Production device of carbon fiber reinforced nylon composite material and preparation method of production device

A nylon composite material and production device technology, applied in the field of composite material production, can solve problems such as unfavorable use, poor composite performance, and low work efficiency, and achieve the effects of increased use strength, excellent composite effect, and simple work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

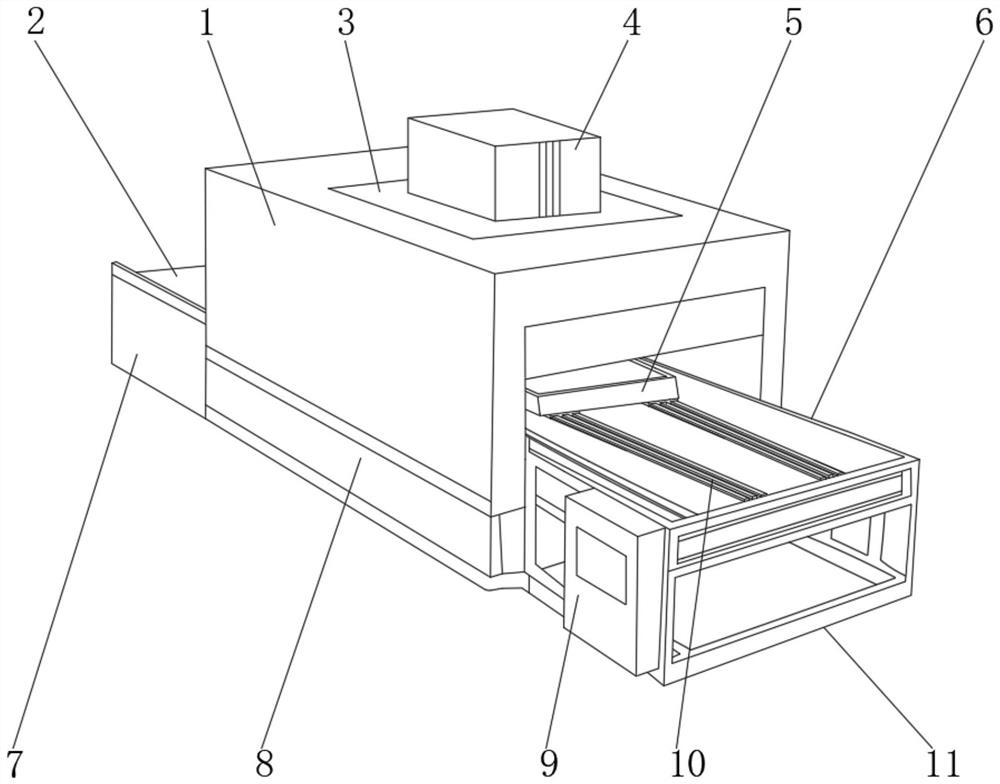

[0030] Such as Figure 1-3 As shown, a production device for carbon fiber reinforced nylon composite materials includes a device main body 1, a discharge chassis 7 is fixedly installed on one side of the device main body 1, and a discharge workbench 2 is installed on the upper end of the discharge chassis 7. The bottom of the main body 1 is positioned with a device base 8, and the other side of the device body 1 is positioned with a feeding chassis 11, and the upper end of the feeding chassis 11 is equipped with a feeding table 6, and one side of the feeding chassis 11 A control box 9 is installed, and a slideway 10 is installed on the upper end of the feeding workbench 6 .

