Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about How to "Reduce heat treatment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abrasion-resistant steel sheet having excellent processability, and method for production thereof

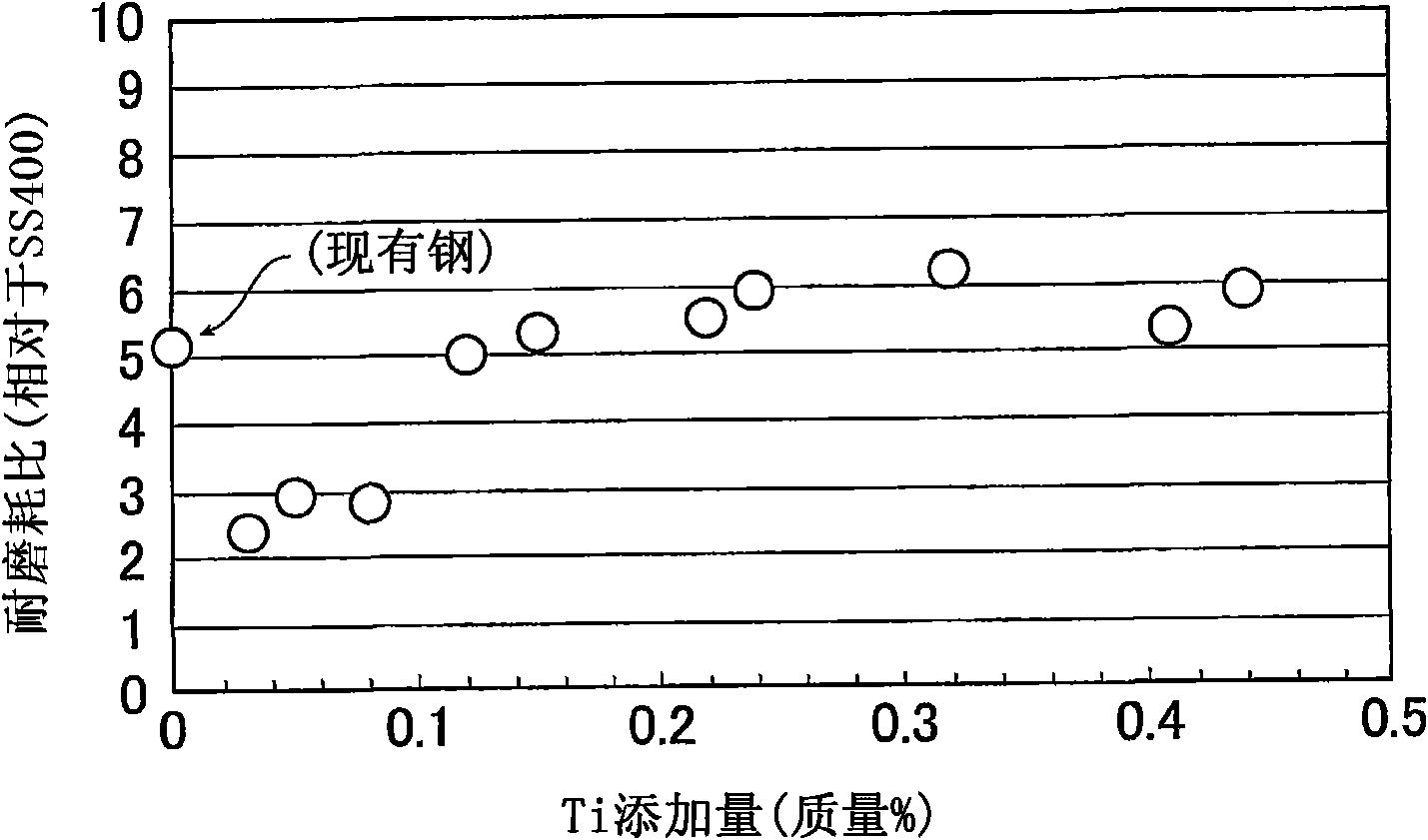

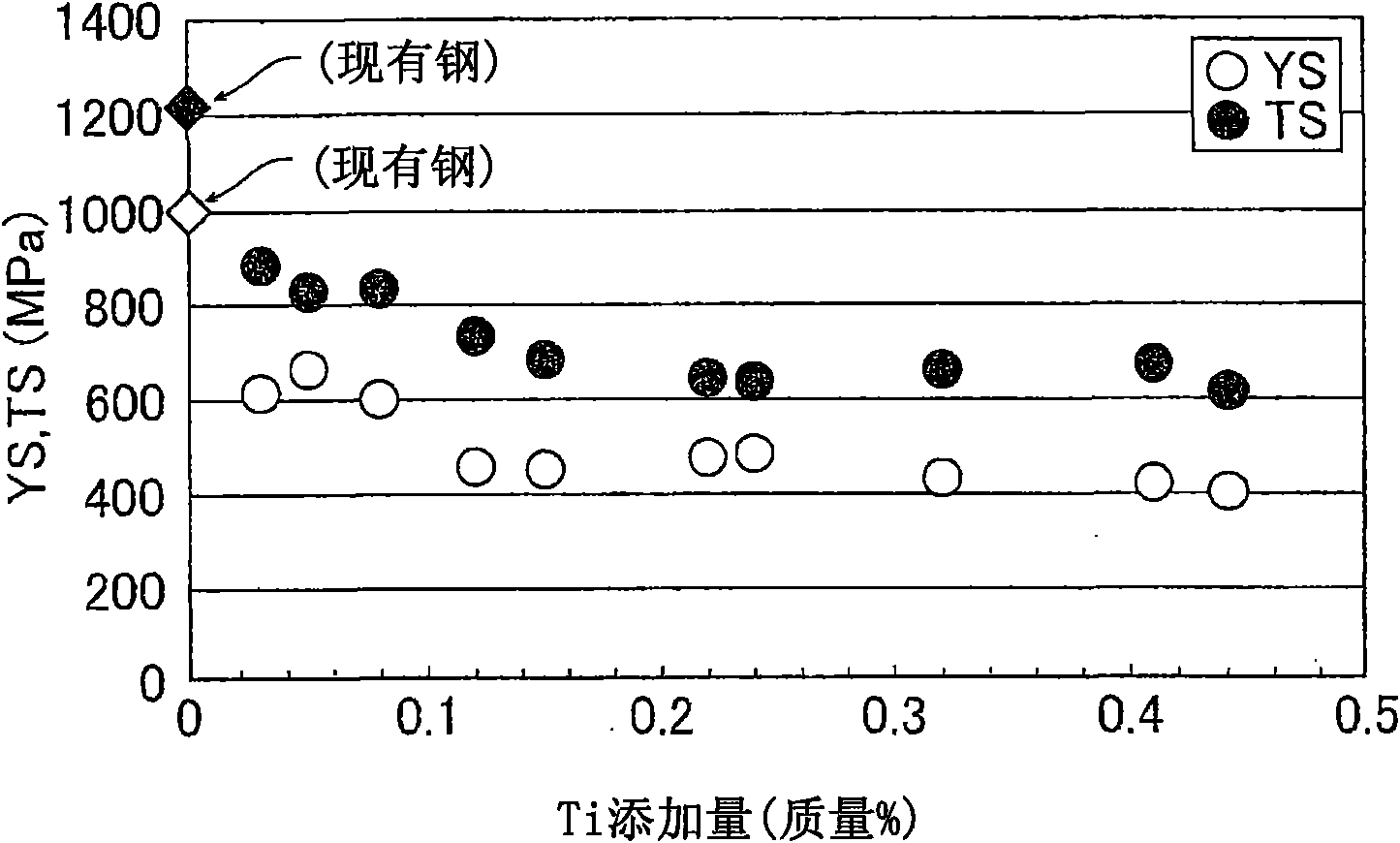

An abrasion resistant steel excellent in bending formability and suitable for members, e.g., power shovels, which come into contact with earth and sand, and a production method thereof are provided. Specifically, the steel contains, on a percent by mass basis, 0.05% to 0.35% of C, 0.05% to 1.0% of Si, 0.1% to 2.0% of Mn, 0.1% to 1.2% of Ti, 0.1% or less of Al, at least one element of 0.1% to 1.0%of Cu, 0.1% to 2.0% of Ni, 0.1% to 1.0% of Cr, 0.05% to 1.0% of Mo, 0.05% to 1.0% of W, and 0.0003% to 0.0030% of B, if necessary at least one element of 0.005% to 1.0% of Nb and 0.005% to 1.0% of V,and the remainder including Fe and incidental impurities, where DI* represented by the following formula is less than 60. DI * = 33.85 0.1 C * 0.5 0.7 Si + 1 3.33 Mn + 1 0.35 Cu + 1 0.36 Ni + 1 2.16 Cr + 1 3 Mo * + 1 1.5 W * + 1 where C* = C - 1 / 4 (Ti - 48 / 14N), Mo* =; Mo (1 - 0.5 (Ti - 48 / 14N)), and W* = W (1 - 0.5 (Ti - 48 / 14N)).

