Graphene-doping conductive polymer modified metal bipolar plate of proton exchange membrane fuel cell and preparation method of metal bipolar plate

A conductive polymer and proton exchange membrane technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve the problems of large volume and weight, shortened battery life, poor thermal conductivity, etc., and achieve simple preparation process and extended The effect of long service life and high bonding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

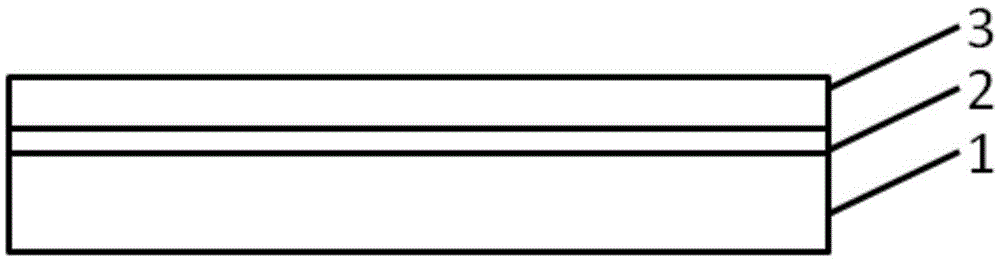

[0040] A metal bipolar plate of a proton exchange membrane fuel cell modified by a graphene-doped conductive polymer of the present embodiment, the bipolar plate is composed of a 316L stainless steel plate 1, a polar oxide film layer 2, a conductive polyaniline / graphene film layer 3 composition, as attached figure 1 As shown, the polar oxide film layer 2 covers the surface of the stainless steel plate 1, the conductive polyaniline / graphene film layer 3 covers the surface of the polar oxide film layer 2, and the conductive polyaniline / graphene film layer 3 The thickness of the polar oxide film layer is about 0.03mm, the thickness of the polar oxide film layer is about 10nm, and the thickness of the stainless steel plate 1 is 0.3mm.

[0041] The preparation method of the metal bipolar plate of the proton exchange membrane fuel cell modified by graphene-doped polyaniline described above in this embodiment is as follows:

[0042] (1) Preparation of electrolyte: disperse conductiv...

Embodiment 2

[0046] A metal bipolar plate of a proton exchange membrane fuel cell modified by a graphene-doped conductive polymer of the present embodiment, the bipolar plate is composed of a 316L stainless steel plate 1, a polar oxide film layer 2, a conductive polyaniline / graphene film layer 3, the polar oxide film layer covers the surface of the metal plate, the graphene-doped conductive polymer film layer covers the surface of the polar oxide film layer, the conductive polyaniline / graphene film layer 3 The thickness is about 0.035mm, the thickness of the polar oxide film layer is about 10nm, and the thickness of the stainless steel plate 1 is 0.3mm.

[0047] (1) Preparation of electrolyte: disperse conductive polymer monomer, carboxylated graphene and inorganic acid in deionized water, then disperse ultrasonically for 30 minutes while stirring, to obtain electrolyte, leave it for later use, in the electrolyte h 2 SO 4 The concentration is 0.5mol L -1 , the concentration of aniline m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com