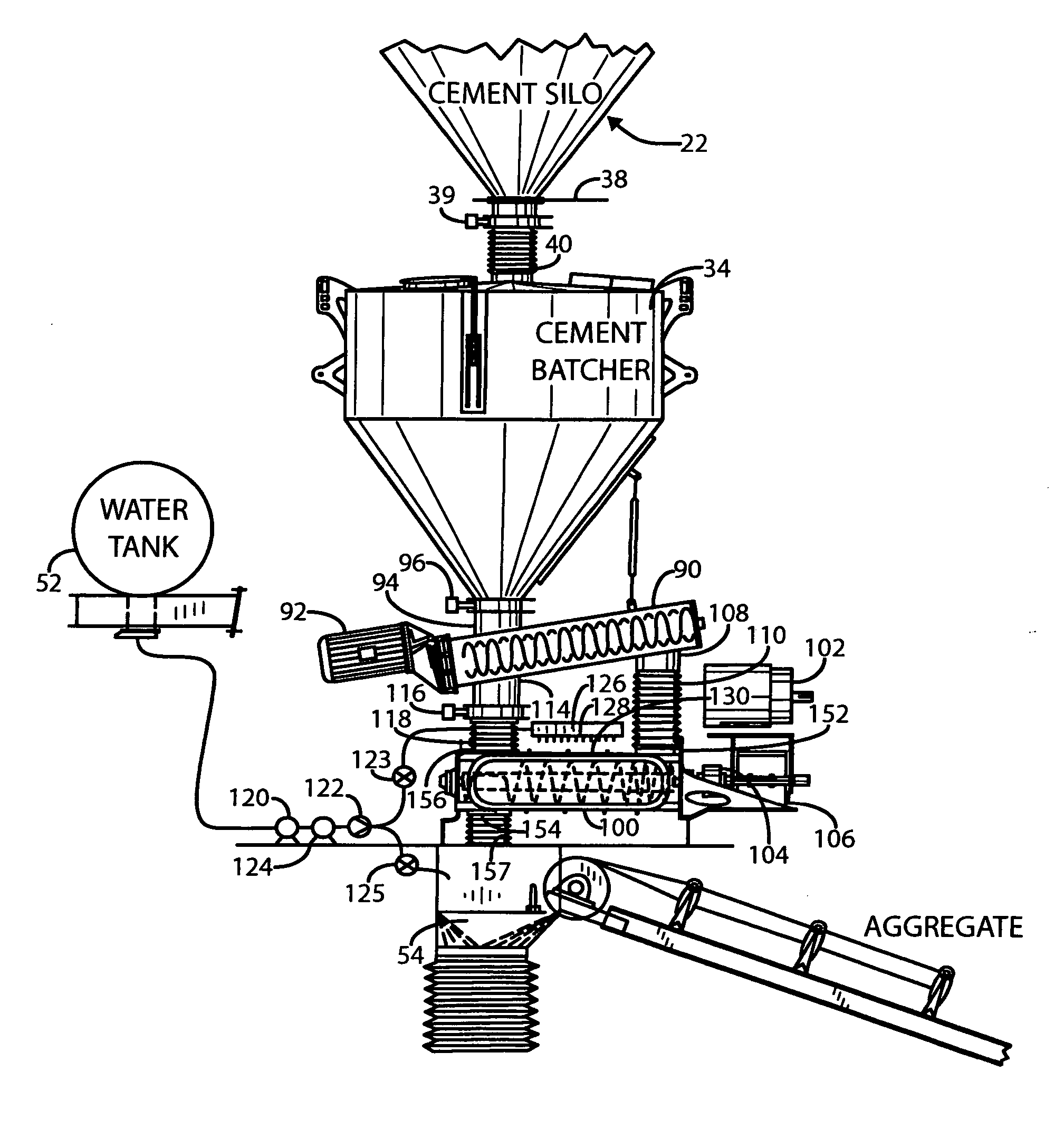

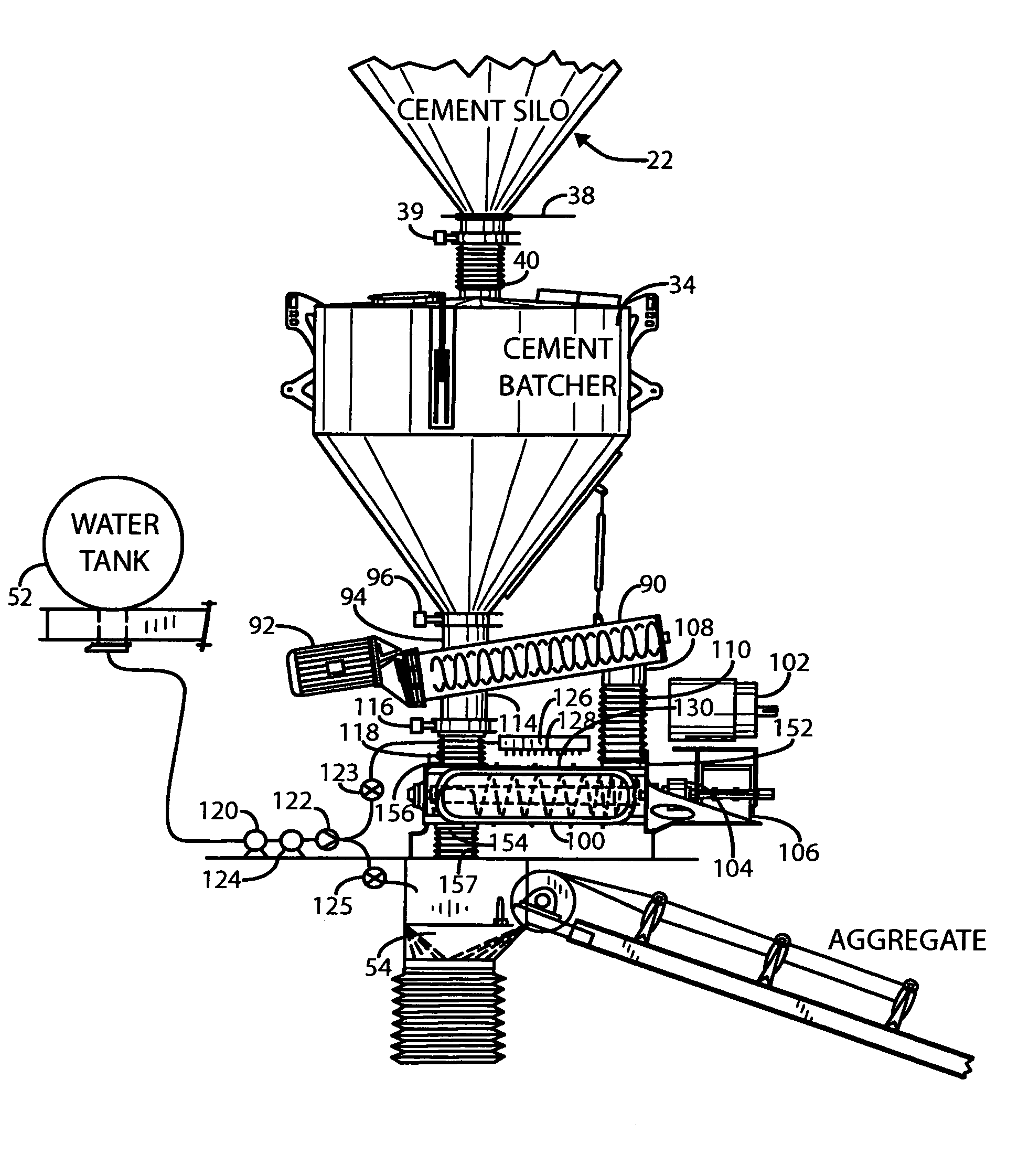

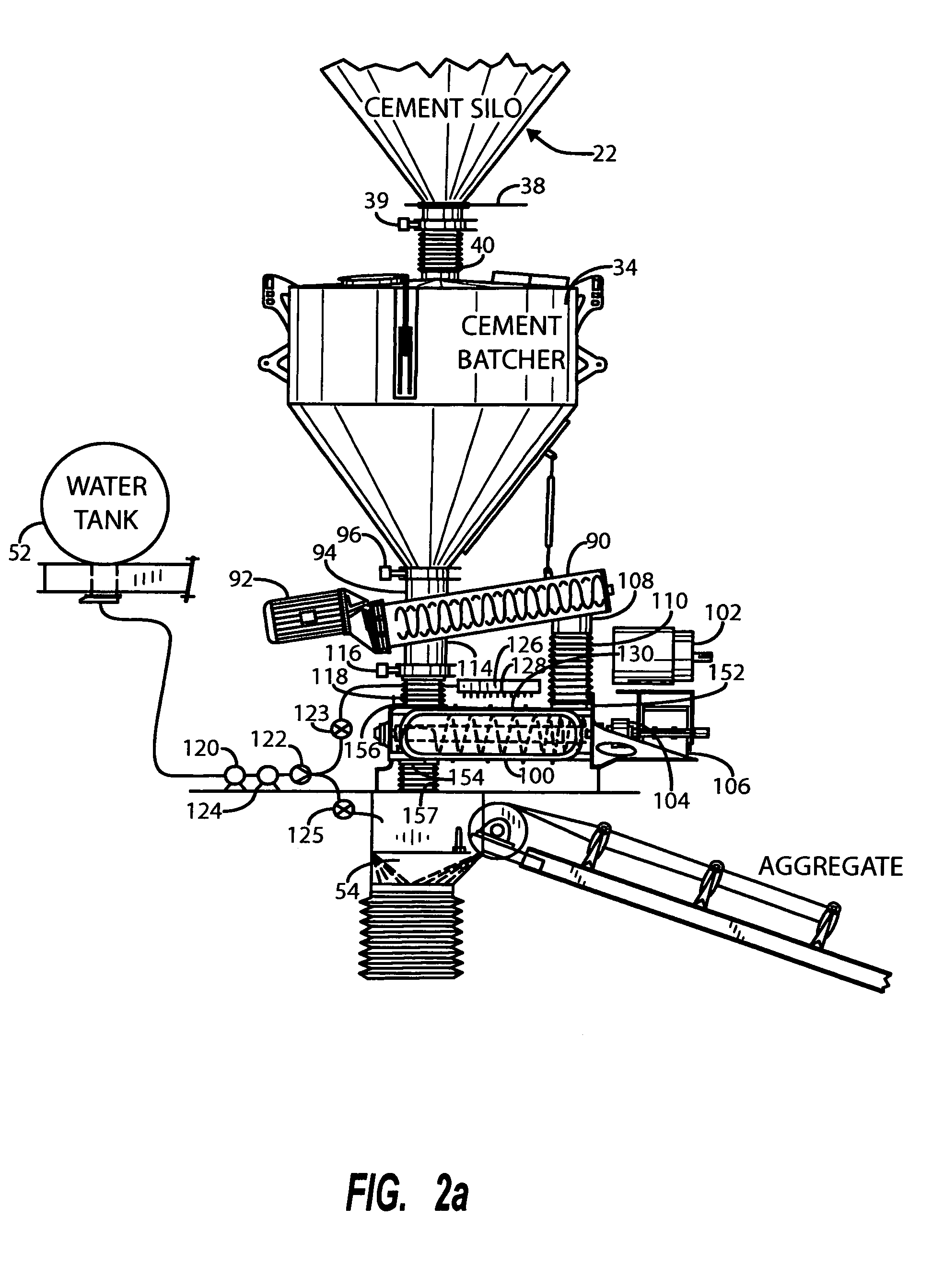

Concrete batching pre-mixer and method

InactiveUS20050219939A1Eliminate buildupWell mixedTransportation and packagingMixing operation control apparatusTruckMixed systems

A pre-mixer agglomerator and method of pre-mixing batching ingredients used to produce concrete mixes is disclosed. Specifically, this invention involves a pre-mix system which blends the wetting agents and the cementitious ingredients in relation to each other at any selected ratio in an adjustable and repeatable manner. The pre-mixer is a twin screw, preferably counter-rotating, pre-mixer agglomerator unit for pre-mixing these materials prior to combining them with aggregates in a drum of a transit mixer truck or other final mixing vessel.

Owner:MCNEILUS TRUCK & MFG INC

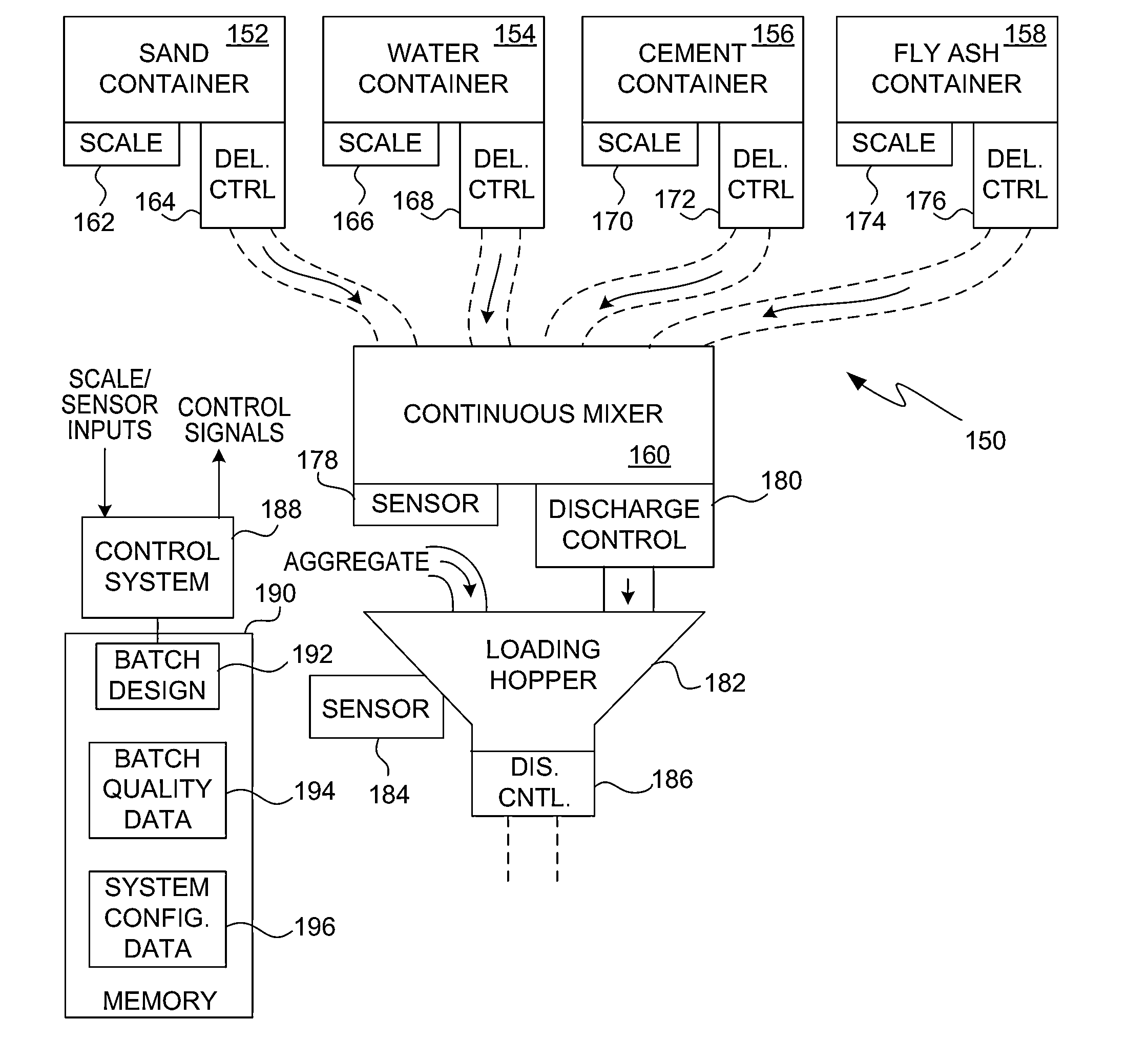

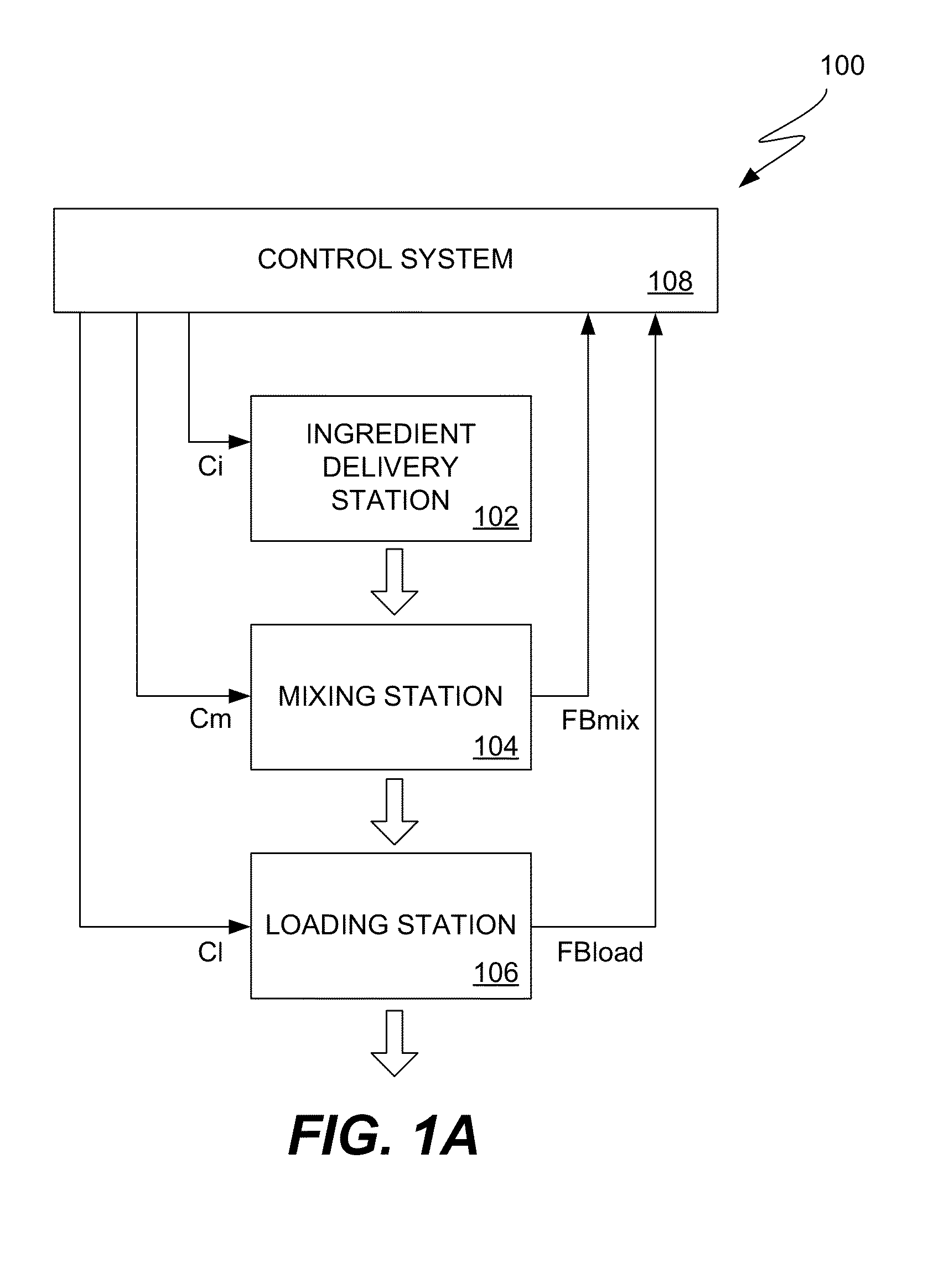

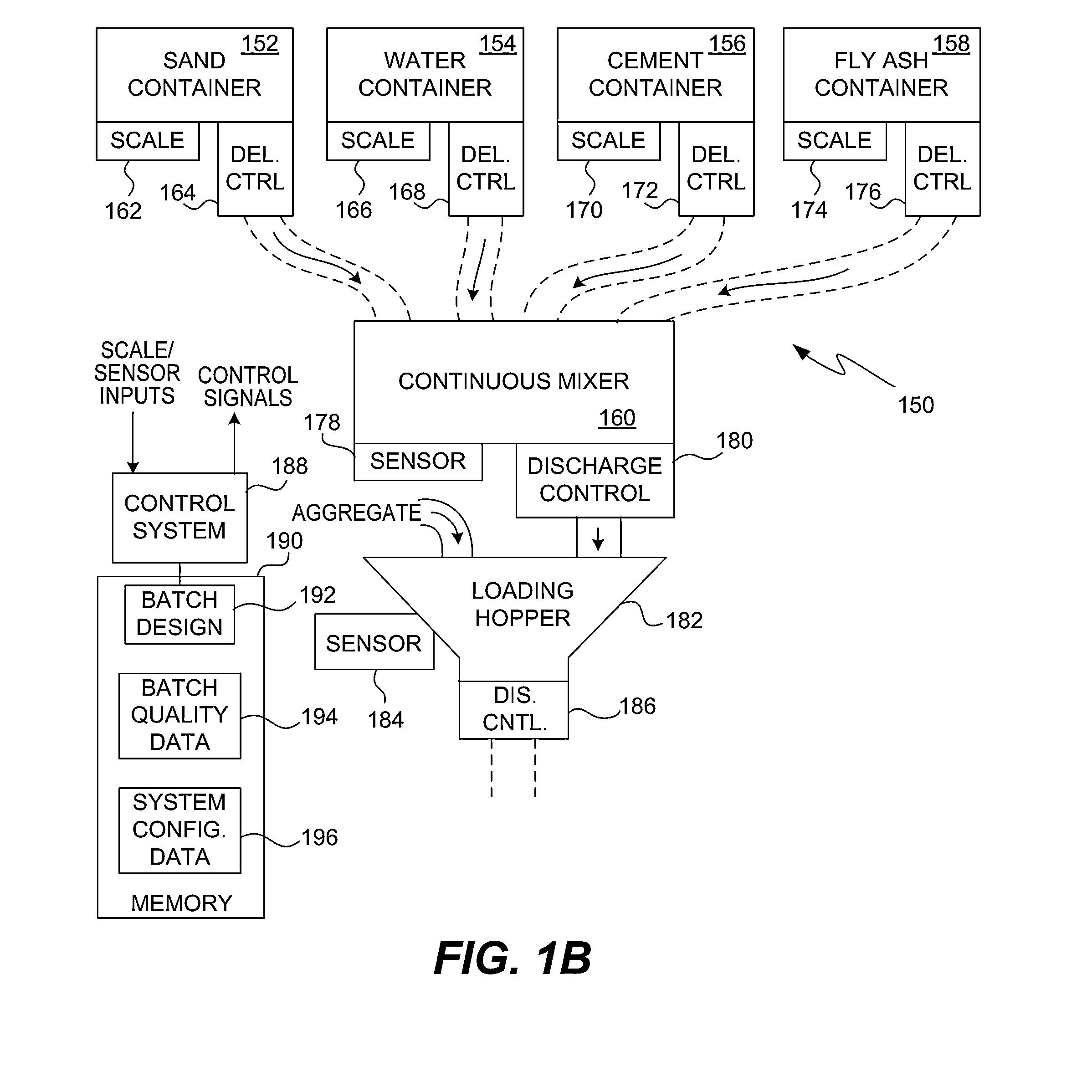

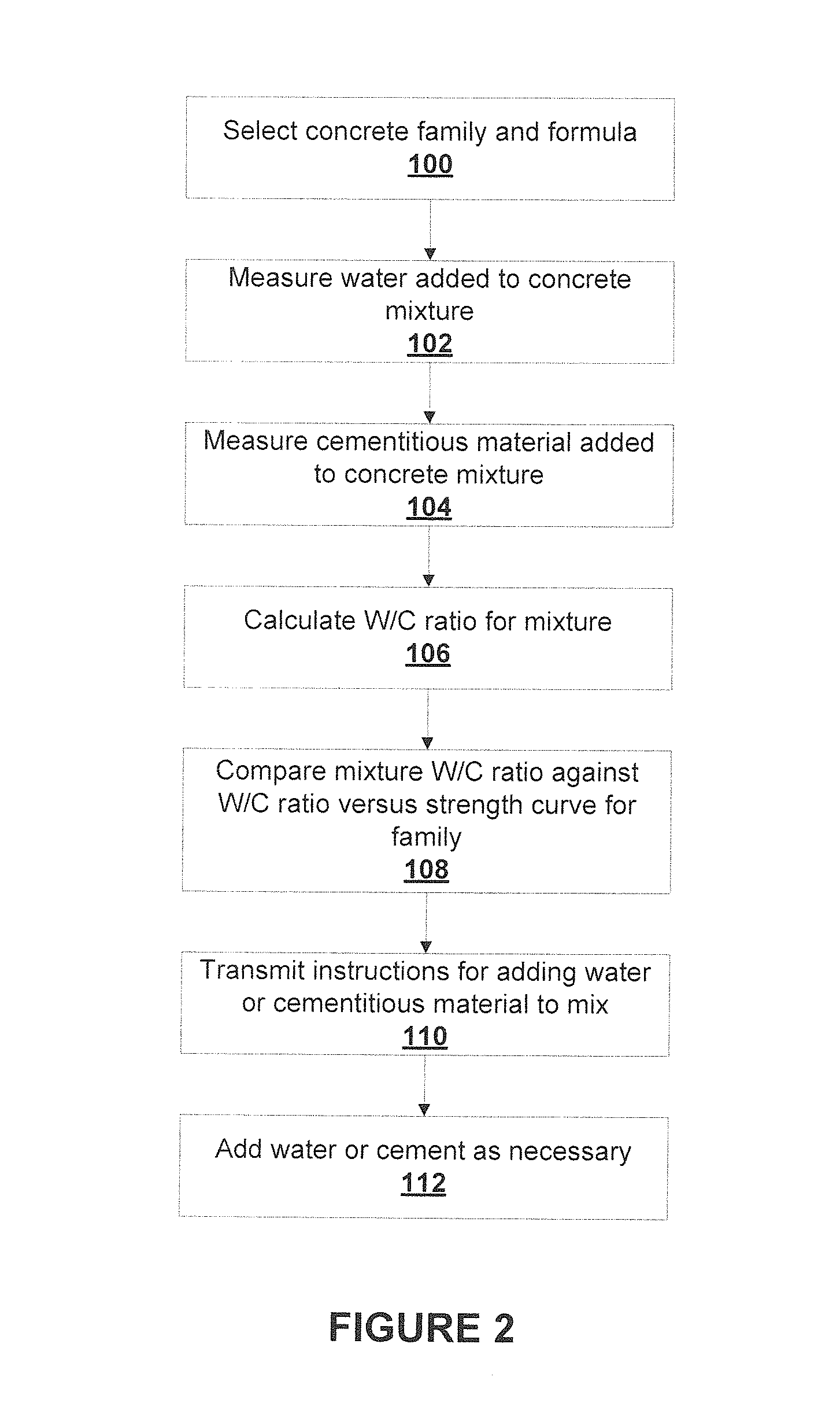

Feedback Controlled Concrete Production

ActiveUS20140355372A1Easy loadingEfficient productionRotary stirring mixersMixing operation control apparatusControl systemStructural engineering

Techniques or processes for efficiently producing concrete using dynamic feedback are disclosed. A concrete plant can use a control system to manage concrete production based on the dynamic feedback. The dynamic feedback can control mixing of concrete ingredients so as to yield uniform particle distribution for the concrete ingredients. The dynamic feedback can also avoid overflow situations as well as yield improved loading of the resulting concrete into a concrete transport vehicle (e.g., concrete truck).