Owner:JFE STEEL CORP

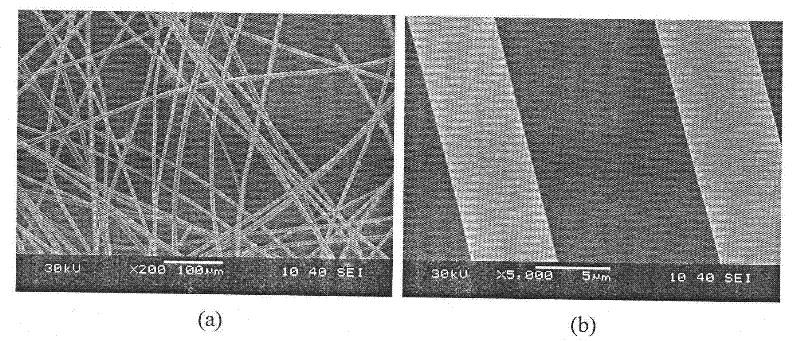

Method for preparing thin-diameter zirconium oxide fibers and fiber board thereof

ActiveCN102181962ALow costHigh purityFibreboardInorganic material artificial filamentsYttriumAdhesive

The invention relates to a method for preparing thin-diameter zirconium oxide fibers and a fiber board thereof. The method comprises the following steps of: preparing poly zirconium sol spinning solution by adopting basic zirconium carbonate, glacial acetic acid, water and yttrium nitrate as raw materials, obtaining thin-diameter poly zirconium sol fibers by ultrahigh-speed centrifugal swinging and high-speed hot airflow blowing and drafting, and performing thermal treatment and sintering on the thin-diameter poly zirconium sol fibers to obtain the thin-diameter zirconium oxide fibers; and performing vacuum suction molding and pressure leveling to prepare a wet fiber board blank by adopting the thin-diameter zirconium oxide fibers as a raw material and adopting poly zirconium sol spinningsolution diluted by adding water as adhesive, and drying and calcining the wet blank to obtain the zirconium oxide fiber board. The raw materials are easily obtained, the preparation of the adhesive is simple and convenient, and the method has low cost and no pollution and is suitable for large-batch industrialized production; the prepared thin-diameter zirconium oxide fibers have good bending flexibility; and the prepared zirconium oxide fiber board has uniform thickness, flat surface, accurate and controllable thickness, and good mechanical property and high-temperature bending resistance.

Owner:南京理工宇龙新材料科技股份有限公司

Steel wire for low-temperature annealing and method for producing same

ActiveCN102227512AImprove yieldImprove productivityFurnace typesHeat treatment bathsImpurityVolume percent

Provided is a steel wire for low-temperature annealing which comprises, by mass%, C: 0.10% to 0.60%, Si: 0.01% to 0.40%, Mn: 0.20% to 1.50%, P: 0% to 0.040%, S: 0% to 0.050%, and N: 0.0005% to 0.0300%, and further comprises one or more selected from Cr: 0.03% to 0.4%, V: 0.03% to 0.2%, and Mo: 0.03% to 0.2%, with Fe and inevitable impurities as the remainder. The volume percent of pearlite structure is between 1.40*(C%)*100% and 100%, the volume percent of proeutectoid ferrite is between 0% and (1 - 1.25*(C%))*50%, and the volume percent of bainite structure is between 0% and 40%. The tensile strength is between 480 + 850*Ceq. MPa and 580 + 1130 Ceq. MPa.

Owner:NIPPON STEEL CORP

Quenching equipment for completing quenching, isothermal treatment or tempering in same slot by transferring through hanging basket

ActiveCN103924047ASimple transmission structureImprove reliabilityQuenching devicesThermal energySaline water

The invention relates to thermal treatment equipment and specifically relates to quenching equipment for completing quenching, isothermal treatment or tempering in the same slot by transferring through a hanging basket. The quenching equipment comprises a heating furnace, a discharging table, a quenching slot, an isothermal slot, an air-cooling slot, a saline water cleaning slot, a clear water cleaning slot and an unloading table, wherein the quenching slot, the isothermal slot, the air-cooling slot, the saline water cleaning slot and the clear water cleaning slot are arranged between the discharging table and the unloading table in sequence; the quenching slot and the isothermal slot are formed by dividing a liquid-connected large slot through an adjustable baffle plate; a transfer mechanical hand is arranged above the discharging table and the unloading table; a material taking hook of the transfer mechanical hand is equipped with the hanging basket for hanging and transferring workpieces. The quenching equipment disclosed by the invention can sufficiently utilize heat energy and lower thermal treatment process cost; by adopting a mode that liquid transfers heat for workpieces, tempering and isothermal temperatures of workpieces are more uniform, and better thermal treatment effect is obtained; the mechanical hand can realize automatic transfer of workpieces in different working media, and can realize various quenching processes.

