Mounting assisting device for three-point spherical bearing and mounting-welding method of mounting assisting device

A technology of spherical support and installation assistance, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding equipment, etc., can solve problems such as easy deformation, and achieve the effects of short manufacturing period, shortened manufacturing period, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

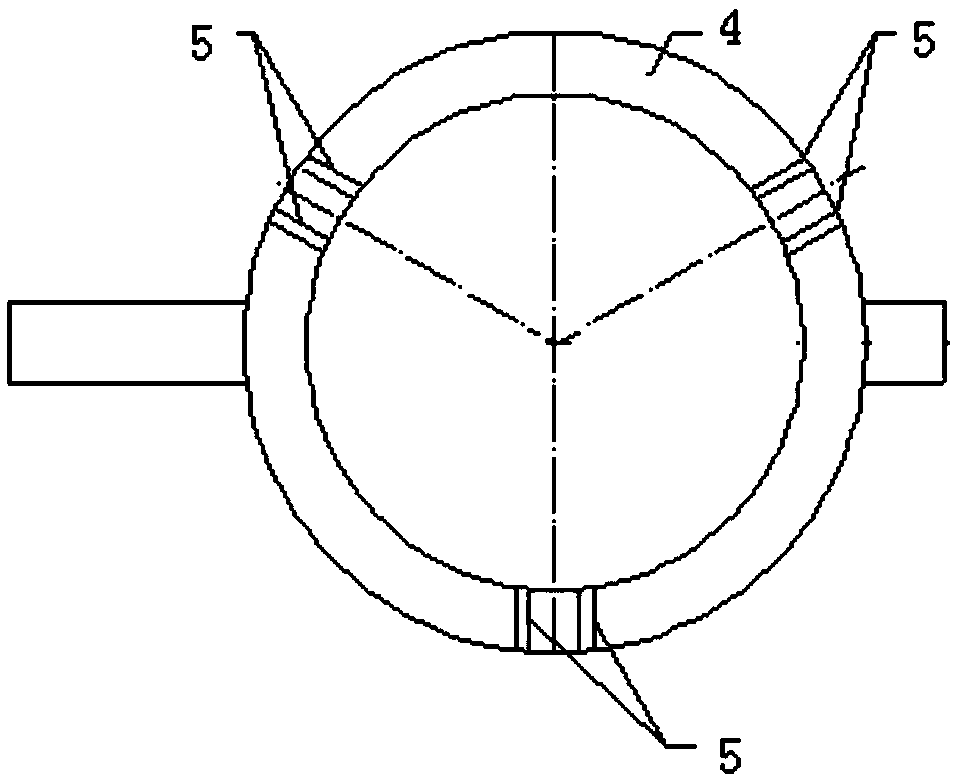

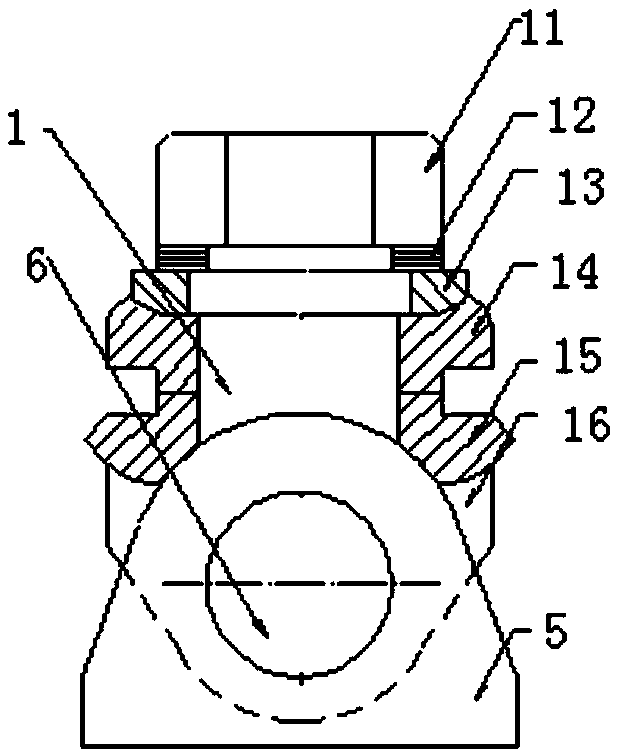

[0072] combine Figure 1-5 , a three-point spherical support installation auxiliary device, including a three-point support seat 5, a false shaft pin 6 and a temporary rigid support II112, spaced 120° along the circumferential direction of the support ring 4, forming three points evenly distributed, the center of these three points A three-point support seat 5 is arranged symmetrically on both sides of the line, and the dummy shaft pin 6 is located between the inner sides of the two mutually symmetrical three-point support seats 5, and on the outside of the two mutually symmetrical three-point support seats 5, with respect to the center line A temporary rigid support II112 is arranged symmetrically, one end of the temporary rigid support II112 is welded on the support ring 4, and the other end is welded on the top of the outer surface of the three-point support seat 5. Both sides of the three-point support seat 5 are supported by the temporary rigid support II112, and a false ...

Embodiment 2

[0112] This embodiment is the same as Embodiment 1, wherein the auxiliary device is installed with three-point spherical support, the shaft hole is finished first, and the deformation is precisely controlled by welding, so that the original secondary processing and secondary assembly procedures are reduced to one-time completion. The manufacturing cost is effectively reduced and the manufacturing period is shortened.

[0113] The three-point spherical support device is connected to the three-point support seat 5 on the upper part of the support ring 4 with three support pins at 120° each other, which can swing freely on the pin shaft, and its upper part is connected to the furnace shell through two pairs of spherical washers The pin holes of the flange are locked with nuts. Under the lock nuts (nut 11), there is a group of four corrugated washers with small height and large load-bearing capacity. The supporting bolts can swing freely against the two pairs of spherical surfaces....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com