Method using laser tracker to measure aspherical surface peak curvature radius

A laser tracker and vertex curvature technology, applied in the field of optical testing, can solve problems such as inability to achieve in-situ measurement, and achieve the effects of shortening the production period, widening the measurement range, and reducing the measurement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Various details involved in the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, and do not serve as any limitation.

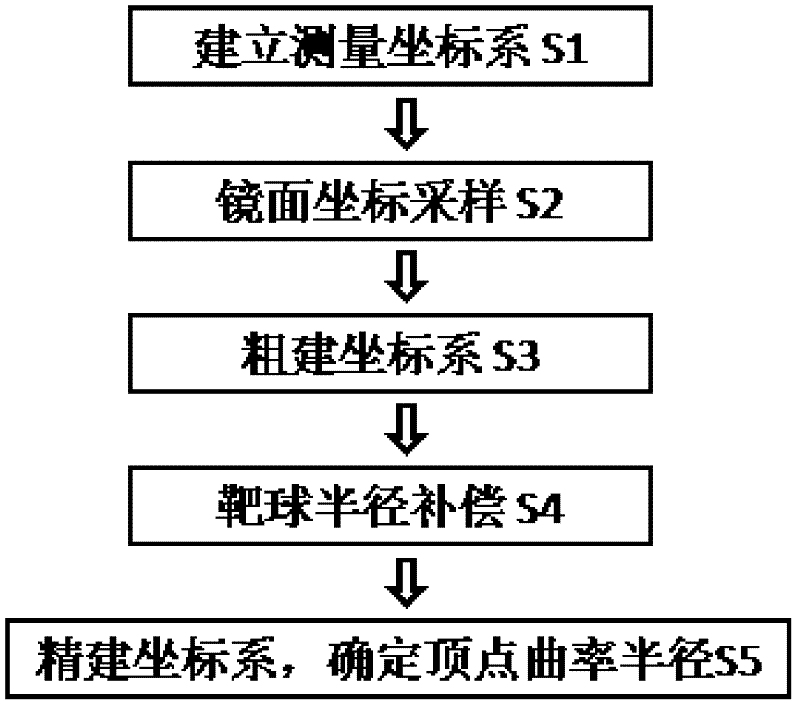

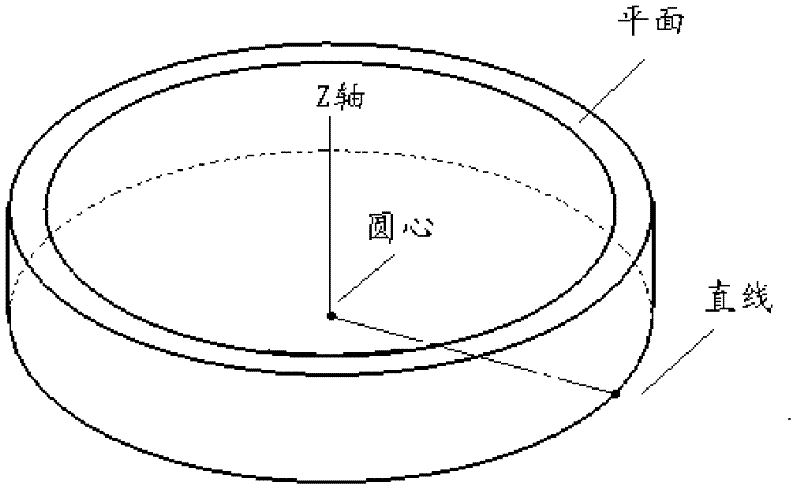

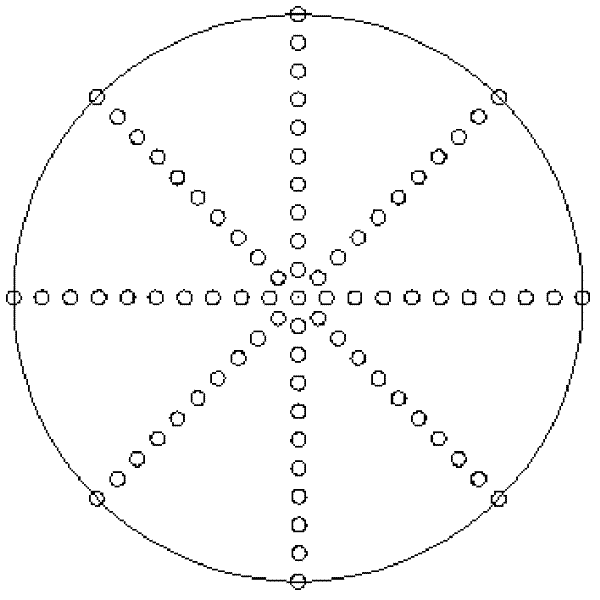

[0023] (1) if figure 1 The flow chart of the method for measuring the radius of curvature of an aspheric surface using a laser tracker is shown. First, a laser tracker should be used to establish an aspheric measurement coordinate system. The measurement coordinate system should make the rotation axis of the aspheric surface coincide with a certain coordinate axis, and the aspheric surface vertex coincides with the axis origin. The establishment of the aspheric measurement coordinate system can provide a reasonable initial value for the subsequent search for the best fitting aspheric surface, and avoid calculation errors. The establishment of the measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com