Owner:TANGSHAN YAJIE MACHINERY

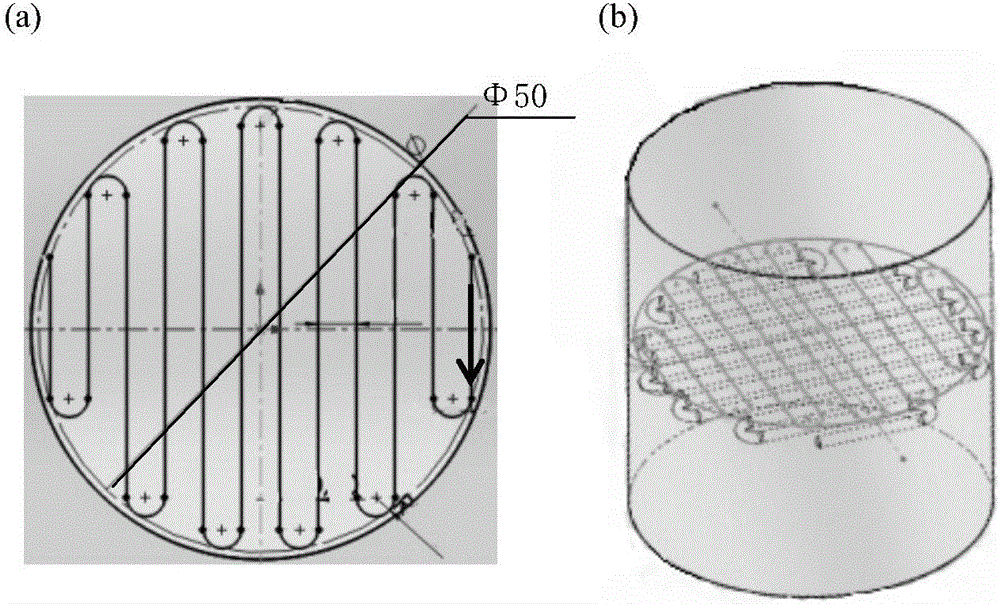

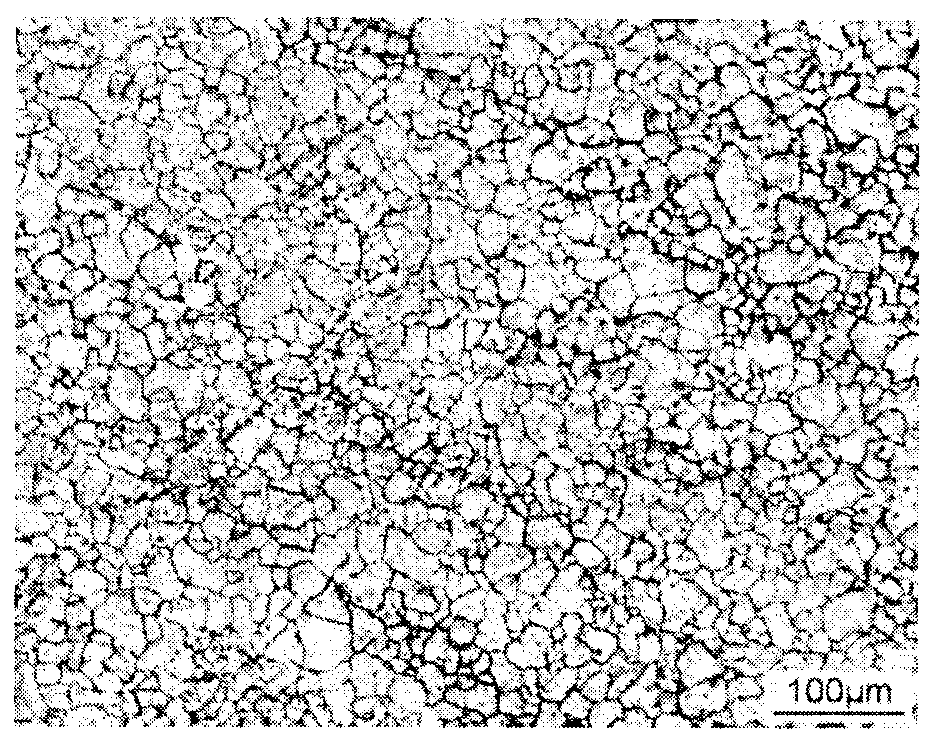

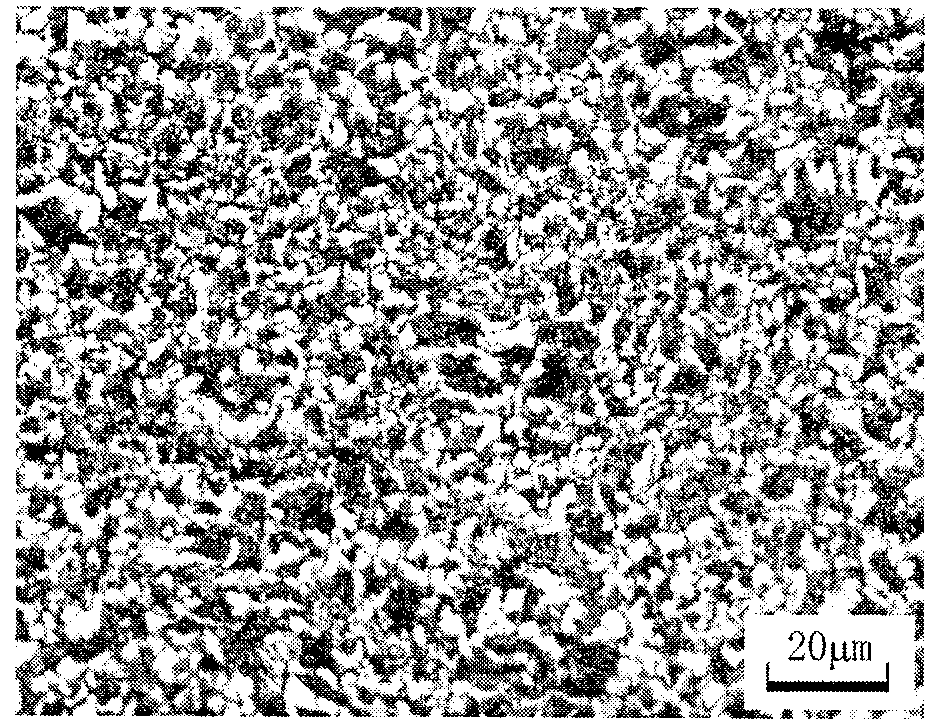

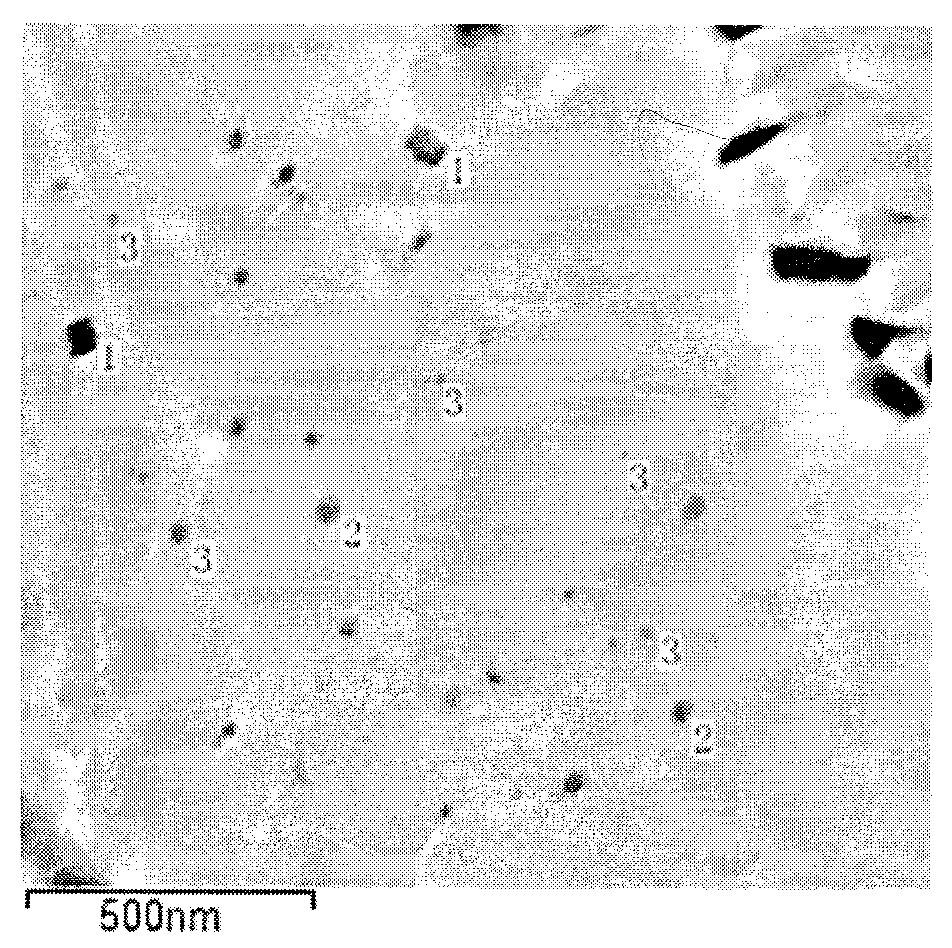

Method for laser additive manufacturing of 12CrNi2 alloy steel

ActiveCN107175330AShort processSmall machining allowanceAdditive manufacturing apparatusIncreasing energy efficiencyAlloy steelHardness

The invention discloses a method for laser additive manufacturing of a 12CrNi2 alloy steel material. The method comprises the laser direct deposition forming step of adopting a semiconductor laser device for depositing 12CrNi2 alloy steel powder onto a substrate material. According to the method, the 12CrNi2 alloy steel powder is selected, a laser direct deposition forming technical process is optimized, the alloy steel material free of defects such as cracks is prepared, and the material is high in hardness and has good toughness. According to the method, a nuclear power emergency diesel generator crankshaft can be integrally prepared; the technological process is short, the subsequent allowance for machining is small, and the material utilization rate is high; and the problems that in the process of producing the nuclear power emergency diesel generator crankshaft through a traditional forging method, the technological process is complex, the period is long, and the cutting quantity is large are solved. According to the method, the mechanical property of the12CrNi2 alloy steel material can be improved, and the production cost of a forging and pressing mold and the like can be reduced.

Owner:NORTHEASTERN UNIV

Fine-grain ferrite + pearlite type N80-1 non-quenched and tempered seamless oil bushing, and production method thereof

InactiveCN103290324AAvoid it happening againEasy to controlDrilling rodsDrilling casingsFurnace temperatureAustenite

The invention relates to a fine-grain ferrite + pearlite type N80-1 non-quenched and tempered seamless oil bushing. The components of the oil bushing comprise 0.35-0.40mass% of C, 0.20-0.35mass% of Si, 1.55-1.75mass% of Mn, 0.020mass% or less of P, 0.010mass% or less of S, 0.20mass% or less of Cu, 0.10mass% or less of Ni, 0.30mass% or less of Cr, 0.05mass% or less of Mo, 0.105-0.145mass% of V, 0.02mass% or less of Nb, 0.005-0.025mass% of Ti, 0.0085-0.0140mass% of N, and the balance Fe and inevitable impurities, wherein the sum of the mass percentages of As, Sn, Pb, Sb and Bi is not greater than 0.050%. A production method of the oil bushing comprises a step of blank material heating, a step of perforating, a step of tube rolling, a step of phase transition recrystallization and temperature-controlled crude tube cooling to 500DEG C or less, a step of reheating for controlling the furnace temperature in a range of 900-950DEG C, a step of sizing or reducing, and a step of air cooling. The method avoids the large maneuverability difficulty of the control of the steel tube deformation parameters and the cooling speed, effectively controls the phase transition recrystallization and the reheating furnace temperature through the reasonable matching and addition of alloy elements, and refines and improves the structure through fully utilizing the carbonitride precipitating effect of V in austenite in order to improve the toughness without reducing or substantially reducing the strength.

Owner:HENGYANG VALIN STEEL TUBE

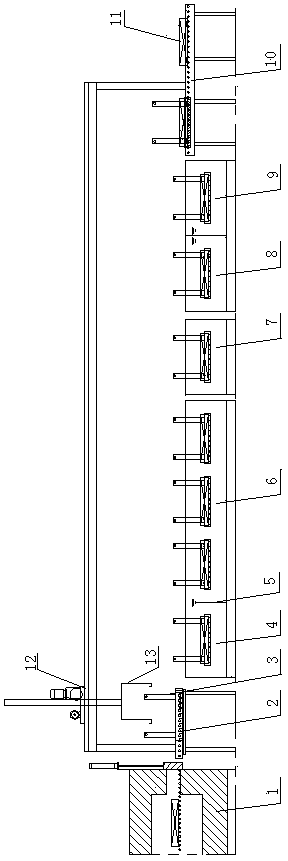

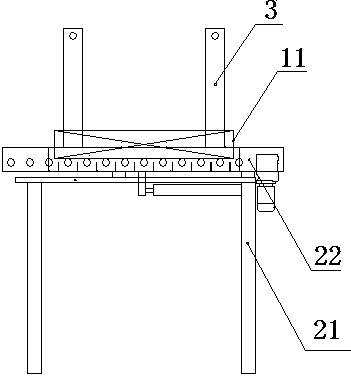

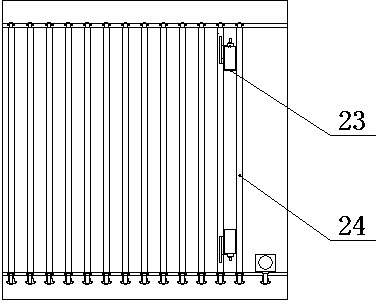

Bearing steel ball special continuous heat treatment roller type production line and process

PendingCN109504842AReduce heat treatment costsPrevent leakageFurnace typesHeat treatment furnacesProduction lineSteel ball

The invention relates to a bearing steel ball special continuous heat treatment roller type production line and process. The production line comprises a drying device, a drum type heating furnace, a steel ball blank quenching system, a cleaning machine and a tempering furnace, wherein the drum type heating furnace comprises a furnace body, a drum, a spiral flow guide part, a heating assembly and adriving assembly, wherein the feed end is located at one end of the furnace body; steel ball blanks are fed to the feed end of the spiral flow guide part through a spiral feeder; the discharge end islocated at the other end of the furnace body and communicates with the discharge end of the spiral flow guide part; the cleaning machine comprises a rack, a cleaning tank, an oil-water separator, a circulating system used for circulating separated water to the cleaning tank, a conveying system, a first oscillator, a second oscillator, a heater and a temperature controller; the temperature controller controls the temperature of cleaning fluid in the cleaning tank to 45+ / -5 DEG C. Through the bearing steel ball special continuous heat treatment roller type production line, on one hand, the output is increased, and the quality is stable on the premise of implementing continuous heat treatment on steel balls; and on the other hand, the phenomena of ball adhering and ball mixing are avoided, and the cleaning effect can also be improved.

