Fe-based nanocrystalline soft magnetic alloy and preparation method

A technology of iron-based nanocrystals and soft magnetic alloys, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., to achieve high magnetic performance stability, low coercive force, and small magnetic crystal anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] In the present embodiment, the molecule of iron-based nanocrystalline soft magnetic alloy material is Fe 69.8 Si 12 B 8 Nb 2.6 Cu 0.6 P 1 Al 6 .

[0064] The concrete preparation method of this iron-based nanocrystalline alloy is as follows:

[0065] (1) Fe, Si, FeB, FeP, FeNb, Cu and Al of industrial purity are used as raw materials according to Fe 69.8 Si 12 B 8 Nb 2.6 Cu 0.6 P 1 Al 6 A quenched amorphous strip with a width of about 1 mm and a thickness of about 23 μm was prepared by batching, master alloy smelting, and single-roll quenching technology, and the copper roll speed was 30 m / s.

[0066] (2) NETZSCH DSC404C differential scanning calorimeter (DSC) was used to measure the crystallization temperature of the alloy strip at a heating rate of 0.67K / s.

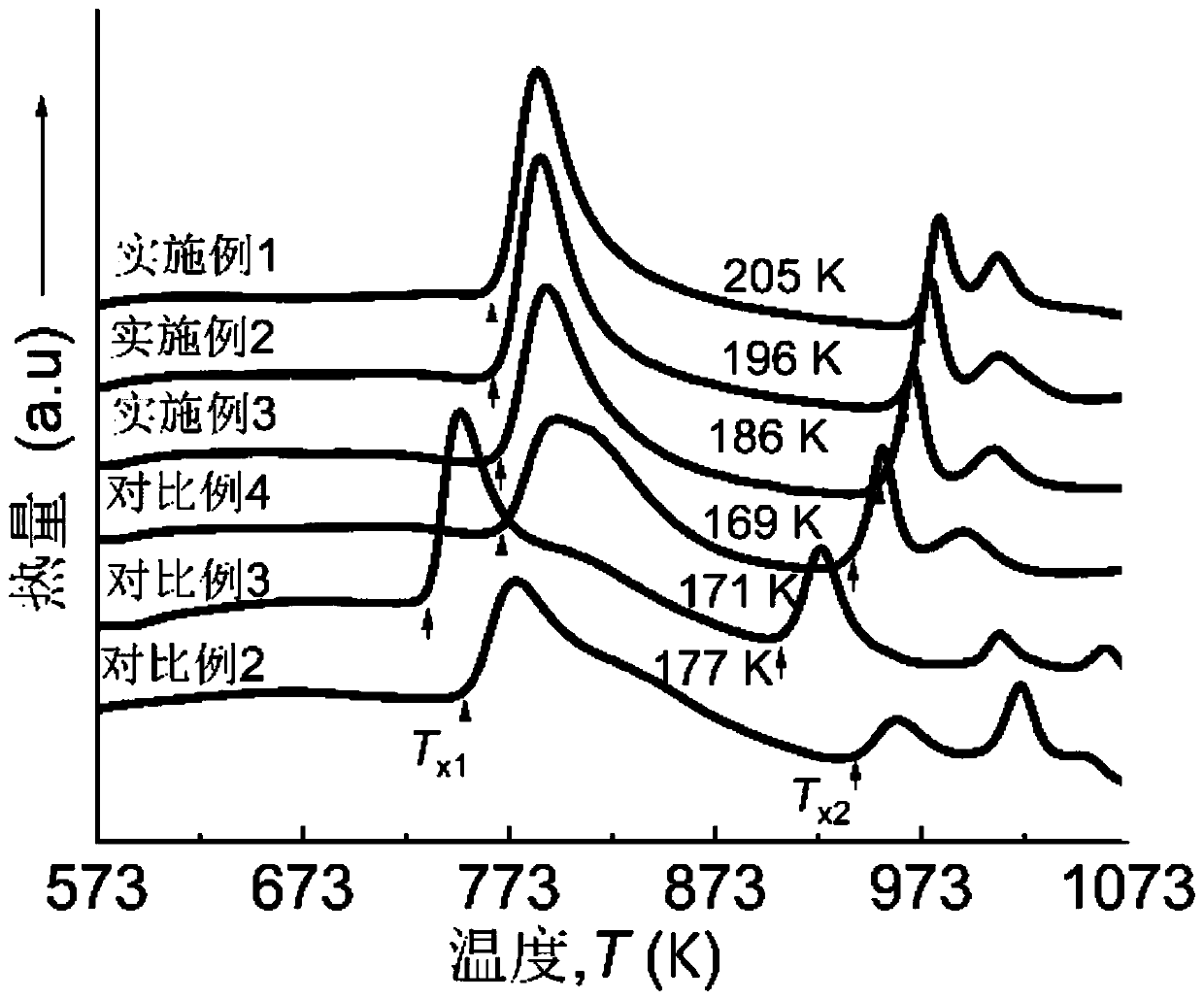

[0067] Such as figure 1 As shown, the temperature at which α-Fe nanocrystals start to precipitate is the temperature at which the first crystallization peak begins to crystallize (T x1 ) is 768K, ...

Embodiment 2

[0076] In the present embodiment, the molecule of iron-based nanocrystalline soft magnetic alloy material is Fe 71.8 Si 12 B 8 Nb 2.6 Cu 0.6 P 1 Al 4 .

[0077] The concrete preparation method of this iron-based nanocrystalline alloy is as follows:

[0078] (1) Fe, Si, FeB, FeP, FeNb, Cu and Al of industrial purity are used as raw materials according to Fe 71.8 Si 12 B 8 Nb 2.6 Cu 0.6 P 1 Al 4 A quenched amorphous strip with a width of about 1 mm and a thickness of about 23 μm was prepared by batching, master alloy smelting, and single-roll quenching technology, and the copper roll speed was 30 m / s.

[0079] (2) The crystallization temperature of the quenched amorphous strip was measured by DSC at a heating rate of 0.67K / s. Such as figure 1 As shown, the T of the quenched amorphous strip x1 770K, T x2 is 966K, and the heat treatment temperature window ΔT is 196K.

[0080] (3) to Fe 71.8 Si 12 B 8 Nb 2.6 Cu 0.6 P 1 al 4 The alloy is heat treated for nanoc...

Embodiment 3

[0089] In the present embodiment, the molecule of iron-based nanocrystalline soft magnetic alloy material is Fe 73.8 Si 12 B 8 Nb 2.6 Cu 0.6 P 1 al 2 .

[0090] The concrete preparation method of this iron-based nanocrystalline alloy is as follows:

[0091] (1) Fe, Si, FeB, FeP, FeNb, Cu and Al of industrial purity are used as raw materials according to Fe 73.8 Si 12 B 8 Nb 2.6 Cu 0.6 P 1 al 2 A quenched amorphous strip with a width of about 1 mm and a thickness of about 23 μm was prepared by batching, master alloy smelting, and single-roll quenching technology, and the copper roll speed was 30 m / s.

[0092] (2) The crystallization temperature of the rapidly quenched amorphous strip was measured by DSC at a heating rate of 0.67K / s. Such as figure 1 As shown, the T of the rapidly quenched amorphous strip x1 for 771K, T x2 is 957K, so the heat treatment temperature window ΔT is 186K.

[0093] (3) to Fe 73.8 Si 12 B 8 Nb 2.6 Cu 0.6 P 1 al 2 The alloy is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com