Electric deposition preparation method of Ni-Co-B alloy substituted hard chromium plating

A 1. ni-co-b, electrodeposition technology, applied in the field of preparation of Ni-Co-B alloy instead of hard chromium coating, can solve the problems of trivalent chromium coating such as poor gloss, unreachable hardness, low concentration, etc. Achieve the effect of good appearance, high hardness, good corrosion resistance and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

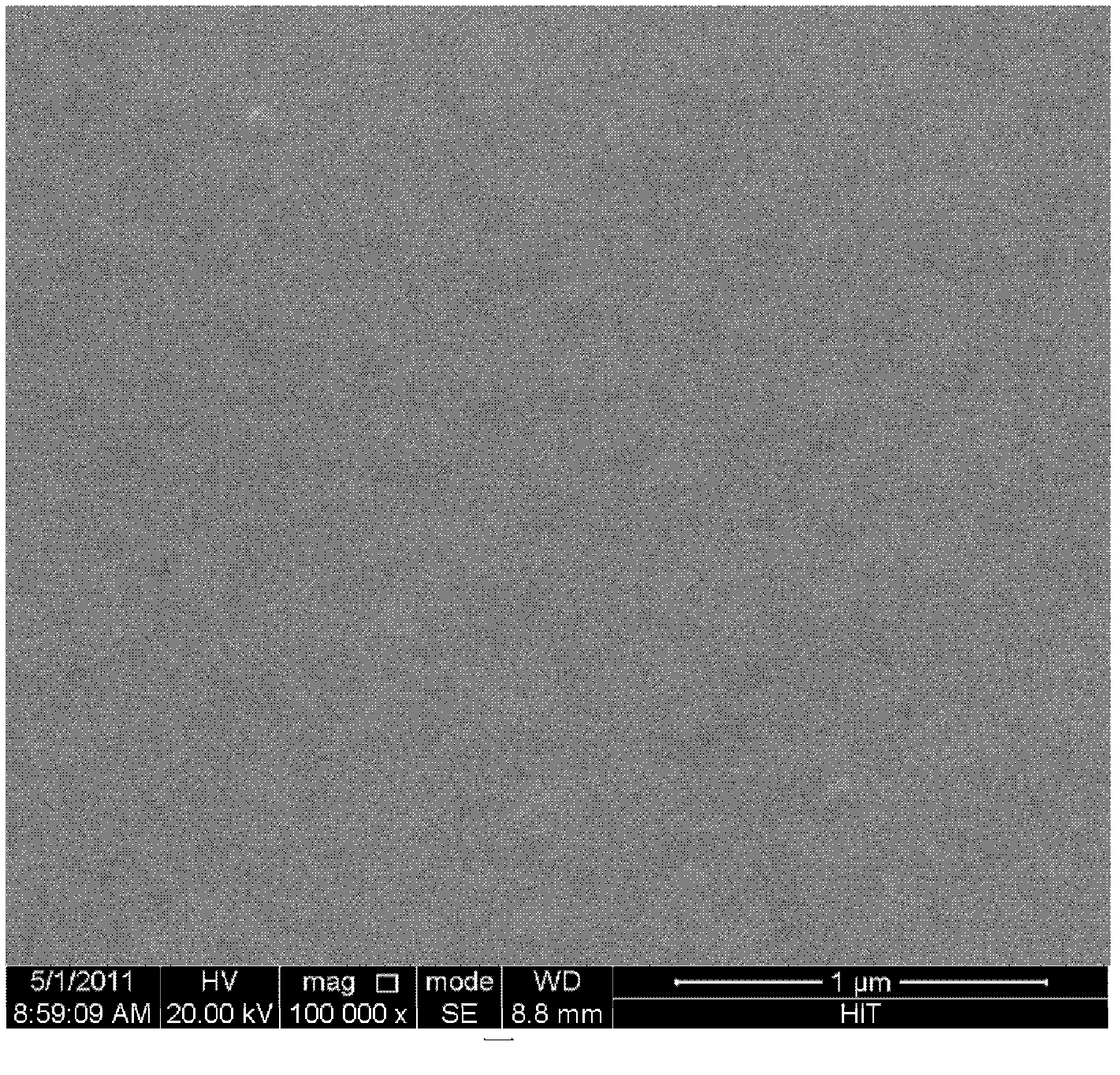

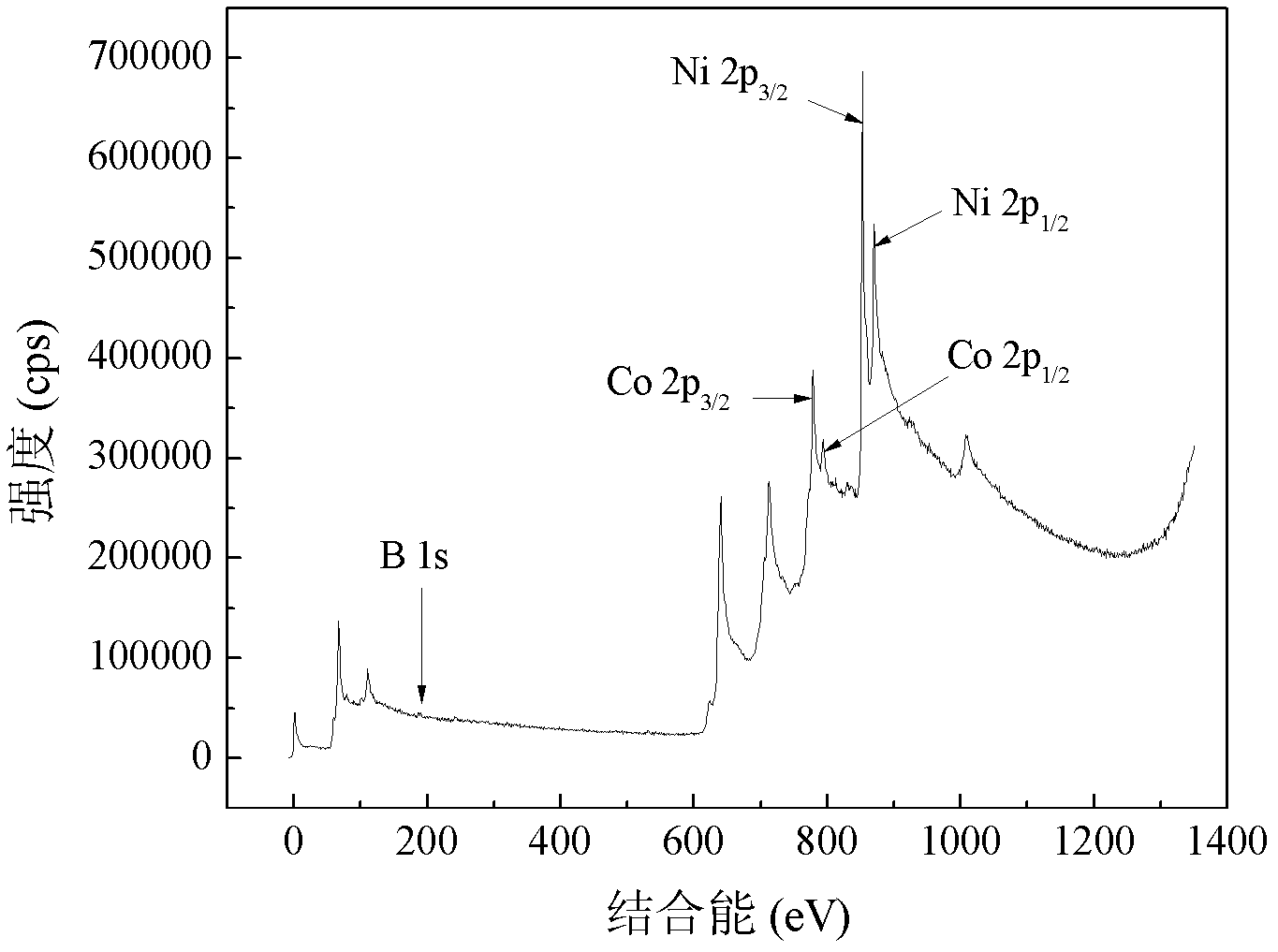

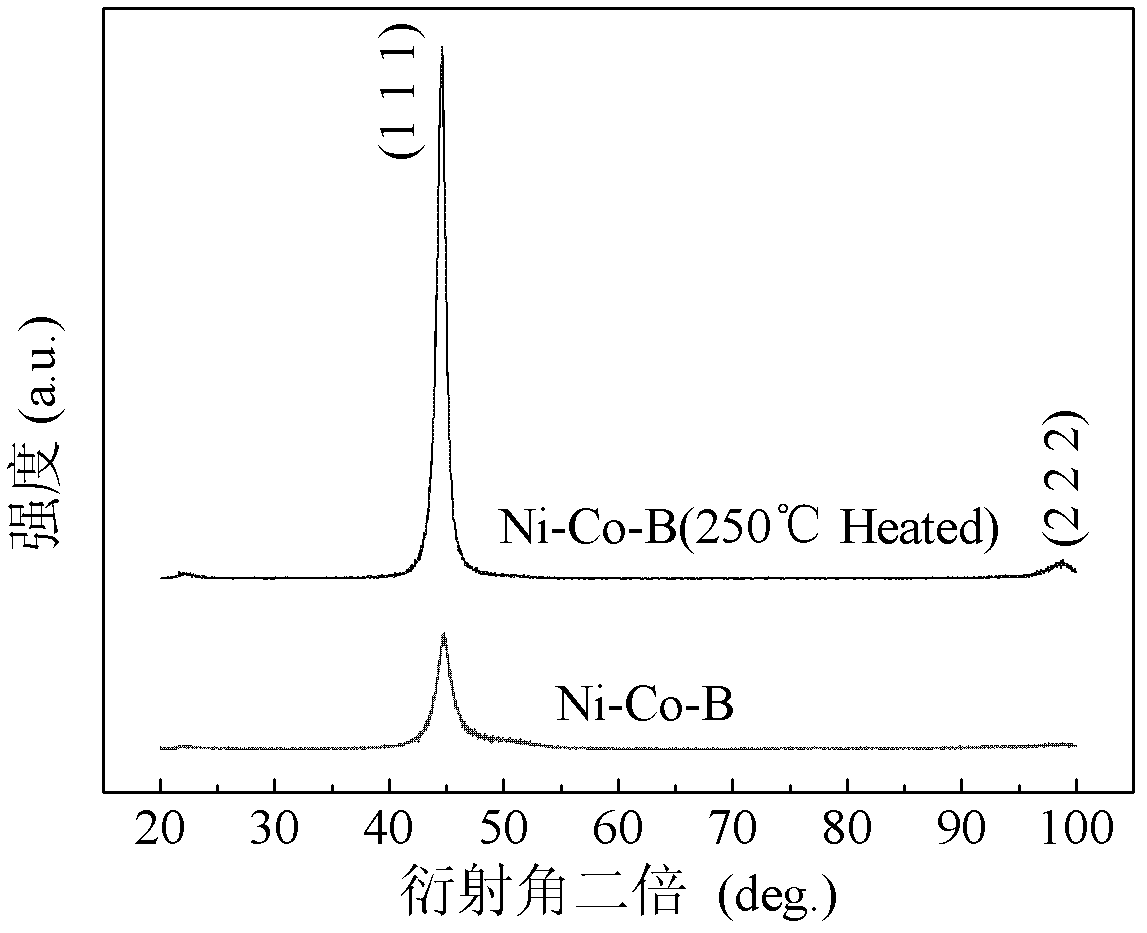

[0014] Specific embodiment one: the electrodeposition preparation method of the Ni-Co-B alloy substitution hard chromium coating of this embodiment is carried out according to the following steps: 1. Weigh 60-240g of nickel salt, 6-24g of cobalt salt, 15-40g of Nickel chloride, 20-50g boric acid, 1-10g amine boron compound, 1-10ml NI3 # Quick and high-level nickel plating gloss agent A and 0.01-0.1g of sodium lauryl sulfate; 2. Dissolve the weighed boric acid in 200-600ml of water at 50-70°C, and then add nickel in turn Salt, cobalt salt, nickel chloride and amine boron compound and stir until dissolved, then