Low melting temperature silver braze alloy

a technology of braze alloy and low melting temperature, which is applied in the direction of manufacturing tools, electrochemical generators, and solventing apparatus, to achieve the effect of being below the melting point of silver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

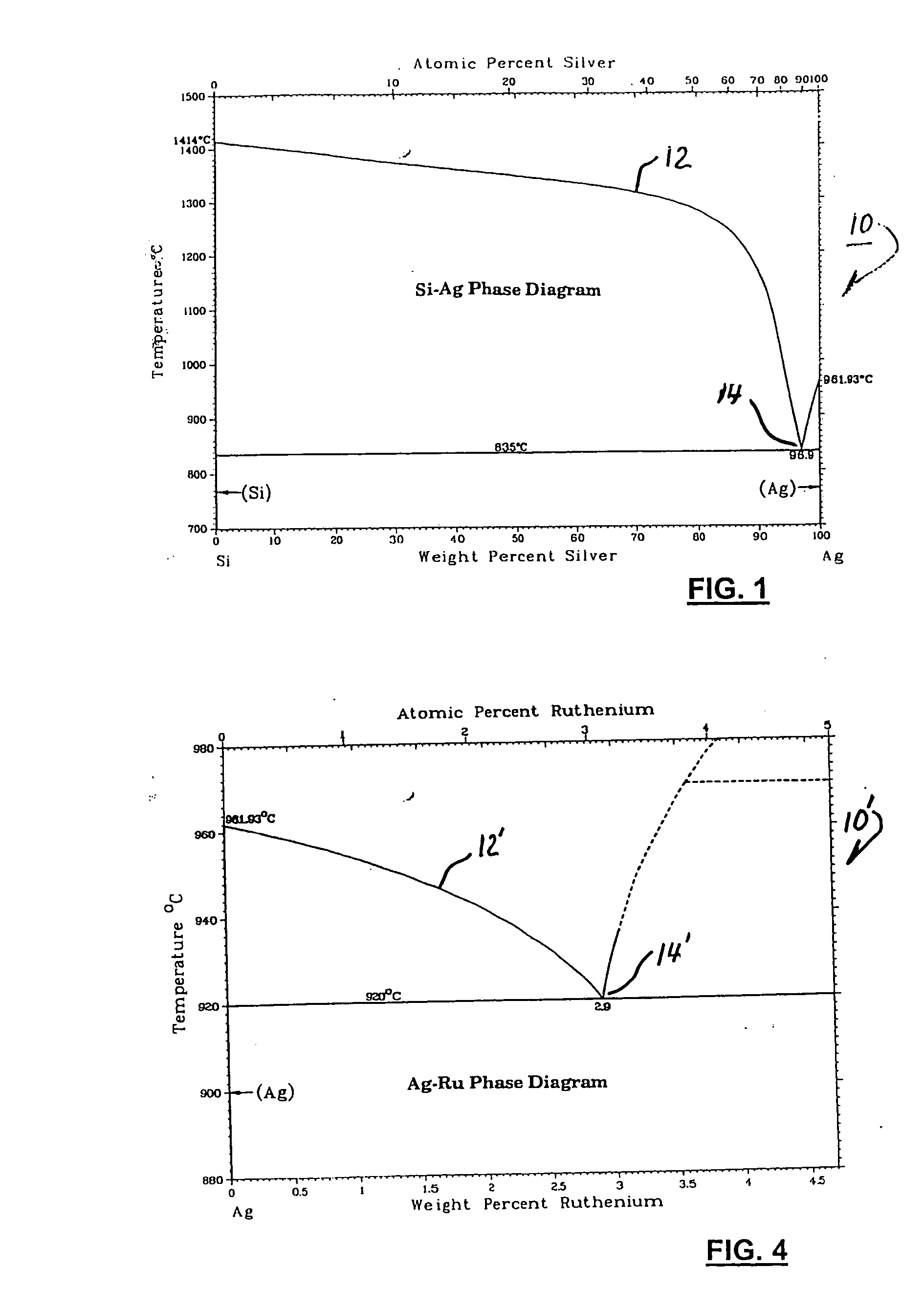

[0014] Referring to FIG. 1, a phase diagram 10 for silver and silicon alloy mixtures is conventionally displayed, having temperature on the vertical axis as a function of weight percent silicon on the horizontal axis. The solidus / liquidus curve 12 for alloys of silver and silicon extends from pure silver (MP of about 962° C.) to pure silicon (MP 1414° C.). Addition of relatively small amounts of silicon to pure silver serves to depress the alloy liquidus temperature significantly; a eutectic point 14 of about 835° C. exists at a silver / silicon ratio of about 97 / 3. Useful liquidus temperature depressions below the 962° C. melting temperature of silver exist up to about 5% silicon.

[0015] Referring to FIG. 4, a phase diagram 10′ for silver and ruthenium alloy mixtures of a second embodiment, including solidus / liquidus curve 12′ and eutectic point 14′, is shown. In a silver / ruthenium ratio between about 96 / 4 and 99 / 1, preferably about 97 / 3, a liquidus temperature of about 920° C. is ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com