Owner:SUZHOU ZHONGMENZI IND FURNACE TECH CO LTD

Method of bainite hardening steel in use for plastic die

A bainite quenching method for a plastic mold steel is to cool down mid-carbon, Cr, Ni Mn and Mo hard plastic mold steel in air or N atmosphere equal to the air cooling speed after austenite, the surface of the piece and core are converted to get the bainite group at 400deg.C and get the hardness at 40 minus or plus IHRC.

Owner:SHANGHAI JIAO TONG UNIV

Steel wire rod for furniture spring and production method of steel wire rod

ActiveCN104745958AMeet the requirements of excellent comprehensive performanceReduce production and processing costsProcess efficiency improvementWire rodSpring steel

The invention relates to a steel wire rod for a furniture spring, which comprises the following main components in percentage by weight (wt%): 0.58-0.67 percent of C, 0.19-0.25 percent of Si, 0.60-0.68 percent of Mn and the balance of Fe. The steel wire rod further comprises the following residual components in percentage by weight (wt%): less than 0.027 percent of P, less than 0.012 percent of S, less than 0.04 percent of Cu, less than 0.03 percent of As, less than 0.028 percent of Sn, less than 0.03 percent of Ti, less than 0.005 percent of Nb, less than 0.0005 percent of B, less than 0.097 percent of Cr, less than 0.03 percent of Ni, less than 0.005 percent of V, less than 0.01 percent of Mo and less than 0.005 percent of Als. The steel wire rod has the characteristics of simple production process, low processing cost, excellent comprehensive performance and the like and can meet the requirement of wire rod raw materials of a mattress spring.

Owner:SGIS SONGSHAN CO LTD

Manufacturing method for low-cost, high-toughness and thin-specification 9Ni steel plate

The invention discloses a manufacturing method for a low-cost, high-toughness and thin-specification 9Ni steel plate. Molten steel comprises 0.03%-0.06% of C, 0.1%-0.2% of Si, 0.5%-0.8% of Mn, 8.6%-9.1% of Ni, 0.02%-0.05% of Mo, 0.015%-0.035% of Als, smaller than or equal to 0.005% of S, smaller than or equal to 0.007% of P, smaller than or equal to 0.007% of N, and the balance Fe and impurities, wherein the impurities cannot be removed. A vacuum furnace with the vacuum degree smaller than or equal to 50 Pa is used for conducting smelting and alloying; the heating temperature ranges from 1,160 DEG C to 1,220 DEG C, the heat preservation time ranges from 90 min to 180 min, and the thickness of a blank ranges from 120 mm to 150 mm after cogging; two-stage controlled rolling is adopted, after rolling, the current temperature is kept for 10 s-15 s, then accelerated cooling is conducted to the temperature ranging from 440 DEG C to 550 DEG C with the cooling rate of 15-40 DEG C / s, and then air cooling is conducted to the room temperature; and the steel plate is heated to 575 DEG C-605 DEG C, and air cooling is conducted to the room temperature after tempering is conducted for 45 min-70 min. According to the manufacturing method, the characteristics of 9Ni steel materials and the thin-specification steel plate cooling characteristics are utilized, controlled rolling and controlled cooling are organically combined with a heat treatment technology, the material performance is improved, meanwhile, the technology process is shortened, the technology energy consumption is reduced, and the purpose of reducing the production cost of the high-toughness and thin-specification 9Ni steel plate is achieved.

Owner:NANJING IRON & STEEL CO LTD

Preparation method of gradient pore structure carbon paper

ActiveCN113322713AEnhanced mass transferImprove heat transfer performanceCell electrodesSynthetic cellulose/non-cellulose material pulp/paperFiberCarbon fibers

The invention discloses a preparation method of carbon paper with a gradient pore structure, which comprises the following steps: separately degumming and oxidizing carbon fibers with different length-diameter ratios, and respectively dispersing the treated carbon fibers in a dispersant solution to form carbon fiber slurry with different length-diameter ratios; sequentially carrying out gradient layering and inclined net forming on the carbon fiber slurry according to the length-diameter ratio of carbon fibers from high to low to obtain a carbon felt precursor with a three-dimensional net structure; dipping the carbon felt precursor in a resin solution, taking out the dipped precursor, and conducting drying to obtain a carbon felt; and firstly hot-pressing the carbon felt into carbon paper body paper, and then conducting carbonization and graphitization treatment to obtain the gradient pore structure carbon paper. According to the invention, gradient layering is carried out in sequence from high to low according to the length-diameter ratio of the slurry carbon fiber, so that the prepared carbon paper has a gradient pore structure, communicating pores are formed in the carbon paper, the pore diameter changes in a gradient manner along the normal direction on the plane of the carbon paper, a pressure gradient is formed in a diffusion channel, the gas conveying efficiency can be improved, and the mass transfer and heat transfer performances of the carbon paper are effectively improved.

