Sizing and compounding method of composite filter material

A composite substrate and filter material technology, which is applied in the direction of winding strips, thin material processing, and sending objects, can solve the problems of paper base and composite substrate misalignment, easy creases, and poor sizing methods. , to achieve better composite effect, prolong service life, unique effect of sizing and repressing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

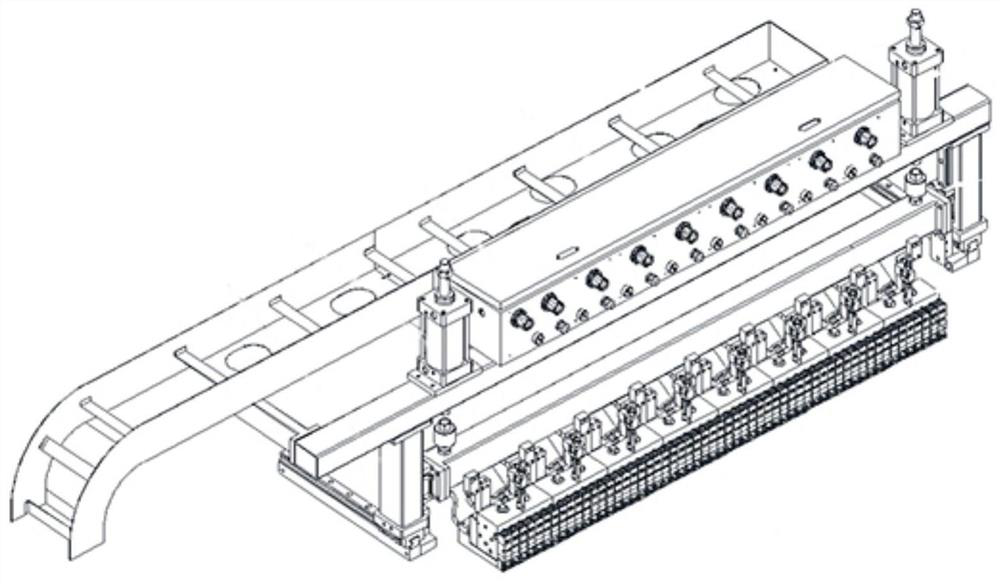

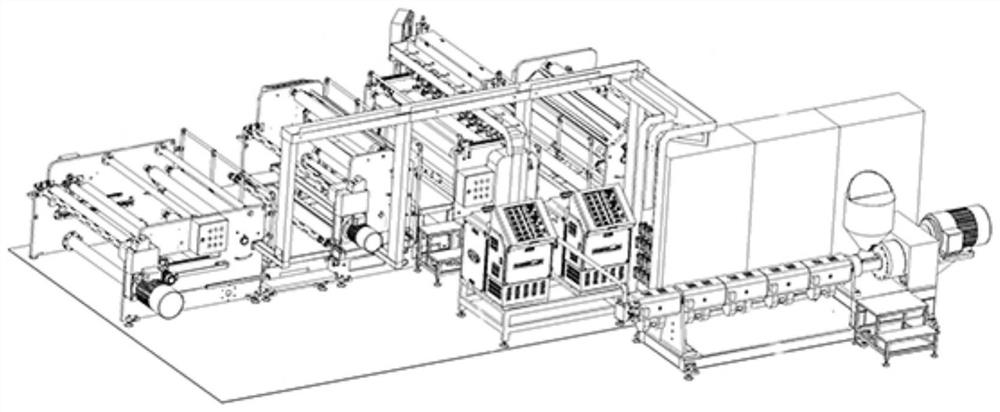

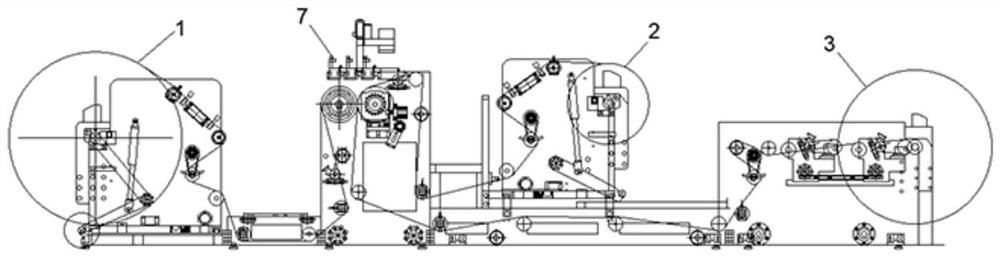

[0032] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0033] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, a compound method for sizing a composite filter material, comprising the following steps:

[0034] a) The composite substrate is unwound by the control of the unwinding motor 4, the unwinding adjustment roller 5 and the unwinding oil cylinder 6;

[0035] b) While the composite substrate is unwinding, the photoelectric deviation correction device is used for displacement correction;

[0036] b') Perform tension detection on the composite substrate, and adjust the speed and torque of the motor through the change of the tension signal;

[0037] c) Unwind the paper base in the same manner as step a);

[0038] d) While the paper base is unwinding, the photoelectric deviation correction device is used for displacement correction;

[0039] d') Perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com