Owner:BLACK MELVIN L +1

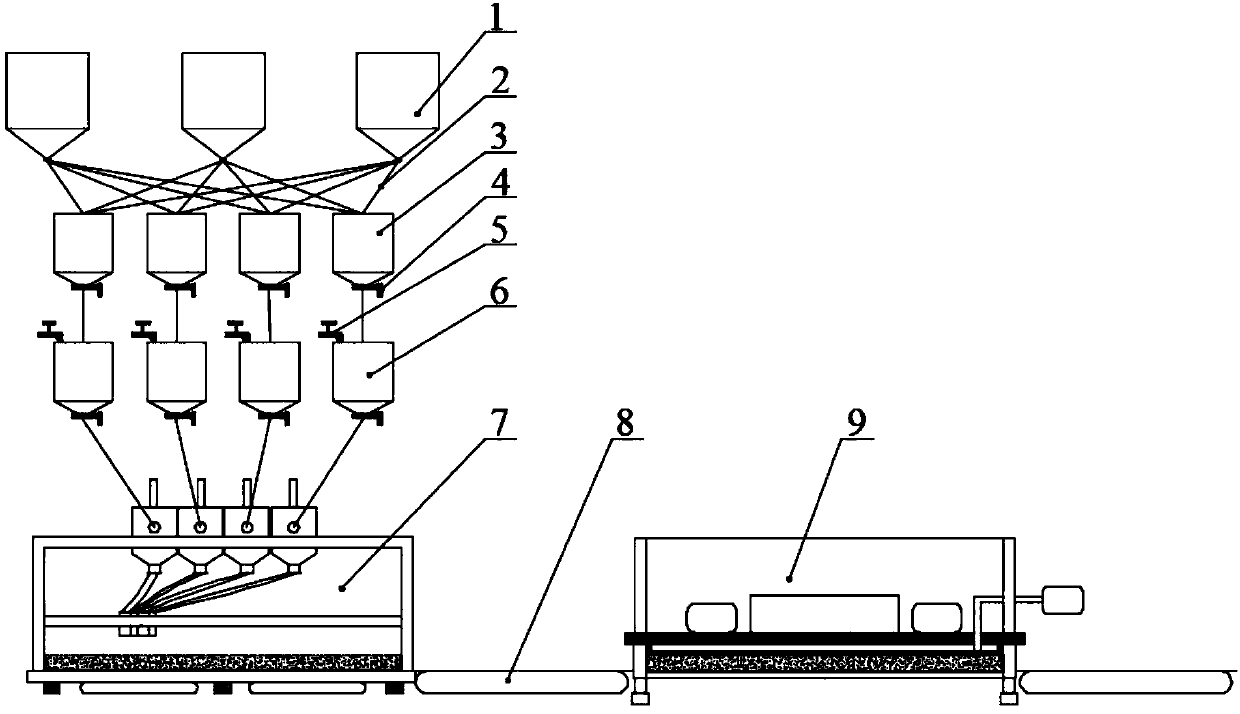

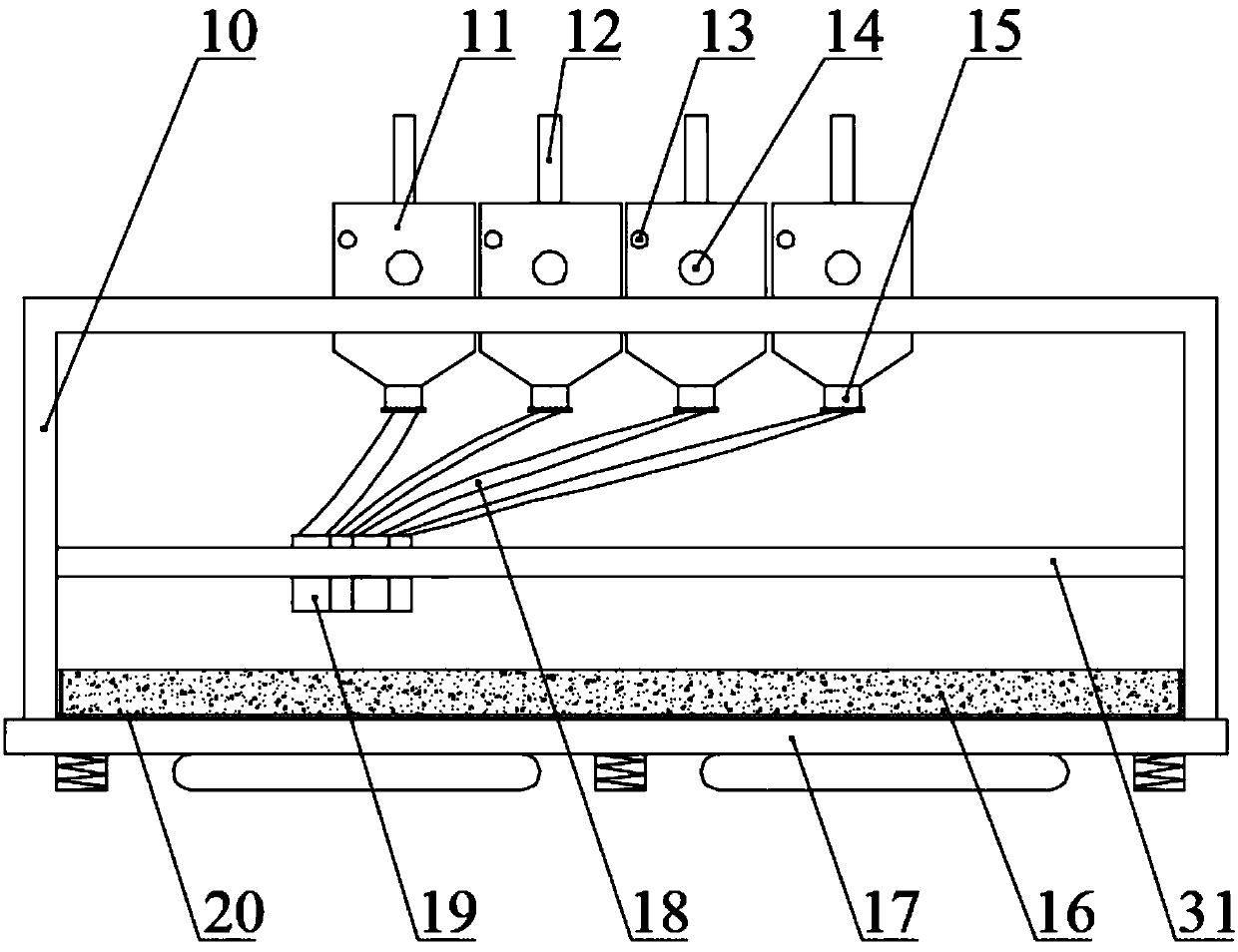

Analog simulation experiment system and method based on 3D printing rapid prototyping technology

InactiveCN105034139A3D printing rapid prototypingHigh precisionMixing operation control apparatusEarth material testingRock engineeringEngineering

The invention discloses an analog simulation experiment system and method based on a 3D printing rapid prototyping technology. A blending module is connected with an experiment module through a printing material laying module. A control module is connected with and controls the blending module, the printing material laying module and the experiment module. The control module is used for forming a 3D digital model of an analog simulation experiment. The control module controls the experiment module to be adjusted to a state suitable for printing the 3D digital model, controls the blending ratio of the blending module through electromagnetic valves and controls the printing material laying module to carry out 3D material laying at the experiment module through a direction control mechanism and reversing valves. The analog simulation experiment system and method can be used for laying rock models on complex geological structures, where the models cannot be laid through traditional measures, such as fold, faults and collapse columns, the model size precision is high, and therefore the system and method can be better used for observation and study of complex rock engineering such as the working seam overlaying strata movement rule, the roof caving regularity, and the relation between the roof moving features and forms and stability time after working face mining.

Owner:SHANDONG UNIV OF SCI & TECH

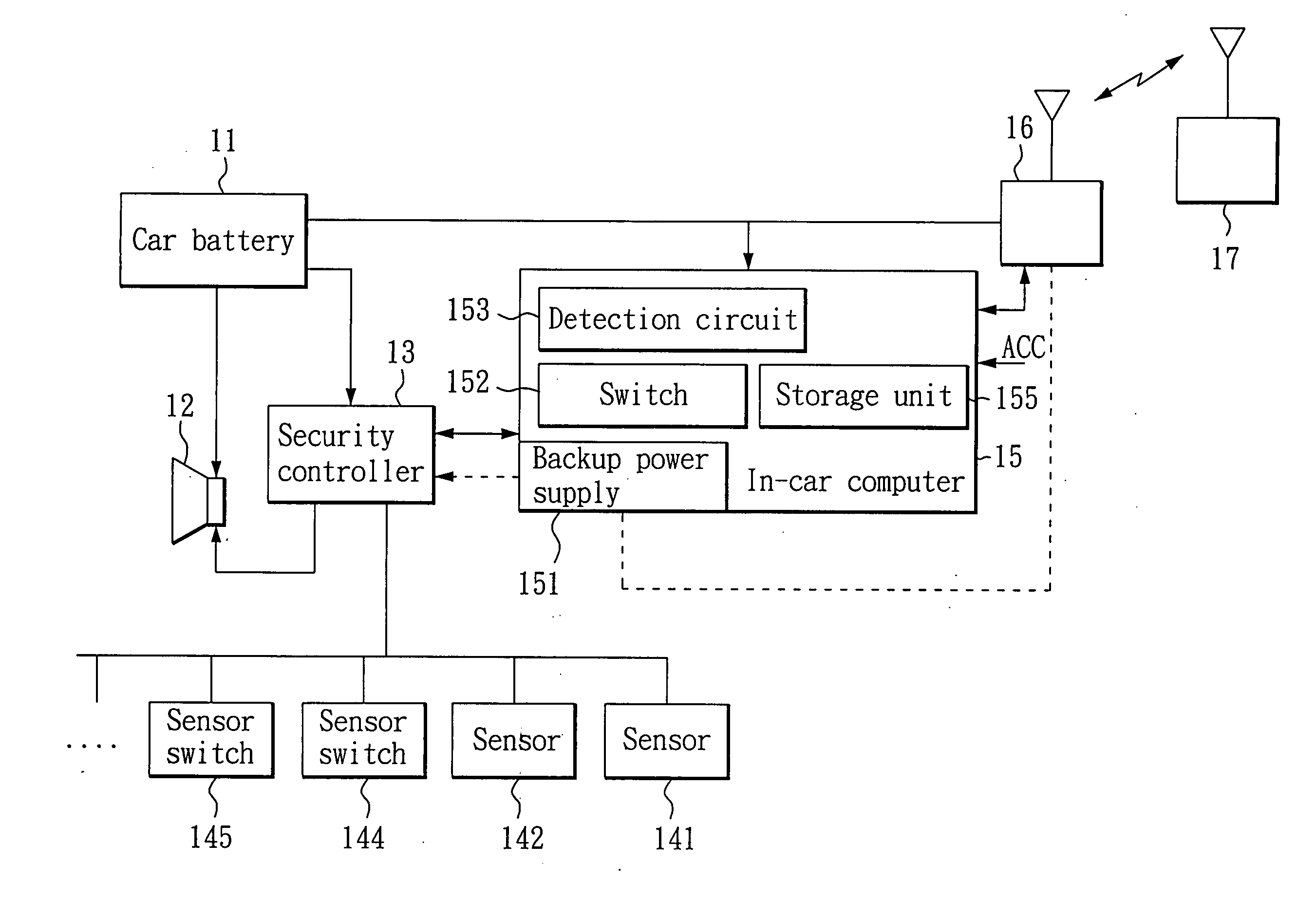

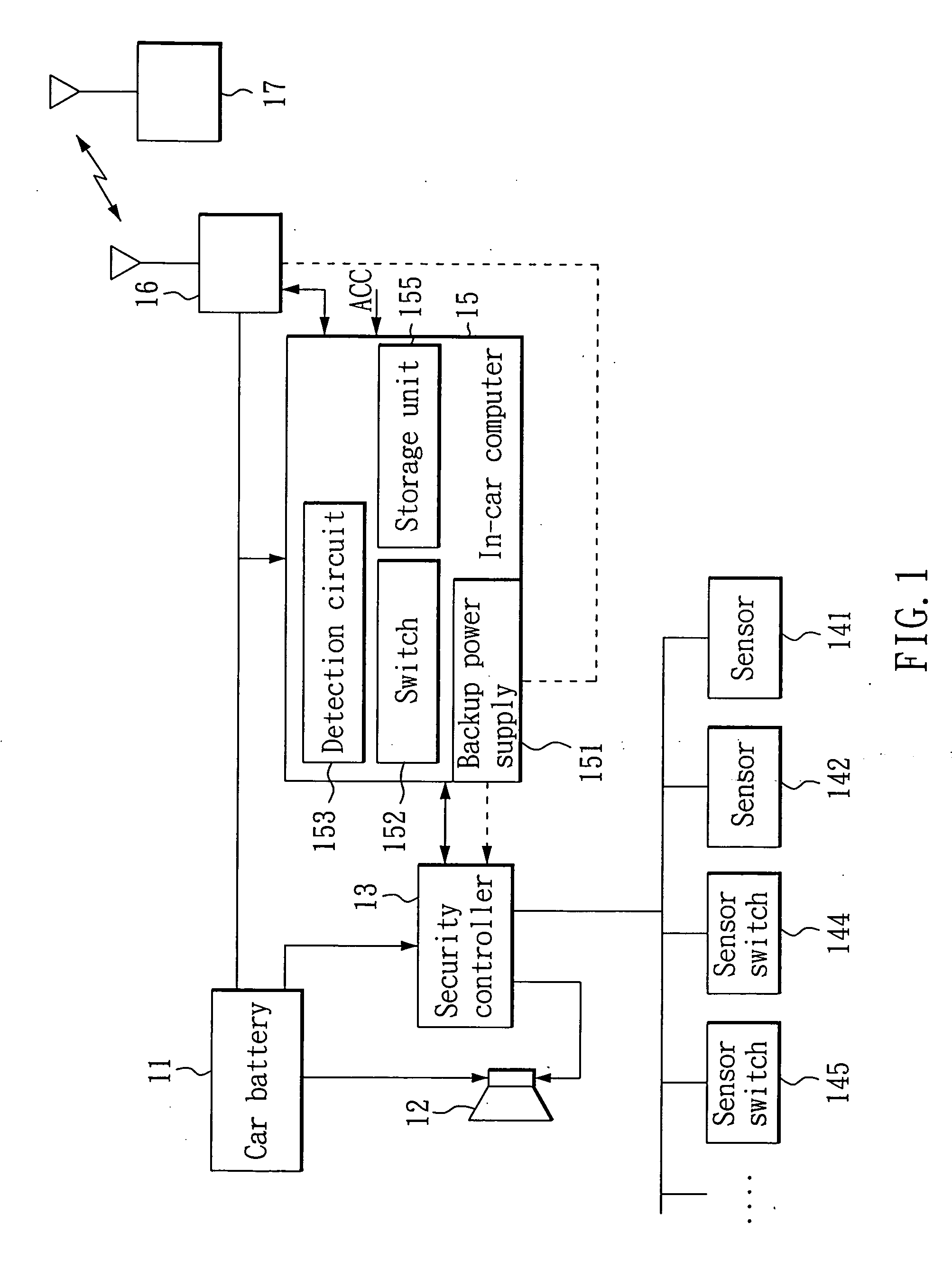

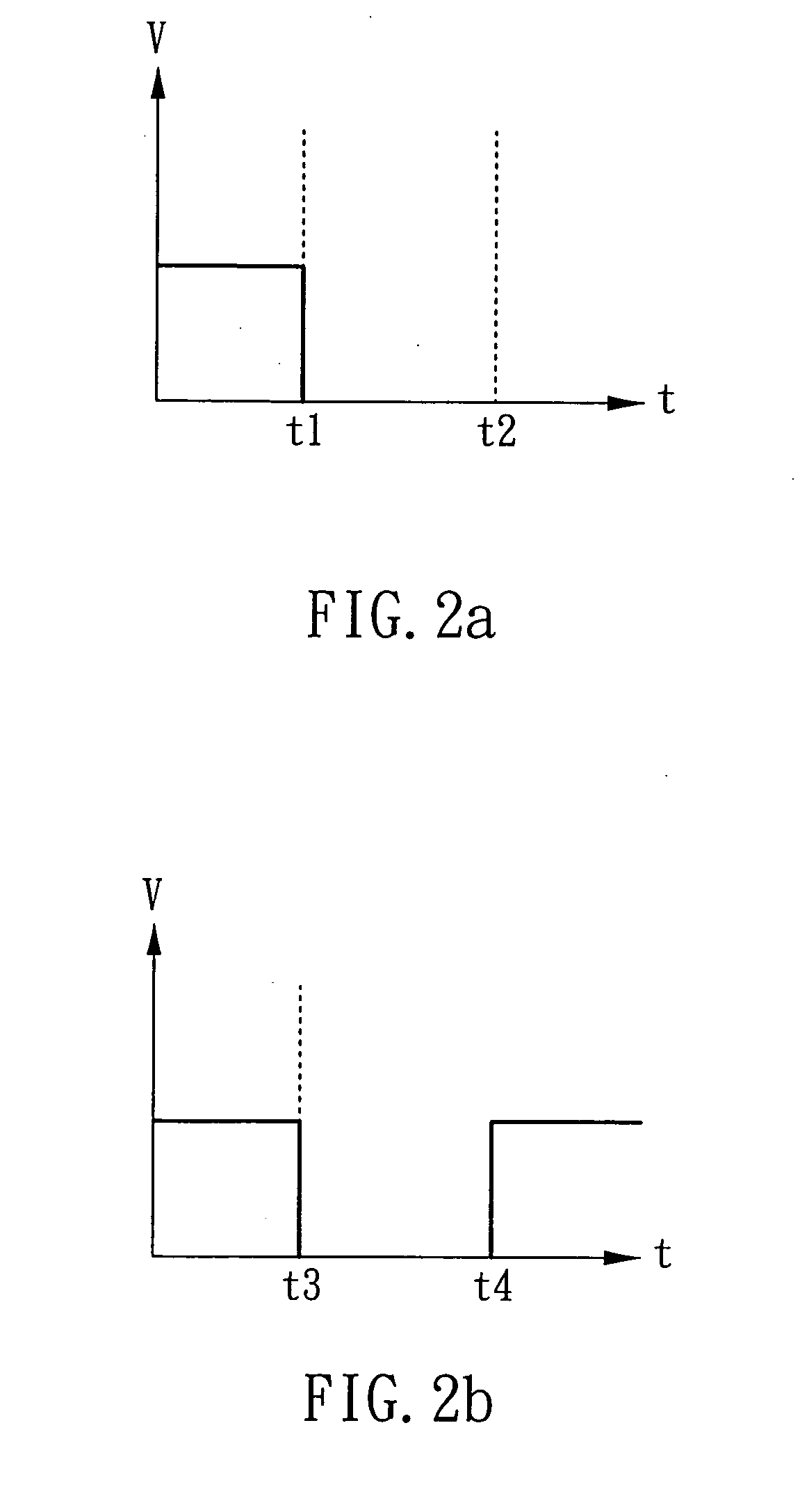

Vehicle security system

Disclosed is a vehicle security system, which uses a detection circuit to detect the supply of electric power from the car battery to the in-car computer and the status of the car ignition switch, and to start a backup power supply for the in-car computer, and drives the in-car computer to send an informing message to a remote receiver via a wireless communication module when the supply of electric power from the car battery to the in-car computer is terminated or when the car ignition switch is switched on during the alert mode of the vehicle security system.

