Automatic grouting system

An automatic grouting and cement slurry technology, which is applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problem of high labor cost, achieve the effect of reducing labor cost, reducing manual pulping and monitoring requirements, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the present invention will be further described in conjunction with the drawings and specific embodiments.

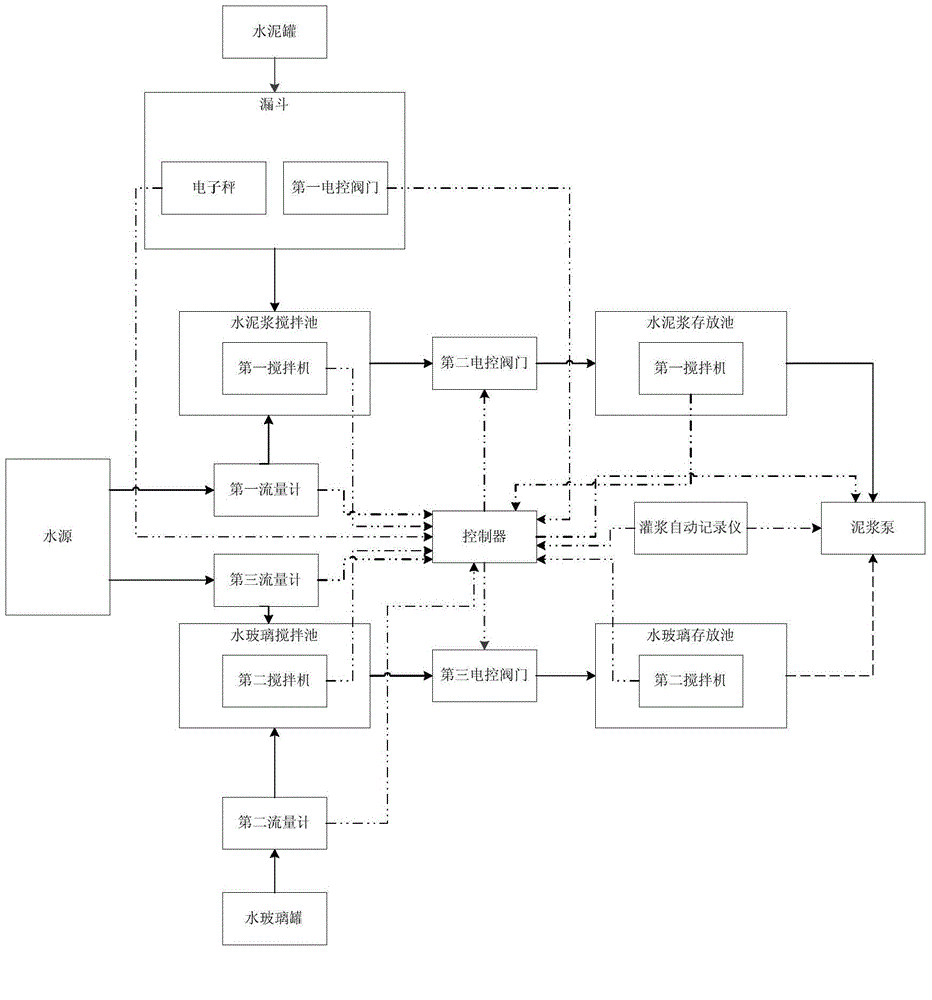

[0041] Such as figure 1 As shown, an automatic grouting system includes: a cement tank, a funnel, a first electric control valve, a cement slurry mixing pool, a cement slurry storage pool, a second electric control valve, a mud pump, an automatic grouting recorder, a first A water injection pipeline, a first flowmeter, a controller, a water glass tank, a water glass stirring tank, a delivery pipeline, a second flowmeter, a water glass storage tank, a second water injection pipeline and a third flowmeter.

[0042] The cement tank communicates with the funnel through the screw machine, and the electronic scale for weighing the weight of cement is arranged in the said funnel. The first electronically controlled valve is installed at the outlet of the funnel. The outlet of the funnel communicates with the cement slurry mixing tank. The cement slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com