Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Copper high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for preparing tungsten-copper or molybdenum-copper high-voltage contact materials by direct forming

InactiveCN102286740ASimple processPrevent high temperature deformationElectric switchesPressure inorganic powder coatingCopper highHigh pressure

A method for preparing tungsten-copper or molybdenum-copper high-voltage contact materials by direct forming. Firstly, the raw material powder is uniformly mixed according to the composition ratio of the high-voltage contact, and then the mixed raw material powder is input into the powder feeding system of the cold spraying system. Or spraying with heated gas, under the action of high-pressure gas, the raw material powder collides with the copper substrate to undergo plastic deformation, and then deposits on the surface of the copper base to form a high-voltage contact material, and finally the formed tungsten copper or molybdenum copper high-voltage contact material Use directly or after annealing at 1000-1400°C for 30-60 minutes. The invention simplifies the process, overcomes the high-temperature deformation of the copper base, distributes the copper solidified phase finely and uniformly, reduces the equipment cost of cold spraying, improves the safety of the working process, is suitable for online processing, and saves spraying cost.

Owner:SHENYANG GOLDEN HEADPOWER NEW MATERIALS

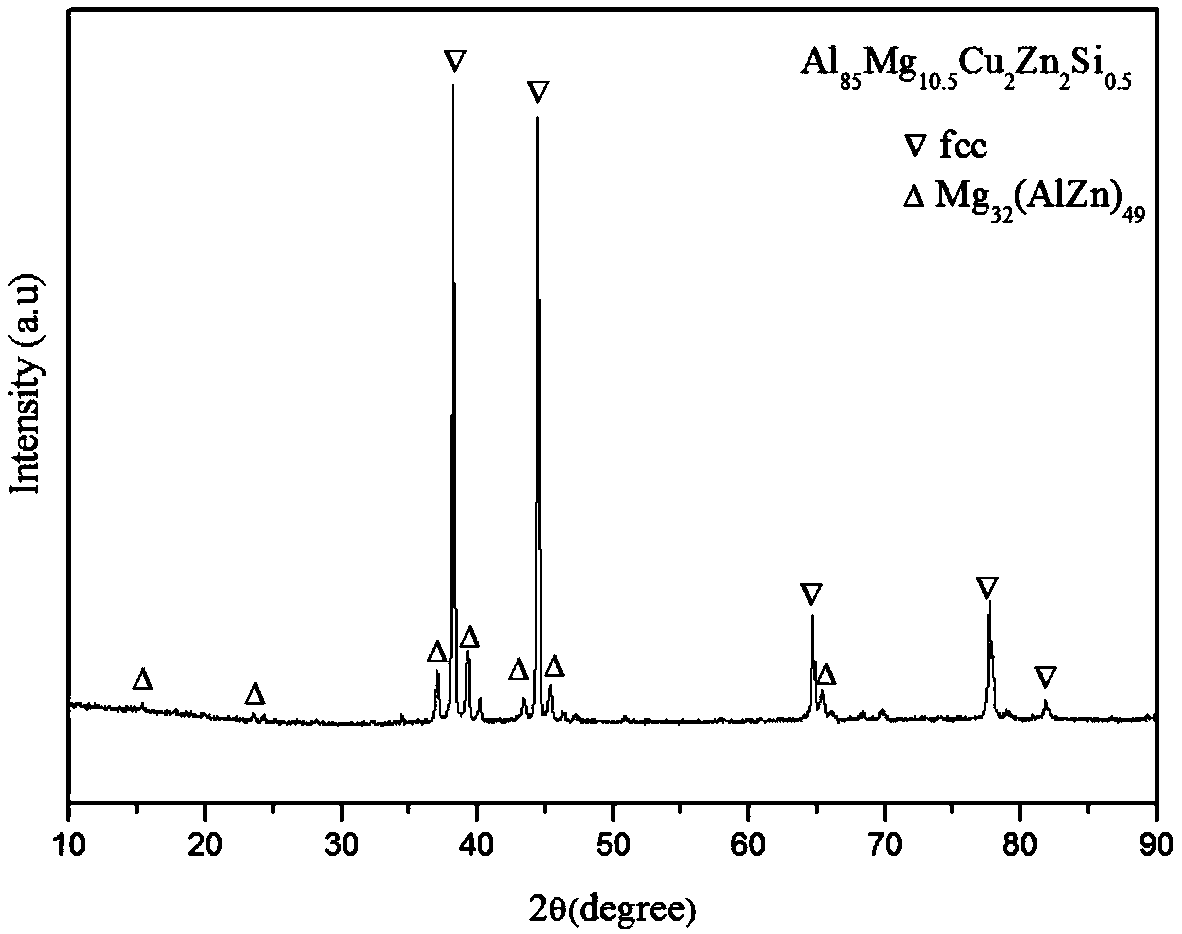

Light-mass and high-strength aluminum magnesium copper high-entropy alloy and preparation method thereof

