Electric spark processing method for sealing grooves of aero engine guide vane

A technology for aero-engines and guide vanes, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of difficulty in ensuring the position of sealing grooves, fluctuations in electrode positions, and affecting processing accuracy, so as to ensure processing accuracy and position The effect of reducing the frequency of electrode replacement and improving the processing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

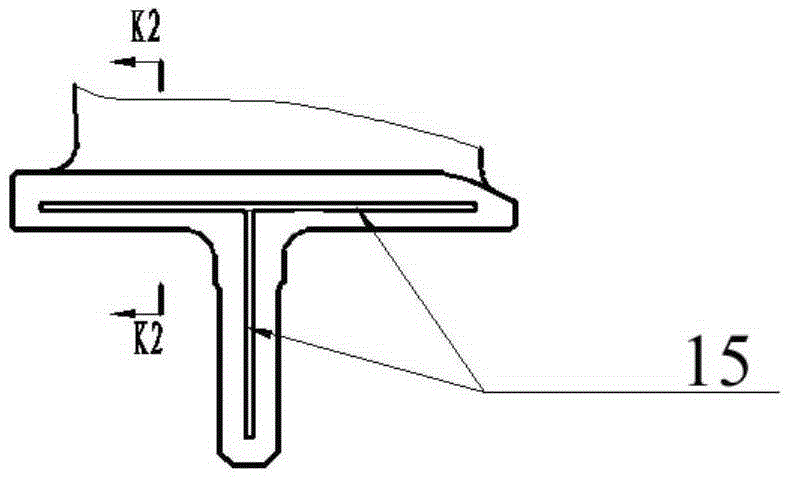

[0033] In this embodiment, adopt the method described in the present invention to process such as figure 1 The radial surface 10 of the large edge plate basin and the radial surface 11 of the small edge plate basin of the shown aeroengine power turbine multi-connected guide vane, the four sides on the back radial surface 12 of the large edge plate and the back radial surface 13 of the small edge plate A sealing groove, wherein, the structural schematic diagram of the sealing groove 14 on the radial surface and the back radial surface of the large edge plate basin of the multi-connected guide vane is as follows figure 2 As shown, the structural schematic diagram of the sealing groove 15 on the radial surface and back radial surface of the small edge plate basin of the multi-connected guide vane is as follows image 3 as shown, Figure 4 yes figure 2 The K1-K1 view and image 3 The view of K2-K2, the multi-connected guide vanes are made of superalloy K438, the processing re...

Embodiment 2

[0040] In this embodiment, adopt the method described in the present invention to process such as figure 1 The radial surface 10 of the large edge plate basin and the radial surface 11 of the small edge plate basin of the shown aeroengine power turbine multi-connected guide vane, the four sides on the back radial surface 12 of the large edge plate and the back radial surface 13 of the small edge plate A sealing groove, wherein, the structural schematic diagram of the sealing groove 14 on the radial surface and the back radial surface of the large edge plate basin of the multi-connected guide vane is as follows figure 2 As shown, the structural schematic diagram of the sealing groove 15 on the radial surface and back radial surface of the small edge plate basin of the multi-connected guide vane is as follows image 3 as shown, Figure 4 yes figure 2 The K1-K1 view and image 3 The view of K2-K2, the multi-connected guide vanes are made of superalloy K438, the processing re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com