Method for assembling and detecting barrel connecting pipe

A technology of assembly inspection and cylinder body, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve problems such as unfavorable input and output, contradicting cost reduction and efficiency increase, complex and cumbersome, etc., to improve assembly quality, The effect of improving production efficiency and enhancing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

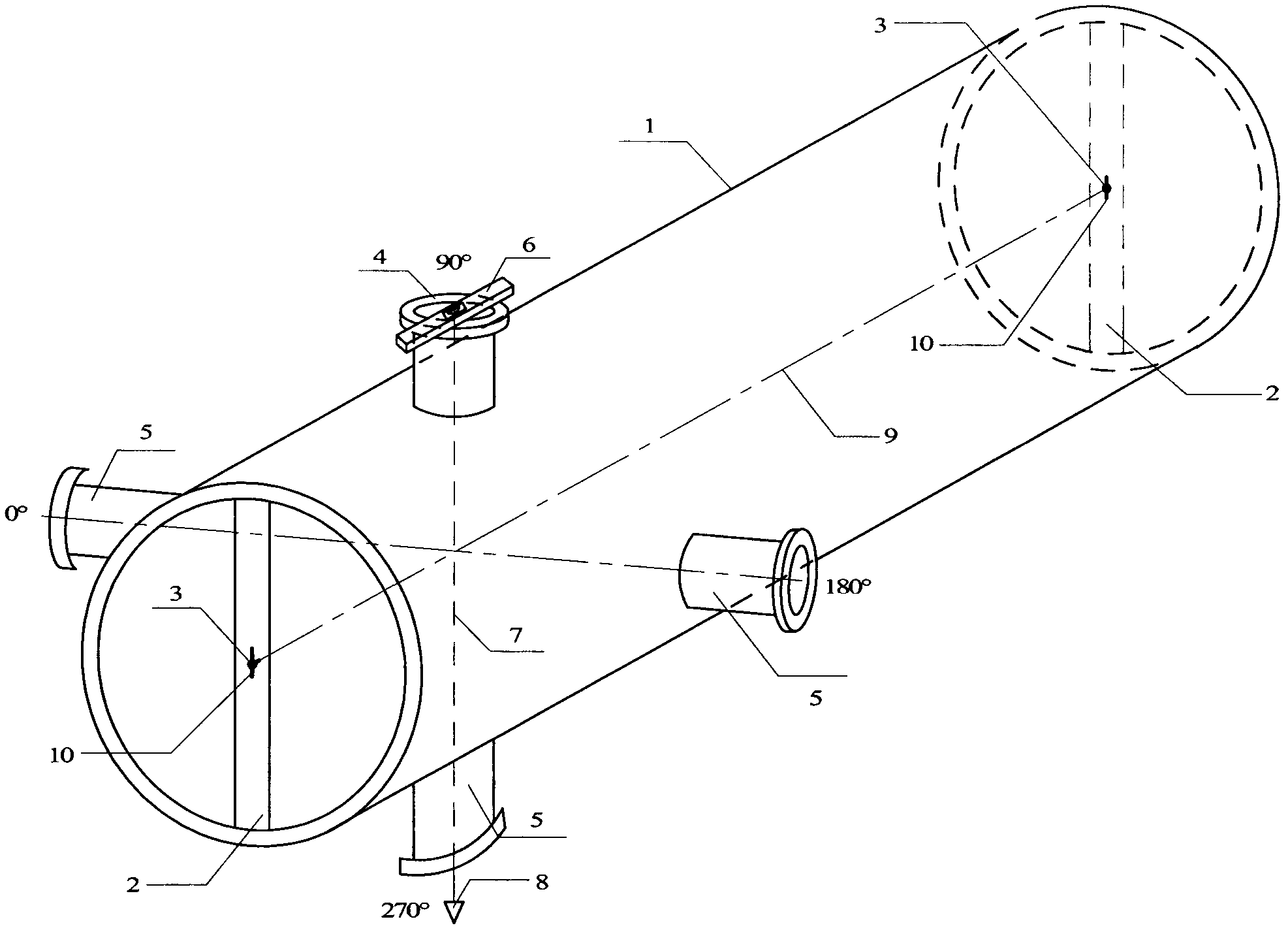

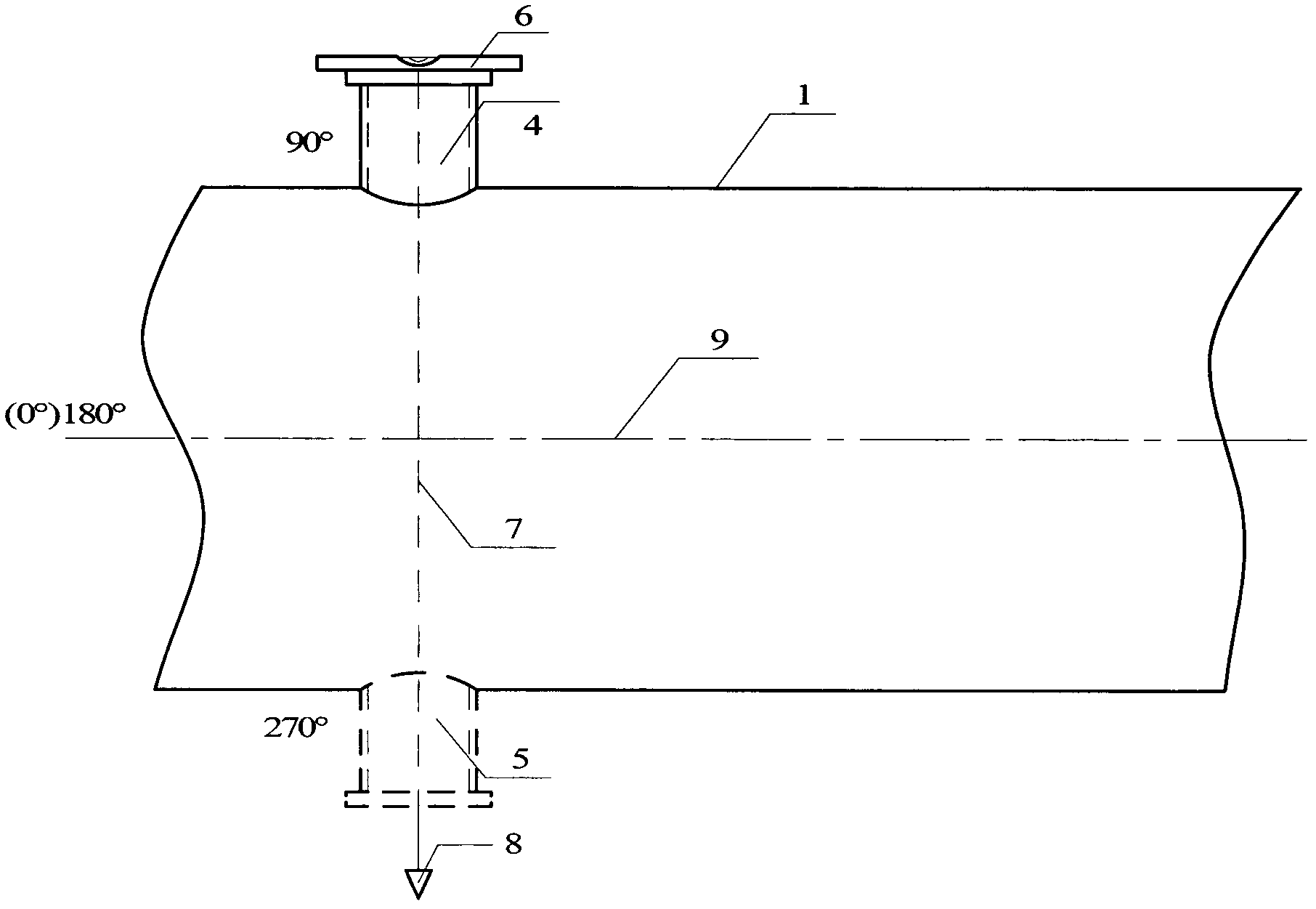