ActiveCN107675046ANo pollution in the processReduce energy consumptionHigh entropy alloysCopper high

The invention relates to a light-mass and high-strength aluminum magnesium copper high-entropy alloy and a preparation method thereof. A component atom formula of the designed high-entropy alloy is AlxMgyCuzZnvSiw, wherein x+y+z+v+w=100, x=55-90, y=7-35, z=1-5, v=1-5, and w=0.3-1. A phase structure relating to the alloy uses face center cubic (FCC) solid solution as a main material. The inventionfurther provides the preparation method of the AlxMgyCuzZnvSiw high-entropy alloy; an alloy cast ingot is prepared by vacuum inductive smelting and direct casting; no pollution is generated in the preparation process; the energy consumption is low; the cost is low; and the preparation of the light-mass massive high-entropy alloy becomes possible.

Owner:UNIV OF SCI & TECH BEIJING

Method for molding via hole of printed circuit board

ActiveCN101605434AReduce area occupationExcellent electrical performancePrinted element electric connection formationCopper highEngineering

The invention relates to a method for molding a via hole of a printed circuit board, which comprises the steps of: film attachment, in which the surfaces of upper and lower surface copper layers of an insulating dielectric layer drilled with the via hole are attached with photosensitive films, and the positions, which correspond to the via hole, on the photosensitive films are provided with film openings; hole-sealing electroplating, in which an orifice end, which is near a first surface, of the via hole is closed through a copper electroplating process on the first surface of the insulating dielectric layer; hole-filling electroplating, in which the via hole is completely filled with copper, and the filled copper is connected with the surface copper layer of a second surface of the insulating dielectric layer, namely the connection of solid via holes between upper and lower adjacent line layer patterns is realized; and the post-treatment, in which the two surfaces of the insulating dielectric layer are subjected to subsequent treatment respectively, and a level conducting surface which is convenient for implementing subsequent pattern line production working procedures is obtained by removing the photosensitive films, removing the filled copper higher than the surface copper layers, and leveling the board surface. The method has the advantages of simple, convenient and feasible process, low cost, and small area occupation, and upper and lower corresponding line rackets of the hole are integrally preserved, are not damaged by the via hole and have good electrical properties.

Owner:美龙翔微电子科技(深圳)有限公司

Iron-based copper for treating organic sewage and sewage treatment method

InactiveCN102849824AImprove degradation efficiencyIncrease potential differenceWater/sewage treatmentElectrolysisElectrochemical degradation

The invention relates to an iron-based copper high-efficient microelectrolytic material which contains a lot of nonuniform iron-copper microelectrode primary batteries and is formed by coating copper on cast iron granular carrier surfaces in a crystal grain form by a chemical conversion method. When organic sewage flows through a fixed bed reactor formed by the material, the reaction efficiency is controlled by the flow rate. With the material and the fixed bed reaction technology, the problem of low electrochemical degradation efficiency of organic pollutant macromolecules in sewage by common granular iron-carbon microelectrolytic materials and granular iron-copper microelectrolytic materials in current sewage treatment process is solved.

Owner:WUHAN COMEON ENVIRONMENT ENG

Diamond/copper high-thermal conductivity composite material and preparation method thereof

ActiveCN102108458AMeet needsImprove interface binding statePhotography auxillary processesProcess efficiency improvementCopper highThermal expansion

The invention provides a diamond / copper high-thermal conductivity composite material and a preparation method thereof. The composite material comprises a base material copper, and reinforced materials are diamond particles coated with chromium or molybdenum or tungsten or titanium, wherein the volume fraction of the reinforced materials in the composite material is 15-65%. The preparation method of the composite material comprises the following steps: firstly, mixing the diamond particles with pure chromium powder or molybdenum powder or tungsten powder or titanium powder in a mixer; carryingout high-temperature treatment; and then, preparing the high-thermal conductivity composite material by adopting an electroplating process. The invention solves the problem of poor diamond / copper interface combination, and avoids the problems of diamond graphitization and the like at high temperature. The prepared composite material has higher thermal conductivity and lower thermal expansion coefficient, thereby meeting the requirements of high-power integrated circuit packaging materials.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

