Method for synthesizing nanometer Ni2O3/Co3O4 cathode material on copper sheet current collector through two-step method

A technology of negative electrode material and current collector, applied in the field of synthesizing nanometer Ni2O3/Co3O4 negative electrode material, can solve the problems of poor cycle stability, affecting wide application, etc., and achieve the effect of improving mechanical strength, not easy to fall off, and improving the degree of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

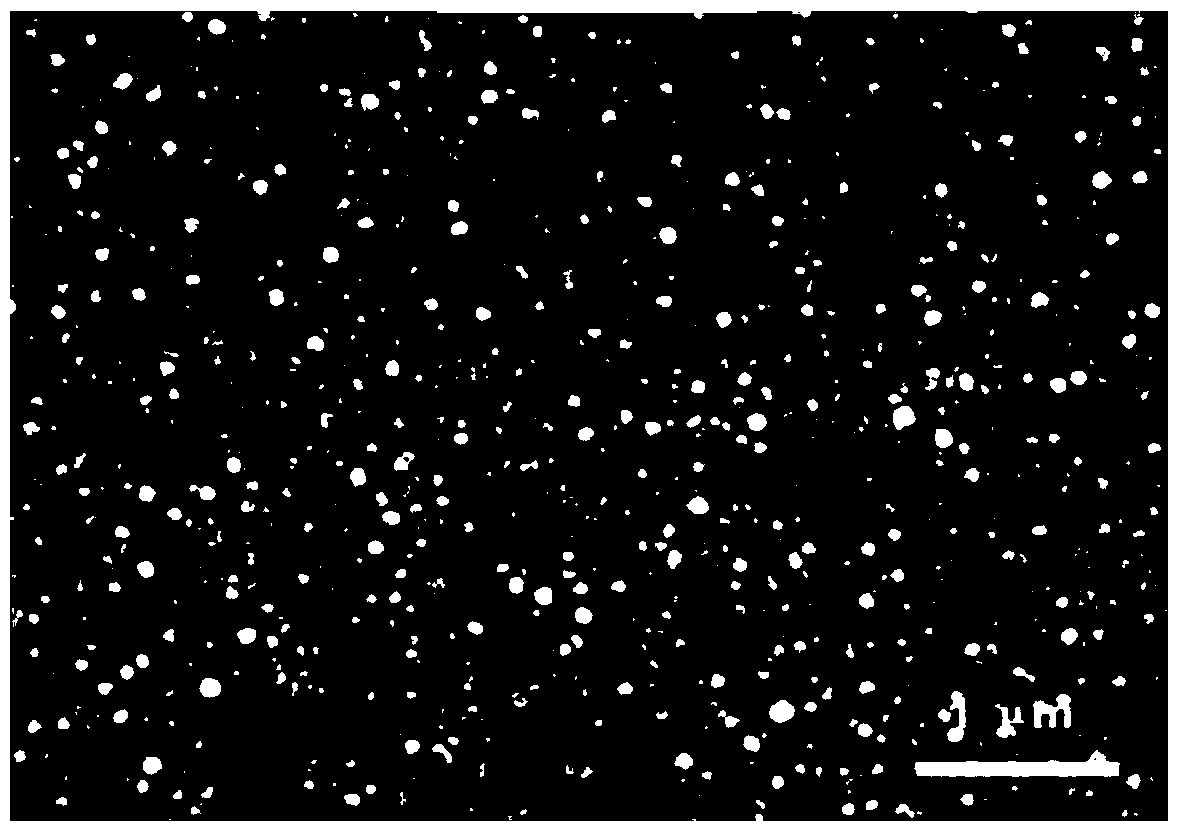

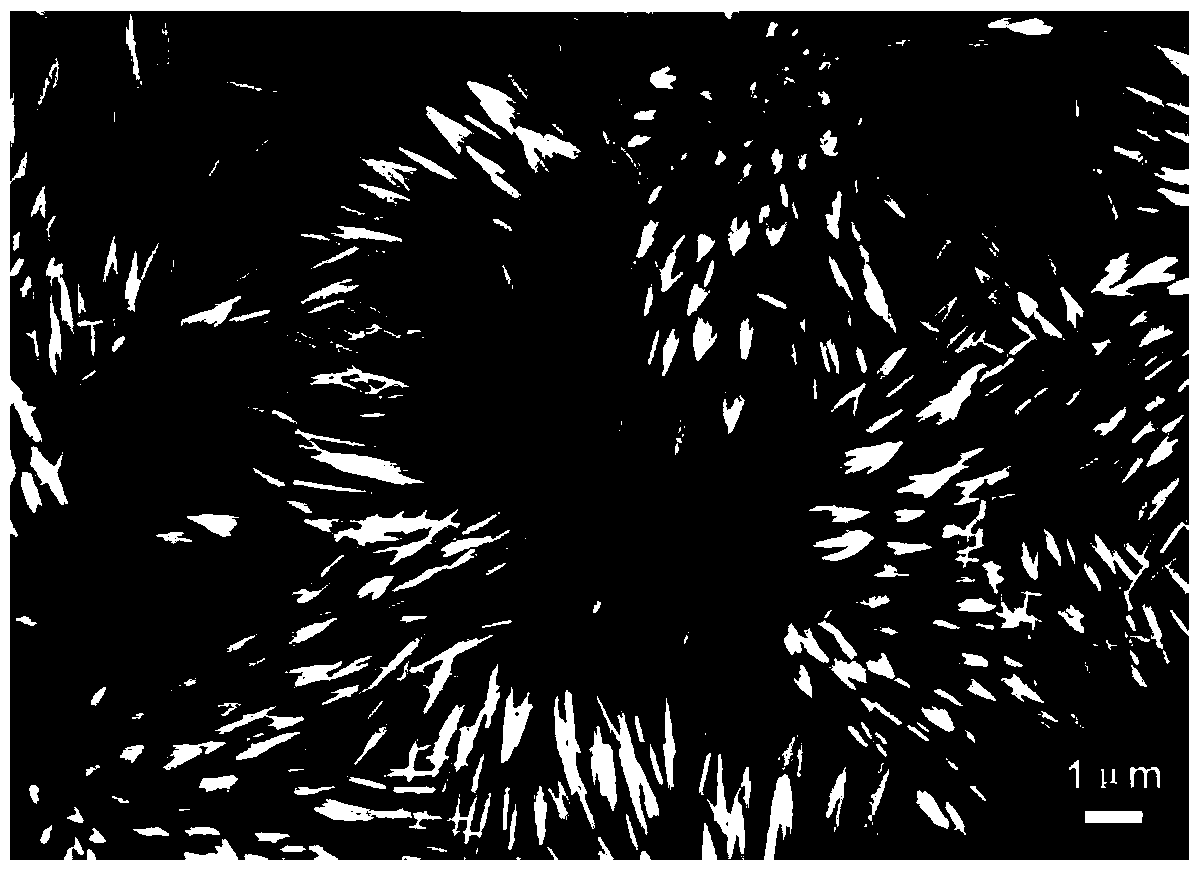

Embodiment 1

[0029] Cut the polished pure copper sheet into a size of 1×3cm, and pretreat it under mixed acid (concentrated sulfuric acid, nitric acid, hydrochloric acid) for one minute. 250g / L nickel sulfate, 30g / L nickel chloride, 35g / L boric acid, 0.1g / L sodium lauryl sulfate are mixed and dissolved in distilled water as an electroplating solution. The magnetic stirring speed is 700r / min and the temperature is 45°C Under the constant current method, double electrodes are used for electroplating, and the current density is 0.75A / dm 3Next, the electroplating time is 10s, the treated copper sheet is used as the working electrode, and the pure nickel sheet is used as the counter electrode. After electroplating, it is washed several times and dried by nitrogen gas. Then dissolve 1.46g of cobalt nitrate, 0.37g of ammonium fluoride and 1.5g of urea in 50mL of distilled water, stir slowly for about 30 minutes, then transfer 35ml of the solution to the inner lining of the autoclave, and place th...

Embodiment 2

