Method for combined welding of austenitic stainless steel moderate thickness plate

A technology of austenitic stainless steel and welding method, used in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problem of inability to guarantee the back side of the weld, unstable quality of welded joints, and difficulty in achieving stainless steel penetration, etc. problems, to prevent heat accumulation, no cracks and undercut defects, and the process is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 304 austenitic stainless steel plate 2 with a thickness of 10mm, the test plate size is 180mm×160mm×12mm, its chemical composition is C 0.06%, Si 0.40%, Mn 1.62%, P 0.026%, S 0.012%, Ni 8.14%, Cr 18.03%, Fe balance.

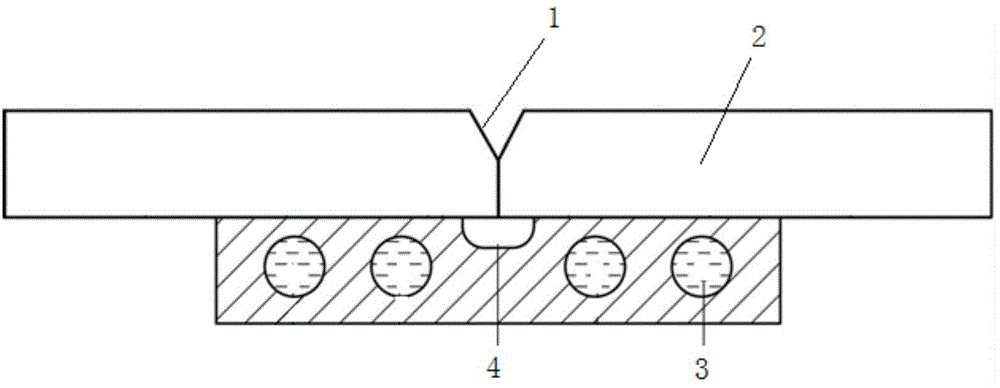

[0038] (1) Preparation before welding

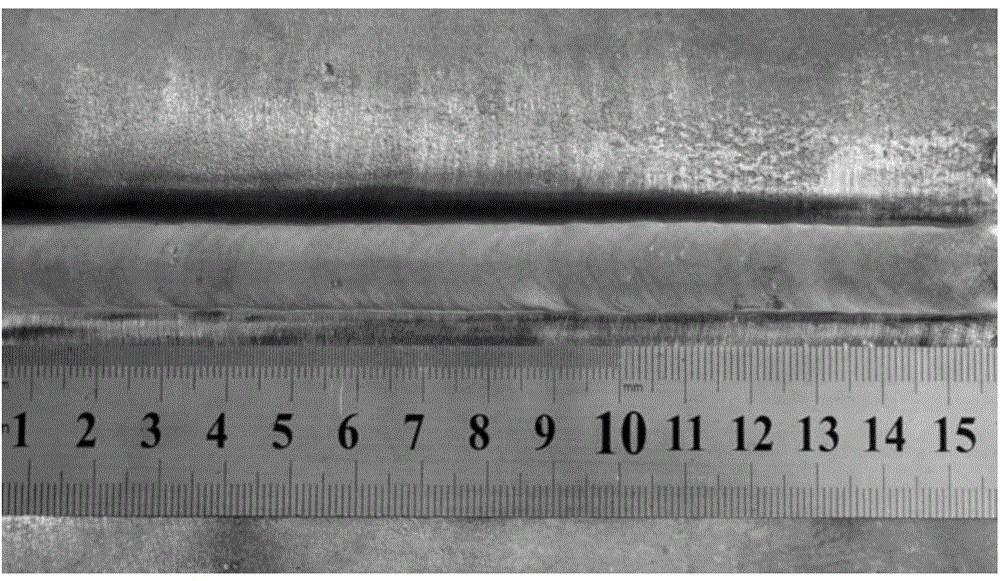

[0039] like figure 1As shown, the butt joint of the test plate to be welded is machined with a V-shaped groove 1, the angle of the V-shaped groove 1 is 60°, each side is 30°, and the blunt edge is 7mm. Use an electric angle grinder to grind the surface of the workpiece to be welded and the groove to remove burrs, oil stains and scales, and clean the groove and the surface of the workpiece with acetone and absolute ethanol in turn. Use fixtures to tightly assemble and fix the workpiece without gaps, and use manual tungsten argon arc welding to fix the arc starting plate, arc extinguishing plate and spot welding between the test plates. German IDA Hi-Tech EWM-422 pulse plasma arc welding machine and WSM-400 inverter...

Embodiment 2

[0047] A 304L strain-strengthened austenitic stainless steel plate with a thickness of 12mm, its chemical composition is C 0.03%, Si 0.50%, Mn 1.60%, P 0.024%, S 0.014%, Ni 11.00%, Cr 19.80%, Fe balance, try The plate size is 160mm x 130mm x 12mm. The EWM-422 pulse plasma arc welding machine and WSM-400 inverter pulse argon arc welding machine are selected from Germany.

[0048] (1) Preparation before welding

[0049] Use a lathe to process a V-shaped groove at the butt joint of the test plate to be welded. The groove angle is 60°, each side is 30°, and the blunt edge is 8mm. Use an electric angle grinder to grind the surface of the workpiece to be welded and the groove to remove burrs, oil stains and scales, and clean the groove and the surface of the workpiece with acetone and absolute ethanol in turn. Use fixtures to tightly assemble and fix the workpiece without gaps, and use manual tungsten argon arc welding to fix the arc starting plate, arc extinguishing plate and spo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com