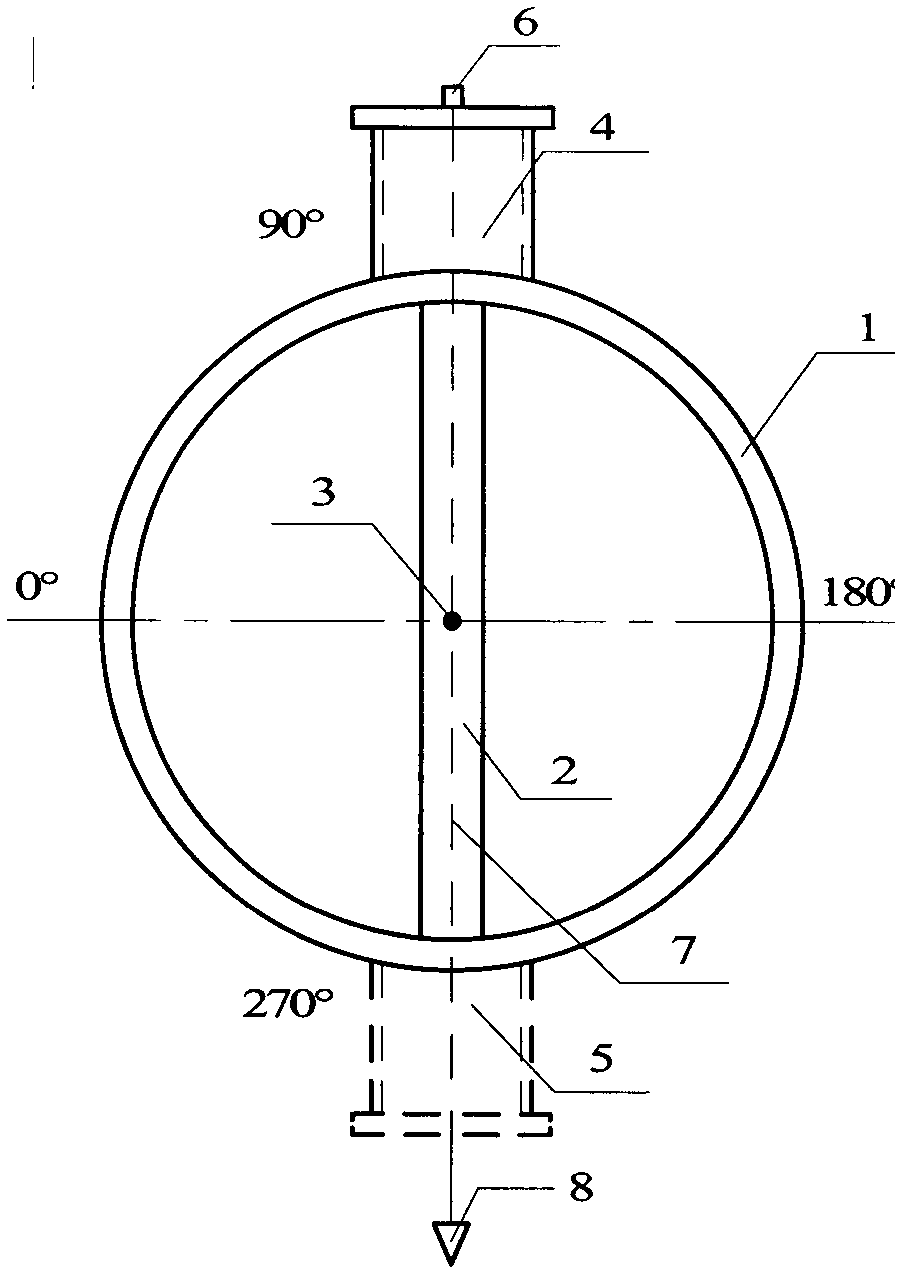

[0038] Such as figure 1 , 2 As shown in , 3, the four connection pipes 4 and 5 of the gasifier (in the connection pipe 4 and the connection pipe 5 to be installed) are docked and installed with the cylinder body 1, and the central axes of the four connection pipes must be centripetal to the central axis of the cylinder body 1 , and are evenly distributed around the circumference of cylinder 1 at equal angles (90°), and the central axes where the four connecting pipes meet must be on the same plane and perpendicular to the central axis of the cylinder. The assembly process is as follows:

[0039] Step 1, calibrate the central axis of the cylinder

[0040] Such as figure 1 As shown, a channel steel 2 is respectively supported and welded at the inner diameters of the two ends of the cylinder body 1, and a central datum point (hole) 3 is respectively drilled on the two channel steels 2. Use a piano wire to pass through two central reference points (holes) 3, and tighten the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com