Owner:XINGYI SCI & TECH

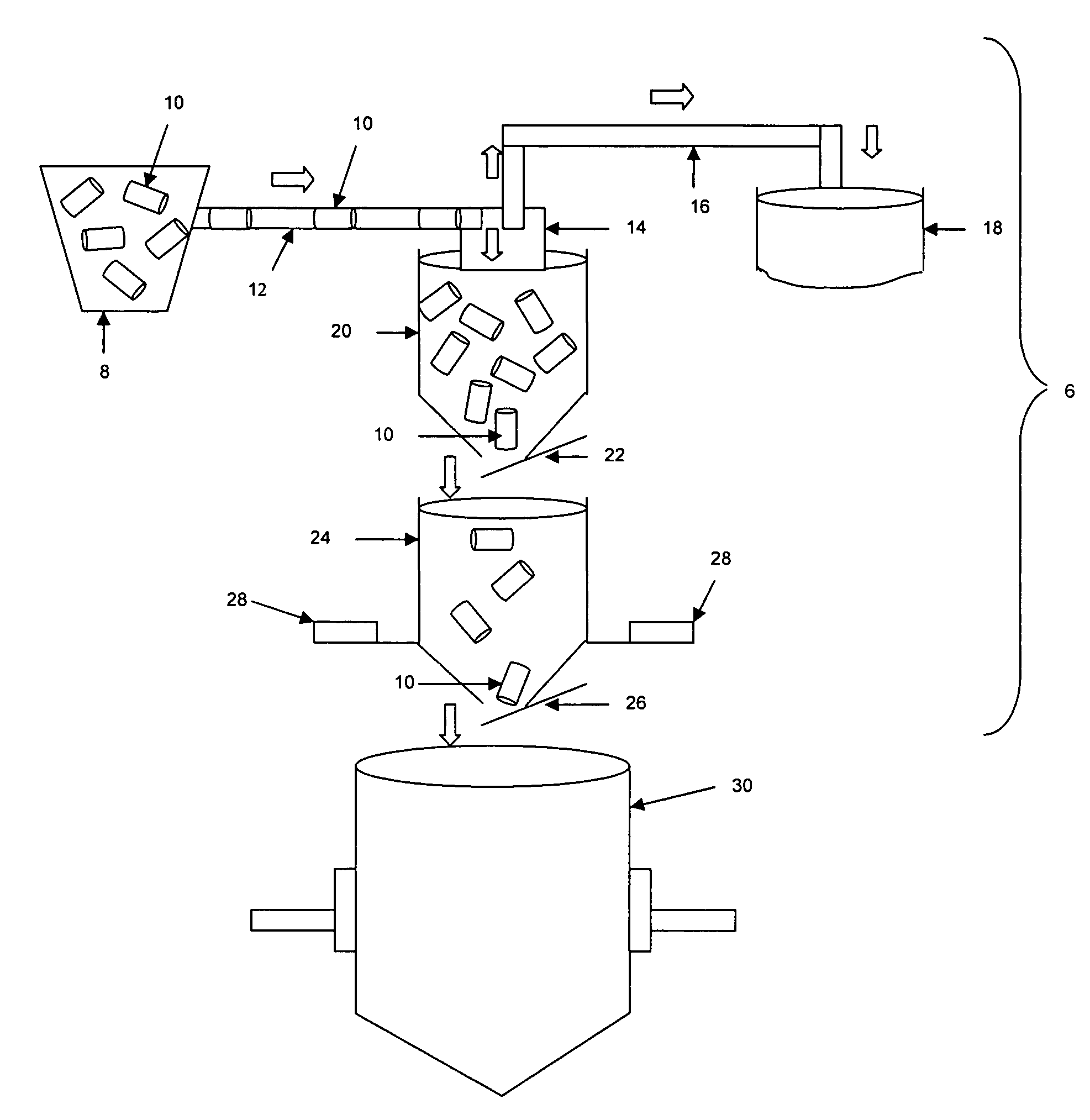

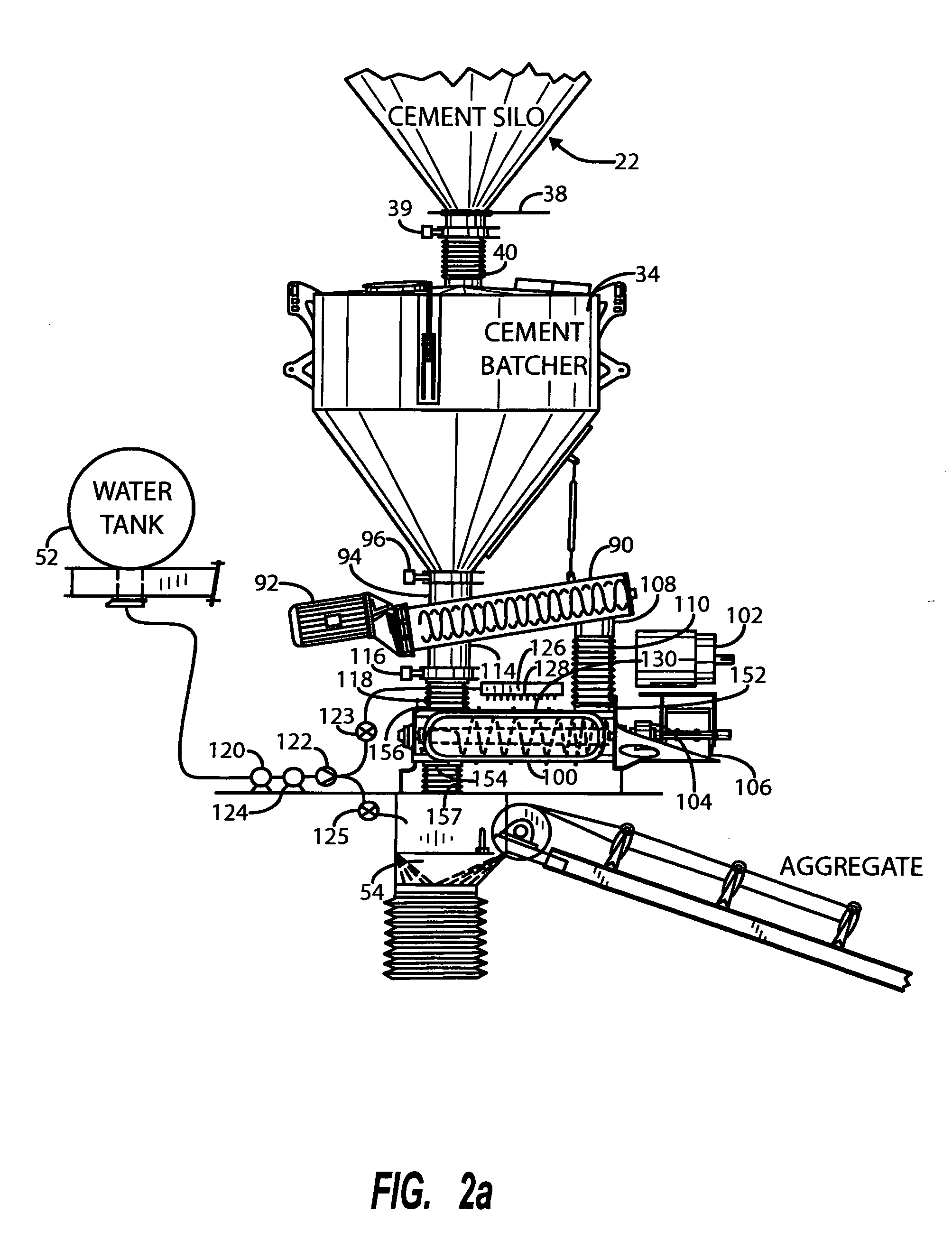

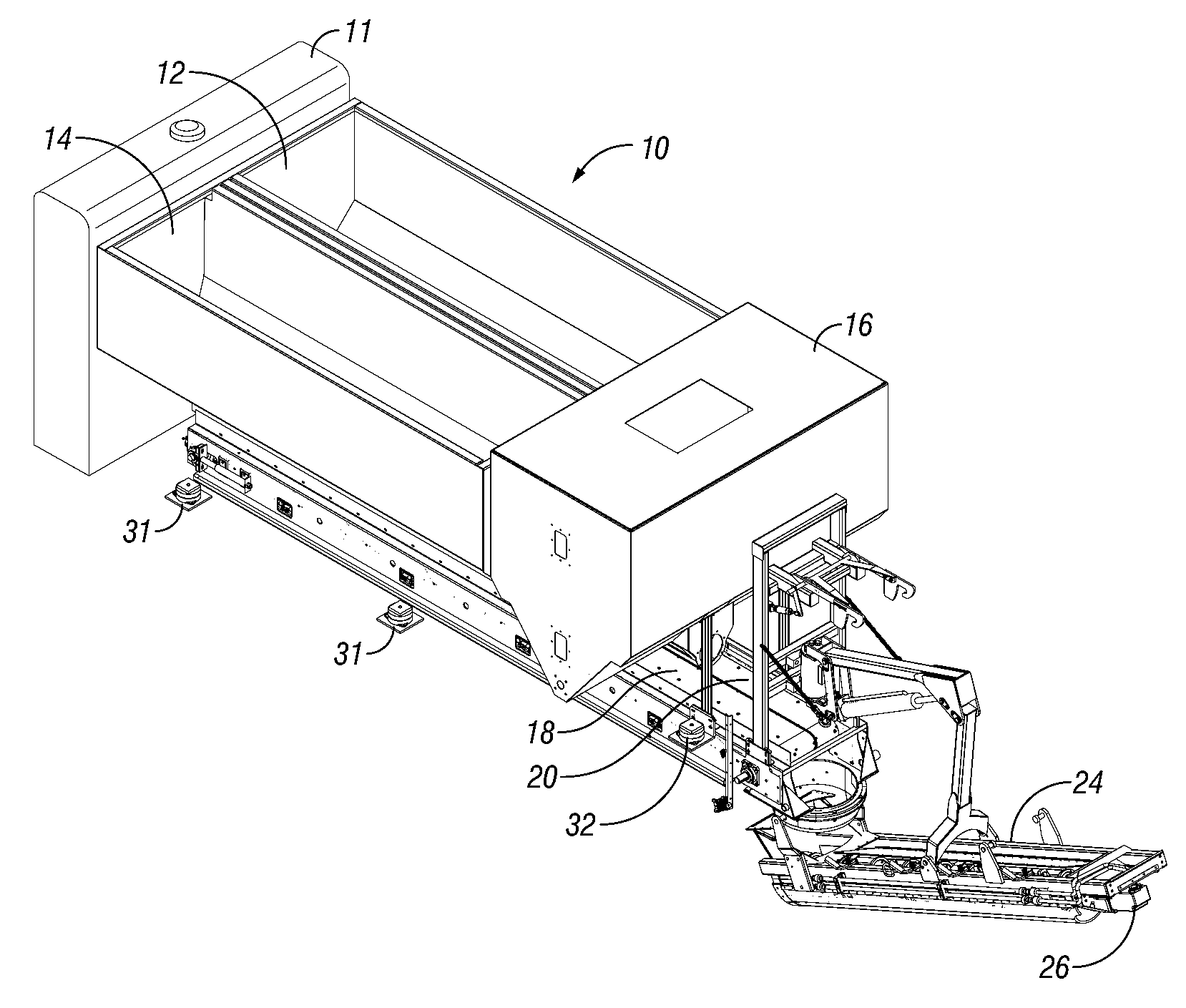

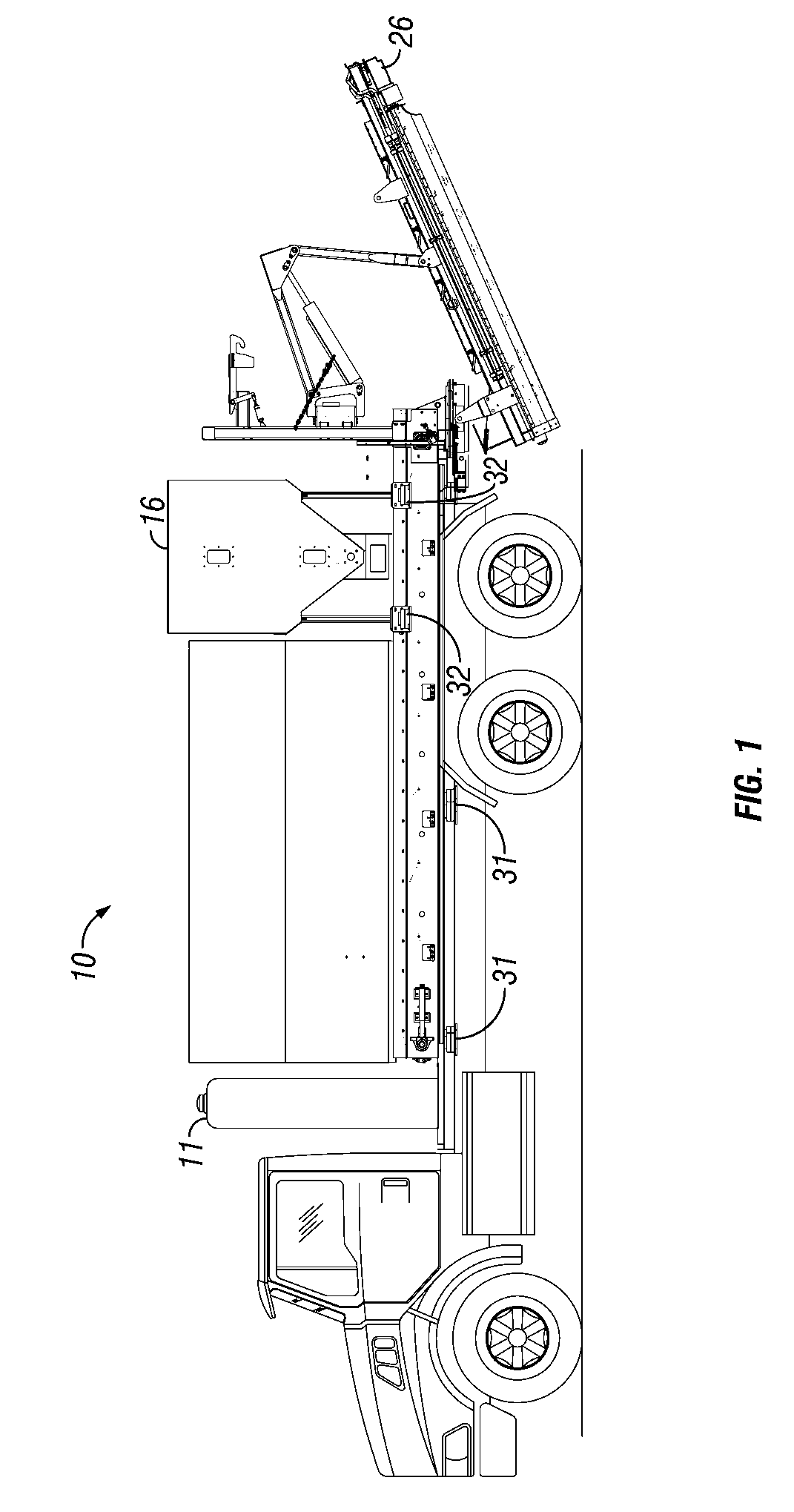

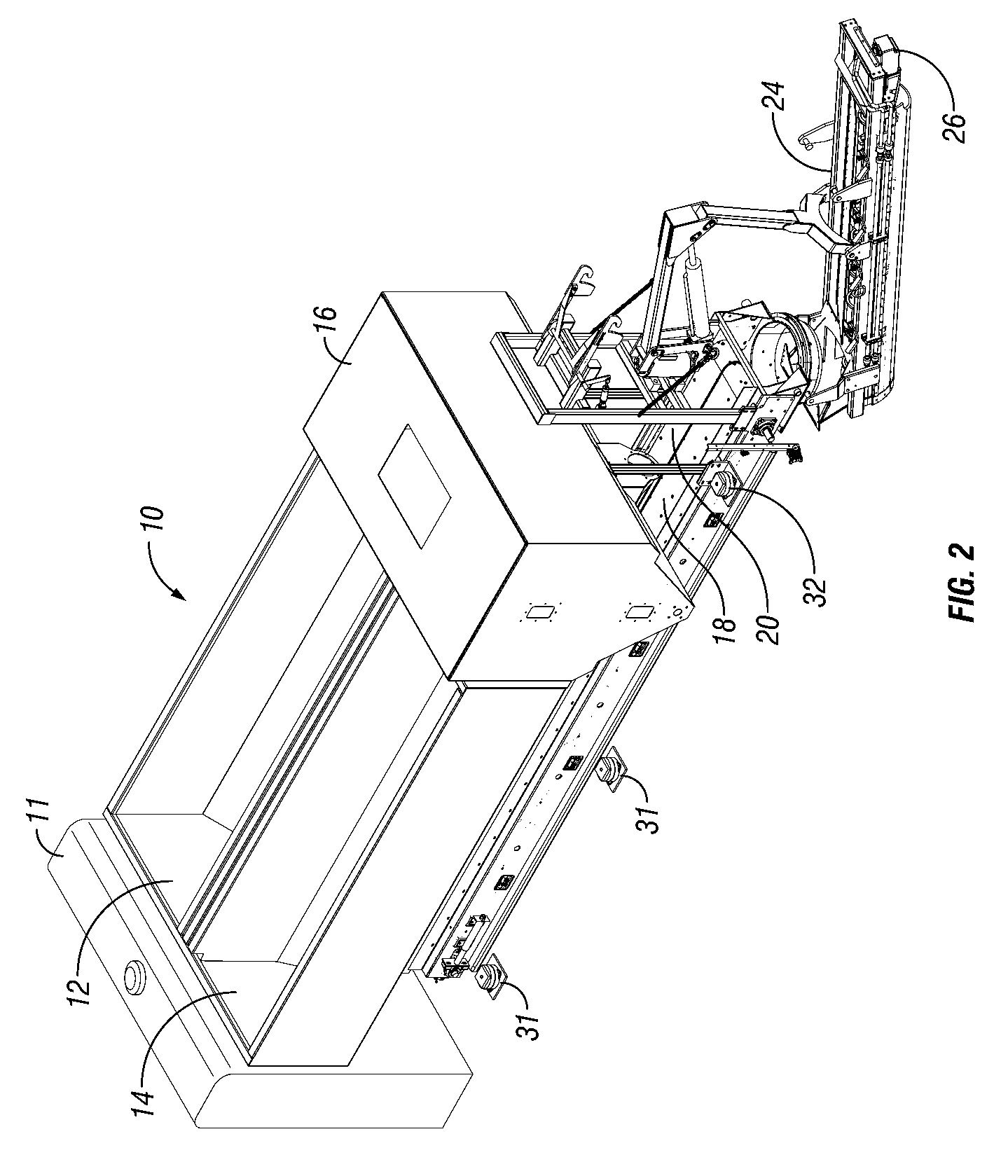

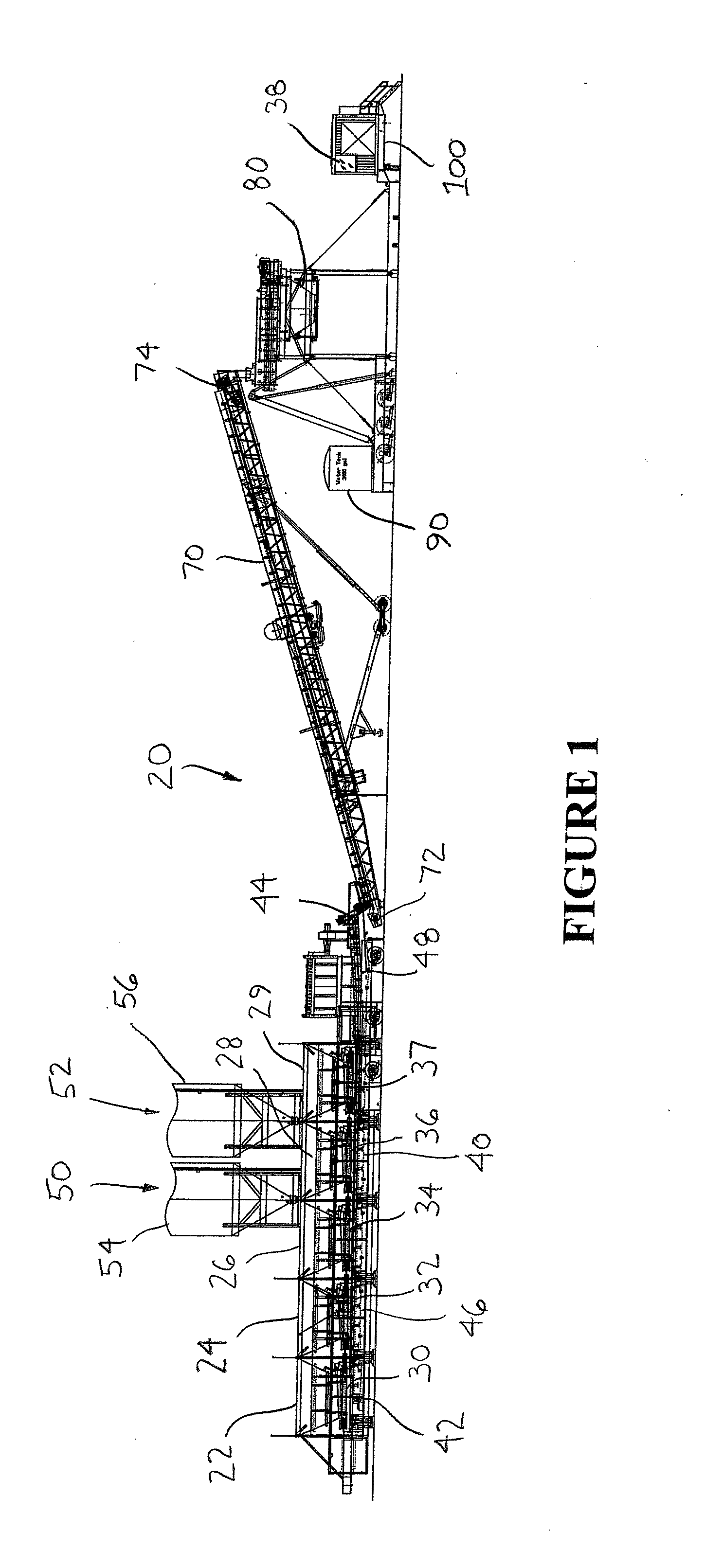

Volumetric concrete mixing method and apparatus

ActiveUS20090180348A1Mixing operation control apparatusIngredients proportioning apparatusAdditive ingredientControl theory

An improved volumetric concrete mixing system and method of the present invention utilizes load cells for measuring weight loss from the aggregate and cement bins. Load cells may also be used for measuring weight loss from the water tank. The load cells provide input data corresponding to the weight loss of each container to a controller which automatically adjusts the delivery of ingredients to a mixing boot so as to achieve a desired concrete mix ratio.

Owner:CEMEN TECH

Concrete batching facility and method

ActiveUS7320539B2Optimizes production and strengthAvoid material accumulationDischarging apparatusMixing operation control apparatusHybrid systemAdditive ingredient

A concrete batch mixing system and method are disclosed that enable the batch master to measure and control both the water and cementitious ingredient feeds in relation to each other so as to be able to blend the two ingredients in a known, selected, adjustable and repeatable manner, and to agglomerate these ingredients in a counter-rotating twin screw mixing apparatus for use in the preparation of batches of mixed concrete in a concrete batching process.

Owner:MCNEILUS TRUCK & MFG INC

Quantitative mixer for producing ceramics

InactiveCN104924461AImprove practicalityIncrease productivityMixing operation control apparatusIngredients proportioning apparatusHydraulic cylinderEngineering

The invention discloses a quantitative mixer for producing ceramics. The quantitative mixer comprises a mixer body, a hydraulic cylinder and a controller, wherein a feeding funnel is connected to the center of the upper side of the mixer body, a first electronic scale is disposed at the bottom end of the feeding funnel, a first electromagnetic valve is disposed at the center of the first electronic scale, a pulverizer is disposed at the left end of the upper side of the mixer body, and the bottom of the pulverizer is connected with the mixer body. The quantitative mixer has the advantages that an upper mixing mechanism and a lower mixing mechanism mix materials, the lower mixing mechanism can move up and down and left and right, mixing effect is guaranteed, mixing efficiency is increased, quantitative feeding and processing can be achieved, two different materials can be fed simultaneously according to proportion, mixer practicality is increased, ceramic producing efficiency is increased, the mixer can be moved freely and conveniently, and high practicality and convenience are achieved.

Owner:陆丽曼

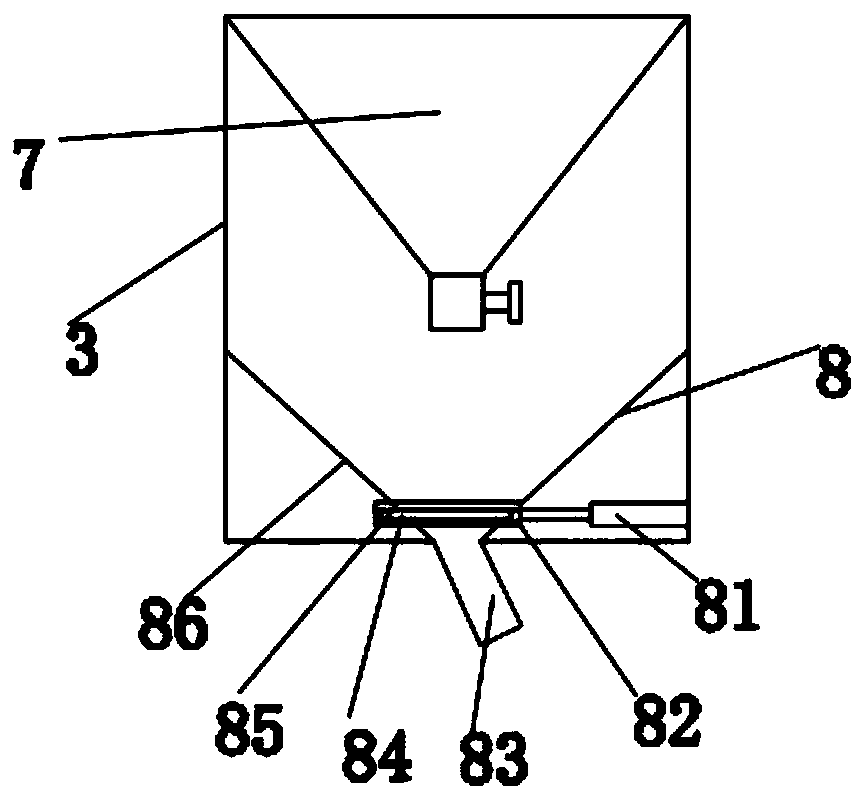

Bin gate for providing variable output flow rates

InactiveUS20070215238A1Precise and Efficient ControlPromote sportsClosuresMovable measuring chambersEngineeringTarget weight

An assembly for controlling delivery of material from a bin opening includes a movable bin gate for closing the bin opening and providing a high flow rate of material when the movable gate is open, wherein a low flow aperture is formed in the bin gate to provide a low flow rate of material when the bin gate is positioned such that only the low flow aperture is open. A two-stage flow enhancer within the bin includes a first stage for impelling material in the direction of the low flow aperture and a second stage for impelling material to exit through the low flow aperture. A controller controls operation of the bin gate to adjust a flow rate of material from the bin opening. The controller may include a sensor for providing an actual weight value of material present in a receiving bin and a memory for storing a target weight value for the amount of material in the receiving bin, wherein the controller adjusts the position of the bin gate and the low flow aperture in response to the actual weight value and the target weight value. The bin gate may also be adjusted in response to one or more tolerance values defining proximity to the target weight value and / or in response to one or more threshold weight values, wherein the threshold weight values are less than the target weight value. A method for controlling delivery of material from a bin opening includes the steps of providing at the bin opening a movable bin gate with a low flow aperture and selectively positioning the bin gate using a single actuator to expose only the low flow aperture to the bin opening for material flow or to expose substantially all of the bin opening for material flow.

