Rapid preparation method of copper-tungsten alloy

A copper-tungsten alloy, fast technology, applied in the field of rapid preparation of copper-tungsten alloy, can solve the problems of low heating rate and energy conversion efficiency, and achieve the effect of fast heating rate, prevention of alloy surface oxidation, and excellent alloy performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

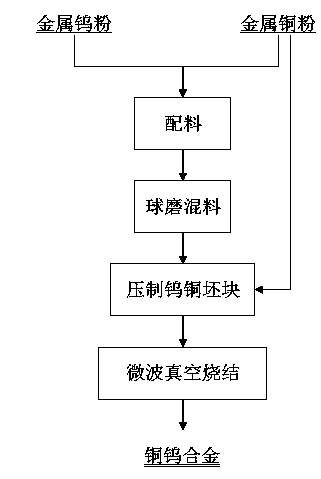

Method used

Image

Examples

Embodiment approach 1

[0021] Embodiment 1: The rapid preparation method of the copper-tungsten alloy of this embodiment is:

[0022] (1) The metal tungsten powder and copper powder were ball milled and mixed according to the mass percentage of 92wt%: 8wt%, and the ball milled

[0023] According to the ball-to-material ratio of 50:1 and the speed of 100r / min, ball milling was carried out for 40 minutes; the particle size of metal tungsten powder and copper powder was 10-20 μm, and the purity was greater than 99.8wt%.

[0024] (2) Press the tungsten powder and copper powder mixed by ball milling in step (1) into a compact, and the pressure is controlled at 30MPa to make a cylindrical tungsten skeleton compact;

[0025] (3) Put the tungsten skeleton block into the mullite crucible, and cover the tungsten skeleton block with copper powder with a thickness of 3mm, and then place it under the conditions of microwave frequency 2400MHz, power 5KW, and vacuum degree 0.08KPa. Maintain a heating rate of 20°C...

Embodiment approach 2

[0026] Embodiment 2: The rapid preparation method of the copper-tungsten alloy of this embodiment is:

[0027] (2) The metal tungsten powder and copper powder are ball milled and mixed according to the mass percentage of 80wt%: 20%.

[0028] According to the ball-to-material ratio of 30:1 and the speed of 200r / min, ball milling was performed for 20 minutes; the particle size of metal tungsten powder and copper powder were both less than 200 mesh, and the purity was greater than 99.8wt%.

[0029] (2) Press the tungsten powder and copper powder mixed by ball milling in step (1) into a compact, and the pressure is controlled at 45MPa to make a tungsten skeleton compact;

[0030] (3) Put the tungsten skeleton block into the mullite crucible, and cover the tungsten skeleton block with copper powder with a thickness of 2mm, and then place it under the conditions of microwave frequency 2500MHz, power 3KW, and vacuum degree less than 0.1KPa , maintain a heating rate of 15°C / min, rais...

Embodiment approach 3

[0031] Embodiment 3: The rapid preparation method of the copper-tungsten alloy of this embodiment is:

[0032] (1) The metal tungsten powder and copper powder are ball milled and mixed according to the mass percentage of 95wt%: 5%, and the ball milled

[0033] According to the ball-to-material ratio of 1:1 and the speed of 300r / min, ball milling was performed for 10 minutes; the particle size of metal tungsten powder and copper powder were both less than 200 mesh, and the purity was greater than 99.8wt%.

[0034] (2) Press the tungsten powder and copper powder mixed by ball milling in step (1) into a compact, and the pressure is controlled at 25MPa to make a tungsten skeleton compact;

[0035] (3) Put the tungsten skeleton block into the mullite crucible, and cover the tungsten skeleton block with copper powder with a thickness of 5mm, and then place it under the conditions of microwave frequency 2450MHz, power 3.5KW, and vacuum degree less than 0.1KPa , maintain a heating ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com