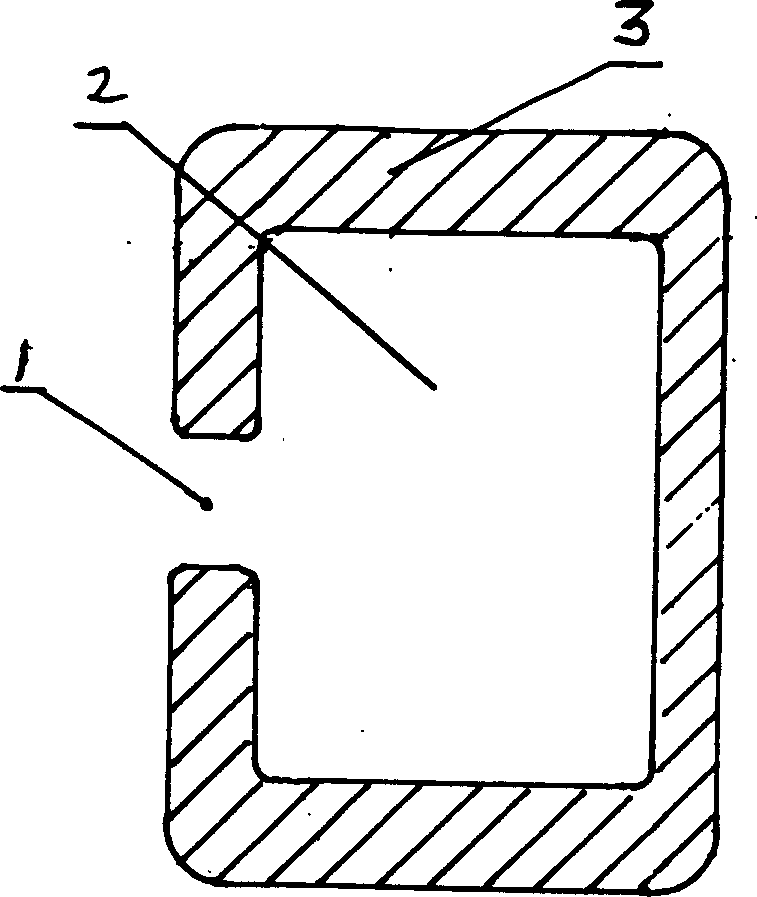

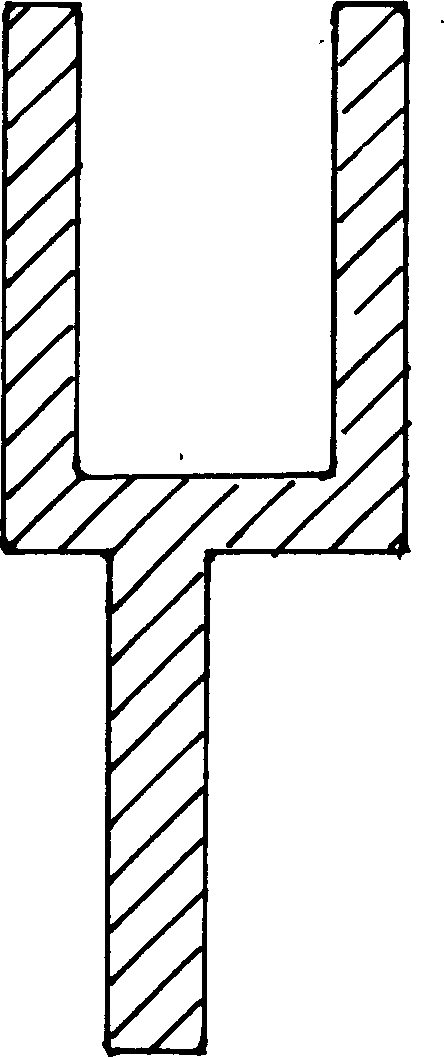

Method for producing pure copper high precision semi hollow section bar

InactiveCN1473671ASolve the strength problemGive full play to the range of plastic deformationCopper highHomogeneous deformation

The production process of high precision semi-hollow pure copper section bar includes extruding V-shaped blank in V-shaped hot extruding mold at about 850 deg.c and cold drawing in combined mold withlocating slot and core rod having hem. The V-shaped hot extruding mold has opening larger than that required in producing C-shaped section bar, and the combined mold is combined structure of separated core mold and outer mold with hem to make the blank enter to the mold cavity smoothly for homogeneous deformation. The drawn head is forged into size smaller than the aperture of the outer mold for penetrating through and is clamped with a clamp for drawing out to obtain finished product. The said method can produce section bar with precise and stable size and high strength in high yield.