Owner:MIXER SYST

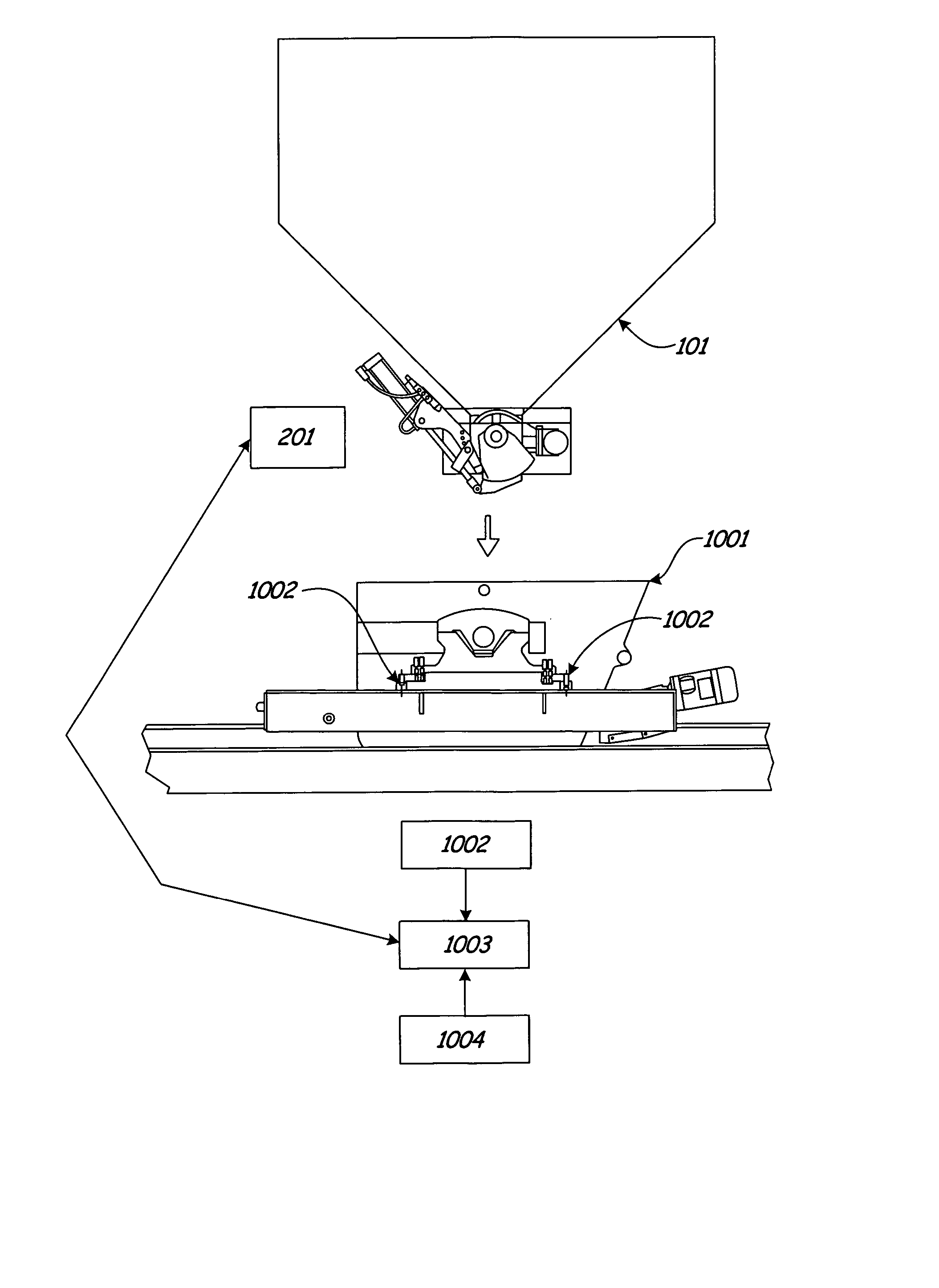

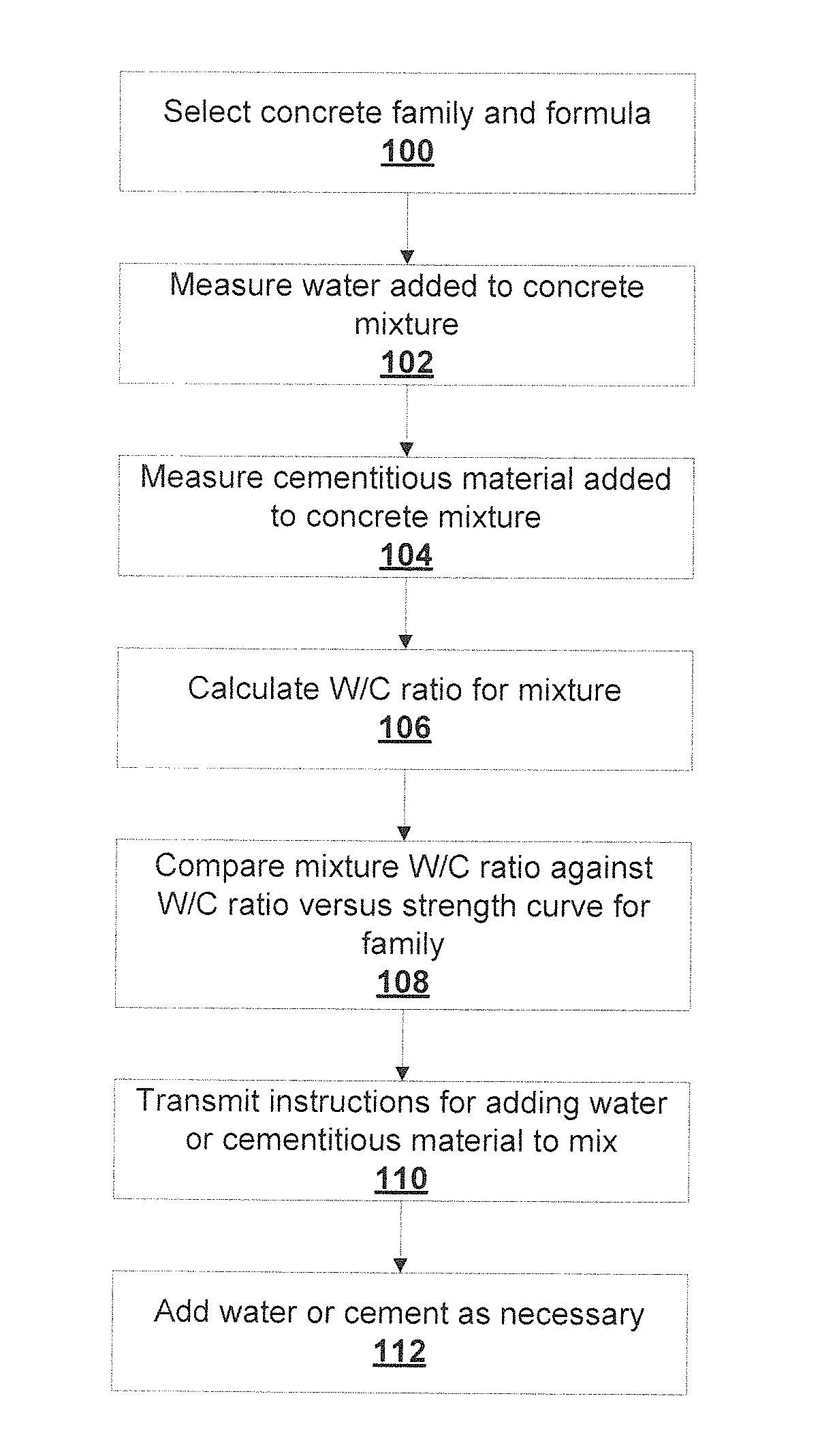

System and Process for Mixing Concrete Having Desired Strength Characteristics

ActiveUS20140241104A1Mixing operation control apparatusIngredients weighing apparatusUltimate tensile strengthFamily characteristics

A method and system for system for rapidly determining the predicted strength of concrete prior to pouring the concrete is disclosed herein. The system and process provides for a database storing concrete family characteristics that may be updated as actual strength of poured concrete is determined. The process also allows construction workers to pour concrete with a keener knowledge of the resulting concrete strength.

Owner:COMMAND ALKON

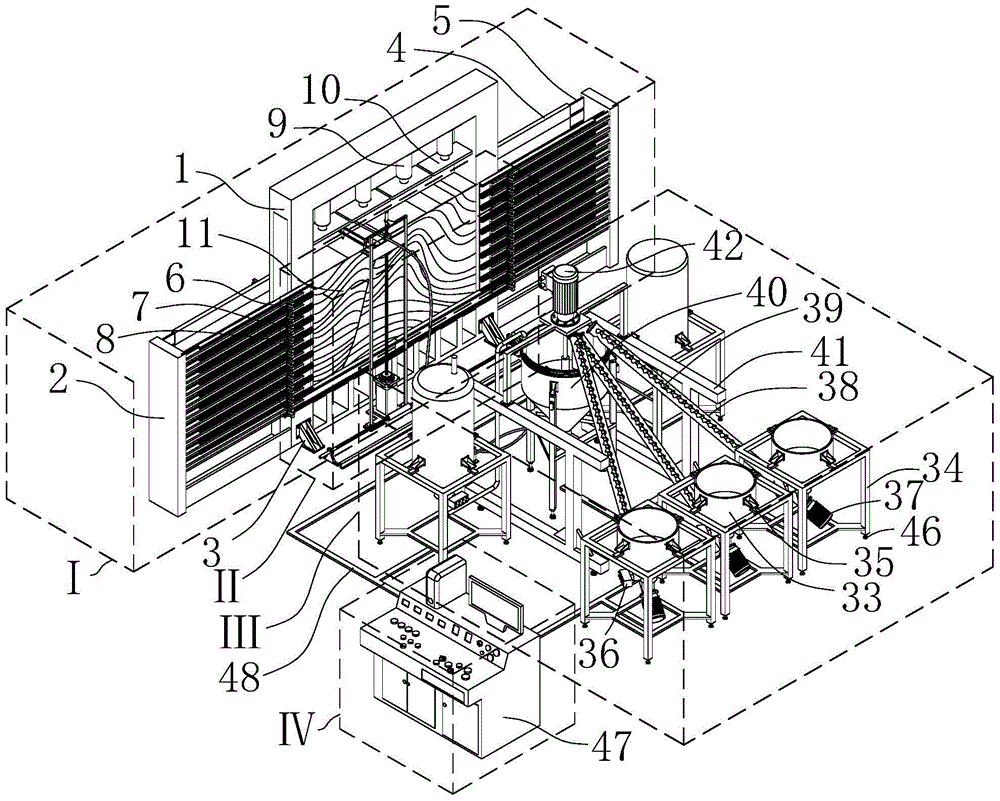

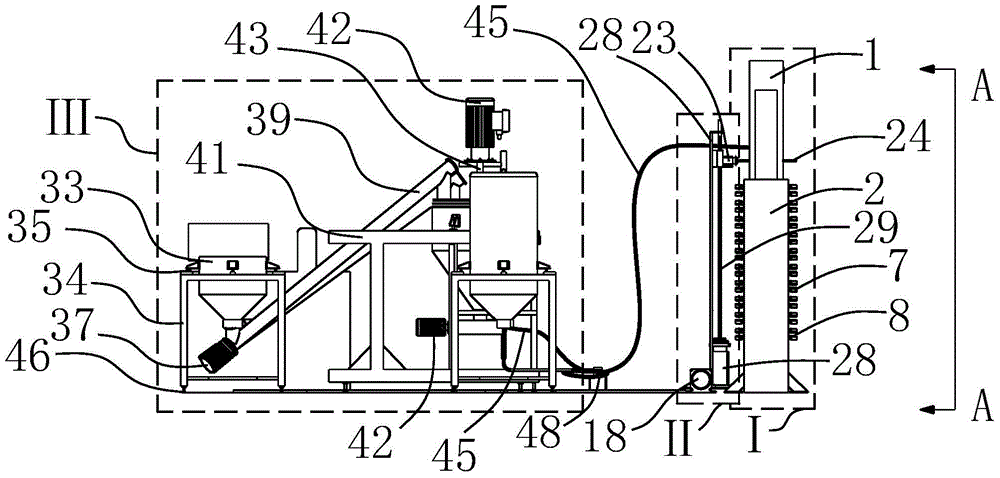

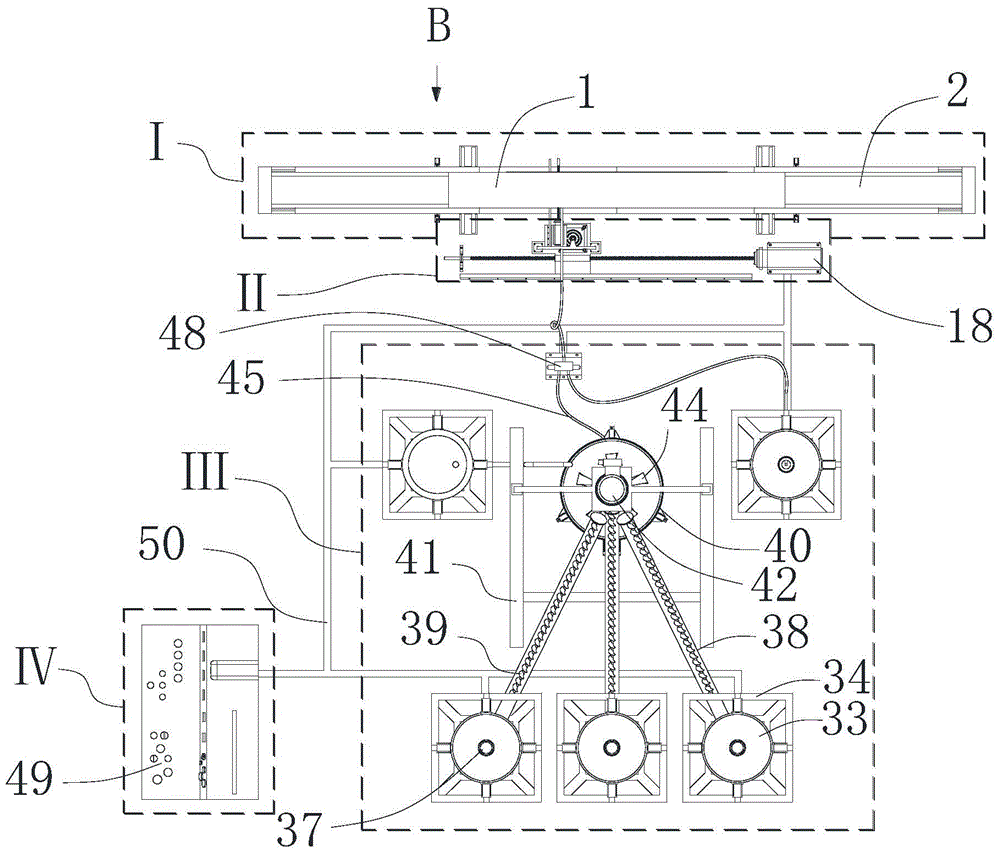

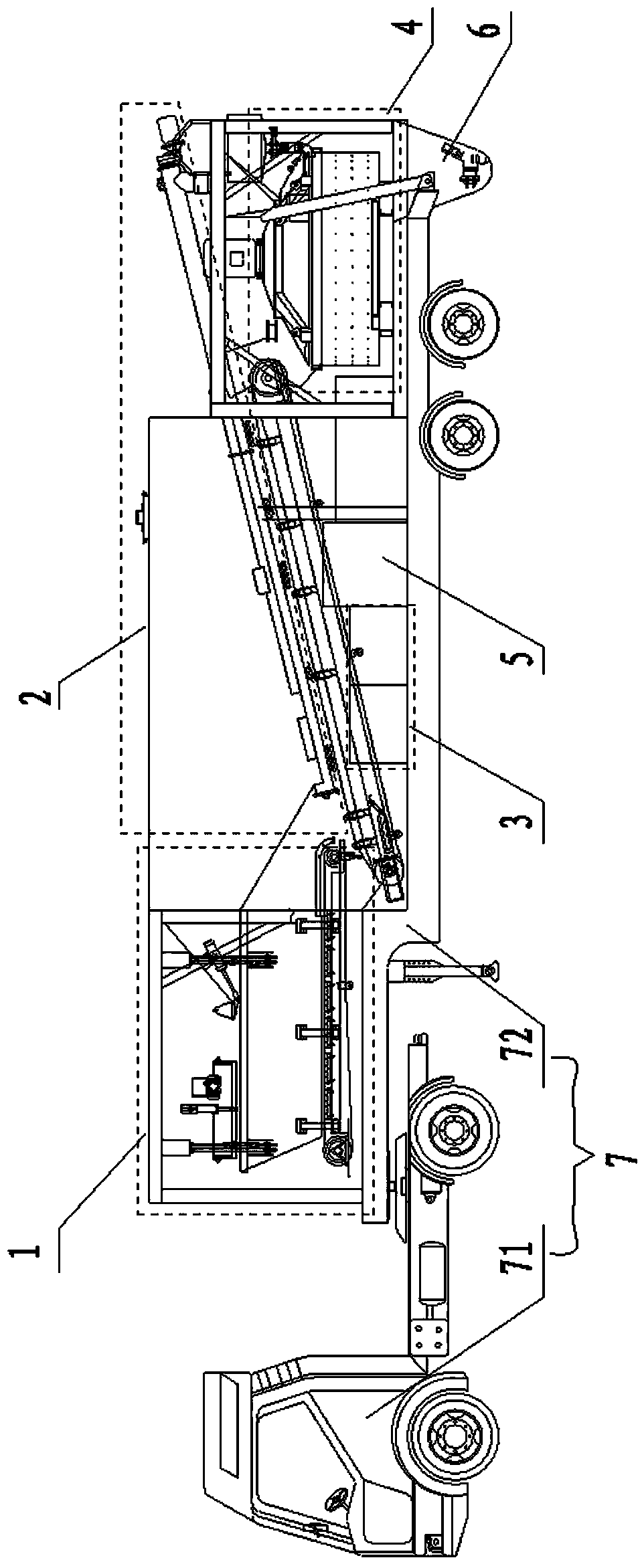

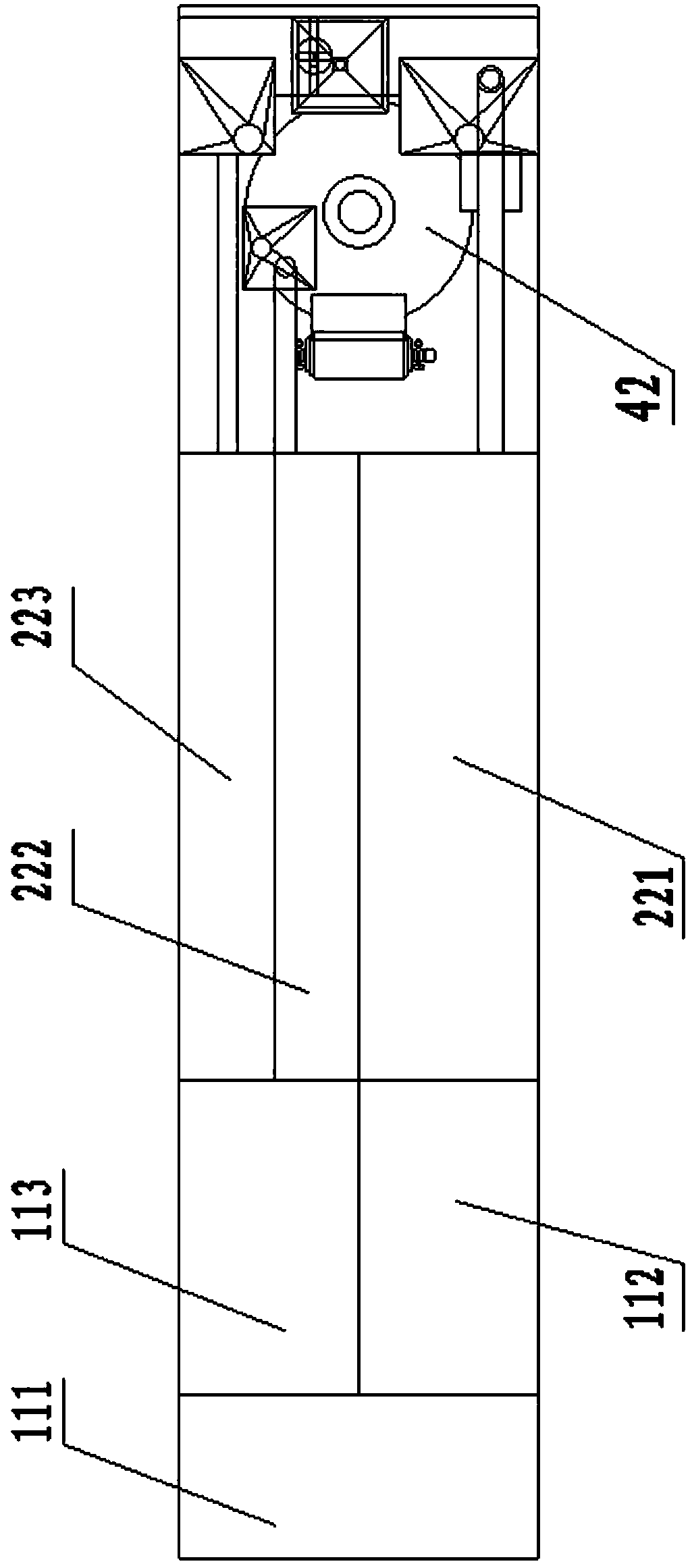

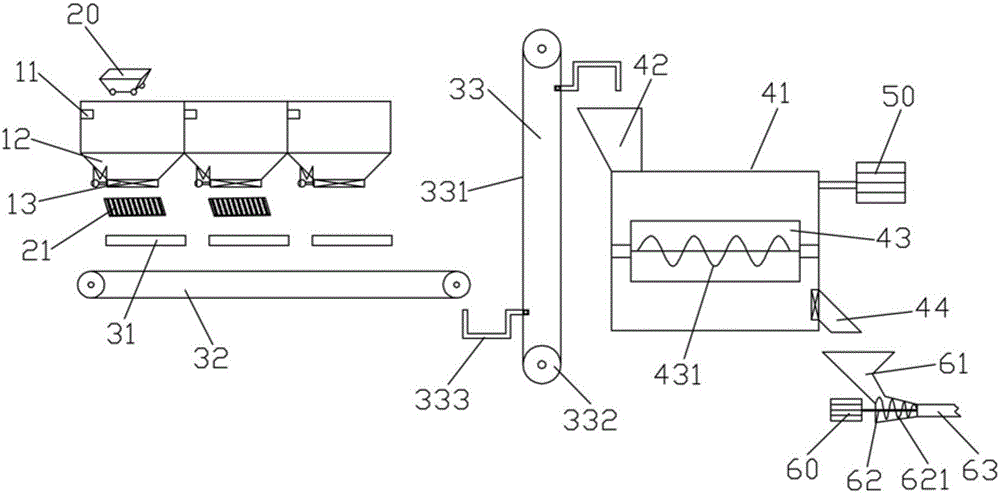

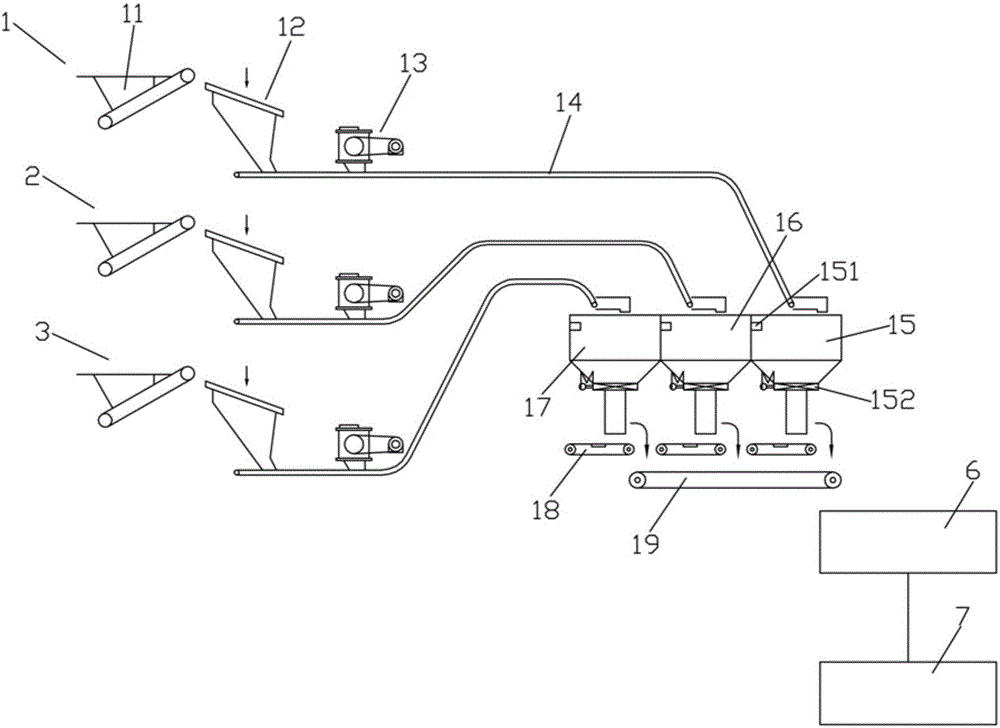

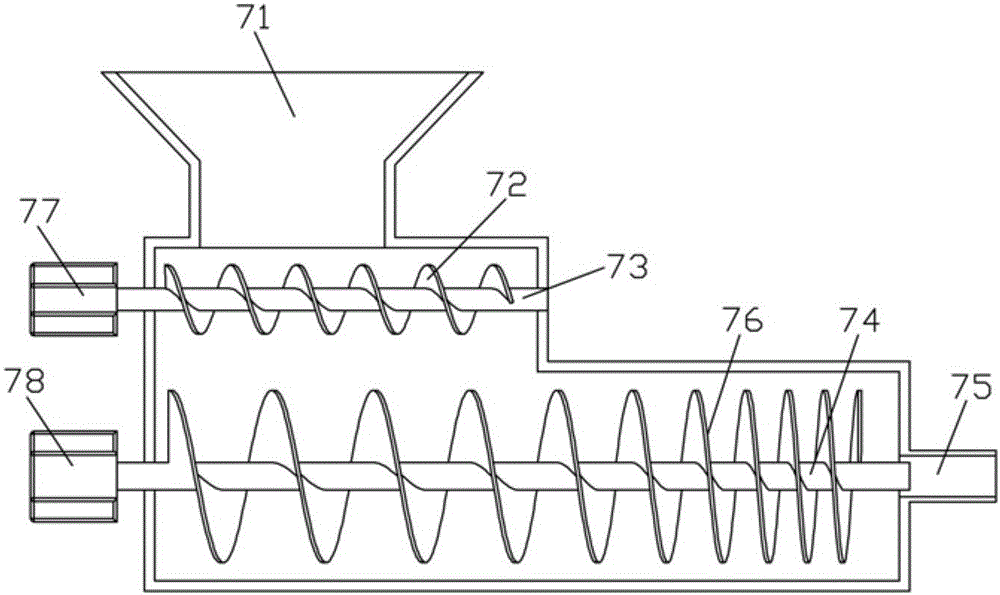

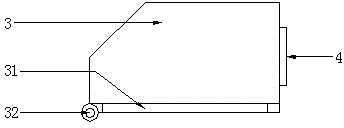

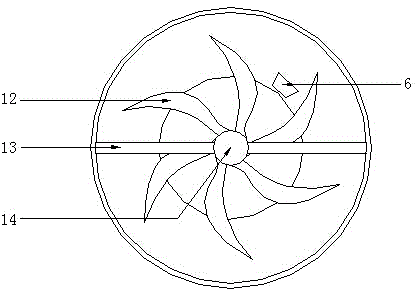

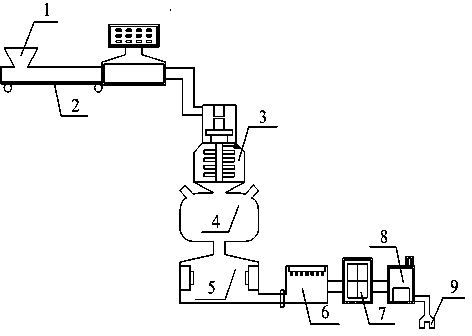

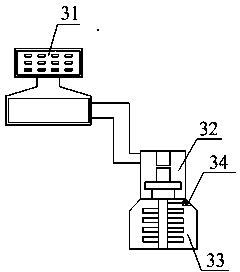

Quickly-moving type concrete mixing station

ActiveCN103660040AShorten the production periodIncrease productivityDischarging apparatusIngredients weighing apparatusMaterial supplyDelivery system

The invention discloses a quickly-moving type concrete mixing station, and relates to the technical field of concrete production equipment. The station comprises an aggregate supplying system, a powdered auxiliary material supplying system, a liquid auxiliary material supplying system, a stirring system, a control panel, a pump delivery system, and a transportation system; wherein the transportation system comprises traction equipment and a trailer plate, the aggregate supplying system, the powdered auxiliary material supplying system, the liquid auxiliary material supply system, the stirring system, the control panel, and the pump delivery system are all arranged on the trailer plate; the aggregate supplying system, the powdered auxiliary material supplying system, and the liquid auxiliary material supplying system all communicate with the stirring system, the stirring system comprises a frame and a stirrer, the stirrer is arranged on the frame; and the pump delivery system is arranged below the material unloading door of the stirrer. The quickly-moving type concrete station has the advantages of compact structure, user-friendliness, and rapid movement, can shorten the construction time and guarantee the concrete quality, satisfies the using requirement of small-batch concrete, improves the construction efficiency, and saves the construction cost.

