Steel plate having excellent fine blanking processability and method for manufacture thereof

A technology with excellent workability and a manufacturing method that can solve problems such as manufacturing, difficulty in securing stretch flangeability, and reduction in product yield when applied to the field of steel sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] The steel raw materials (billets) having the compositions shown in Table 1 were subjected to hot rolling and hot-rolled sheet annealing shown in Table 2 to obtain hot-rolled steel sheets (thickness: 4.3 mm).

[0110] For the obtained hot-rolled steel sheet, the microstructure, FB workability, and stretch flangeability after FB working were investigated. The research method is as follows.

[0111] (1) Organization

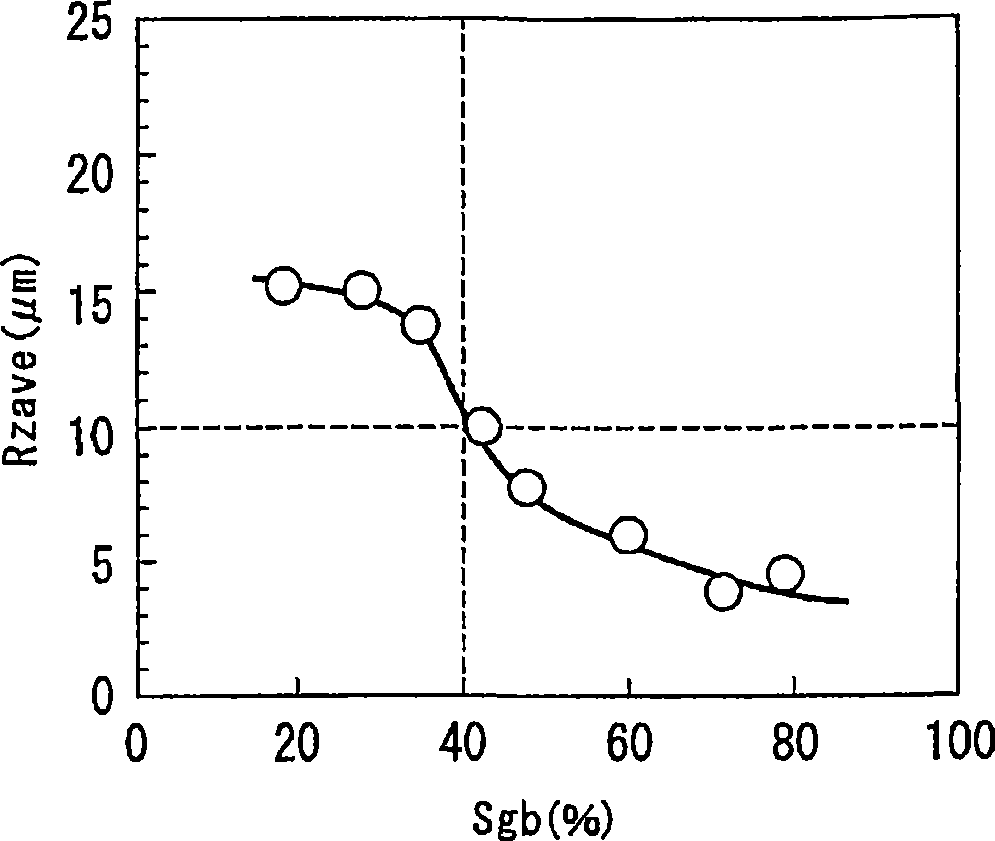

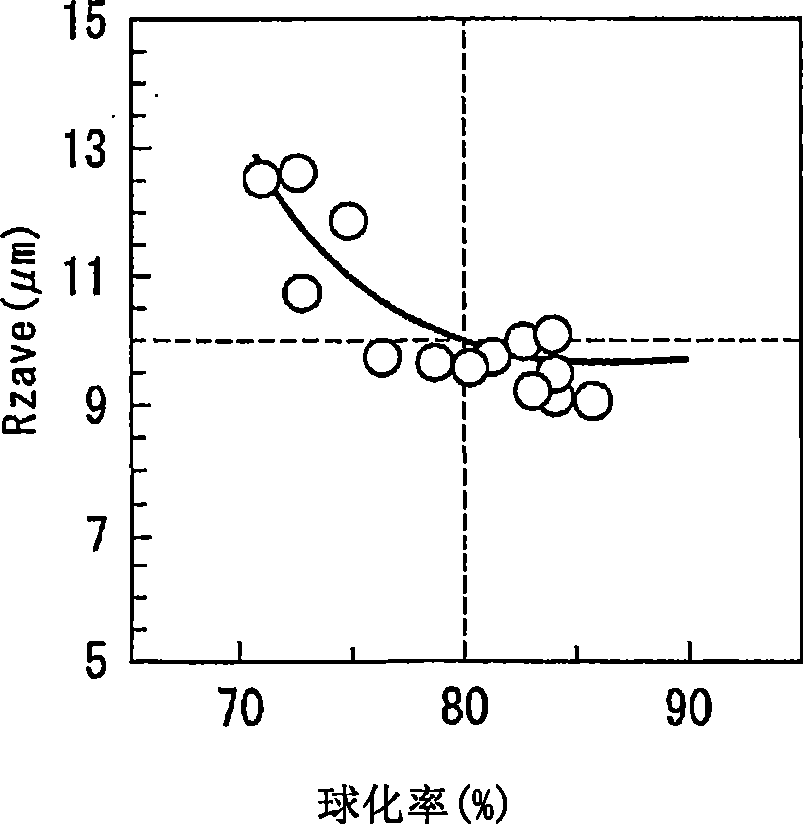

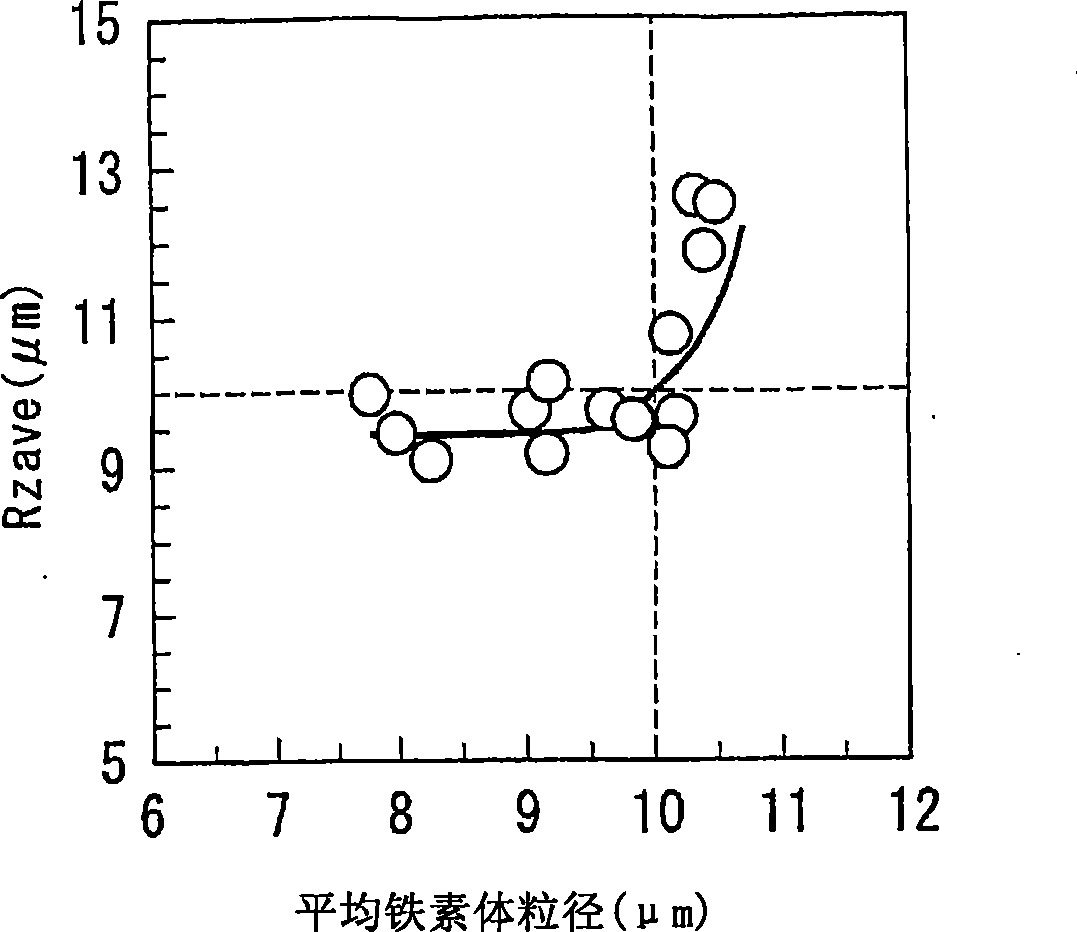

[0112] A test piece for structure observation was taken from the obtained steel plate. Then, the cross section of the test piece parallel to the rolling direction was ground, etched with nital, and observed with a scanning electron microscope (SEM) (magnification, ferrite: 1000 times, carbide: 3000 times) to observe the 1 / 4 position of the plate thickness. The metal structure (number of views: 30 places), the volume ratio of ferrite and carbide, the particle size of ferrite, the spheroidization rate of carbide, the amount of carbide at ferrite grain boundary,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com