Owner:CENT SOUTH UNIV

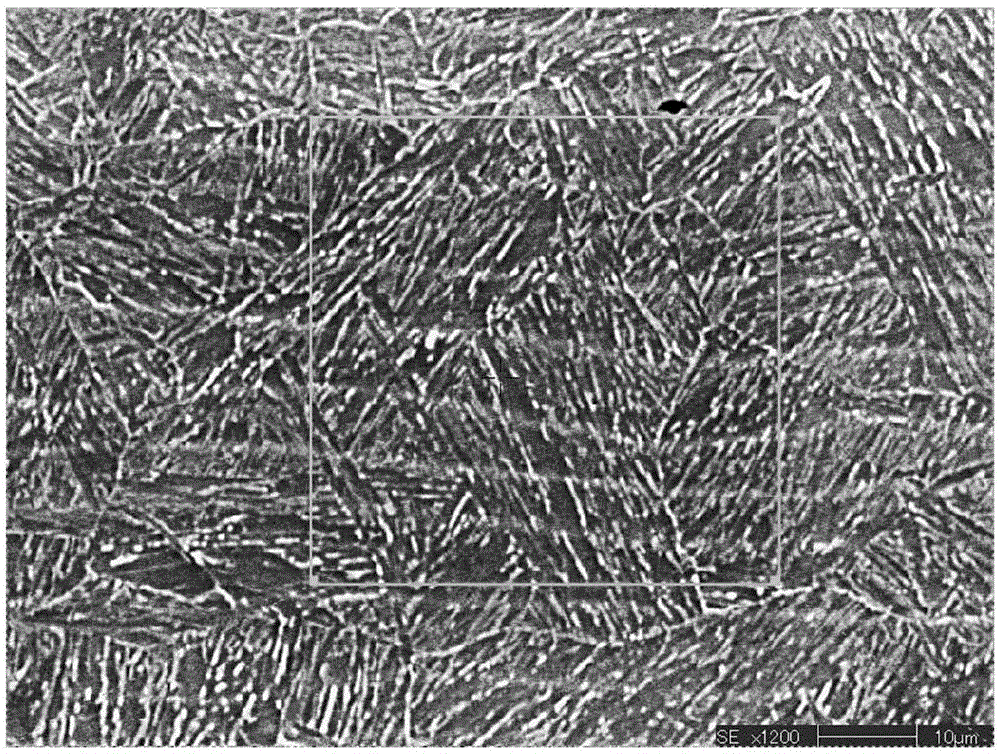

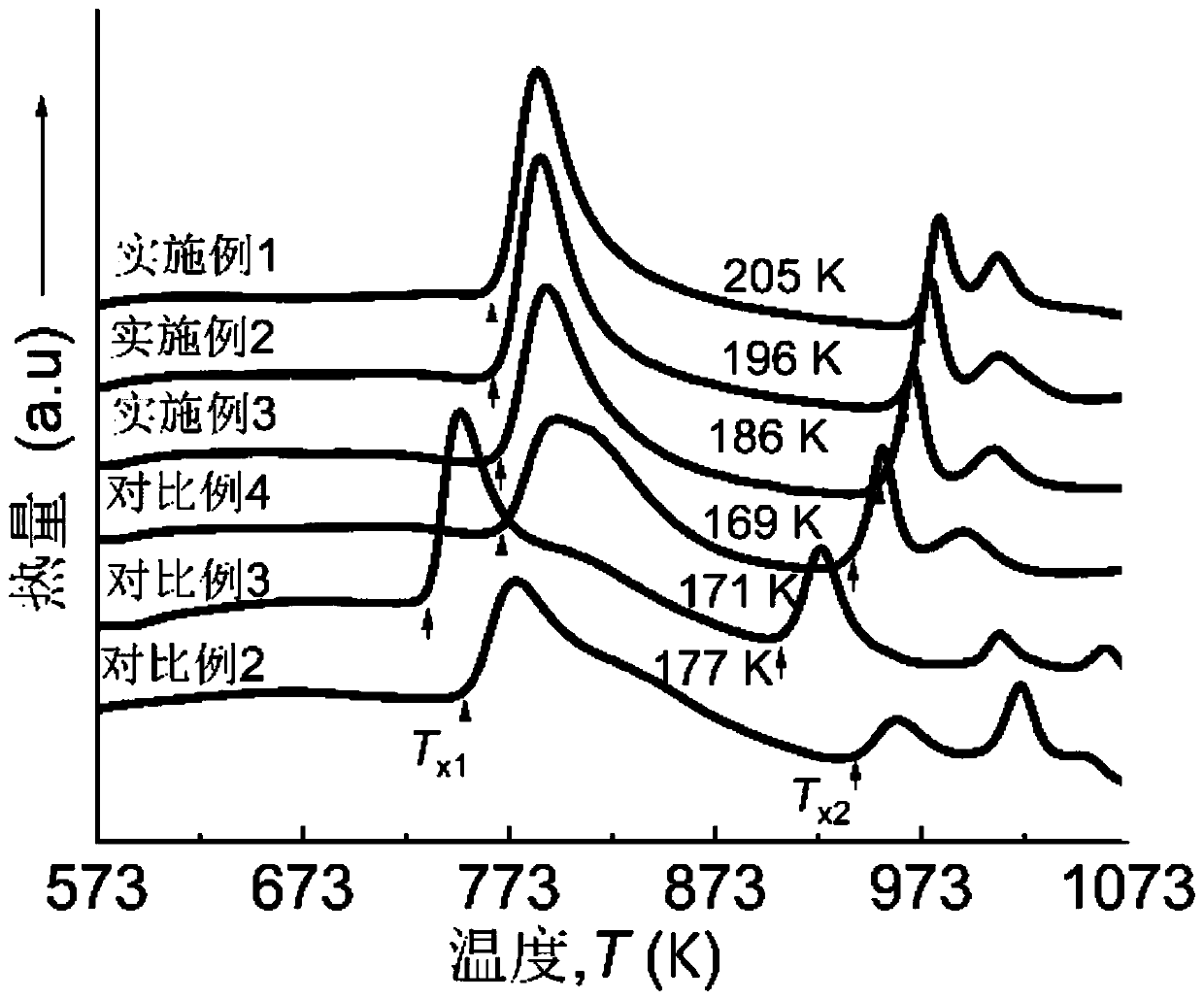

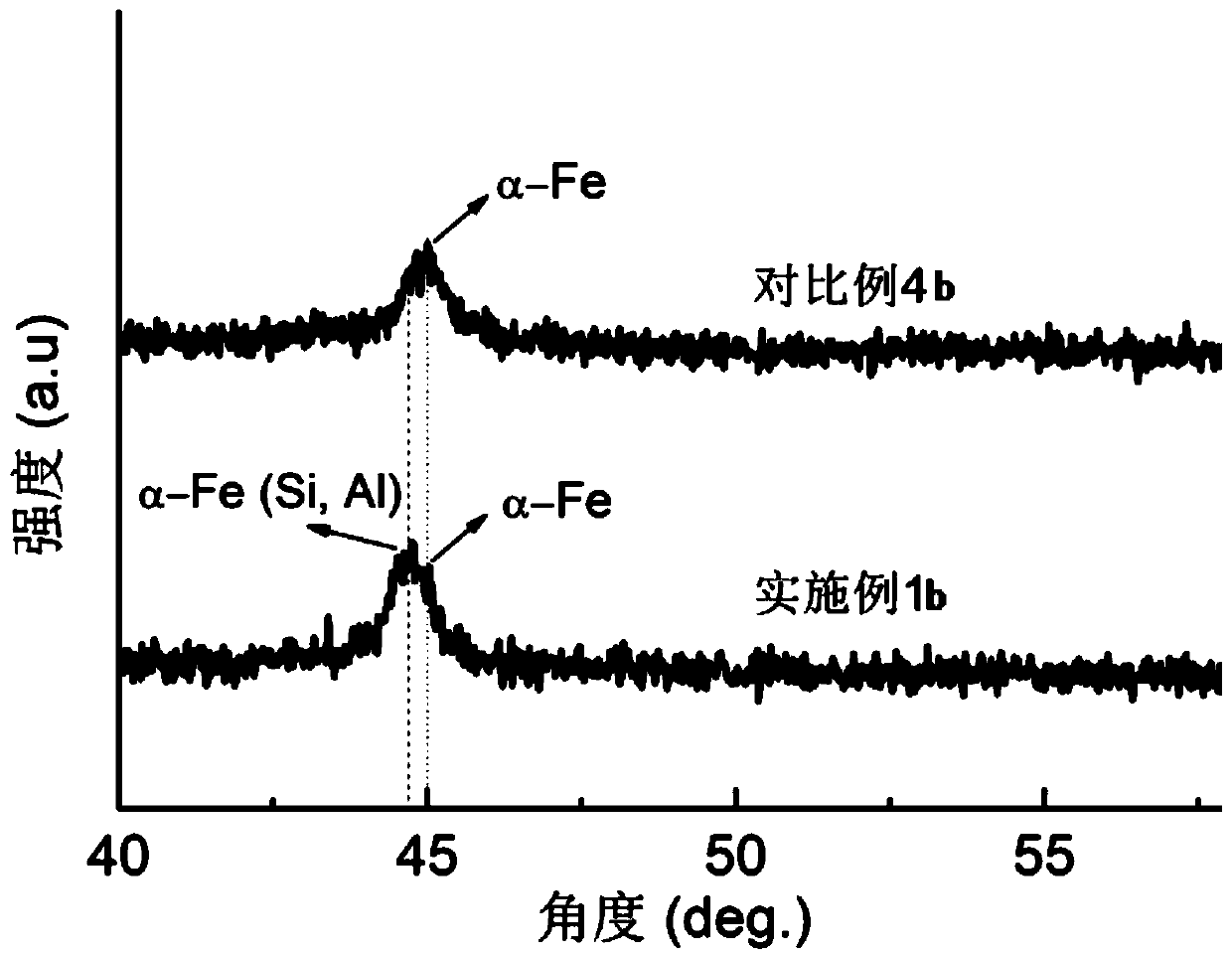

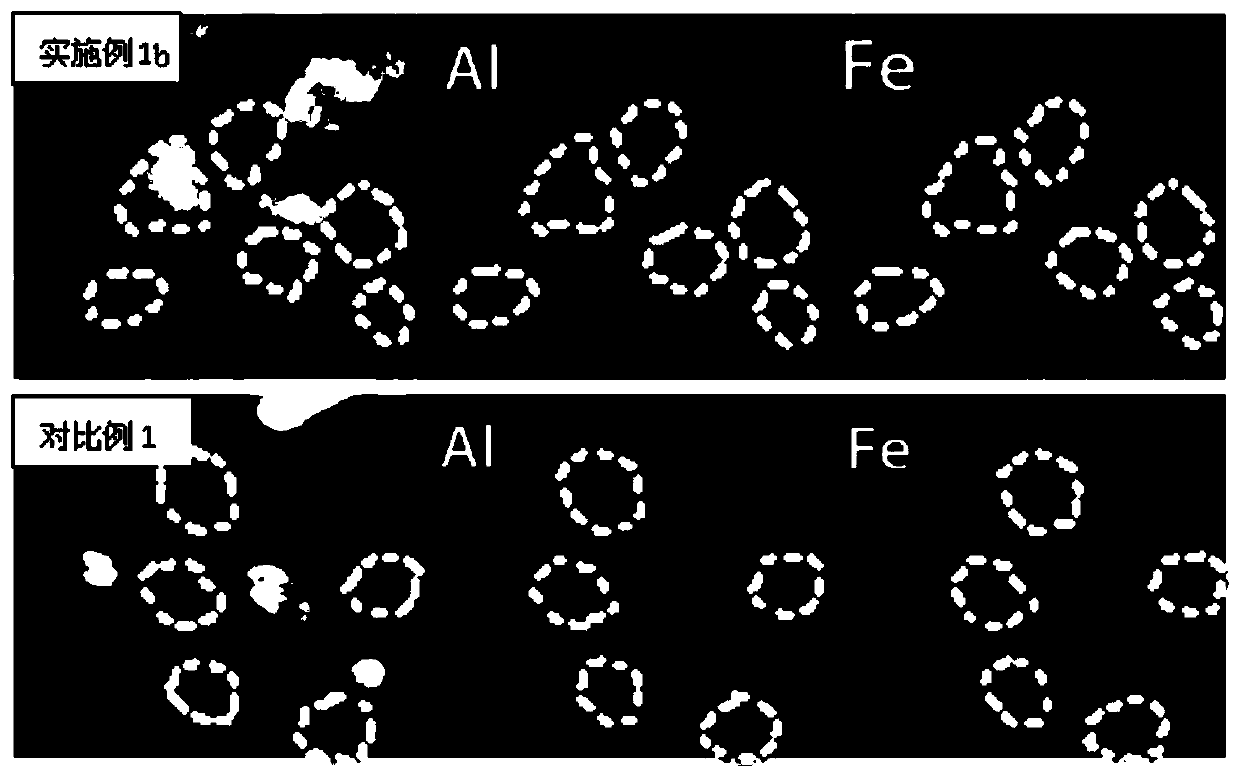

Fe-based nanocrystalline soft magnetic alloy and preparation method

ActiveCN111020410AReduce the content of precious metal elementsImprove thermal stabilityMagnetic materialsAmorphous matrixHeat treated

The invention discloses an Fe-based nanocrystalline soft magnetic alloy. The molecular formula of the alloy is FeaSibBcMdCuePfAlg, M refers to the metallic element Nb, Mo, V, Mn or Cr, a, b, c, d, e,f and g are mole percentage content of corresponding atoms, b is larger than or equal to 6 but smaller than or equal to 15, c is larger than or equal to 5 but smaller than or equal to 12, d is largerthan or equal to 0.5 but smaller than or equal to 3, e is larger than or equal to 0.5 but smaller than or equal to 1.5, f is larger than or equal to 0.5 but smaller than or equal to 3, g is larger than or equal to 0.5 but smaller than or equal to 10, and the balance is Fe and inevitable trace impure elements; the structure of the Fe-based nanocrystalline soft magnetic alloy is the two-phase alloywith the Fe adopting the body-centered cubic structure and Fe(Si, Al) mixed nanocrystalline grains embedded in an amorphous matrix, and the average size ranges from 10 nm to 13 nm. The invention further provides a preparation method of the Fe-based nanocrystalline soft magnetic alloy. The method includes two-step heating and two-step cooling heat treatment. The Fe-based nanocrystalline soft magnetic alloy has the advantages of low cost, excellent soft magnetic property, high corrosion resistance as well as good manufacturability and heat treatment processability, and has the broad applicationprospects in the fields of noise suppression, filtration, wireless charging and the like in complex and harsh environments.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Heat treatment method of perforating head

InactiveCN101012492AUniform temperatureUniform atmosphereFurnace typesHeat treatment process controlAlcoholPunching

The invention discloses a heat processing method of punching bow, which comprises the following steps: (1) heating furnace temperature to 850 deg.c; loading bow in the furnace; dripping alcohol in the furnace at 5-6ml / min; finishing dripping alcohol after 1h; starting dripping the composite liquid of alcohol and water with bulk rate at 1: 4; (2) heating to 1000 deg.c; insulating 4h; keeping pressure of furnace to 0.6-1.0Kpa; (3) cooling temperature to 850 deg.c; fetching bow out of furnace; transmitting bow through high-temperature fan; making the temperature in the furnace evenly.

