Device and method for evaluating influence of pressure change on completeness of cement sheath

A cement sheath and integrity technology, which is applied in the field of devices for evaluating the impact of downhole pressure changes on the integrity of the cement sheath, can solve the problems of destroying experimental equipment, endangering the quality and safety of the project, and not being able to truly simulate the cement sheath anti-channeling experiment. The effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

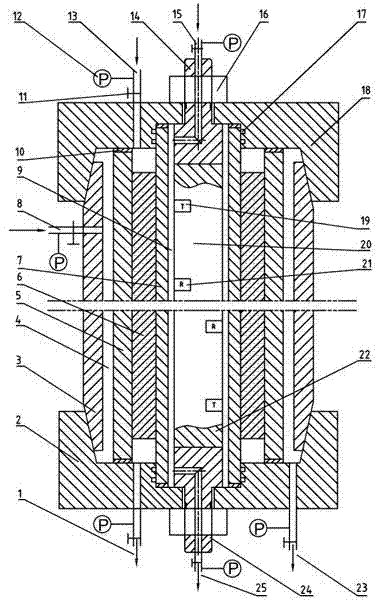

[0020] As shown in the drawings, the device proposed by the present invention mainly includes: the second air outlet 1, the lower plug 2, the outer pipe 3, the outer annular space 4, the middle pipe 5, the cement sheath 6, the sleeve pipe 7, the first injector Air port 8, inner annular space 9, copper gasket 10, air valve 11, pressure gauge 12, second air injection port 13, first joint 14, third air injection port 15, nut 16, rubber sealing ring 17, upper plug 18, Transmitting probe 19 , long source distance sector cement bonded logging tool (SBT) 20 , receiving probe 21 , conversion joint 22 , first gas outlet 23 , second joint 24 , and third gas outlet 25 .

[0021] In order to make the purpose of the invention, technical solutions and advantages of the present invention clearer, the following in conjunction with the attached figure 1 The specific embodiment of the present invention is set forth, and its detailed steps are as follows:

[0022] Step 1: Inject cement slurry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com