Owner:SHIJIAZHUANG TIEDAO UNIV +2

Automatic proportioning system of concrete mixing station

ActiveCN105690568AAccurate weighingPrecise deliveryDischarging apparatusMixing operation control apparatusControl systemBucket elevator

The invention discloses an automatic proportioning system of a concrete mixing station. The automatic proportioning system comprises a raw material storage system, a raw material weighing system, a mixer system, a raw material conveying system and a control system, wherein the raw material storage system comprises three silos which are arranged side by side; the raw material conveying system is composed of a belt conveyor and a bucket elevator; and the raw material weighing system comprises three belt weighers which are positioned above the belt conveyor, and are positioned below the openings of the silos. The automatic proportioning system can meet a large-scale concrete manufacturing process, can be used for precisely weighing and conveying various raw materials, and further can realize precise control and efficient management on a concrete proportioning process while the product quality is guaranteed, so that the problems such as a complex and out-of-order procedure in a convention producing and proportioning process, confused record management in a proportioning process, severe proportioning resource waste and the like are obviously avoided.

Owner:陕西恒盛混凝土有限公司

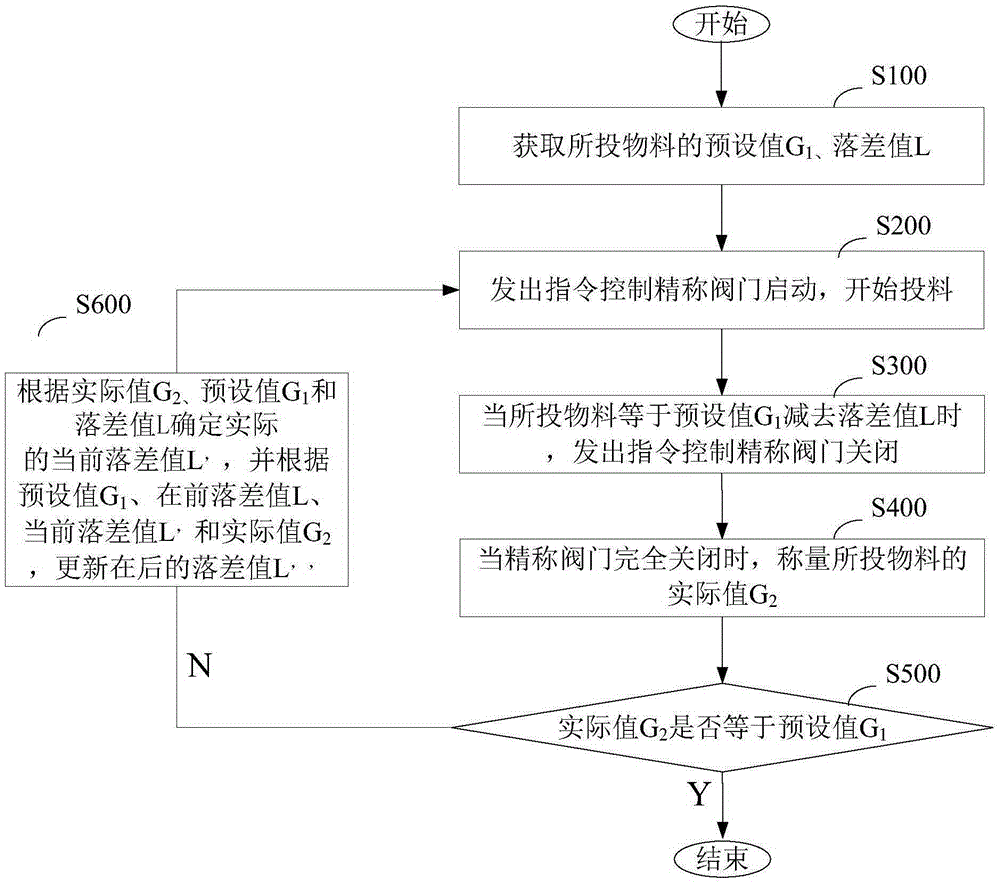

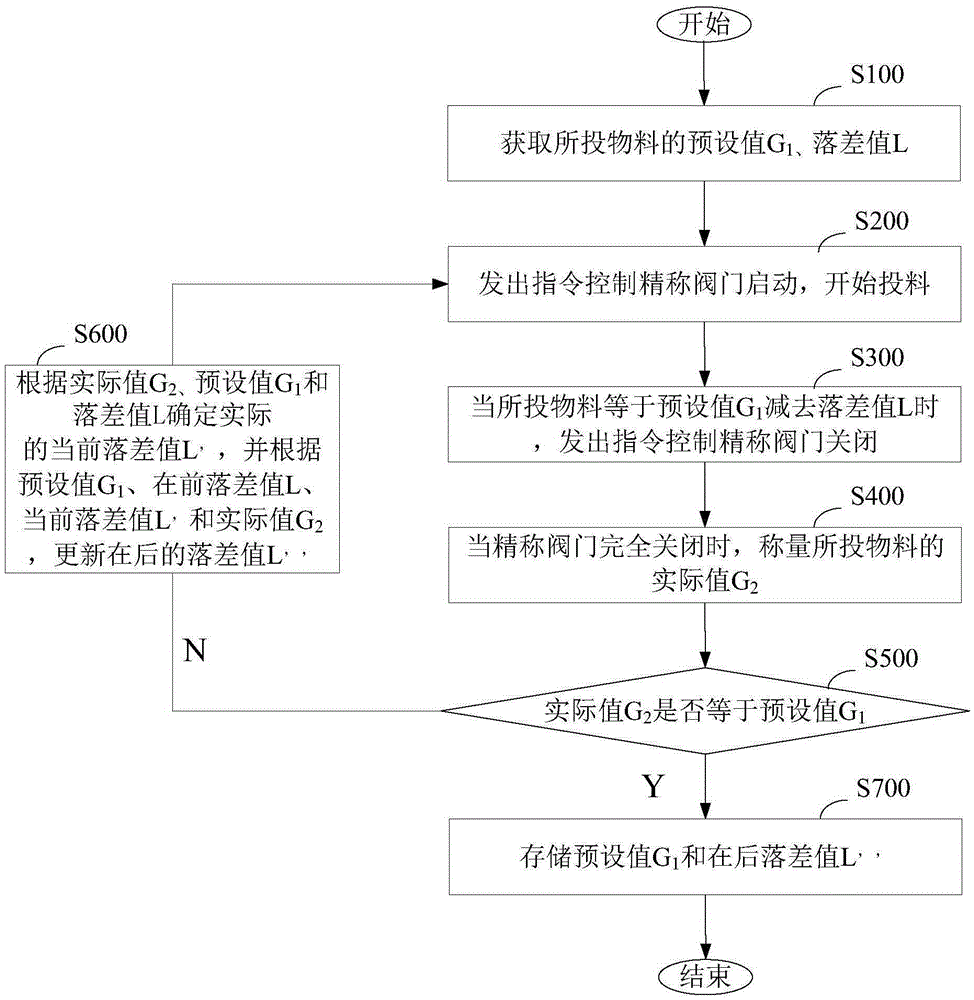

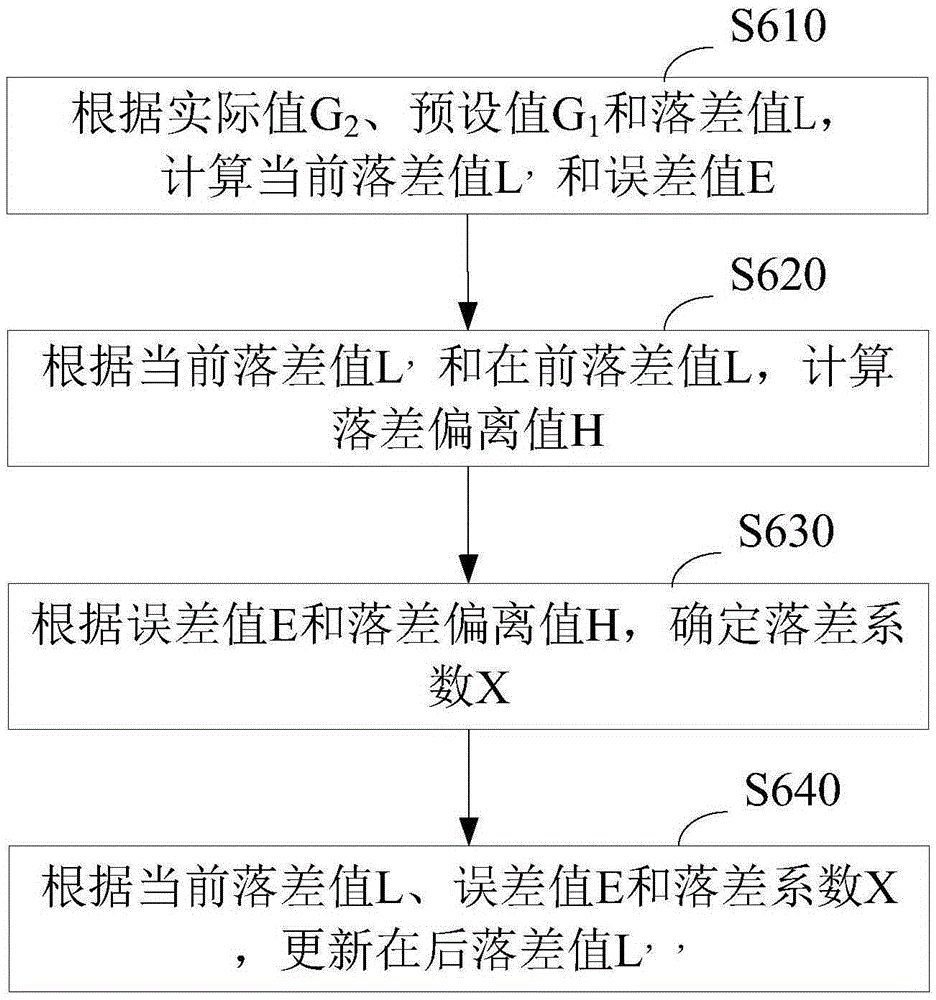

Preset value adjusting method for ingredients, mixing plant ingredient control method and systems

ActiveCN105425641AHigh precisionIncrease productivityMixing operation control apparatusIngredients proportioning apparatusLoop controlAdditive ingredient

The invention discloses a preset value adjusting method and system for ingredients. Later fall value L'' is updated according to a preset value G1, a previous fall value L, a current fall value L' and an actual value G2, the closure time of a precision weighing valve is fed back and adjusted to form closed-loop control, and the adjustment is repeated, so that the actual value G2 of the discharge quantity is equal to the preset value G1 and accurate ingredients are ensured. Further, the preset value adjusting method and system for ingredients are particularly suitable for a mixing plant ingredient control method and system, thus improving the ingredient accuracy in the precision weighing phase, improving the production efficiency and the quality and reducing the production cost.

Owner:HUNAN SANY ROAD MACHINERY

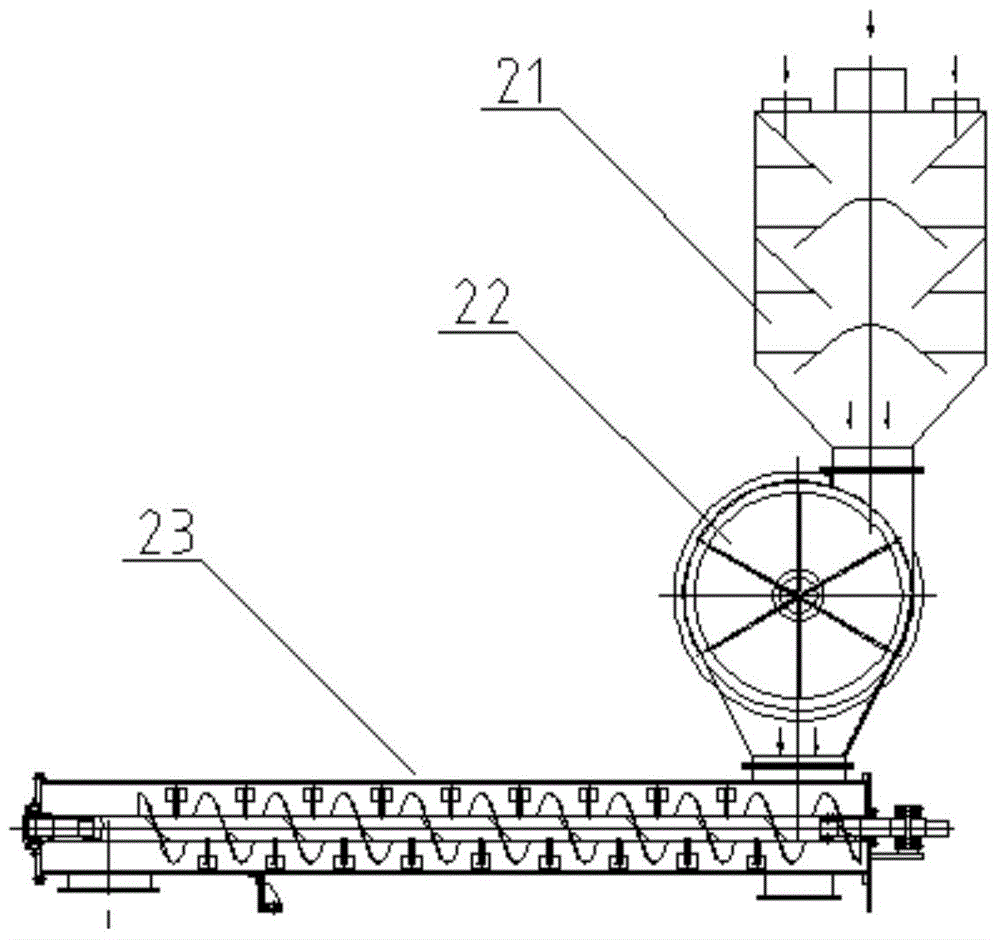

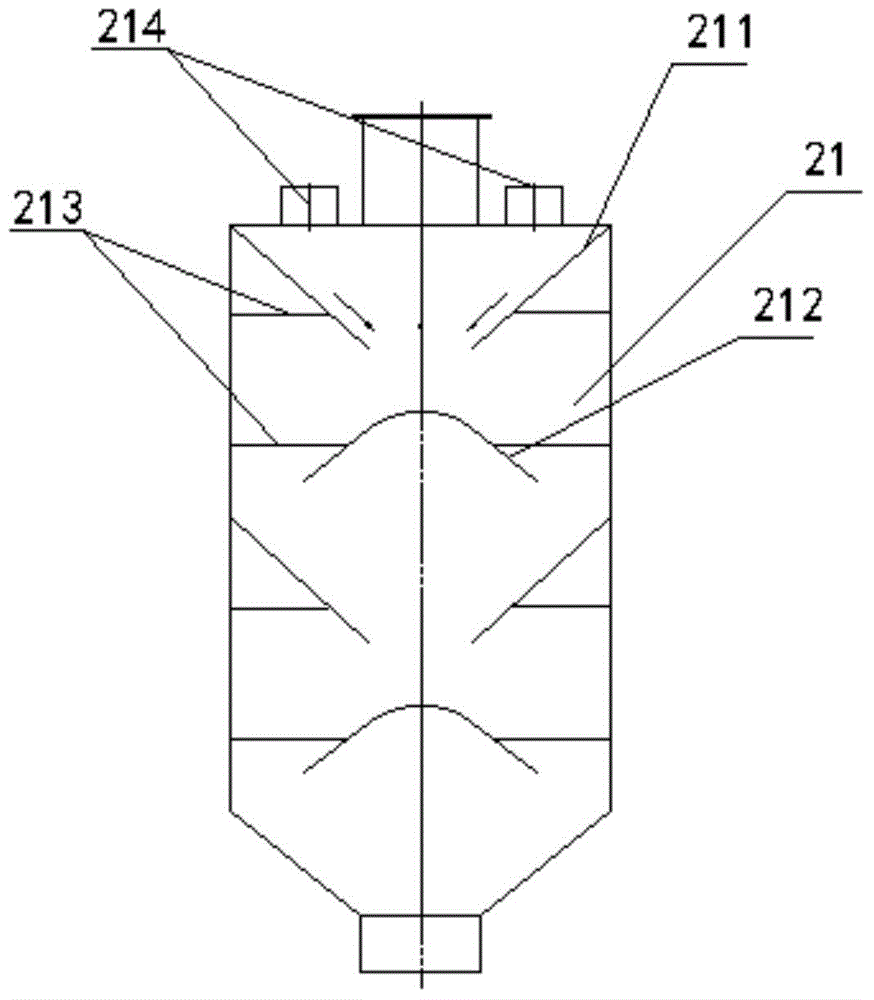

Apparatus and method for a concrete plant

InactiveUS20150103614A1Mixing operation control apparatusTransportation and packagingConcrete plantScrew conveyor

A concrete plant comprising an aggregate feed bin adapted to hold and release aggregate materials, a feed conveyor adapted to receive the aggregate materials from the aggregate feed bin, a collecting belt conveyor adapted to receive the aggregate materials from the feed conveyor, a silo assembly adapted to hold and release components of concrete, a screw conveyor adapted to receive the components of concrete from the silo assembly and convey the components of concrete to the collecting belt conveyor, and a mixer adapted to receive the aggregate materials and components of concrete from the collecting belt conveyor and mix the aggregate materials and components of concrete with water. The amount of aggregate materials received by the collecting belt conveyor from the conveyor and the amount of concrete components received by the collecting belt conveyor from the conveyor are precisely and accurately controlled.

Owner:ASTEC

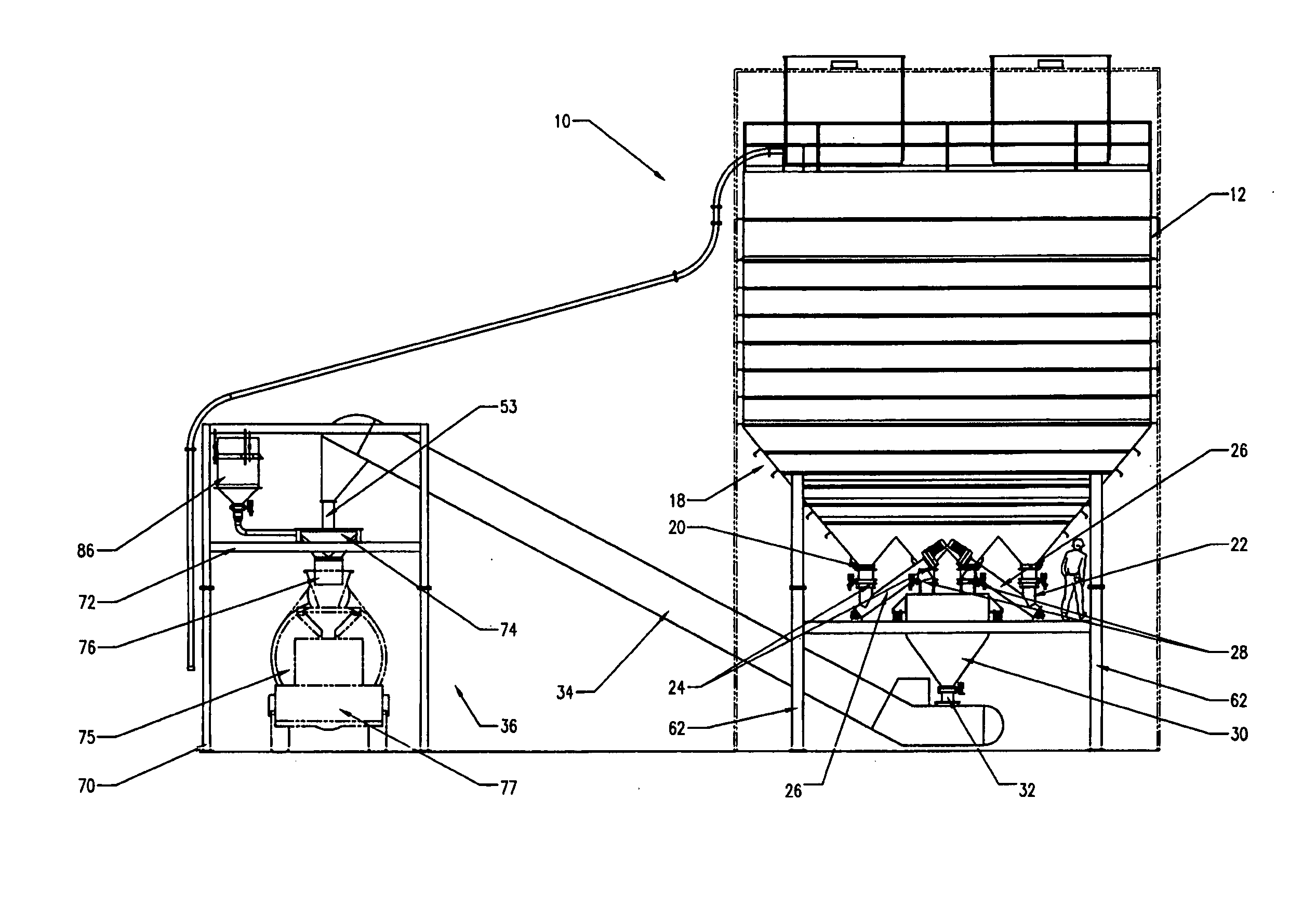

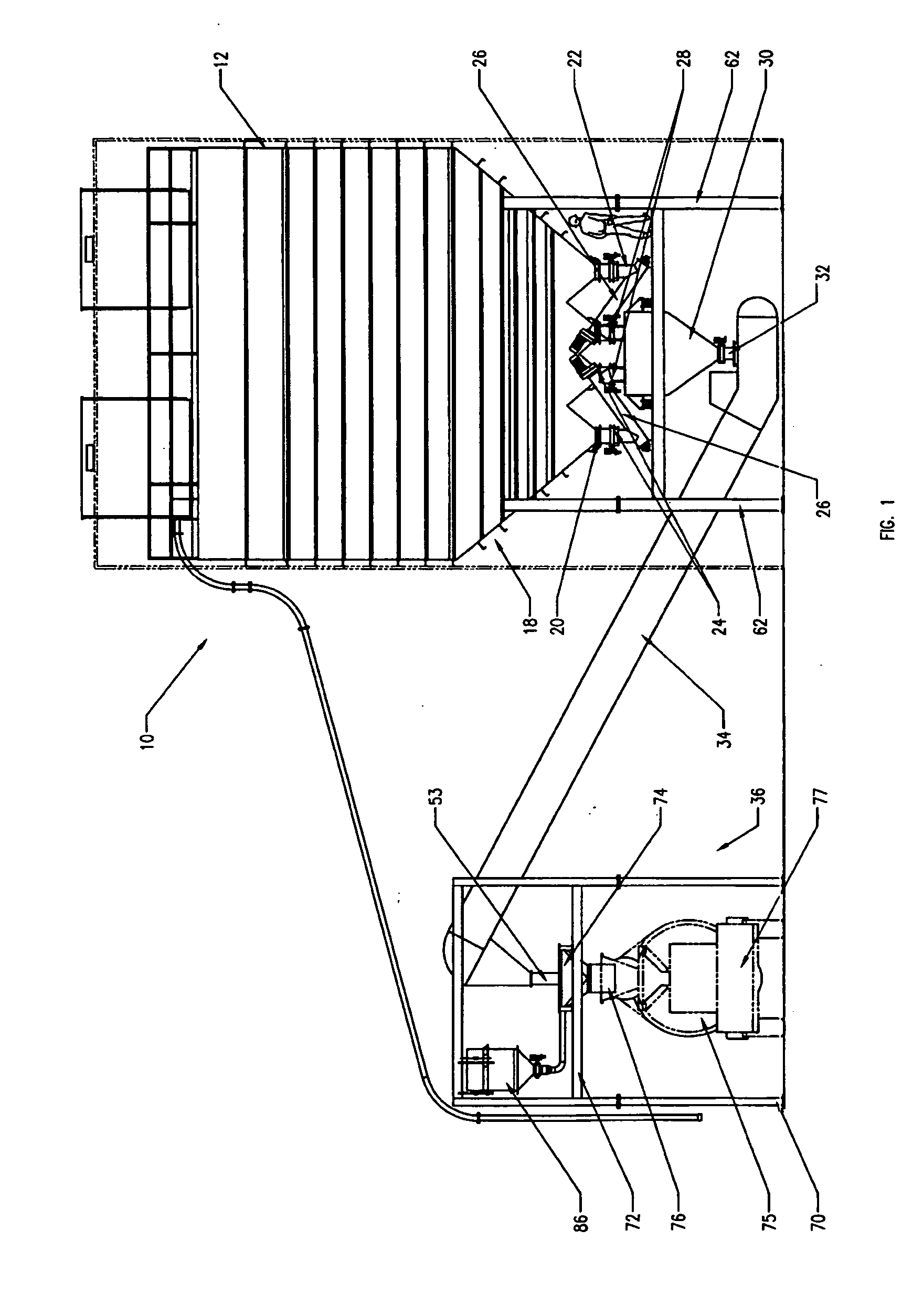

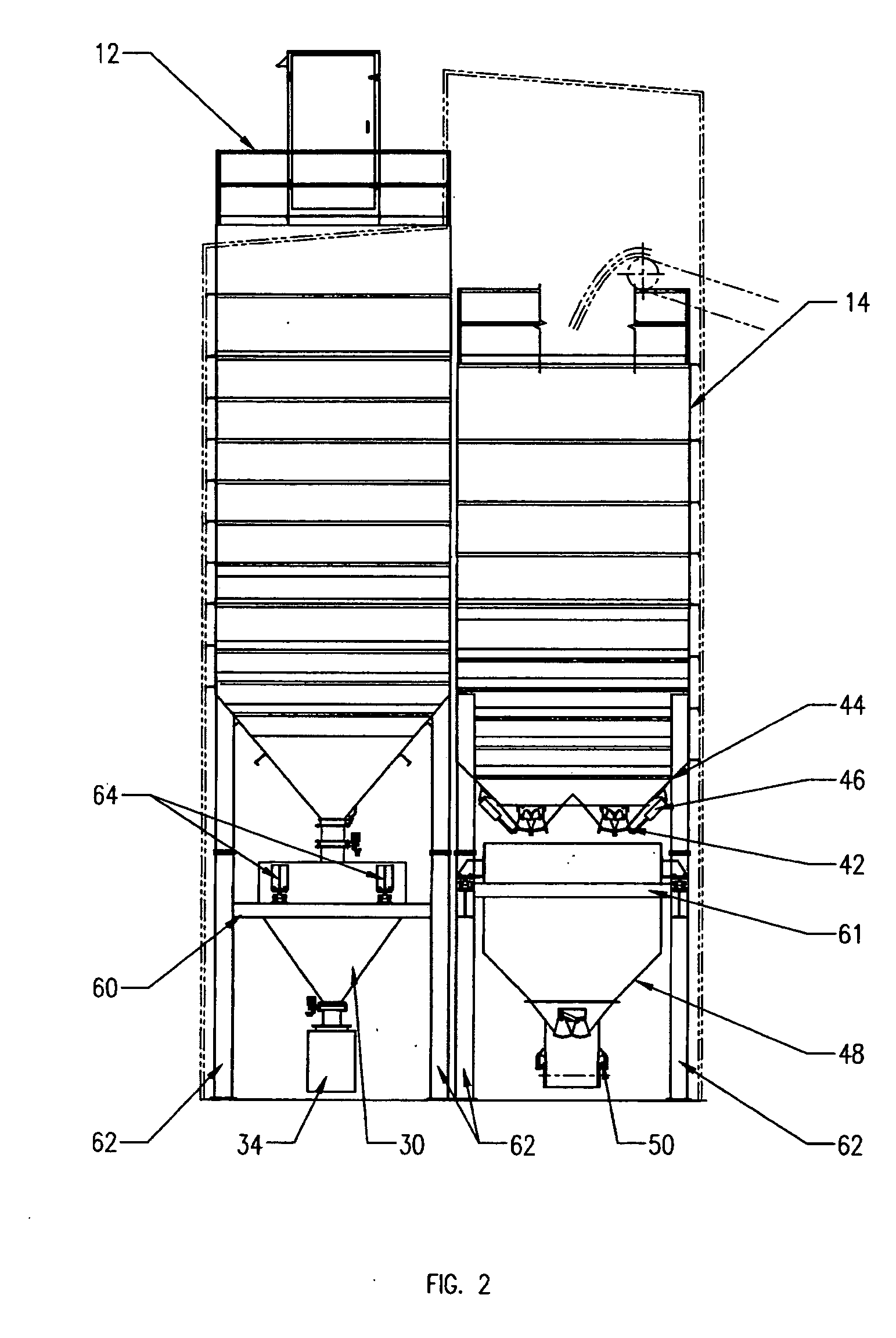

Aggregate handling system

An aggregate handling system includes an aggregate delivery station, which includes one or more delivery bays for receiving aggregate from a delivery truck. The system includes storage apparatus associated with each delivery bay and adapted to receive aggregate by gravity feeding from that delivery bay, wherein each storage apparatus includes one or more storage hoppers. The system also includes weigh apparatus associated with each storage apparatus and adapted to receive aggregate from that storage apparatus, wherein each weigh apparatus includes one or more weigh hoppers, and a conveyor for receiving aggregate from the weigh apparatus and being adapted to transfer aggregate to a batching area.

