High-shear-strength super-thick composite steel plate for generation III nuclear power station and manufacturing method of composite steel plate

A technology of composite steel plate and manufacturing method, which is applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of difficult plate shape, shortened heat treatment cycle, and difficult production, and achieves excellent strength and toughness performance and corrosion resistance. Performance, high mechanical properties and intergranular corrosion resistance, the effect of improving comprehensive usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

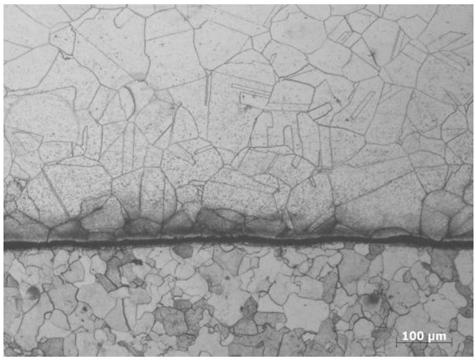

Image

Examples

Embodiment Construction

[0028] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

[0029] The chemical composition of the clad plate is shown in Table 1; the specifications of the clad billet are shown in Table 2; the rolling process of the clad plate is shown in Table 3; the heat treatment process of the clad plate is shown in Table 4; the mechanical properties of the clad plate are shown in Table 4. Table 5; the impact performance of the composite plate is shown in Table 6.

[0030] The chemical composition (wt%) of table 1 composite plate

[0031]

[0032] Table 2 Specifications of Composite Blanks

[0033] Example

Carbon steel intermediate billet thickness / mm

304L stainless steel intermediate billet thickness / mm

1

125

20

2

175

20

3

195

15

4

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com