Method for laser additive manufacturing of 12CrNi2 alloy steel

A laser additive and alloy steel technology, applied in the field of materials, can solve the problems of high cost, long cycle, complex crankshaft production process, etc., and achieve the effect of short process, high material utilization rate, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A 12CrNi2 alloy steel material is prepared by depositing 12CrNi2 alloy steel powder on a substrate material by a laser direct deposition method, and the preparation method comprises the following steps:

[0047] (1) Pretreatment of 12CrNi2 alloy steel powder: Dry and dehumidify the 12CrNi2 alloy steel powder with a constant temperature drying oven. The composition of the steel powder is: according to the mass percentage, the composition is: C: 0.132%, Si: 0.359%, Cr: 0.845%, Ni: 1.9%, Mn: 0.505%, and the balance is Fe; the average particle size It is 75 microns, the powder shape is spherical, and the fluidity is good;

[0048] (2) Pretreatment of substrate materials: first use a grinding wheel to derust the surface of the 200x110x10mm Q235 steel plate to make the surface bright and clean, and then use 100#, 240#, 400#, 600#, 800#, 1000# sandpaper to The surface is polished, using each type of sandpaper to polish for ten minutes, then using acetone to remove oil stains,...

Embodiment 2

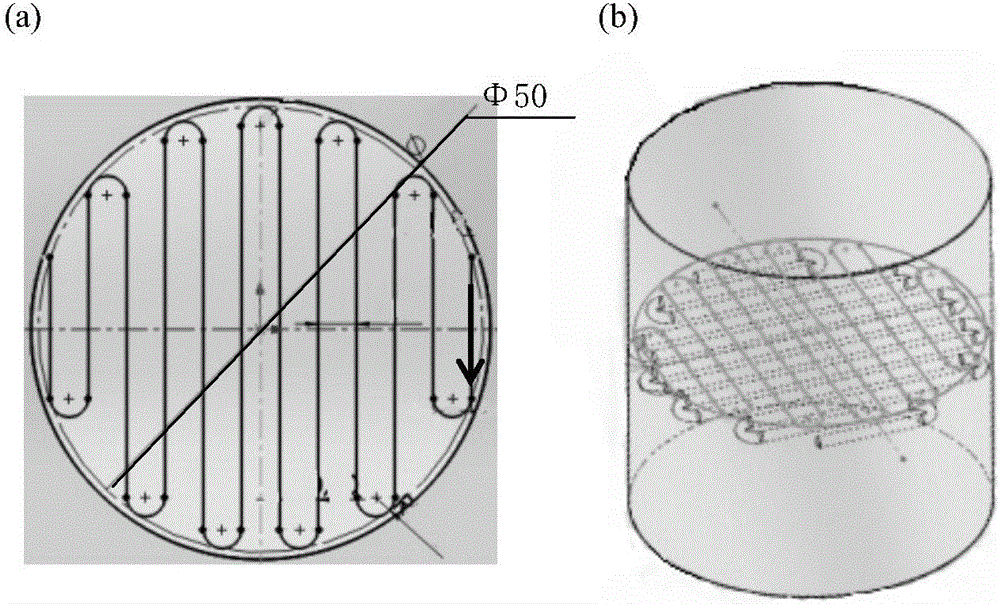

[0056] Using the optimal power 1900W optimized in Example 1, a 12CrNi alloy steel cylinder shaft was prepared using laser additive manufacturing technology, the specific method is as follows:

[0057] (1) according to the method described in step (1)~(2) in embodiment 1, 12CrNiAlloy steel powder and Q235 matrix material are carried out pretreatment;

[0058] (2) Laser direct deposition forming: using a semiconductor laser, the processed 12CrNi2 alloy steel powder is laser deposited on the Q235 steel plate, and the specific operations are as follows:

[0059] a) Start the switch of the semiconductor laser and the control switch of the machine tool, put the Q235 steel plate on the sample stage of the semiconductor laser, place the polished surface upwards, measure the distance from the laser source of the semiconductor laser to the bright surface of the Q235 steel plate with a scale, and use Adjust the distance with the manual remote control to make it 304mm (the focal length of...

Embodiment 3

[0077] A method for laser additive manufacturing of 12CrNi2 alloy steel material, comprising the steps of:

[0078] (1) according to the method described in step (1)~(2) in embodiment 1, 12CrNiAlloy steel powder and Q235 matrix material are carried out pretreatment;

[0079] (2) adopt semiconductor laser, the 12CrNi alloy steel powder laser deposition that will handle is on Q235 bulk body, deposition method is with the step (3) of embodiment 1, and wherein, semiconductor laser process parameter is: power 1900W, scanning speed 5mm / s. The powder feeding rate is 6.4g / min, and the defocus is 4mm. Because there is a horizontal transition section between two adjacent deposition layers in the sample prepared by 1900W power, the overlapping rate should be appropriately increased to eliminate the horizontal transition section. Therefore, 40% and 50% of the overlapping rates of the two groups are set. Prepare a single-layer deposition structure under different overlapping ratios, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com