add sodium lauryl sulfate and N13 # Fast and high-level nickel plating gloss agent A, then use NaOH solution or dilute H 2 SO 4 solution to adjust the pH value of the solution to 2.0-5.5, add water to make the volume to 1L, and obtain the Ni-Co-B alloy plating solution; 3. The plated parts are washed with water after conventional alkaline degreasing or electrochemical d...

Embodiment 1

[0018] The electrodeposition preparation method of Ni-Co-B alloy substitutes hard chrome coating is carried out as follows: one, take by weighing the nickel salt of 60g, the cobalt salt of 9g, the nickel chloride of 15g, the boric acid of 40g, the amine boron compound of 6g, 3ml of NI3 # Quick and high-level nickel plating gloss agent A and 0.01g of sodium lauryl sulfate; 2. Dissolve the weighed boric acid in 500ml of water at 50°C, and then add nickel salt, cobalt salt, and chlorine in sequence Nickel and amine boron compound were stirred until dissolved, then sodium lauryl sulfate and N13 were added # Fast and high-level nickel plating gloss agent A, then use NaOH solution or dilute H 2 SO 4 The solution adjusts the pH value of the solution to 4.0, and then adds water to make the volume to 1L to obtain the Ni-Co-B alloy plating solution; three, the plated parts are washed with water after conventional alkaline degreasing or electrochemical degreasing, and then placed in a ...

Embodiment 2

[0022] The electrodeposition preparation method of Ni-Co-B alloy substitutes hard chrome coating is carried out as follows: one, take by weighing the nickel salt of 240g, the cobalt salt of 18g, the nickel chloride of 35g, the boric acid of 30g, the amine boron compound of 9g, 7ml of NI3 # Quick and high-level nickel plating gloss agent A and 0.05g of sodium lauryl sulfate; 2. Dissolve the weighed boric acid in 400ml of water at 50°C, and then add nickel salt, cobalt salt, and chlorine in sequence Nickel and amine boron compound were stirred until dissolved, then sodium lauryl sulfate and N13 were added # Fast and high-level nickel plating gloss agent A, then use NaOH solution or dilute H 2 SO 4 The solution adjusts the pH value of the solution to 3.0, and then adds water to make the volume to 1L to obtain the Ni-Co-B alloy plating solution; 3. The plated parts are washed with water after conventional alkaline degreasing or electrochemical degreasing, and then placed in a vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com