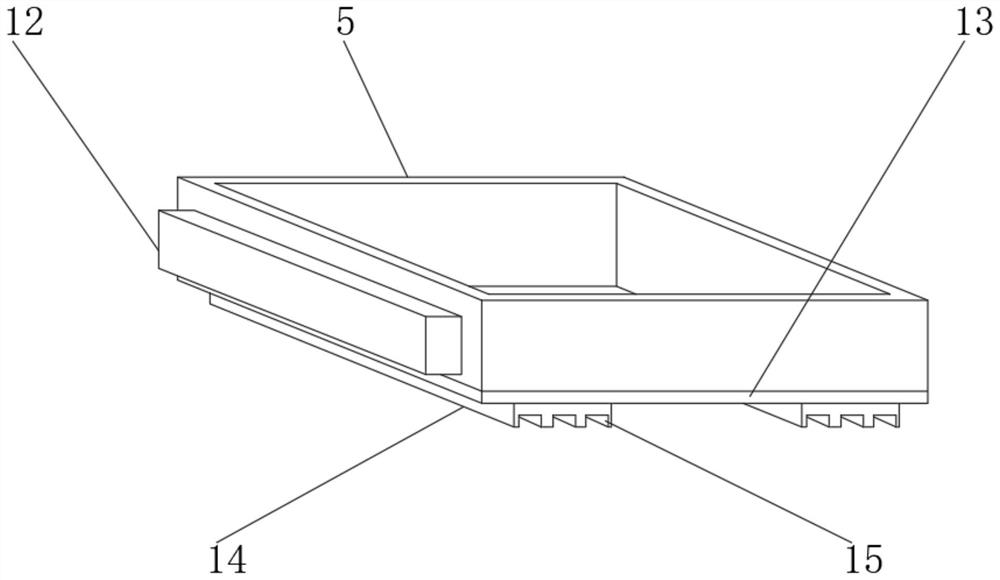

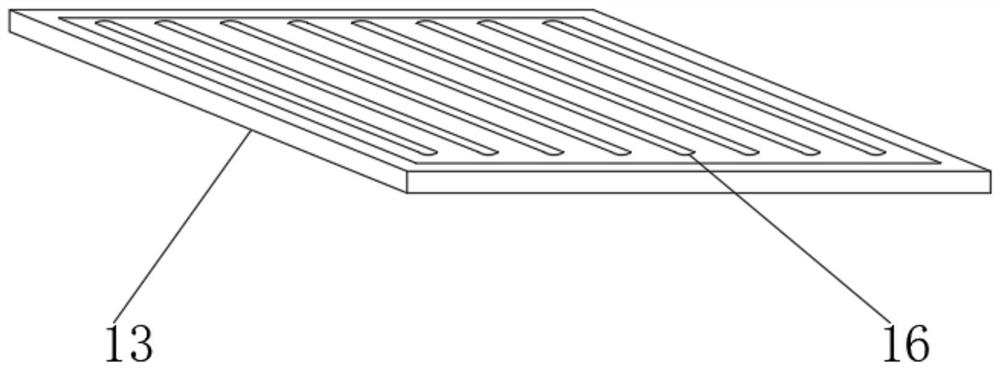

[0031] Further, the upper end of slideway 10 is equipped with slide rail 14, is provided with chute 15 between slide rail 14 and slideway 10, and the upper end of slide rail 14 is equipped with laminated groove box 5, and the laminated groove box 5 A No. 1 heating plate 13 is installed at the bottom, and...

Embodiment 2

[0039] On the basis of Example 1, as figure 1 , 4 As shown in , 5, a production device for carbon fiber reinforced nylon composite materials, including a device main body 1, a discharge chassis 7 is fixedly installed on one side of the device main body 1, and a discharge workbench 2 is installed on the upper end of the discharge chassis 7 , the bottom of the device main body 1 is positioned with a device base 8, the other side of the device body 1 is positioned with a feed chassis 11, the upper end of the feed chassis 11 is equipped with a feed table 6, and the feed chassis 11 One side is equipped with control box 9, and the upper end of feeding workbench 6 is equipped with slideway 10.

[0040] Further, an installation support 3 is installed on the top of the device main body 1, a driving mechanism 4 is installed on the upper end of the installation support 3, a lifting rod 17 is installed on the bottom of the driving mechanism 4, and a mounting support plate 20 is installed...

Embodiment 3

[0048] On the basis of Example 2, such as figure 1 , 6 As shown, a production device for carbon fiber reinforced nylon composite materials includes a device main body 1, a discharge chassis 7 is fixedly installed on one side of the device main body 1, and a discharge workbench 2 is installed on the upper end of the discharge chassis 7. The bottom of the main body 1 is positioned with a device base 8, and the other side of the device body 1 is positioned with a feeding chassis 11, and the upper end of the feeding chassis 11 is equipped with a feeding table 6, and one side of the feeding chassis 11 A control box 9 is installed, and a slideway 10 is installed on the upper end of the feeding workbench 6 .

[0049] Further, the monitoring control mechanism 12 includes a die temperature monitoring sensor module, a die cavity temperature monitoring sensor module, a composite material monitoring sensor module, an Rs485 serial port connection module, a PLC intelligent control module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com