Profiled high conductivity copper-tungsten electrical contact material and processing technique thereof

An electrical contact material, copper-tungsten alloy technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of reducing the connection strength of the weld, reducing the strength and elasticity of the copper, and the interface cannot be welded, so as to solve the problem of forming Difficulty, Elimination of Dispersibility, Conductivity and Improvement of Current Intermittent Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

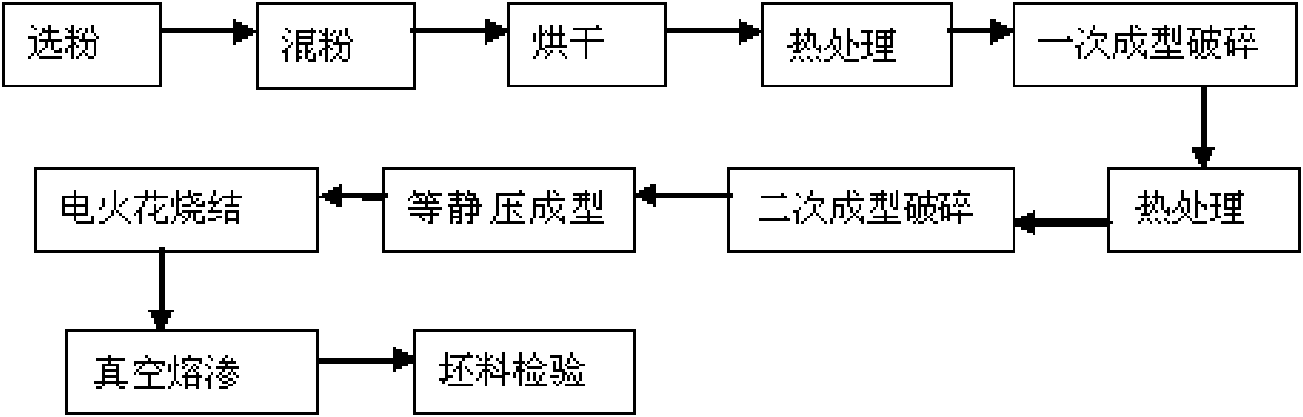

[0022] From figure 1 It can be seen from the figure that the processing process of special-shaped high-conductivity copper-tungsten alloy electrical contact materials is as follows:

[0023] First pass the copper powder through a 400-mesh sieve, select 3--6μm tungsten powder and mix it in a ratio of 0.3-0.8:99.7-99.2 by weight

[0024] Heat-treat the mixed raw material powder at a temperature of 580--620°C for 2--4 hours, at a temperature of 4.5--8.5 tons / cm 2 The pressure molding, crushing; then heat treatment at 620--670 ℃ for 2--4 hours, at 6--8.5 tons / cm 2 The pressure molding, crushing; the third heat treatment at a temperature of 670--700 ℃ for 2--4 hours, at 6--8.5 tons / cm 2 The pressure molding, crushing; finally isostatic pressing into the required shape, and then electric spark sintering into a copper-tungsten alloy billet.

[0025] The prepared pure copper and the sintered billet are vacuum infiltrated to make the copper content reach 8--17%, and various shapes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com