Tungsten carbide welding rod and welding wire

A technology of tungsten carbide and tungsten carbide powder, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of damaging the bonding strength of tungsten carbide and the base metal to be surfacing, and unfavorable wear resistance of the wear-resistant layer , tungsten carbide wear-resistant particles melting loss and other problems, to achieve significant economic and social benefits, convenient operation, and reduce the effect of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

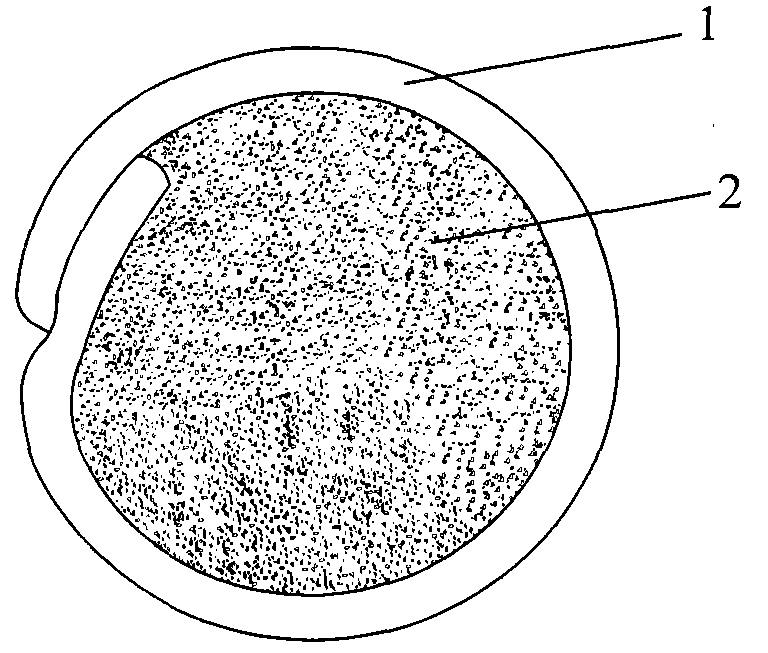

[0034] The skin is made of narrow-band zinc white copper (national standard brand BZn15-20, the content of Ni+Co varies between 13.5-16.5%, the content of Cu is 62-65%, the rest is mainly Zn, and the impurity content is below 0.9%) , through processing to form a tube with a diameter of 6 mm, wherein the outer skin accounts for 39% of the total weight of the electrode, and cast tungsten carbide powder (made by Beijing Dewang Machinery Electric Co., Ltd., WC-W2C, 20-30 mesh) accounts for 61% of the total weight . The product of this embodiment is subjected to an abrasive wear test, and the abrasive wear test is carried out with a dry-type rubber wheel wear tester manufactured according to the ASTM-G6-91 standard. The size after surfacing is 25mm×40mm×3mm. The test load is 13N, the abrasive is No. 120 brown corundum sand, the speed of the rubber wheel is 50r / min, the sand flow rate is 100g / min, and the wear time is 15min. The wear of the coating is expressed by weight loss, and ...

Embodiment 2

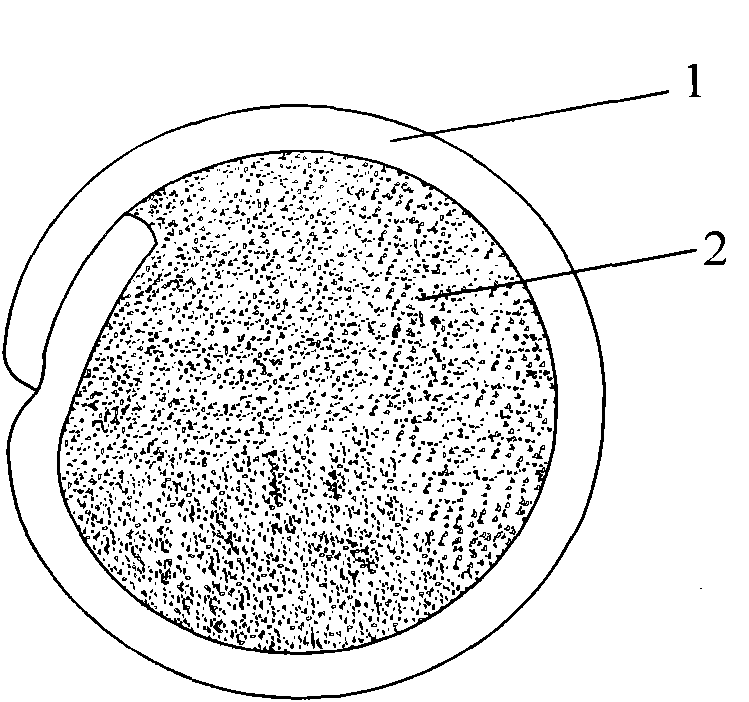

[0036] Red copper (national standard grade T2) is used as the outer skin, and 60% of the total weight is wrapped with cast tungsten carbide powder (manufactured by Beijing Dewang Machinery Electric Co., Ltd., WC-W2C, 48-65 mesh), and 5% Ni is also added. , 2% of Co, 1% of P, 1% of Si, 0.3% of Sn, 0.5% of Fe, 0.3% of Al and 0.5% of Mn alloy element powder, and then rolled, and finally drawn with a diameter of 2.8 mm filamentous. Using the same method as in Example 1, this example was subjected to an abrasive wear test. As a result, the weight loss of the overlay welding layer of the welding wire was 23 mg. The on-site comparison experiment on the roller cone bit also shows obvious advantages, and the operation is very convenient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com