Owner:耿志佳

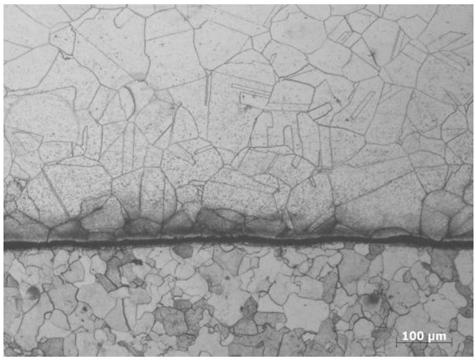

High-shear-strength super-thick composite steel plate for generation III nuclear power station and manufacturing method of composite steel plate

ActiveCN108995323AComposite effect is goodHigh mechanical properties and resistance to intergranular corrosionLaminationLamination apparatusAustenitic stainless steelReduction rate

The invention discloses a high-shear-strength super-thick composite steel plate for a generation III nuclear power station and a manufacturing method of the composite steel plate. The composite steelplate consists of steel-plate carbon steel and 304L austenitic stainless steel. The assembly sequence is as the follows from top to bottom: stainless steel, carbon steel, an isolating agent, carbon steel and stainless steel. Edge sealing is carried out on four edges of a combined billet by welding, vacuumizing treatment is carried out, and the vacuum degree is 100 Pa or lower. The heating temperature of the combined billet is 1200-1270 DEG C, the heating time is 10-15 hours, the single-stroke reduction rate is 5%-15%, the final rolling temperature is controlled to be 1050 DEG C or above, tempering heat treatment is carried out after rolling, the quenching temperature is 870-930 DEG C, the heat preservation time is 2-4 min / mm, and the heating rate is 1.0-1.5 min / mm. The tempering temperature is 620-660 DEG C, the heat preservation time is 3-6 min / mm, and the heating rate is 1.5-2.0 min / mm. The thickness of a finished composite steel plate is 29-110 mm, the shearing strength is good, andthe requirement of steel for composite boards of a nuclear power station is met.

Owner:ANGANG STEEL CO LTD

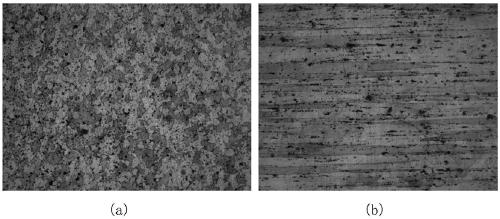

Low-density high-damping aluminum based damping alloy and preparation method thereof

ActiveCN103981405AImprove damping performanceMeet lightweight requirementsLow densityVacuum induction furnace

The invention discloses a low-density high-damping aluminum based damping alloy and a preparation method thereof. The alloy comprises 70-80% of Al, 5-10% of Mg, 5-10% of Zn, 3-5% of Si and 1-6% of Cu. The preparation method comprises the following steps: putting all raw materials in a vacuum induction furnace, carrying out induction melting, heating to 700-900DEG C to form an alloy melt, and carrying out heat insulation for 10min to realize component homogenization; introducing the above obtained melt into a die cavity at 700-800DEG C, applying a pressure of 80-100MPa within 10s by adopting an extrusion casting technology, carrying out die opening after the introduced melt completely solidifies, and taking the obtained casting; carrying out heat treatment on the above obtained material by carrying out heat insulation at 380-450DEG C for 4h and carrying out water quenching to room temperature; and carrying out heat insulation at 120-220DEG C for 20h, and carrying out water cooling to room temperature. The low-density high-damping aluminum based damping alloy id prepared by treating an aluminum alloy as a base, adopting a multi-component alloy technology and controlling the ratio of Mg to Zn. The damping capacity (SDC) of the alloy can reach about 15%, and the density maintains at about 2.7g / cm<3> in order to meet lightweight requirements of alloy materials in the weapon and traffic fields.

Owner:NINGBO SYRNMA METAL MATERIALS CO LTD

Thermal treatment process for plunger of axial plunger pump

InactiveCN102329940AHigh hardnessImprove wear resistanceSolid state diffusion coatingFurnace typesEngineeringPlunger pump

The invention provides a thermal treatment process for a plunger of an axial plunger pump, which is characterized by comprising the following steps of: (1) putting a semi-finished plunger into a vacuum furnace, and heating to 920-940 DEG C via 15-25 min; (2) preserving heat for 25-35 min; (3) cooling to 845-855 DEG C, discharging the plunger, and charging acetylene and nitrogen to the vacuum furnace while preserving heat and cooling to realize carbonitriding on the surface of the plunger; (4) quenching the plunger after discharging, subsequently tempering plunger at the temperature of 130-150 DEG C, and finally air-cooling the plunger to room temperature. In the invention, a hardened layer with high hardness and high wear resistance is formed on the surface of the plunger through carbonitriding on the surface of the plunger. Therefore, the invention has the advantages of wide plunger material selection, high thermal treatment speed, short time consumption and low thermal treatment cost.

Owner:龙工(上海)精工液压有限公司

Heat treatment method for improving yield strength of steel casting

A heat treatment method for improving the yield strength of steel castings, comprising the following steps: a. heating the steel castings to an austenitizing temperature of 880°C-950°C and keeping them warm; b. heating the austenitized steel castings out of the furnace, adopt air cooling + water mist cooling or tap water quenching or polymer quenching to cool the steel castings rapidly, and the cooling speed of the steel castings reaches 30°C / min-120°C / min; c. The cooled cast The steel piece is heated and tempered to 580°C-650°C, and kept warm; the chemical composition of the steel casting and the mass percentage of each component element are as follows: C%=0.12~0.35, Si%=0.20~1.0, Mn%= 0.5~1.8, P%≤0.035, S%≤0.035, Cr%≤2.20, Mo%≤1.20, Ni%≤0.50, the rest are Fe and unavoidable impurity elements.