Owner:INTRAY CONSOL

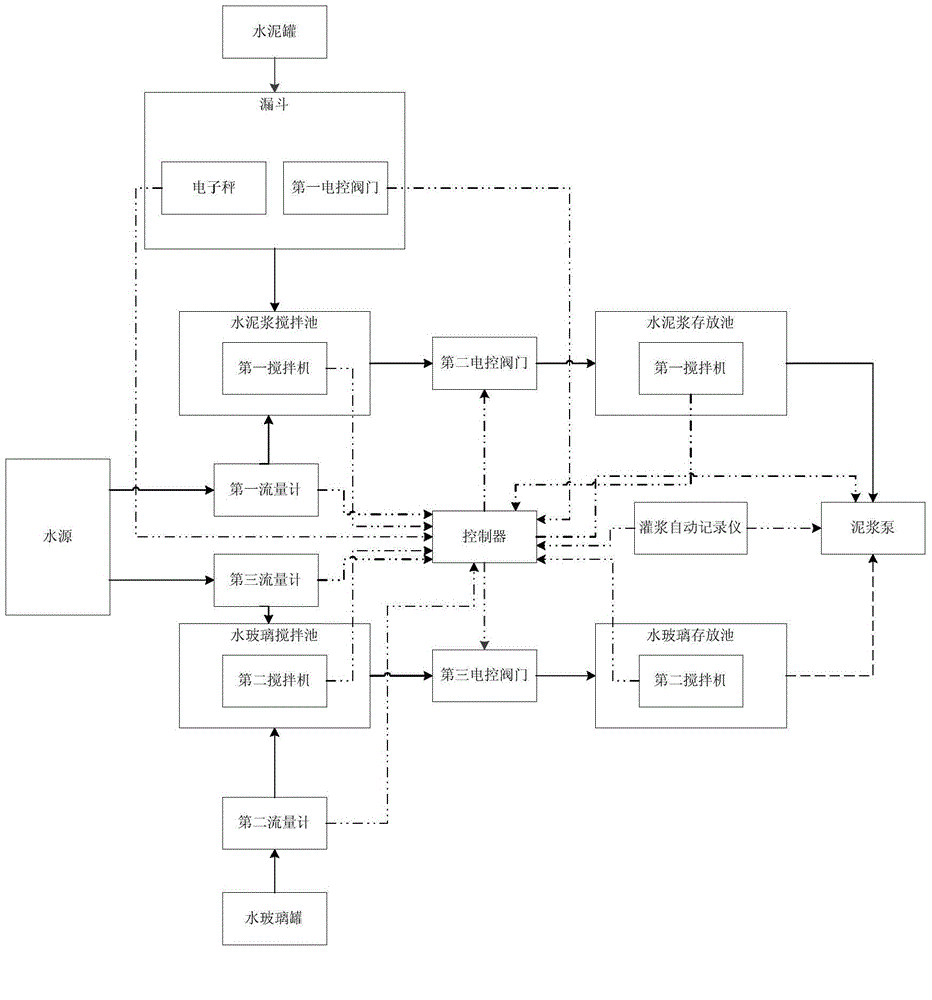

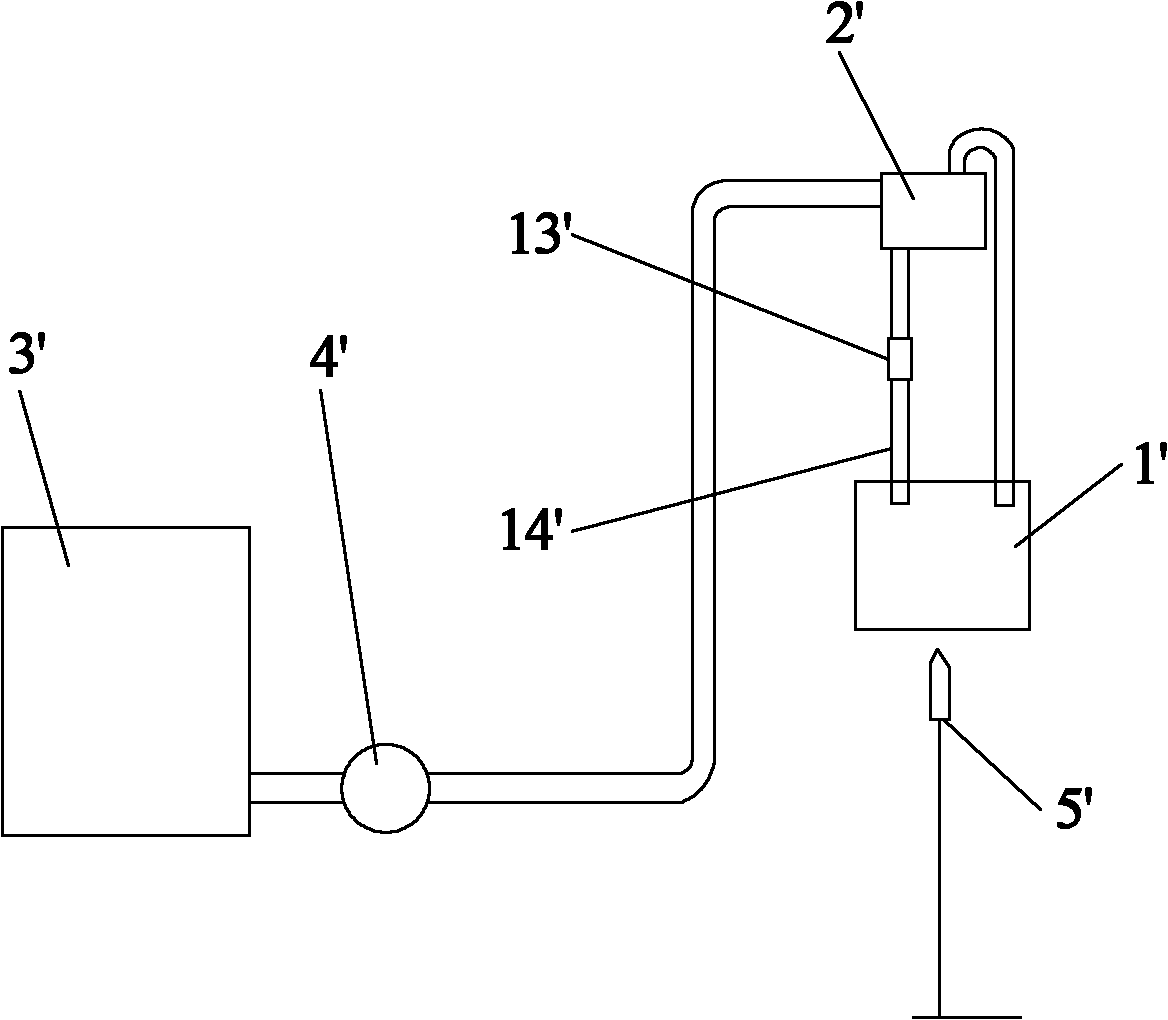

Automatic grouting system

ActiveCN104632252AReduce manual pulpingReduce monitoring requirementsUnderground chambersMixing operation control apparatusCement slurryElectric control

The invention relates to an automatic grouting system comprising a cement tank, a funnel, a first electric control valve, a cement slurry stirring pool, a cement slurry storing pool, a second electric control valve, a cement slurry pump, an automatic grouting recorder, a first water injection pipeline, a first flow meter, a controller, a sodium silicate tank, a sodium silicate tank stirring pool, a conveying pipeline, a second flow meter, a sodium silicate storing pool, a second water injection pipeline and a third flow meter. By the adoption of the automatic grouting system, the slurry manufacturing process is controlled and monitored through an electronic scale, the electronic control valve, the flow meter, the automatic grouting recorder and the controller, the requirements existing during manual slurry manufacturing and monitoring are reduced, the work efficiency is improved, and labor cost is reduced.

Owner:GUANGZHOU XINQIAO CONSTR SERVICE +2

Concrete integral production system

ActiveCN105922438AStir wellAvoid slump lossDischarging apparatusMixing operation control apparatusMaterial supplyBelt machine

The invention discloses a concrete integral production system. The concrete integral production system comprises a dry material supply device, a concrete stirring device, a spiral extrusion conveying device and a control device; the dry material supply device, the concrete stirring device and the spiral extrusion conveying device are joined in sequence, wherein the dry material supply device includes a cement conveying line, a sand conveying line and a bubble conveying line; and cement, sand and bubble are pneumatically conveyed by the dry material supply device to enter a conveying belt machine, and are conveyed to the concrete stirring device by the conveying belt machine. Raw materials are conveyed by using a remote supply system, and are stirred by adding water in scene, so that dry concrete can be transported remotely or even preserved through sealing, the business scope of a concrete mixing plant is widened, the slump loss of concrete in the transportation process is prevented, and the construction while stirring is realized.

Owner:东莞市交港建材有限公司

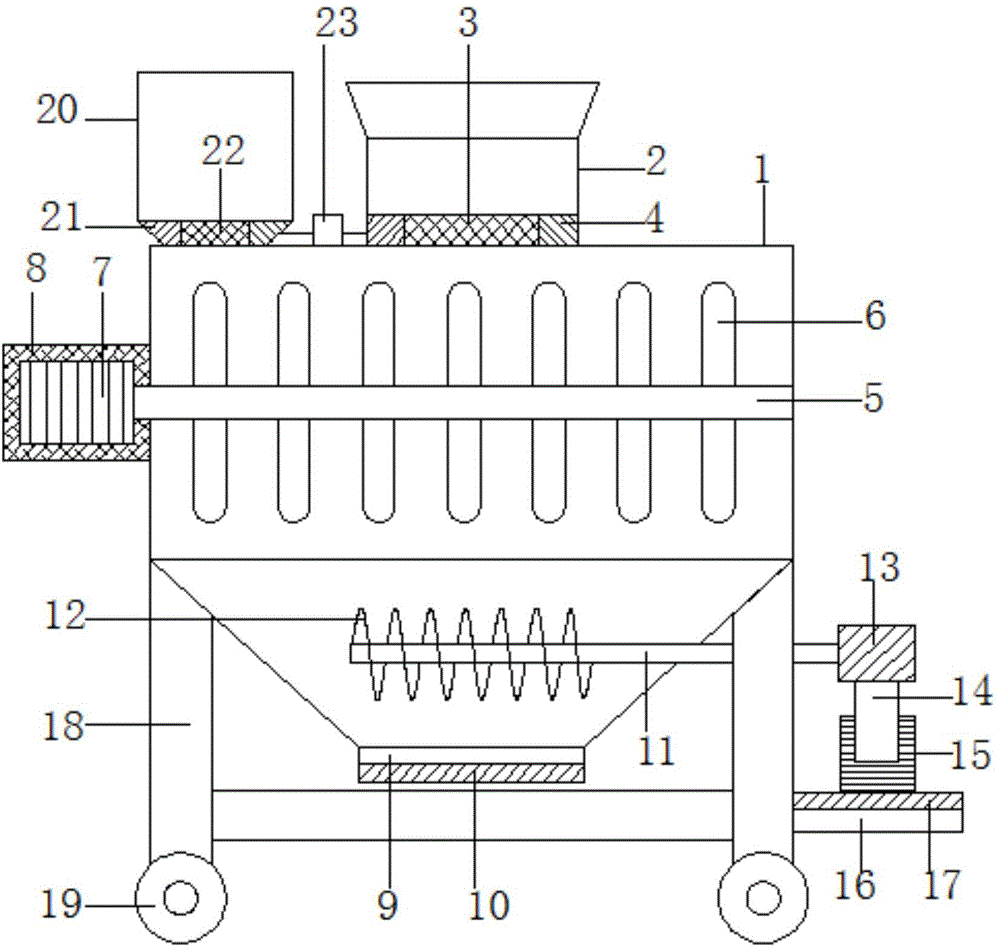

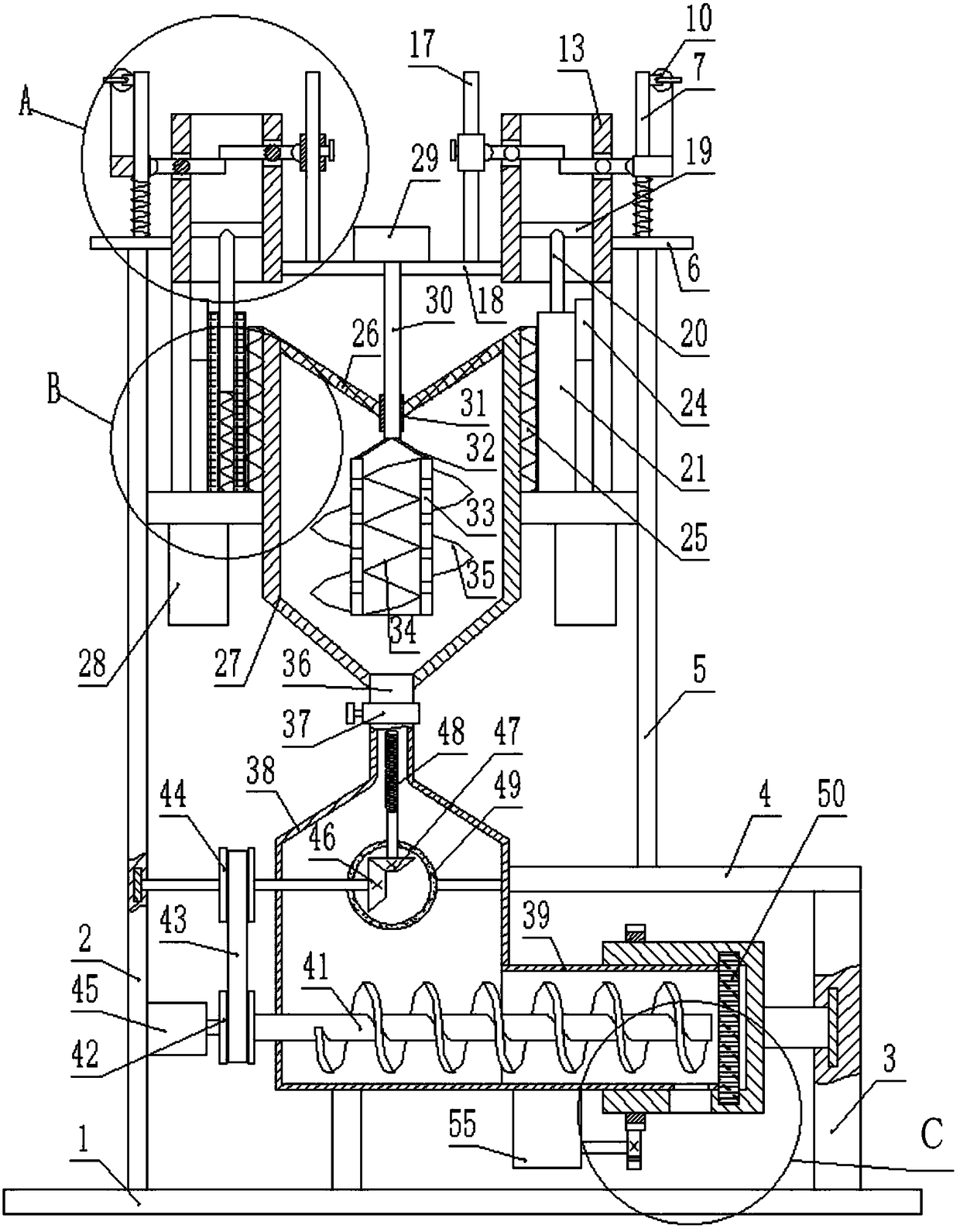

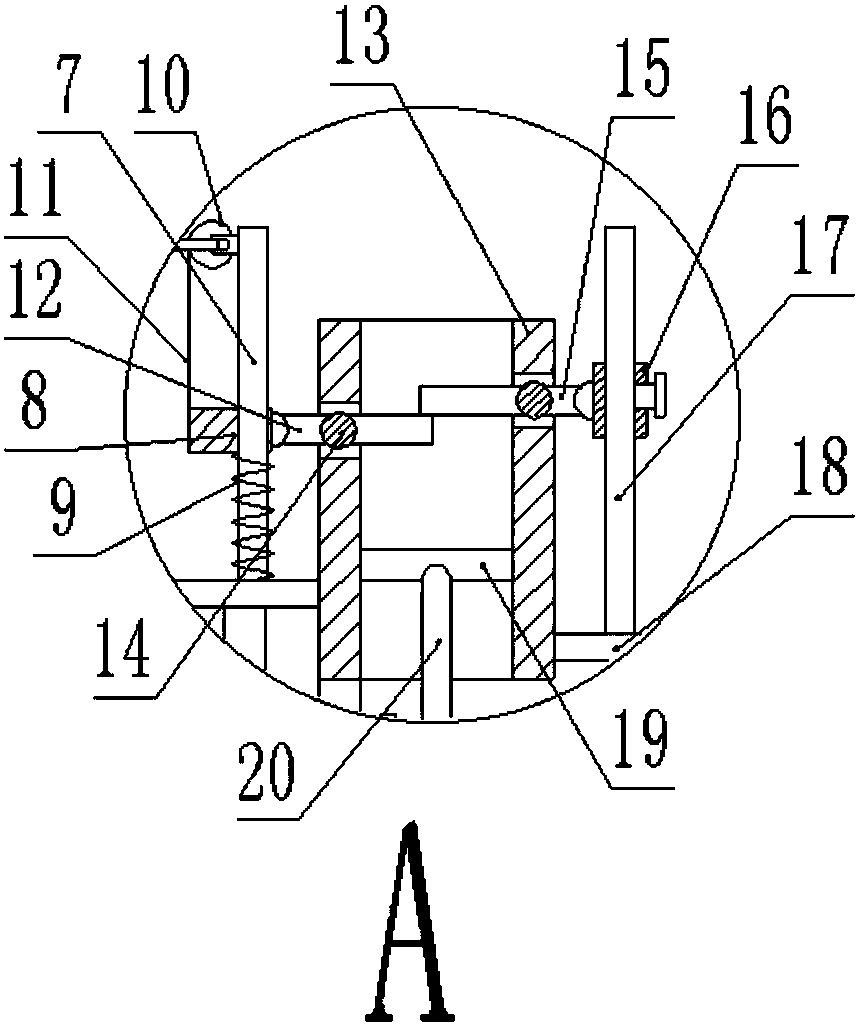

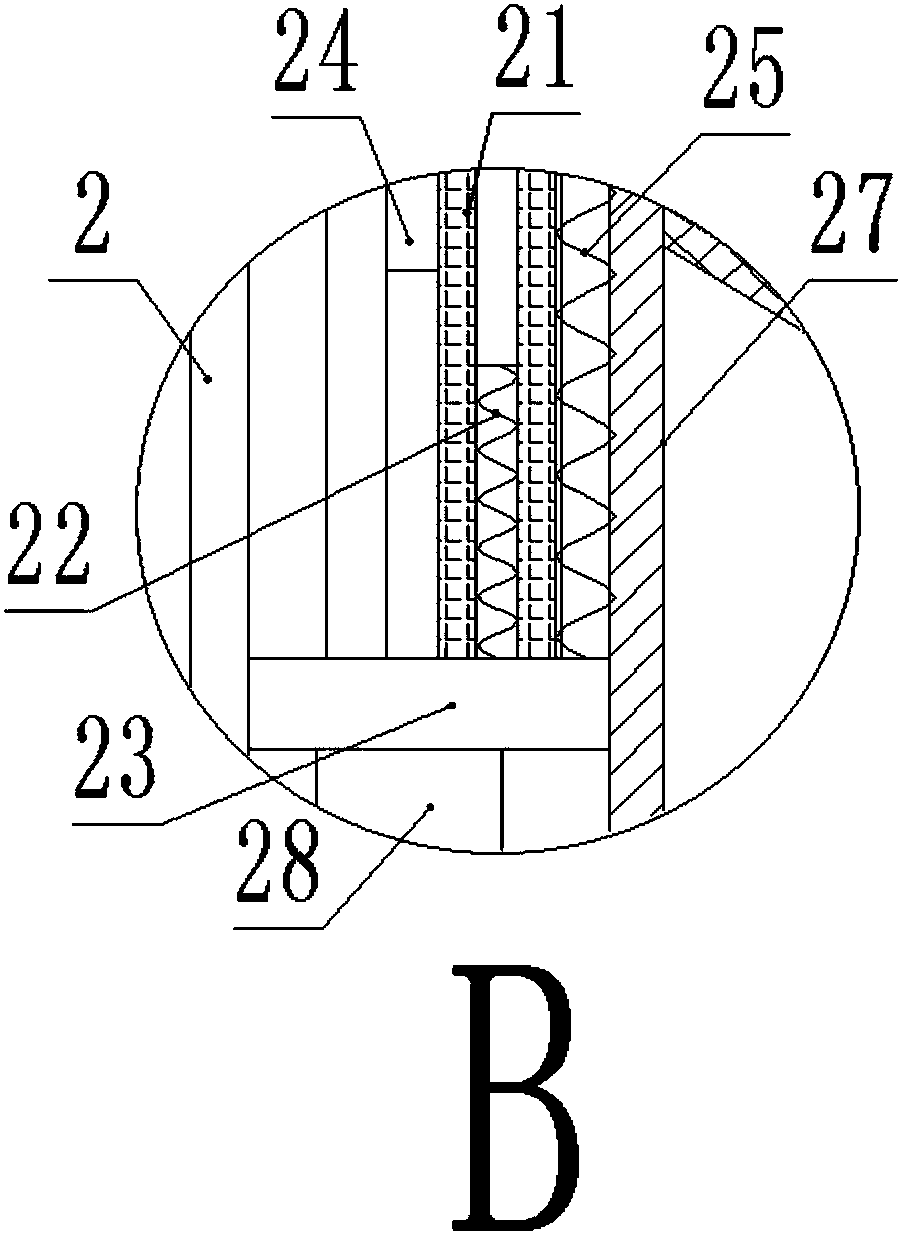

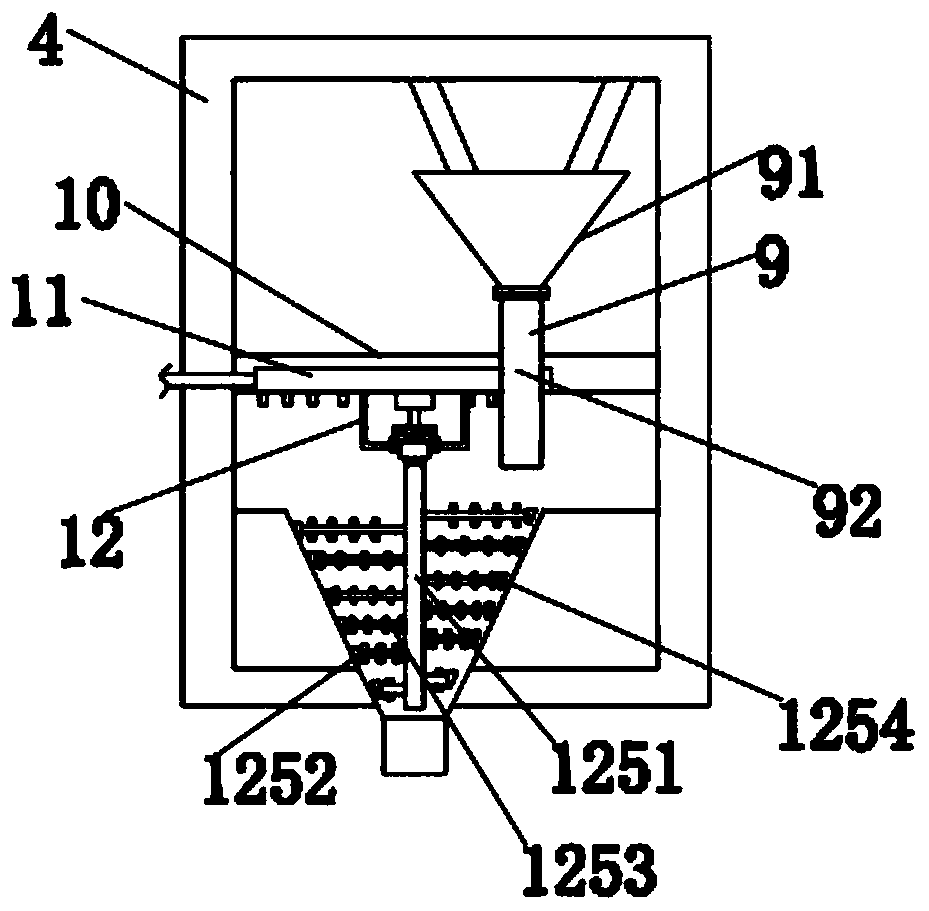

Concrete quantified mixing device

InactiveCN108162194AStir wellGuaranteed finenessMixing operation control apparatusIngredients weighing apparatusEngineering

The invention discloses a concrete quantified mixing device which comprises a base. A supporting rod A and a supporting rod B are fixedly arranged at the top of the base. The top end of the supportingrod B is fixedly connected with a fixed transverse rod. The top end of the fixed transverse rod is fixedly connected with a supporting rod C. The top end of the supporting rod A and the top end of the supporting rod C are fixedly connected with supporting plates. A fixed vertical rod A is connected to each supporting plate. In the design, through rotating control of two striker plates, the rate of adding concrete raw materials can be controlled, and therefore it is guaranteed that the needed raw material quantity can be grasped; through the interaction of weighing plates and shrinkage springs, the quantity of concrete added into a stirring barrel can be controlled more precisely, and therefore quantified mixing is effectively achieved, and the matching time is reduced; and through rotation of two blades different in spiral direction, the concrete on the upper portion in the stirring barrel can be conveyed downwards, the concrete on the lower portion in the stirring barrel can be conveyed upwards, the concrete cyclically flows in the stirring barrel, and the effect of uniform concrete mixing is achieved.

