Method used for planning production line and apparatus thereof

A production line and production module technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of wasting enterprise resources and labor costs, unsatisfactory mold opening height, and delaying the production period, etc., to shorten the production period , Reduce overall debugging time, save resources and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

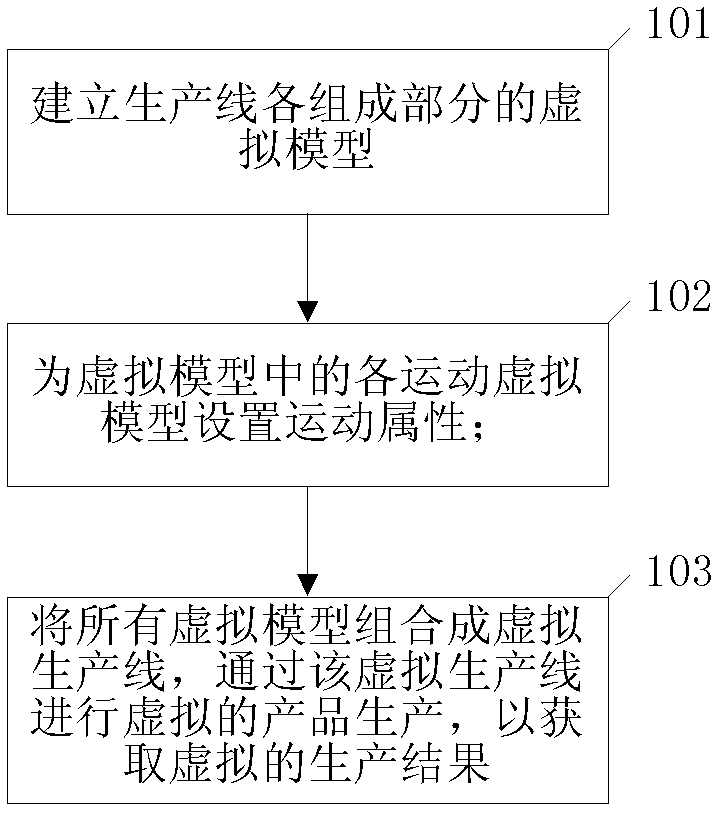

[0043] see figure 1 , Embodiment 1 of the present invention provides a method for planning a production line, which specifically includes:

[0044] 101: Create a virtual model of each component of the production line.

[0045] 102: Define motion attributes for each motion virtual model in the virtual model;

[0046] Wherein, the motion virtual model corresponds to the components of the production line that move during the production line; the motion attributes are consistent with the motion attributes of the components of the production line that move during the production line.

[0047] 103: Combine all virtual models into a virtual production line, and perform virtual product production through the virtual production line to obtain virtual production results.

[0048] The beneficial effect brought by the technical solution provided by the embodiment of the present invention is: by establishing a virtual model of each component of the production line, and defining motion at...

