Method for producing nickel-plated carbon fiber board having electromagnetic shielding property

A nickel-plated carbon fiber and electromagnetic shielding technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of poor electromagnetic shielding efficiency, heavy plate quality, and poor corrosion resistance, and achieve improved corrosion resistance, light weight, and durability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

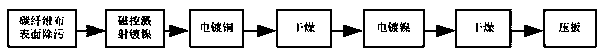

[0038] The following steps are used to make nickel-plated carbon fiber cloth with electromagnetic shielding performance:

[0039] Step 1. Decontamination on the surface of carbon fiber cloth: The pollutants and active agents adsorbed on the surface of carbon fiber cloth are removed by ion bombardment. The travel speed of carbon fiber cloth in the decontamination equipment is 90m / h, and the active agent on the surface of carbon fiber cloth is vaporized , according to the amount of vaporized gas to control the degree of treatment of the dirt on the surface of the carbon fiber cloth, the carbon fiber cloth is T300-3K twill carbon fiber cloth.

[0040]Step 2. Magnetron sputtering nickel plating on the surface of carbon fiber cloth: use magnetron sputtering technology to vacuum nickel-plate the surface of carbon fiber cloth after step 1, and evenly spray nickel ions in the form of nanoparticles to the surface of carbon fiber cloth , form a nickel-plated carbon fiber cloth, and the ...

Embodiment 2

[0046] The following steps are used to make nickel-plated carbon fiber cloth with electromagnetic shielding performance:

[0047] Step 1. Decontamination on the surface of carbon fiber cloth: the pollutants and active agents adsorbed on the surface of carbon fiber cloth are removed by ion bombardment. The travel speed of carbon fiber cloth in the decontamination equipment is 100m / h, and the active agent on the surface of carbon fiber cloth is vaporized , according to the amount of vaporized gas to control the degree of treatment of the dirt on the surface of the carbon fiber cloth, the carbon fiber cloth is T300-3K twill carbon fiber cloth.

[0048] Step 2. Magnetron sputtering nickel plating on the surface of carbon fiber cloth: use magnetron sputtering technology to vacuum nickel-plate the surface of carbon fiber cloth after step 1, and evenly spray nickel ions in the form of nanoparticles to the surface of carbon fiber cloth , form a nickel-plated carbon fiber cloth, and th...

Embodiment 3

[0064] Such as figure 1 As shown, compared with Example 1, the secondary nickel-plated carbon fiber cloth treated in step five is pressed with resin to form a nickel-plated carbon fiber plate with electromagnetic shielding performance, and the resin layer covers the entire surface of the secondary nickel-plated carbon fiber cloth. Other steps are the same as in Example 1 to make a nickel-plated carbon fiber plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com