[0031] Cut the polished pure copper sheet into a size of 1×3cm, and pretreat it under mixed acid (concentrated sulfuric acid, nitric acid, hydrochloric acid) for one minute. 250g / L nickel sulfate, 30g / L nickel chloride, 35g / L boric acid, 0.1g / L sodium lauryl sulfate are mixed and dissolved in distilled water as an electroplating solution. The magnetic stirring speed is 700r / min and the temperature is 45°C Under the constant current method, double electrodes are used for electroplating, and the current density is 0.75A / dm 3 Next, the electroplating time is 10s, the treated copper sheet is used as the working electrode, and the pure nickel sheet is used as the counter electrode. After electroplating, it is washed several times and dried by nitrogen gas. Then dissolve 1.46g of cobalt nitrate, 0.37g of ammonium fluoride and 1.5g of urea in 50mL of distilled water, stir slowly for about 30 minutes, then transfer 35ml of the solution to the inner lining of the autoclave, and place t...

Embodiment 3

[0033] Cut the polished pure copper sheet into a size of 1×3cm, and pretreat it under mixed acid (concentrated sulfuric acid, nitric acid, hydrochloric acid) for one minute. 250g / L nickel sulfate, 30g / L nickel chloride, 35g / L boric acid, 0.1g / L sodium lauryl sulfate are mixed and dissolved in distilled water as an electroplating solution. The magnetic stirring speed is 700r / min and the temperature is 45°C Under the constant current method, double electrodes are used for electroplating, and the current density is 0.75A / dm 3 Next, the electroplating time is 10s, the treated copper sheet is used as the working electrode, and the pure nickel sheet is used as the counter electrode. After electroplating, it is washed several times and dried by nitrogen gas. Then dissolve 1.46g of cobalt nitrate, 0.37g of ammonium fluoride and 0.15g of urea in 50mL of distilled water, stir slowly for about 30 minutes, then transfer 35ml of the solution to the inner lining of the autoclave, and place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com