Electrochemical discharge mechanical milling composite machining tool cathode and using method

A tool cathode and compound processing technology, which is applied in the field of electrolytic electric discharge mechanical milling compound processing, can solve the problems of high-efficiency processing of difficult metal materials, poor surface quality, and poor flatness of the bottom surface, etc., to achieve reduced tool wear, good thermal conductivity, Effect of improving flatness and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

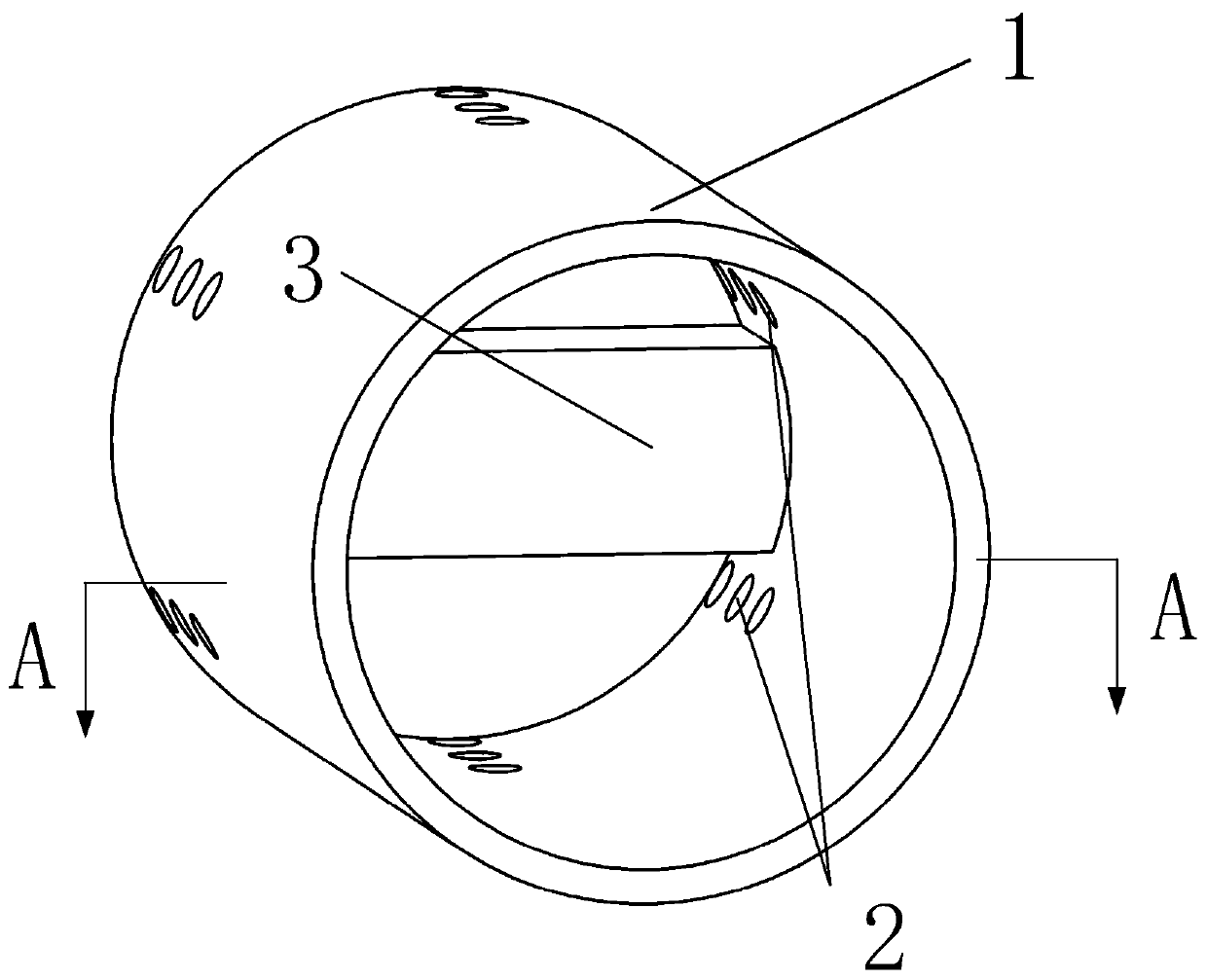

[0023] Such as Figure 1-2As shown, a cathode of an electrochemical discharge mechanical milling composite processing tool is characterized in that: it includes a cathode base 1, the cathode base 1 is a circular electrode, and its center is opened from top to bottom with a blind hole; the side wall at the lower end of the cathode base 1 is arranged Several rows of vertically distributed liquid outlet holes 2; a reinforced boss 3 is arranged on the upper surface of the bottom of the cathode substrate 1 along the diameter direction; the two ends of the reinforced boss 3 are respectively located between the two listed liquid holes 2; A near chute 4 and a far chute 5 are provided below the bottom of the corresponding cathode substrate 1; a first blade 6 is inlaid in the near chute 4, and a second blade 7 is inlaid in the far chute 5; the above two chute shapes are the same , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com