Owner:张志通

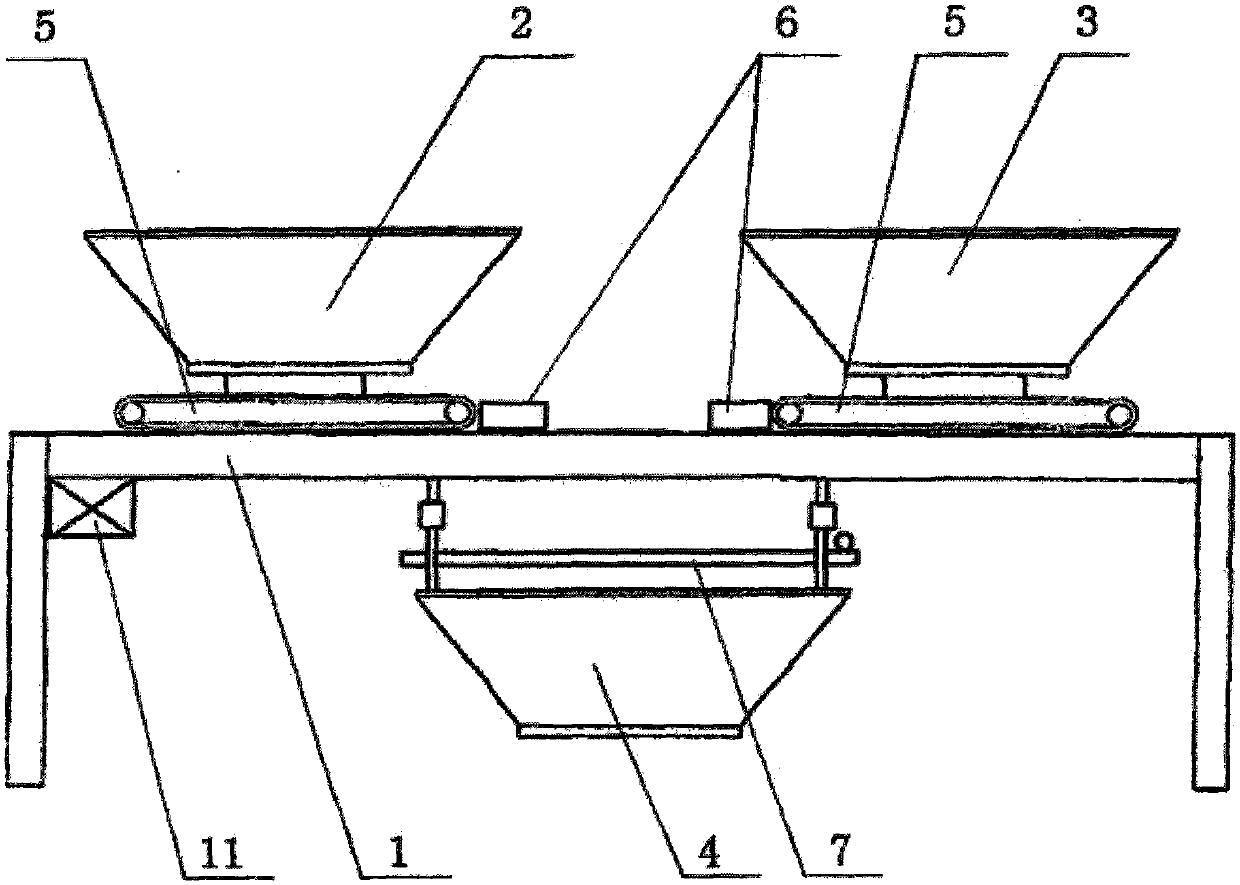

Concrete batching plant

InactiveCN105365051AUniform particlesQuality improvementMixing operation control apparatusIngredients weighing apparatusWaste managementRaw material

The invention relates to a concrete batching plant. The concrete batching plant comprises a support, a stone hopper, a sand hopper and a storage hopper. The stone hopper and the sand hopper are installed above the support, and the storage hopper is installed below the support. Conveying devices are arranged at the bottom of the stone hopper and the bottom of the sand hopper respectively, and a weighing device is arranged at one end of each conveying device. The storage hopper is located below the weighing devices. A vibrating screen is further arranged above the storage hopper. According to the concrete batching plant, the vibrating screen is arranged above the storage hopper, particles of raw materials can be screened accordingly, and the concrete particles are uniform and good in quality. Meanwhile, the weighing devices are further arranged on the concrete batching plant, and all the raw materials can be accurately weighed.

Owner:张琳

Aggregate handling system

Owner:INTRAY CONSOL

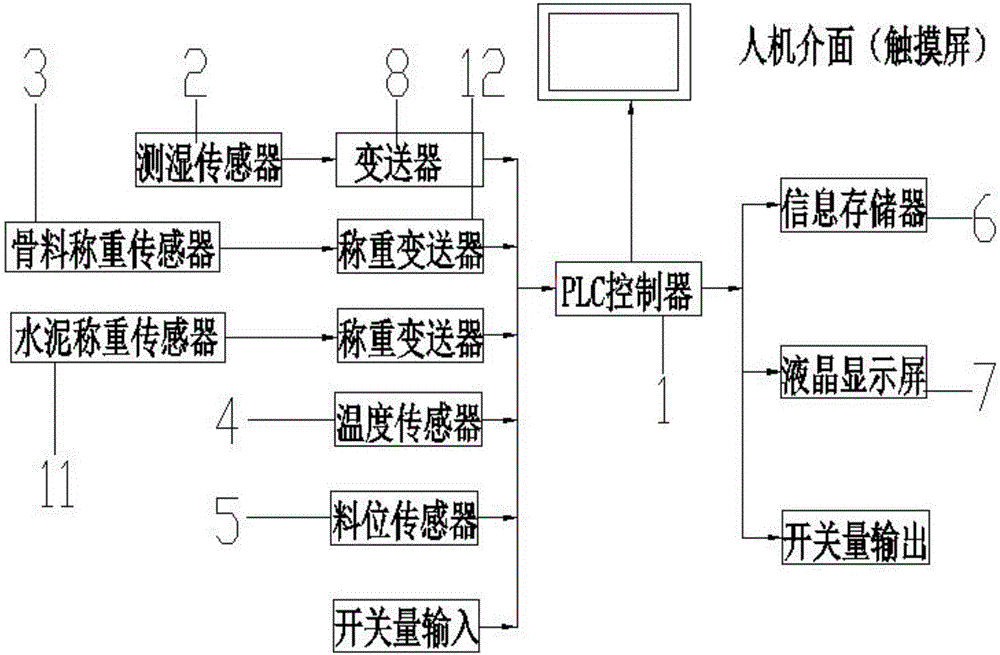

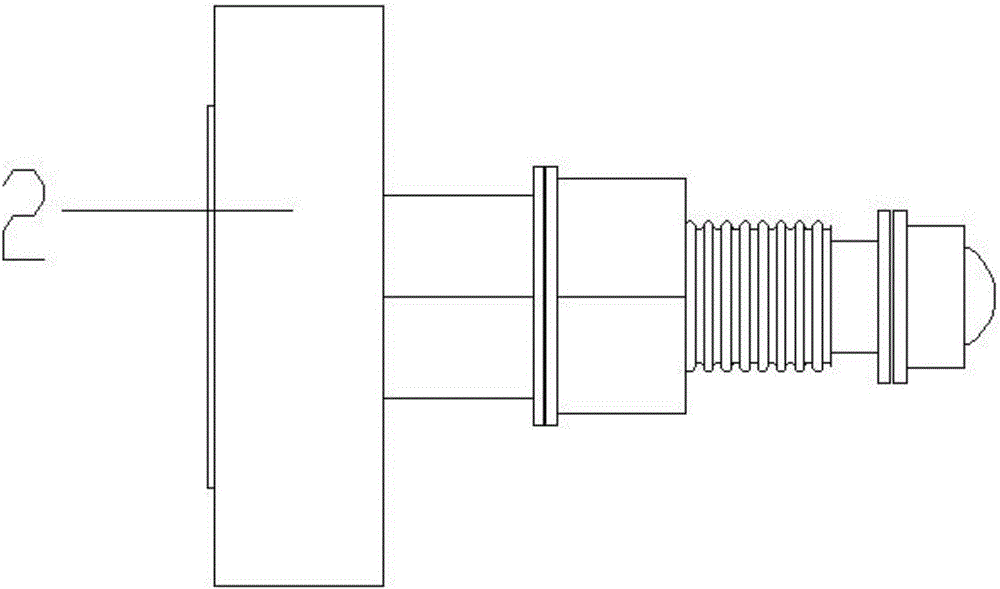

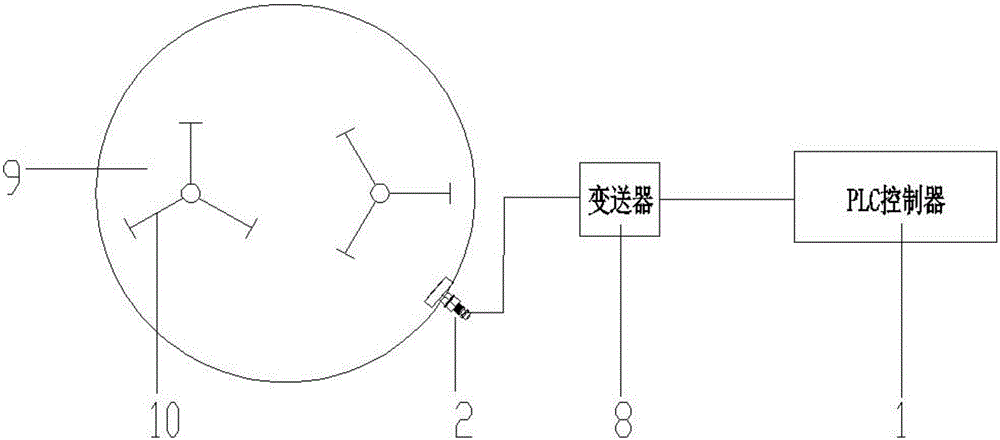

Full-automatic batching and mixing control system adopting method of sand enveloped with cement

InactiveCN106584674AUse Quantity ControlAvoid errorsMixing operation control apparatusIngredients weighing apparatusEngineeringMoisture sensor

The invention discloses a full-automatic batching and mixing control system adopting a method of sand enveloped with cement. The full-automatic batching and mixing control system comprises a PLC, a moisture testing sensor and an information memory, wherein the moisture testing sensor is fixedly mounted in the inner chamber of a mixing tank; and mixing blades are also mounted in the inner chamber of the mixing tank. The method of sand enveloped with cement comprises the following steps: (3) adopting a repeated feeding method, stopping feeding after 90-95% of a material is fed into a scale, and then performing intermittent inching feeding till the required weight is reached; (4) feeding batched sandstone into the mixing tank, adding a proper amount of water, and controlling the water adding precision through the moisture testing sensor; (7) uniformly mixing, then performing moisture testing, and conducting intermittent inching water replenishing; and (8) discharging 30-50% of the material in a mixer when the material exists in an end product hopper, and stopping working. The full-automatic batching and mixing control system adopting the method of sand enveloped with cement adopts intermittent inching feeding and avoids errors caused by once feeding, the sandstone enters the mixer, a proper amount of water is added, then cement is fed, the product strength is improved, and the water adding precision is improved since the moisture sensor is arranged.

Owner:齐跃广

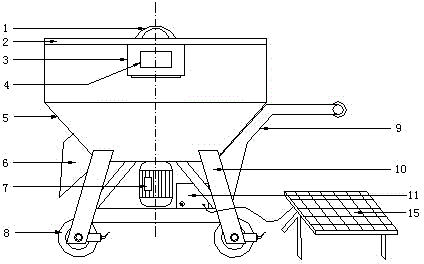

Minitype concrete mixing machine

InactiveCN104626358AEnsure safetyIngredients weighing apparatusCement mixing apparatusArchitectural engineering

The invention discloses a minitype concrete mixing machine, and relates to the technical field of construction equipment. Trundles with brakes are mounted at the lower ends of a rack; a push handle is welded on one side of the rack; a stirring barrel is mounted at the upper end of the rack and is fixedly welded with the push handle and the rack; a barrel cover is arranged at the upper end of the stirring barrel; a pull handle is mounted in the middle of the upper end of the barrel cover; a stirring shaft is vertically mounted inside the stirring barrel; the lower end of the stirring shaft penetrates out of the stirring barrel and is connected with a stirring motor positioned at the lower end of the stirring barrel; a plurality of stirring paddles are uniformly mounted on the outer wall of the stirring shaft; a weighing feeding hopper is hinged with one side of the upper end of the stirring barrel; a discharging hole is formed in one side of the lower end of the stirring barrel. The minitype concrete mixing machine is novel in design, simple in structure, relatively small in size, high in stability and high in practicability, and can conveniently move.

Owner:JINLING INST OF TECH

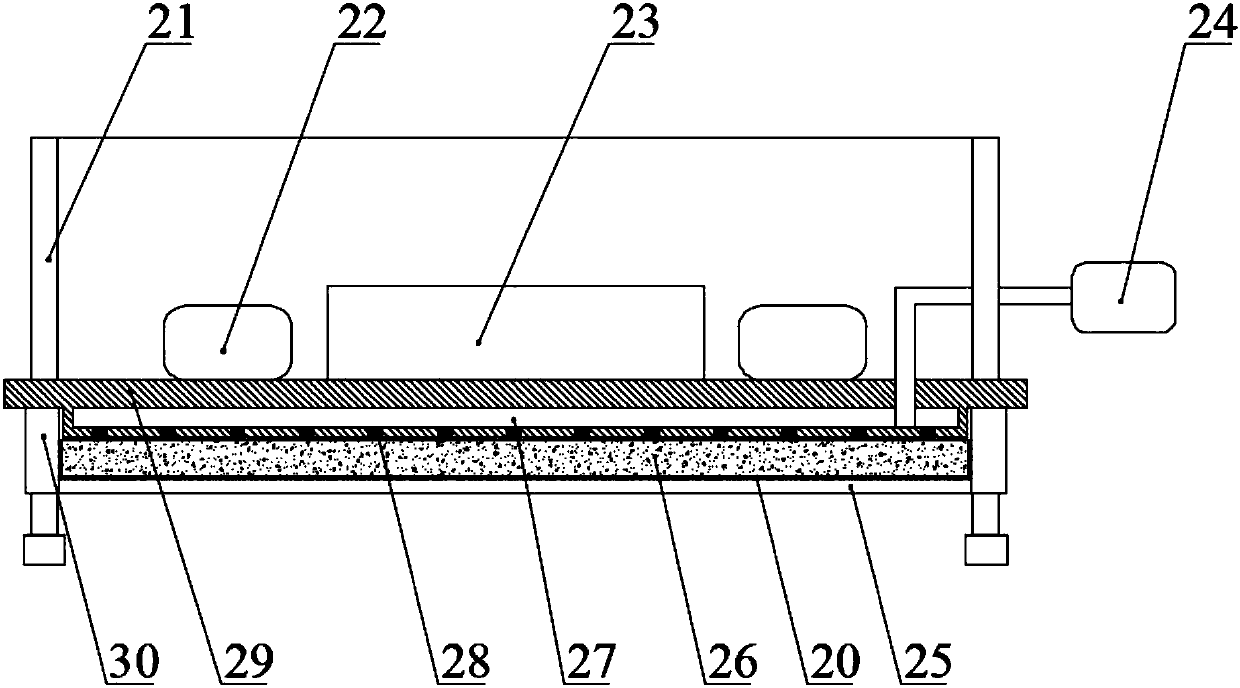

Inorganic noiseless artificial slabstone production system and technology

InactiveCN107775788ATight textureVariety of colorsMixing operation control apparatusCeramic shaping plantsPulp and paper industrySlurry

Provided is an inorganic noiseless artificial slabstone production system. The inorganic noiseless artificial slabstone production system comprises a vacuum press machine and also comprises a raw material tank, a bucket type weighing scale, a vacuum stirring tank and a material spreader connected successively by a sealed conveying device. Dry raw materials are quantitatively conveyed from the rawmaterial tank to the bucket type weighing scale for weighing, the dry raw materials are conveyed into the vacuum stirring tank to be added with water so as to make a slurry, the slurry is conveyed into the material spreader to make slurry plates, and finally the slurry plates are conveyed to the vacuum press machine for pressing to make slabs. The artificial slabstone produced by means of the production system and technology has the advantages of environmental protection and high yield, and the whole production system is precisely controlled by the PLC controller. The produced artificial slabstone has clear texture and distinct color, and the internal texture is tight and has no bubbles, so the artificial slabstone is widely used in the decoration industry.

Owner:孙改名

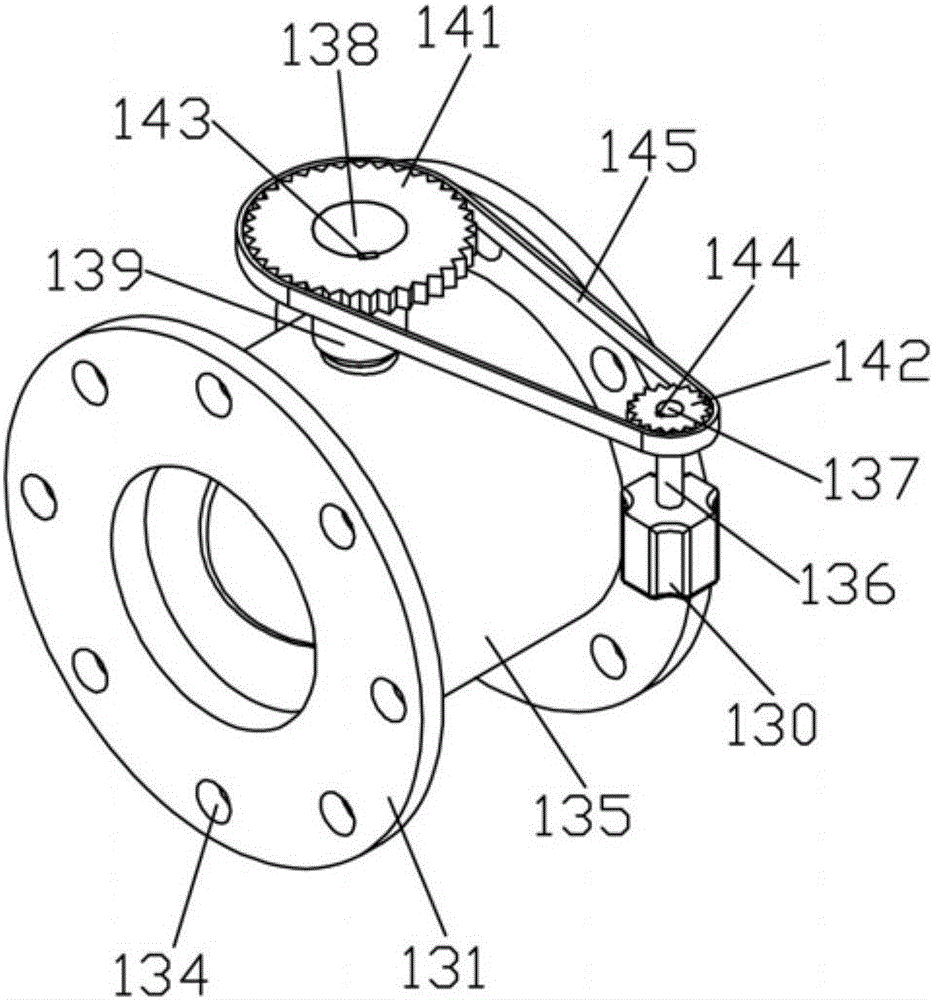

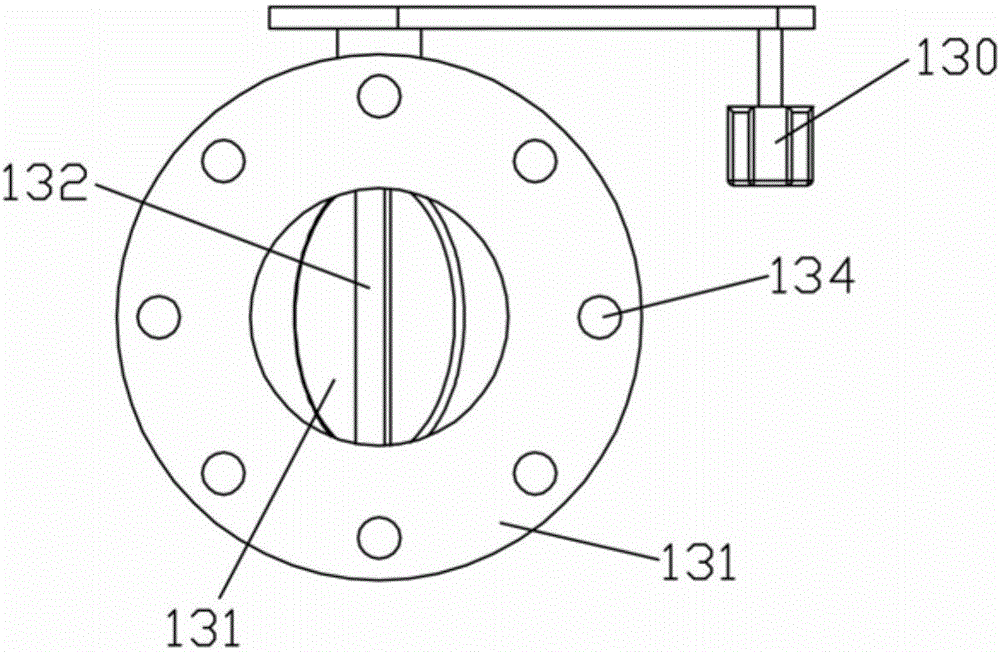

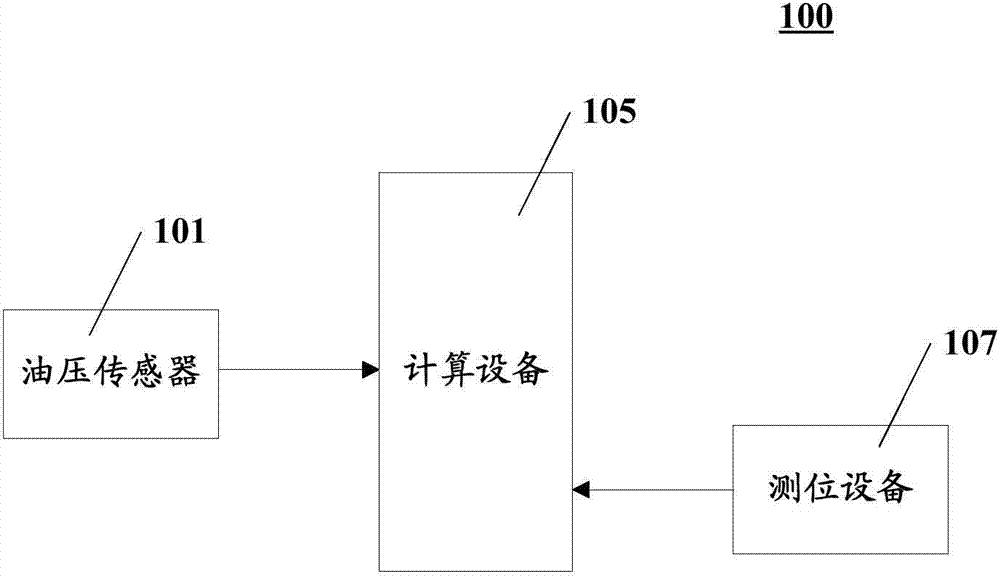

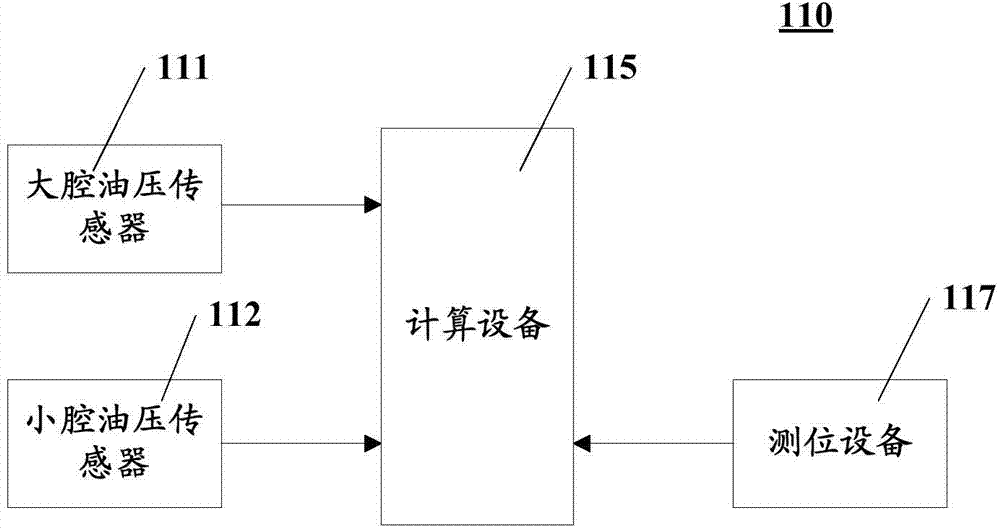

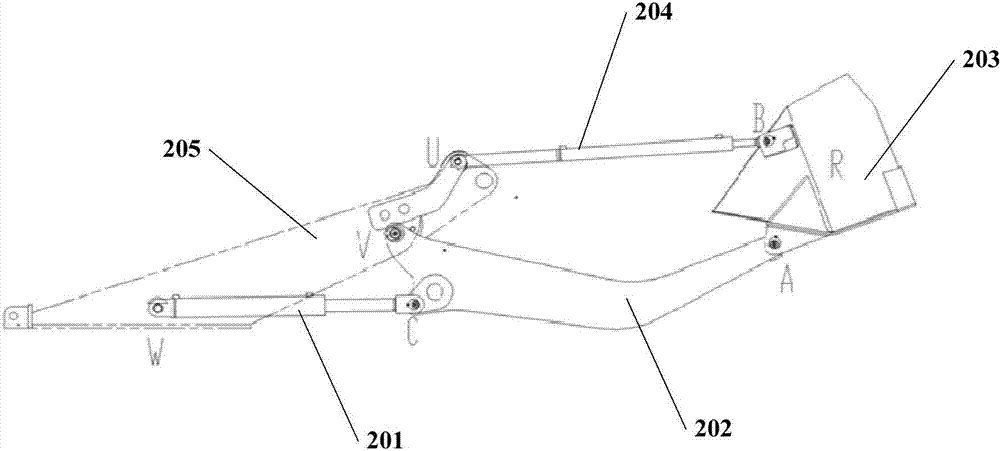

Ingredient weighing metering device and method for material self-loading mixer

ActiveCN104118056ASolve problems such as inconvenient replacementIncrease productivityMixing operation control apparatusIngredients weighing apparatusAdditive ingredientOil pressure