Owner:KOCEL STEEL

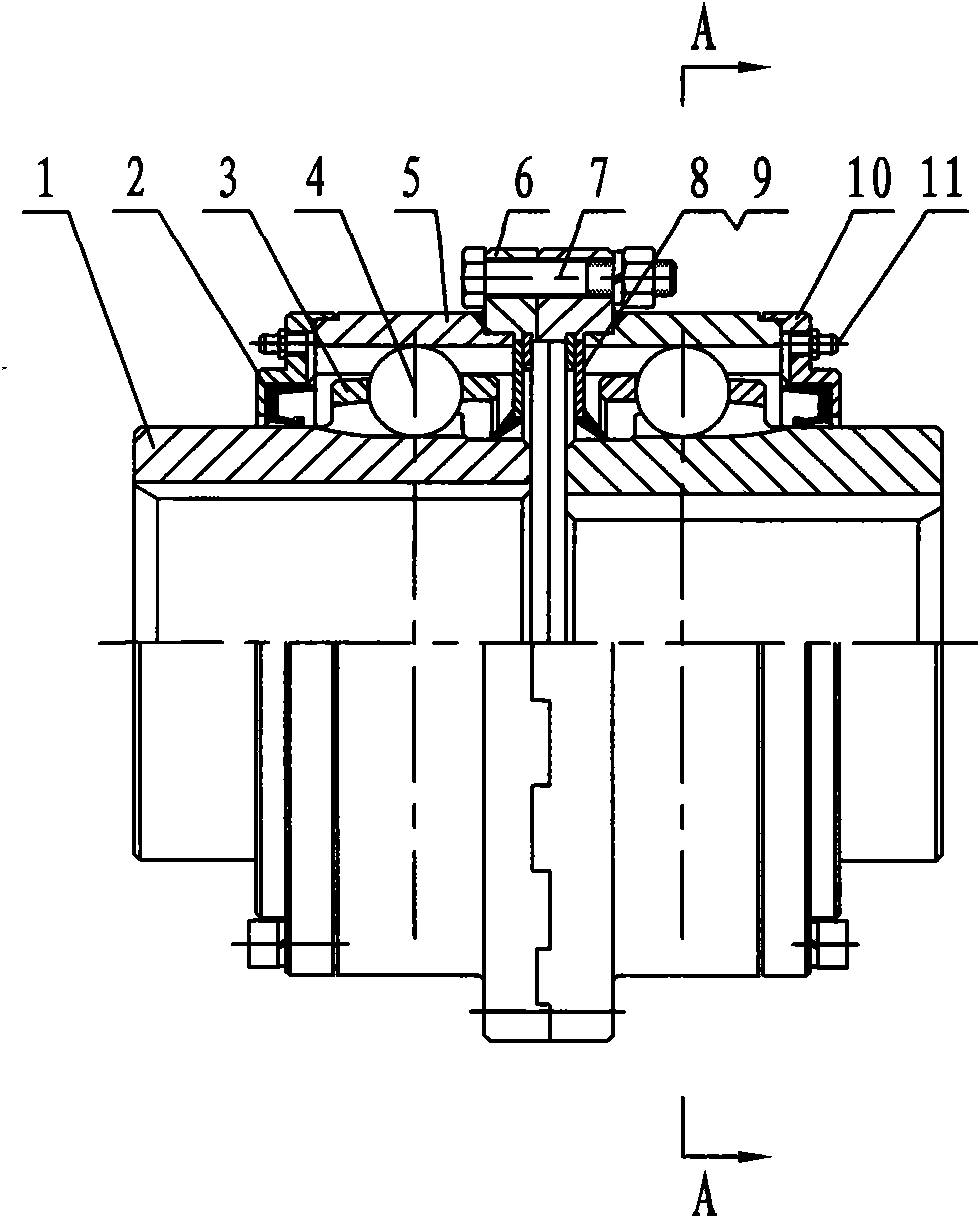

Jacket-welded short CV joint coupling

The invention relates to a jacket-welded short CV joint coupling which is mainly used for power transmission of short distance, small inclination angle and high rotation speed in metallurgical machinery, heavy-duty machinery, mining machinery, hoisting machinery, transport machinery and other industries. The coupling consists of an inner sleeve, an oil seal, a retainer, steel balls, jackets, contrate gears, bolts, a sealing baffle, hole retaining rings, a gland and an oil nozzle, wherein the two contrate gears are installed between the two jackets, the flange bosses of the contrate gears are fixed together by the bolts, and the contact surfaces of the contrate gears are of a dentiform structure and are meshed with each other to realize power transmission from a driving end and a driven end. By dividing the original jackets into the fluted jackets and the contrate gears, the invention realizes that the jackets and the contrate gears can be respectively made of more appropriate materials and made into more appropriate dimensions, thereby greatly improving the material utilization ratio, reducing the process redundancy, lowering the materials loss and the shaping difficulty, facilitating the design and the selection of the connection type of the contrite gears, enabling the organization and the arrangement of production to be more flexible, and having a shorter processing cycle. Thus, the invention meets batch and emergency requirements of modern mechanical industrial equipment.

Owner:XIANGYANG BOYA PRECISION IND EQUIP

Machining method of non-tooth bearing and bearing

InactiveCN106369062ASimple processReduce heat treatment costsShaftsBearing componentsElectromagnetic inductionTreatment costs

The invention discloses a machining method of a non-tooth bearing and the bearing. The machining method comprises the following steps of rough turning, semi-finish turning, thermal treatment, finish turning, marking, drilling, oil hole forming, assembling and storing into a warehouse. According to the machining method of the non-tooth outer ring bearing, an induction heat treatment technology is adopted, an electromagnetic coil is powered on for heating, and compared with a traditional heat treatment technique, the method has the advantages that the process is simple, the heat treatment cost is low, and the quality of the manufactured bearing part is good. According to the machining method of the non-tooth bearing and the bearing, an oil hole is formed in a punching mode, the formed oil hole has the characteristics that the number of burrs is small and the roundness is good compared with an oil hole formed in a traditional drilling mode, and efficiency is also improved by 3-4 times. By application of the machining method of the non-tooth bearing and the bearing, the production cost can be effectively reduced, and benefits are improved.

Owner:安徽远丰回转支承有限责任公司

Low temperature ultrasonic aging treatment method for 7075 aluminium alloy

InactiveCN109023178AImprove heat treatment organizationImprove performance5005 aluminium alloyPhase number

The invention discloses a low temperature ultrasonic aginreatmentg t method for a 7075 aluminium alloy and relates to the technical field of aluminium alloy heat treatment. The low temperature ultrasonic aging treatment method for the 7075 aluminium alloy comprises the steps of oil bath liquid pre-heating, workpiece oil bath heat preservation, ultrasonic aging treatment, cooling and so on. According to the low temperature ultrasonic aging treatment method for the 7075 aluminium alloy, the aging temperature needed by 7075 aluminium alloy traditional aging heat treatment can be reduced, the aging time can be greatly shortened, and the precipitated phase number is increased, the precipitated phase distribution is more dispersed. Compared with a traditional aging heat treatment method, the lowtemperature ultrasonic aging treatment method for the 7075 aluminium alloy has the advantages that requirements on an aging process can be reduced, the heat treatment cost can be reduced, the efficiency can be enhanced, the aluminium alloy aging heat treatment structure can be improved, and the aluminium alloy comprehensive performance can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

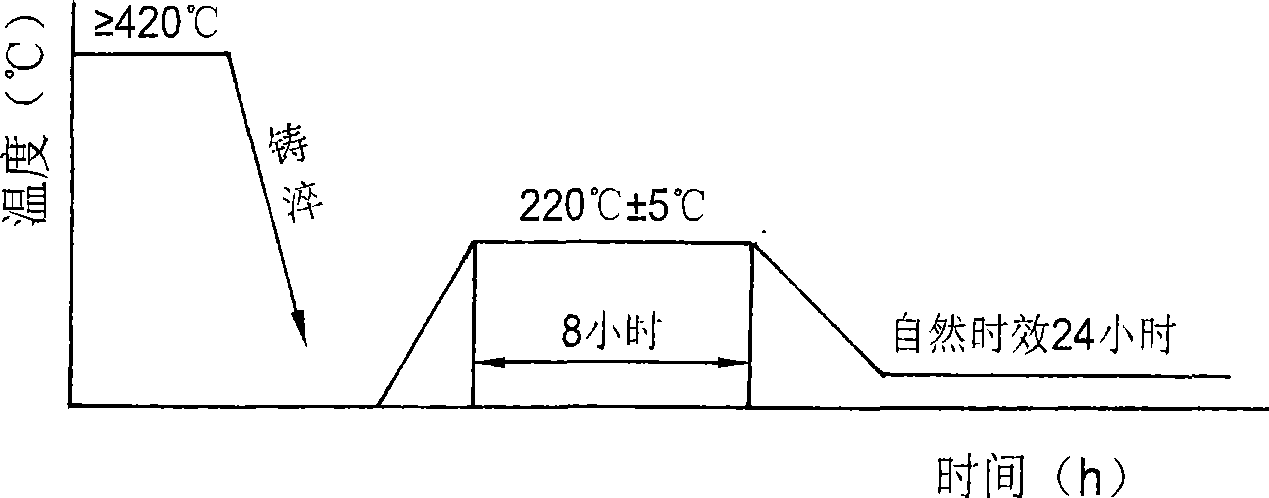

Low temperature heat processing method of single feeder head eutectic Al-Si alloy piston material

A low temperature heat processing method of single feeder head eutectic Al-Si alloy piston material is processed according to following steps: heating a cast piston in a well-type furnace to 480+(-)5 degrees centigrade, keeping the temperature for 1.5 h, then taking out from the furnace; using the water of 50 to 80 degrees centigrade to quench and cool; after quenching, heating the well-type aging furnace to 160+(-) degrees centigrade along the furnace, performing manual aging after keeping temperature for 5 , then taking out from the furnace and performing air cooling, finishing the whole process of heat process of the piston material. Each performance index of the eutectic Al-Si alloy piston material after the low temperature heat processing exceeds the each performance index order by the internal-combustion engine piston technical condition GB / T1148-93. This technical method can guarantees the piston quality and can reduce the manufacturing cost.

Owner:成都银河动力有限公司

Nuclear power station reactor core cooling system safety injection box composite steel plate and manufacturing method thereof

The invention discloses a nuclear power station reactor core cooling system safety injection box composite steel plate and a manufacturing method thereof. The steel plate is composed of carbon steel of tempered sorbite organization and 304L austenitic stainless steel. The steel billets are symmetrically compounded, an upper layer and a lower layer are carbon steel, two layers in the middle are stainless steel, and an isolating agent is added between the two layers of the stainless steel. The vacuum degree of a composite billet is 1.0-5.0 x 10<-2>Pa. A heating temperature is 1200-1250 DEG C, heating time is 10-15 hours, a single-pass pressing rate is 5%-15%, and the final rolling temperature is larger than or equal to 1000 DEG C. The quenching temperature is 890-920 DEG C, the heat preservation time is 2-3 min / mm, the temperature rising rate is 1.0-1.5min / mm, and water is cooled to be less than or equal to 100 DEG C after being discharged from a furnace. The tempering temperature is 630-660 DEG C, the heat preservation time is 4-6 min / mm, and the temperature rising rate is 1.5-2.0 min / mm. According to the manufacturing method, the produced steel plate has high normal temperature andhigh temperature performance, good shearing strength and bonding strength, and meets requirements for the steel usage by the nuclear station.

Owner:ANGANG STEEL CO LTD

Method for preparing thin-diameter zirconium oxide fibers and fiber board thereof

The invention relates to a method for preparing thin-diameter zirconium oxide fibers and a fiber board thereof. The method comprises the following steps of: preparing poly zirconium sol spinning solution by adopting basic zirconium carbonate, glacial acetic acid, water and yttrium nitrate as raw materials, obtaining thin-diameter poly zirconium sol fibers by ultrahigh-speed centrifugal swinging and high-speed hot airflow blowing and drafting, and performing thermal treatment and sintering on the thin-diameter poly zirconium sol fibers to obtain the thin-diameter zirconium oxide fibers; and performing vacuum suction molding and pressure leveling to prepare a wet fiber board blank by adopting the thin-diameter zirconium oxide fibers as a raw material and adopting poly zirconium sol spinningsolution diluted by adding water as adhesive, and drying and calcining the wet blank to obtain the zirconium oxide fiber board. The raw materials are easily obtained, the preparation of the adhesive is simple and convenient, and the method has low cost and no pollution and is suitable for large-batch industrialized production; the prepared thin-diameter zirconium oxide fibers have good bending flexibility; and the prepared zirconium oxide fiber board has uniform thickness, flat surface, accurate and controllable thickness, and good mechanical property and high-temperature bending resistance.

