Vacuum tube group for replacing copper-tungsten contact group of on-load tap changer

A technology of on-load tap changer and vacuum bubble, applied in electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problem of prone to power supply accidents, short lifespan of tap changers, transition contacts, main on-off Contact burning and other problems, to achieve the effect of reducing maintenance and material consumption, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

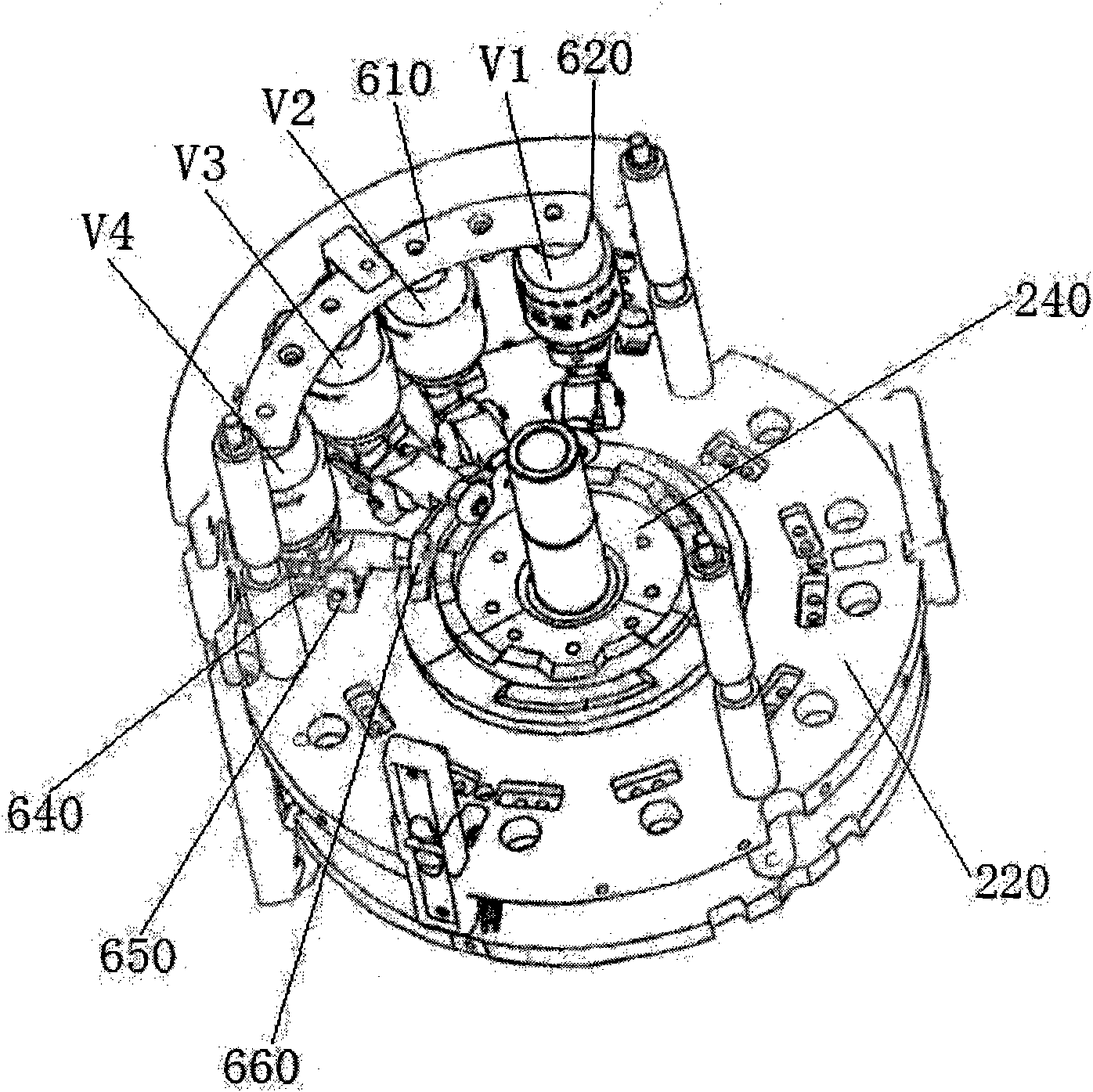

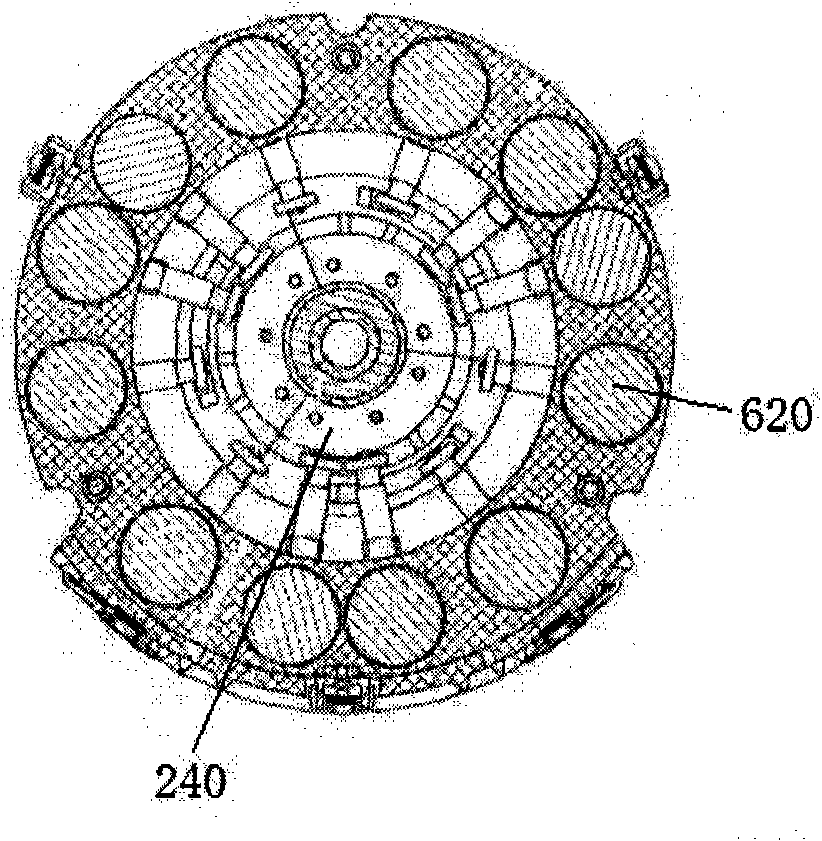

[0022] Such as figure 1 , figure 2 , image 3 As shown, the switching core of the on-load tap-changer of the present invention is divided into three groups of vacuum bubbles by 12 vacuum bubbles, which replace the three-phase copper-tungsten contacts of the existing on-load tap-changer for switching.

[0023] Twelve vacuum bubbles 620 are arranged between the upper and lower splints according to the circumference, and every 4 vacuum bubbles 620 form a group to form a transition switching unit of one-phase vacuum bubbles. The upper ends of the four vacuum bubbles V1, V2, V3, and V4 of each phase of the vacuum bubble transition switching unit are connected by an arc-shaped conductive plate 610 included in the upper splint (not shown in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com