The invention discloses an ingredient weighing metering device and method for a material self-loading mixer. The ingredient weighing metering device for the material self-loading mixer comprises an oil pressure sensor, a position measuring device and a calculation device; when in static weighing, the weight of an ingredient can be calculated by combination of the oil pressure of a large cavity and the oil pressure of a small cavity according the cross-sectional area of the large cavity and the cross-sectional area of the small cavity of a lifting oil cylinder; and / or when in dynamic weighing, the weight of an ingredient can be calculated by combination of the oil pressure of the large cavity and the oil pressure of the small cavity and the time for a lift arm to pass through a dynamic measurement position range according the cross-sectional area of the large cavity and the cross-sectional area of the small cavity of a lifting oil cylinder; the ingredient can be weighed by use of the ingredient weighing metering device and method for the material self-loading mixer.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

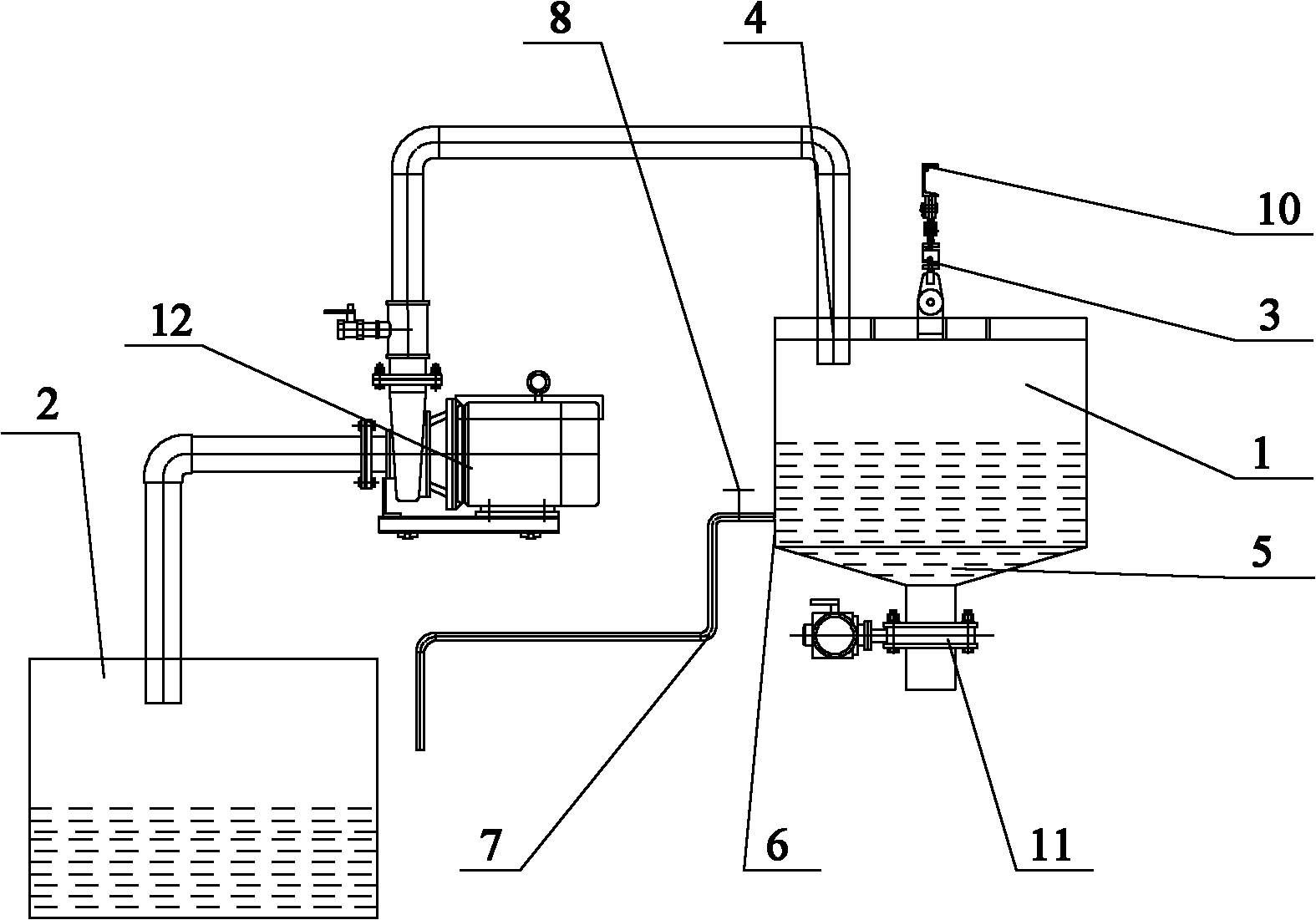

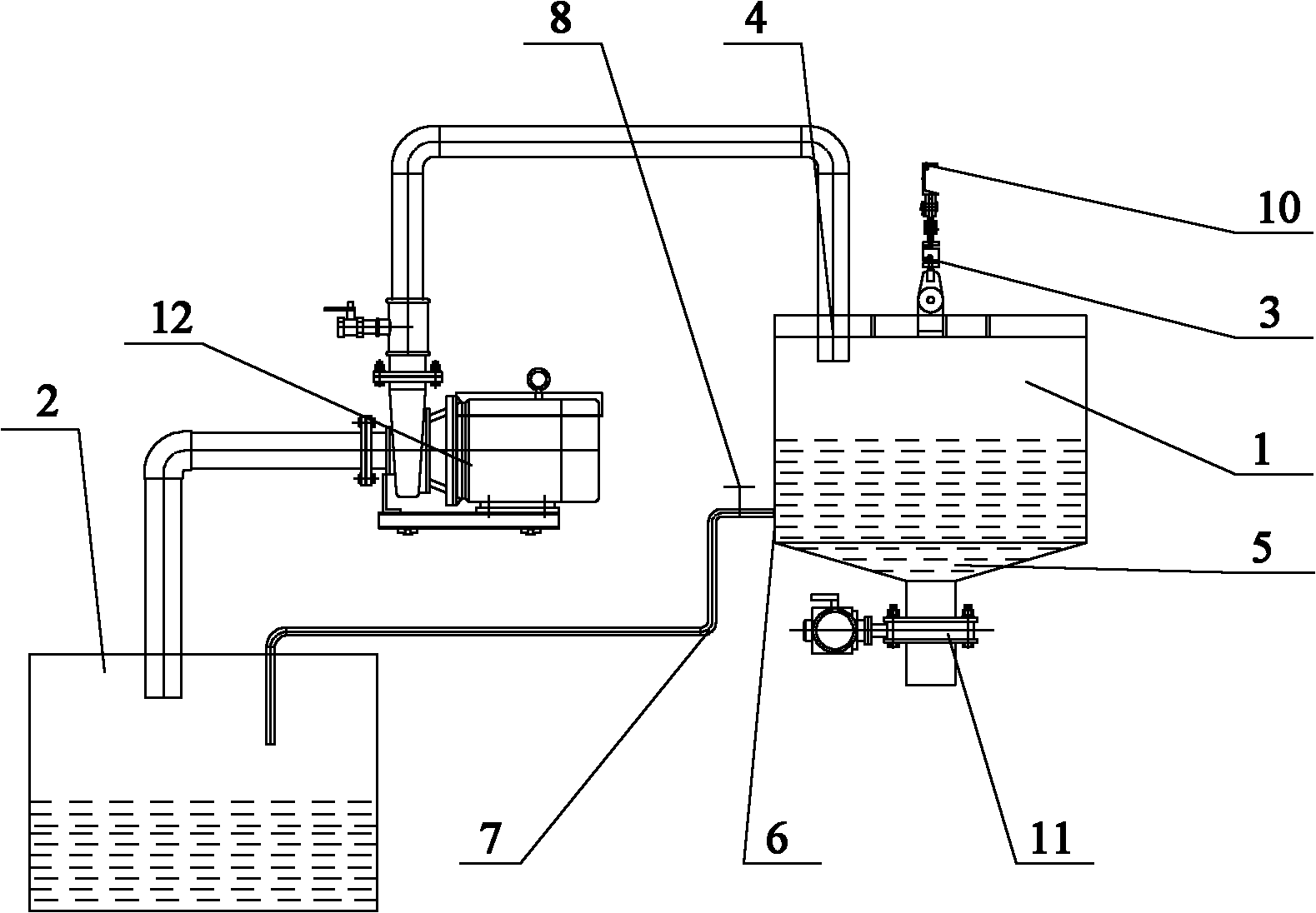

Water supply metering device and concrete stirring equipment comprising same

ActiveCN102133770AReduce shockHigh measurement accuracyIngredients weighing apparatusCement mixing apparatusWater storageWater discharge

The invention provides a water supply metering device of concrete stirring equipment and the concrete stirring equipment comprising the same. The water supply metering device comprises a water storage tank (1) provided with a water inlet (4) and a water discharging port (5), and a weighing sensor (3), wherein a water quantity adjusting port (6) is arranged at the lower end of the water storage box (1) and is connected with a water discharging pipe (7) provided with a valve (8). In the water supply metering device, the weight-reducing method is utilized to adjust the water quantity of a water supply tank accurately, so that the water supply accuracy of the concrete stirring equipment is realized, and the quality of a product produced by the concrete stirring equipment is improved.

Owner:SANY HEAVY IND CO LTD (CN)

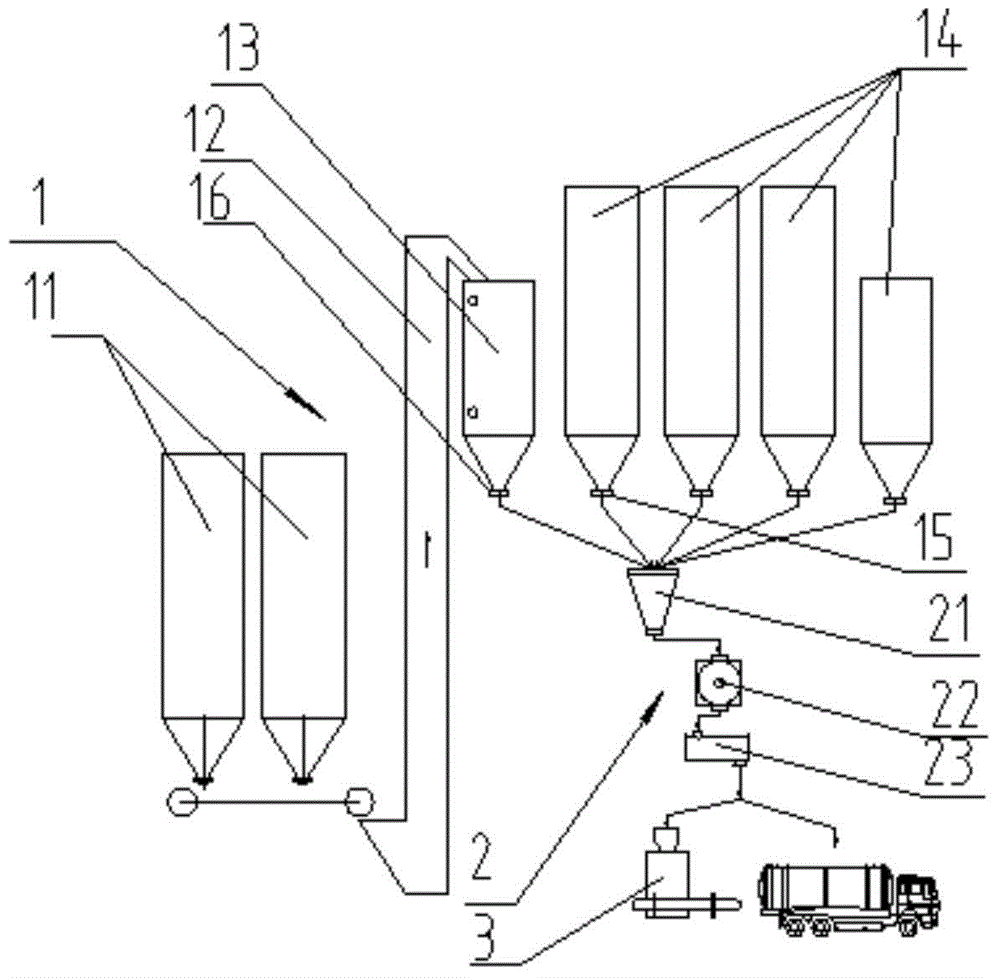

Dry-mixed mortar production line

ActiveCN104669442AIncrease productivityAchieve triple mixingIngredients weighing apparatusControl apparatusProduction lineDry sand

The invention relates to a dry-mixed mortar production line which comprises a dry sand storage bin, a powder bin, a dry sand transfer bin, an elevator, a powder metering mechanism, a sand metering mechanism, a mixing agitator and a packaging machine, wherein the dry sand storage bin is connected with the dry sand transfer bin by virtue of the elevator; the powder bin and the dry sand transfer bin are correspondingly connected with the powder metering mechanism and the sand metering mechanism so as to form a raw material conveying unit; the output ends of the powder metering mechanism and the sand metering mechanism are connected with the mixing agitator; and the output end of the mixing agitator is connected with the packaging machine. The dry-mixed mortar production line provided by the invention has the beneficial effects that three-stage type mixing and stirring can be adopted, so that materials are uniformly mixed, the efficiency is high, and the energy consumption is high; and moreover, in a metering mode, pull sensing and timing measurement by a container with the fixed volume are adopted, the deviation can be automatically corrected, and the precise proportioning effect is achieved.

Owner:JIANGSU MORNING ENVIRONMENTAL PROTECTION TECH CO LTD

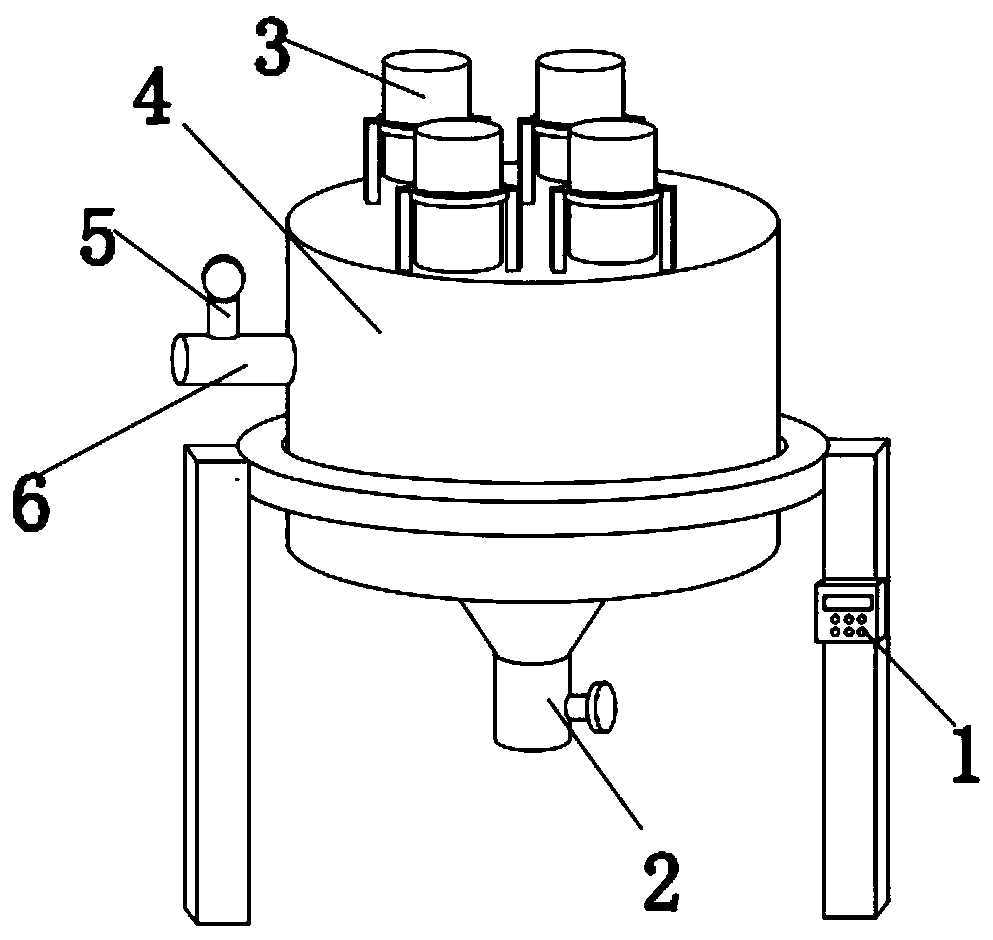

Intelligent concrete additive burdening device

ActiveCN110328754AAffect the service lifeStir wellMixing operation control apparatusIngredients weighing apparatusUltrasonic vibrationEngineering

The invention discloses an intelligent concrete additive burdening device, and relates to the field of concrete additive equipment. The intelligent concrete additive burdening device comprises a tankbody; four sets of burdening tanks are arranged on the tank body; an unloading pipe is arranged at the lower end of the tank body; a water inlet pipe is arranged at the left end of the tank body; a flow meter is arranged at the upper end of the water inlet pipe; storage cavities are formed in inner cavities of the burdening tanks; weighing mechanisms are arranged under the storage cavities; a transverse plate is arranged in an inner cavity of the tank body; a primary mixing mechanism is arranged above the transverse plate; the lower end of the primary mixing mechanism penetrates through the transverse plate, and extends under the transverse plate; a stirring mechanism is arranged at the lower end of the transverse plate; a distributor is arranged in an inner cavity of the transverse plate;and the left end of the distributor is fixedly connected with the water inlet pipe. The intelligent concrete additive burdening device is provided with the distributor and an ultrasonic vibration mechanism for convenient cleaning of equipment, and meanwhile, can preferably, quickly and fully stir materials.

Owner:攀枝花市润泽建材有限公司

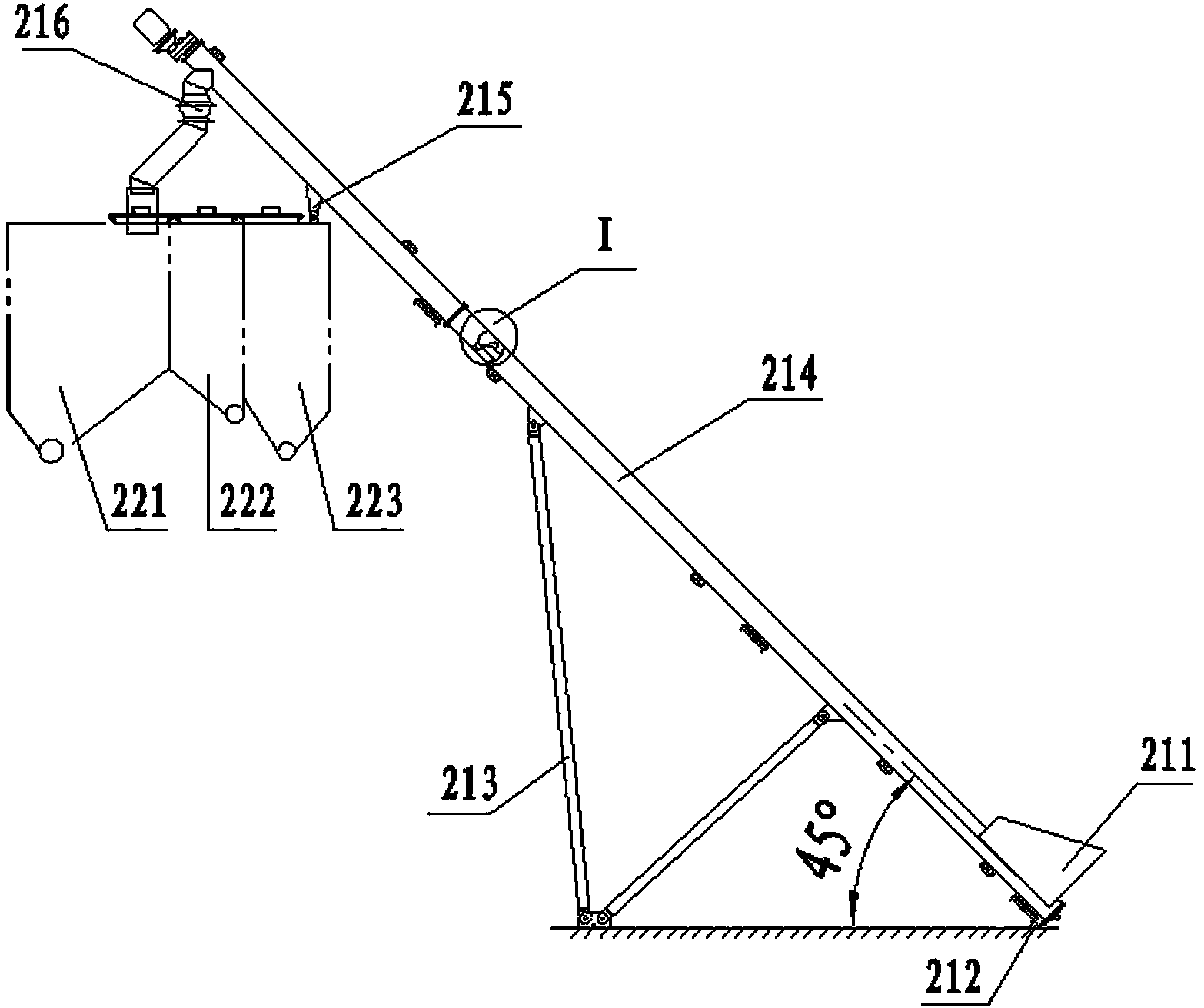

Impermeable wear-resistant concrete and preparation method thereof

PendingCN112976303ANovel structureRealize automatic unloadingMixing operation control apparatusPretreatment controlFiberPolyvinyl alcohol

The invention discloses impermeable wear-resistant concrete and a preparation method thereof, and relates to the technical field of concrete preparation. The impermeable wear-resistant concrete comprises the following raw materials: cement, fly ash, blast furnace slag, quartz sand, broken stone, carbon black, a fiber filler, sodium alkyl benzene sulfonate, a water reducer, polyvinyl alcohol, an impermeable wear-resistant composition and water. The preparation device comprises a batching mechanism, a lifting and conveying mechanism and a mixing and stirring mechanism, wherein the discharging port end of the batching mechanism is connected with the feeding end of the lifting and conveying mechanism; and the discharging end of the lifting and conveying mechanism is connected with the discharging end of the mixing and stirring mechanism. According to the impermeable wear-resistant concrete and the preparation method thereof provided by the invention, prepared materials can be transferred at the same time, so that automatic unloading after weighing is realized; the inner wall of a lifting pipeline can be effectively prevented from being blocked while the materials are lifted and conveyed upwards; and the preparation method is simple, and the prepared concrete has the characteristics that the water-reducing rate is high, the workability and the fluidity of the road concrete are obviously improved, and the impermeability, the freezing resistance, the fracture resistance, the compression resistance, the wear resistance and the durability of the road concrete are improved.

Owner:李思颖

Production equipment of autoclaved aerated concrete blocks

InactiveCN104842446AHigh precisionHigh viscosityMixing operation control apparatusCeramic shaping plantsSlurryMechanical engineering

Owner:HANCHUAN XINXIN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com