Owner:南京理工宇龙新材料科技股份有限公司

Low carbon TMCP technology EH36 boat deck and production method thereof

The invention relates to a low carbon TMCP technology EH36 boat deck and a production method thereof. The boat deck comprises chemical compositions of, by mass, 0.06-0.09% of C, 0.20-0.35% of Si, 1.40-1.55% of Mn, no larger than 0.018% of P, no larger than 0.005% of S, 0.030-0.045% of Nb, 0.030-0.045% of V, 0.008-0.020% of Ti, 0.015-0.050% of Als, and the balance Fe and unavoidable impurities. Theproduction method comprises the following steps of KR molten iron pretreatment, converter smelting, deoxidation alloying, LF refining, VD / RH refining, continuous casting, casting blank off-line slowcooling, casting blank heating, high-pressure water descaling, rough rolling, finish rolling, ACC cooling, straightening, finishing, and testing and warehousing. According to the low carbon TMCP technology EH36 boat deck and the production method thereof, compositions and processes are optimized, a low carbon component design is adopted, a TMCP technology is used for producing and delivery, the addition of Ni precious metal is canceled, normalization heating processing technology is canceled at the same time, production cost is reduced, and manufacturing cycle is shortened; the production cycle of steel plates in rolling process is shortened from 4-5 days to 2-3 days, low cost, low consumption and short process production of the EH36 boat deck is realized indeed, and significant economic and social benefits are achieved.

Owner:SD STEEL RIZHAO CO LTD

Low-carbon multi-element micro-alloyed multipurpose high-strength and high-toughness structural steel

The invention discloses low-carbon multi-element micro-alloyed multipurpose high-strength and high-toughness structural steel. The structural steel is characterized by being formed by smelting 0.22-0.31 part of carbon (C), 0.15-0.30 part of silicon (Si), 0.45-0.85 part of manganese (Mn), 1.10-1.40 parts of chromium (Cr), 0.45-0.75 part of molybdenum (Mo), nickel (Ni) smaller than or equal to 0.25 part, copper (Cu) smaller than or equal to 0.25 part, sulfur (S) smaller than or equal to 0.005 part, phosphorus (P) smaller than or equal to 0.015 part, 0.02-0.10 part of vanadium (V), titanium (Ti) smaller than or equal to 0. 01 part, 0.02-0.05 part of niobium (Nb), 0.001-0.003 part of boron (B) and the balance iron by weight. According to the low-carbon multi-element micro-alloyed multipurpose high-strength and high-toughness structural steel, the heat processing technology risk is small and the rejection rate is low; the heat processing performance is more reliable, and the heat processing cost is lower; clean and civilized production can be realized. The multi-element micro-alloyed multipurpose high-strength and high-toughness structural steel can serve as carburizing steel; the surfaces of parts can have enough abrasive resistance through quenching and high-temperature tempering after carburization, and base bodies have good toughness.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

Heat treatment technology of steel castings

The invention discloses a heat treatment technology of steel castings. The heat treatment technology comprises: (1) normalizing, comprising determining types of the steel castings, then determining different normalizing temperatures in accordance with different types, determining insulation time in accordance with thickness of the steel castings, and naturally cooling to a normal temperature; (2) quenching, comprising heating for a certain time, meanwhile observing a heated color of the steel castings until the steel castings is completely burnt, taking out of a furnace and quenching, cooling with water so as to reach a critical cooling rate, and then crystallizing into a martensite; and (3) tempering, comprising tempering the steel castings of step (2) in the furnace, heating the furnace to be below a quenching temperature and then keeping for a while, keeping warm, taking out of the furnace and cooling with water. The technology is easy and understandable, improves mechanical properties of the steel castings, and is quite low in heat treatment cost, small in post-treatment workload on casting surfaces, and high in size precision of the castings.

Owner:QINGDAO MELPER PRECISION CASTING & MACHINERY

Heat treatment method and system for preparing high-performance iron-based nano crystal alloy magnetic core

ActiveCN106128747ARaise the furnace temperatureReduce the temperatureFurnace typesInductances/transformers/magnets manufactureMagnetic coreHeating system

The embodiment of the invention discloses a heat treatment method and system for preparing a high-performance iron-based nano crystal alloy magnetic core. The heat treatment time is shortened by increasing the charging temperature and heating rate, magnetic ordering inside the magnetic core can be effectively controlled to some extent, the magnetocrystalline anisotropy is reduced, and the performance of the magnetic core is improved. The heat treatment method for preparing the high-performance iron-based nano crystal alloy magnetic core comprises the steps that a heating system is started; a preset temperature T0 is set for the heating system, and preset temperature information is sent to a heat treatment furnace; the heat treatment furnace controls a furnace chamber to be heated to the preset temperature T0 from room temperature; the well wound magnetic core is put into the furnace chamber of the heat treatment furnace; the heating system starts an air exhaust program; air in the furnace chamber is exhausted through the heat treatment furnace till the furnace chamber is in a vacuum state; the heating system starts an air injection program; gas is injected into the furnace chamber through the heat treatment furnace; the heating system starts a first heating accelerating program, the first heating rate v1 is set, and heating is conducted at first target temperature T1 for a first heat preservation time t1.

Owner:GUANGDONG UNIV OF TECH

65Si2CrVA spring steel and production process thereof

The invention discloses 65Si2CrVA spring steel and a production process thereof. The 65Si2CrVA spring steel comprises the following components in percentage by weight: 0.52-0.60% of C, 1.40-2.00% of Si, 0.70-1.00% of Mn, not greater than 0.025% of P, not greater than 0.025% of S, 0.15-0.35% of Cr, not greater than 0.10% of Ni, not greater than 0.25% of Cu, and the balance Fe and inevitable impurities. The production process comprises the following procedures: electric furnace smelting, LF refining, vacuum degassing, continuous casting, slow cooling, bar rolling, heat treatment, fine inspection, performance detection, and packaging and warehousing. The 65Si2CrVA spring steel disclosed by the invention has the characteristics of a small decarburization tendency, high tempering stability, high hot workability, excellent performance after heat treatment, and the like; and the spring steel has high cold workability under an air-cooling condition after round steel rolling, has high plasticity and toughness during cold working, and reduces a hot working cost.

Owner:ANHUI HONGQIAO METAL MFG

100 mm-120 mm Q460D extra-thick high-strength steel and preparation method thereof

ActiveCN113249641AReduce production pressureImprove efficiencyFurnace typesHeat treatment furnacesChemical compositionDehydrogenation

The invention relates to 100 mm-120 mm Q460D extra-thick high-strength steel which comprises the following chemical components including, by mass, 0.10% to 0.13% of C, 0.30% to 0.50% of Si, 1.40% to 1.60% of Mn, less than or equal to 0.0070% of P, less than or equal to 0.0020% of S, 0.020% to 0.050% of Nb, 0.008% to 0.020% of Ti, 0.020% to 0.040% of Al, 0.10% to 0.20% of Cu, 0.10% to 0.20% of Cr, 0.10% to 0.20% of Ni and the balance Fe and inevitable impurity elements. The production process flow comprises the following steps of converter smelting, LF refining, RH vacuum degassing, Ca treatment, continuous casting, casting blank dehydrogenation treatment, heating, normalizing rolling, air cooling, steel plate stacking and slow cooling and unstacking. The yield strength of a steel plate ranges from 430 MPa to 470 MPa, the tensile strength ranges from 550 MPa to 570 MPa, the ductility is larger than or equal to 20%, and the Charpy impact energy at the 1 / 4 position and the 1 / 2 position of the thickness of -20 DEG C is larger than or equal to 200 J. The flaw detection result meets the ASTM A 578C level requirement, and the surface of the steel plate has no defect.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method for reducing strip grade of CrMo series semi-axle steel in completely annealed state

ActiveCN111636029AReduce heat treatment costsReduce raw sulfurManufacturing convertersProcess efficiency improvementSteelmakingMolten steel

The invention relates to a method for reducing strip grade of CrMo series semi-axle steel in a completely annealed state. The method comprises the following steps of sequentially carrying out molten iron pretreatment, converter steelmaking, refining, continuous casting, casting blank heating and rolling to obtain steel with the strip grade of less than or equal to 2.5 level, wherein the mass percentage content of sulfur in the molten iron obtained after molten iron pretreatment is less than or equal to 0.01%, the end point of operation in converter steelmaking is that the mass percentage of carbon in molten steel is greater than or equal to 0.08%, the mass percentage of phosphorus is less than or equal to 0.01%, and the slag amount is 5-7 t; the mass percentage of sulfur in the molten steel in the refining process is less than or equal to 0.005%; the content of O in the refined molten steel is less than or equal to 12 ppm, and the mass percentage content of Al is 0.025%-0.035%; the final temperature of rolling ranges from 830 DEG C to 980 DEG C. According to the method provided by the invention, through component design and finish rolling temperature selection in the molten iron pretreatment, converter steelmaking and refining processes, the strip grade in the prepared steel is less than or equal to 2.5 grades, and the heat treatment cost after hot rolling is also remarkably reduced.

Owner:CHENGDE JIANLONG SPECIAL STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com