Embodiment 2

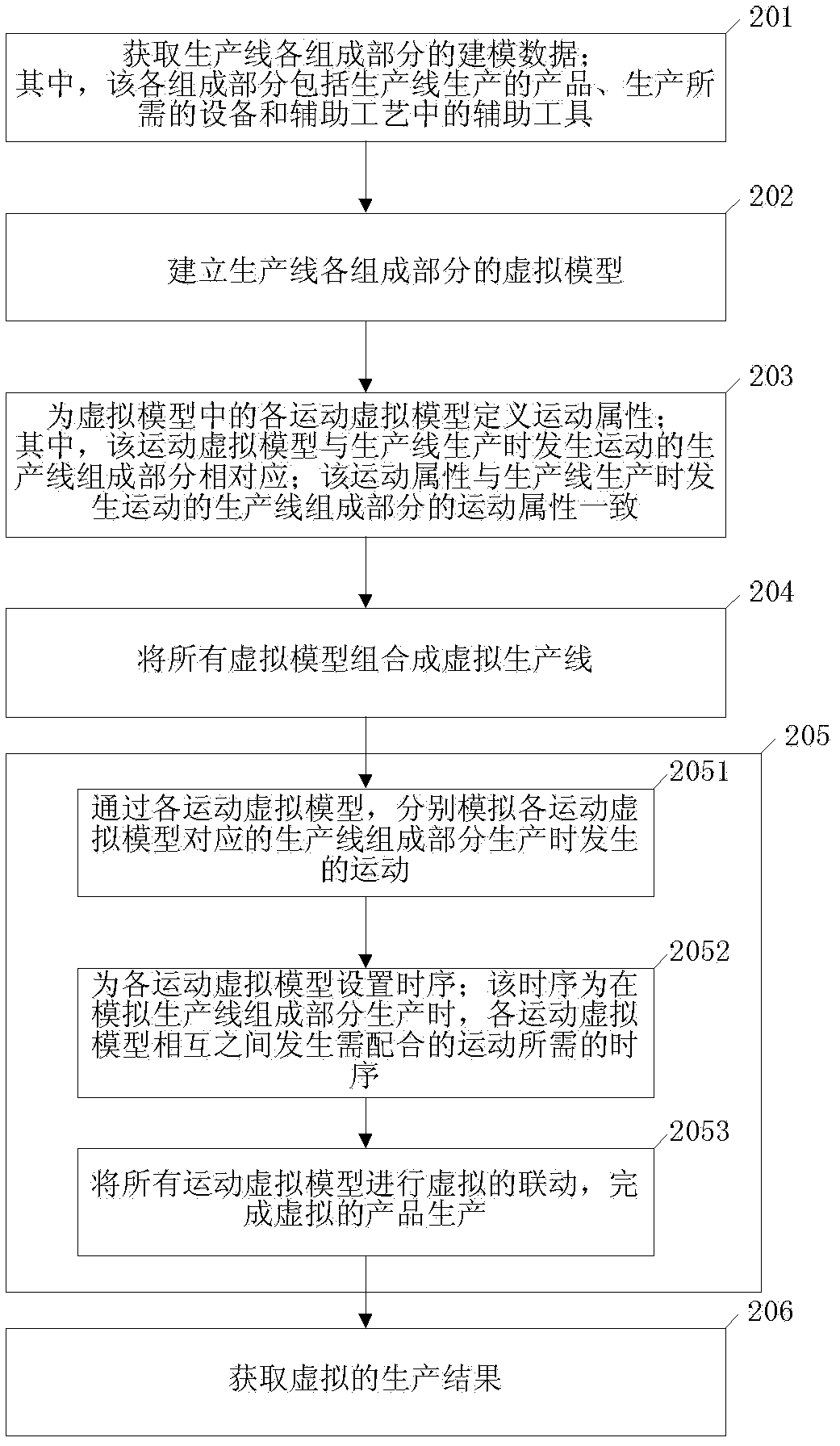

[0050] In order to facilitate the understanding of the method of the present invention, Embodiment 2 of the present invention will take a stamping production line as a preferred example to illustrate the method. see figure 2 , Embodiment 2 of the present invention provides a method for planning a production line, which specifically includes:

[0051] 201: Obtain the modeling data of each component of the production line;

[0052] Among them, the various components include the products produced by the production line, the equipment required for production and the auxiliary tools in the auxiliary process.

[0053]Among them, the modeling data specifically includes the part size of the product, equipment and auxiliary tools, the model diagram of the part and the assembly relationship, etc. The modeling data of the products to be produced and the equipment required for production are generally acquired based on the three-dimensional models of the products and equipment. Specif...

Embodiment 3

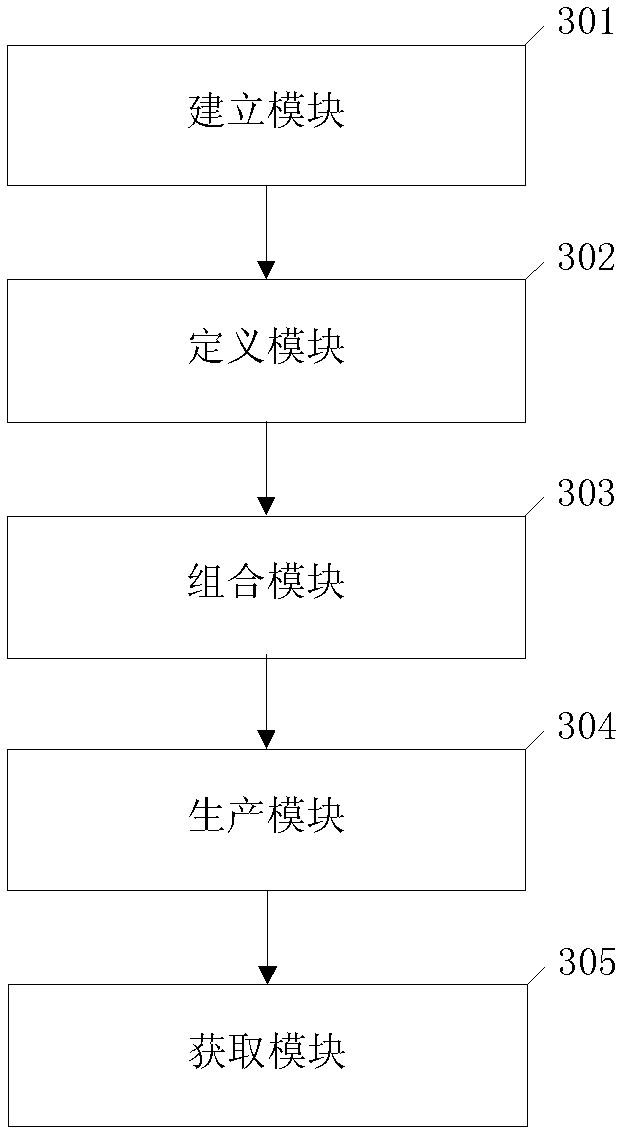

[0086] see image 3 , Embodiment 3 of the present invention provides a device for planning a production line, which specifically includes:

[0087] The establishment module 301 is used to establish a virtual model of each component of the production line.

[0088] A definition module 302, configured to define motion attributes for each motion virtual model in the virtual model;

[0089] Wherein, the motion virtual model corresponds to the components of the production line that move during the production line; the motion attributes are consistent with the motion attributes of the components of the production line that move during the production line.

[0090] Combining module 303, configured to combine all virtual models into a virtual production line.

[0091] The production module 304 is used for virtual product production through a virtual production line.

[0092] Obtaining module 305, configured to obtain virtual production results.

[0093] The beneficial effect broug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com