Owner:董云伟

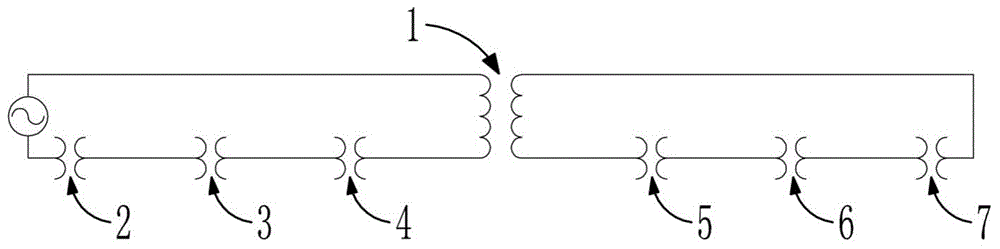

Distribution transformer coil material identification method

ActiveCN103604837AImprove recognition accuracyThe implementation conditions are simpleTransformers/inductances coils/windings/connectionsMaterial resistanceDistribution transformerCopper high

The invention discloses a distribution transformer coil material identification method. The distribution transformer coil material identification method comprises the following steps of 1, respectively preparing pure copper high-voltage and low-voltage standard coils, pure aluminum high-voltage and low-voltage standard coils, and copper-aluminum high-voltage and low-voltage standard coils having 50% copper content and 50% aluminum content, 2, connecting the three high-voltage standard coils and the three low-voltage standard coils to a heating circuit of a distribution transformer to be detected and carrying out heating simultaneously, 3, connecting the three high-voltage standard coils, the three low-voltage standard coils and the distribution transformer to be detected to a direct-current circuit in series, synchronously carrying out gradual cooling, and carrying out real-time acquisition on direct-current resistance values of the high-voltage and low-voltage standard coils, and high-voltage and low-voltage coils of the distribution transformer to be detected, and 4, comparing the direct-current resistance values and recognizing materials of the high-voltage and low-voltage coils of the detected distribution transformer. The distribution transformer coil material identification method has simple processes, is convenient for operation, is operated under the same environmental conditions, has high identification accuracy and is suitable for on-site application.

Owner:STATE GRID CORP OF CHINA +2

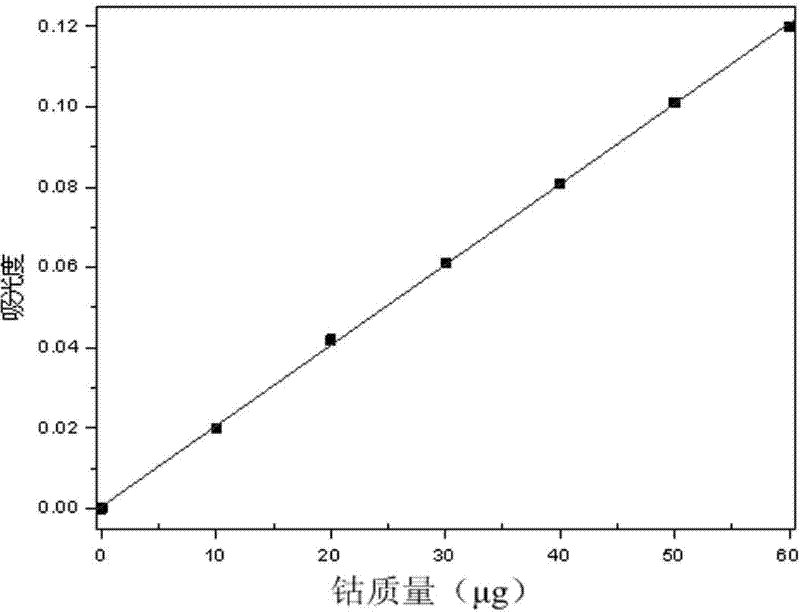

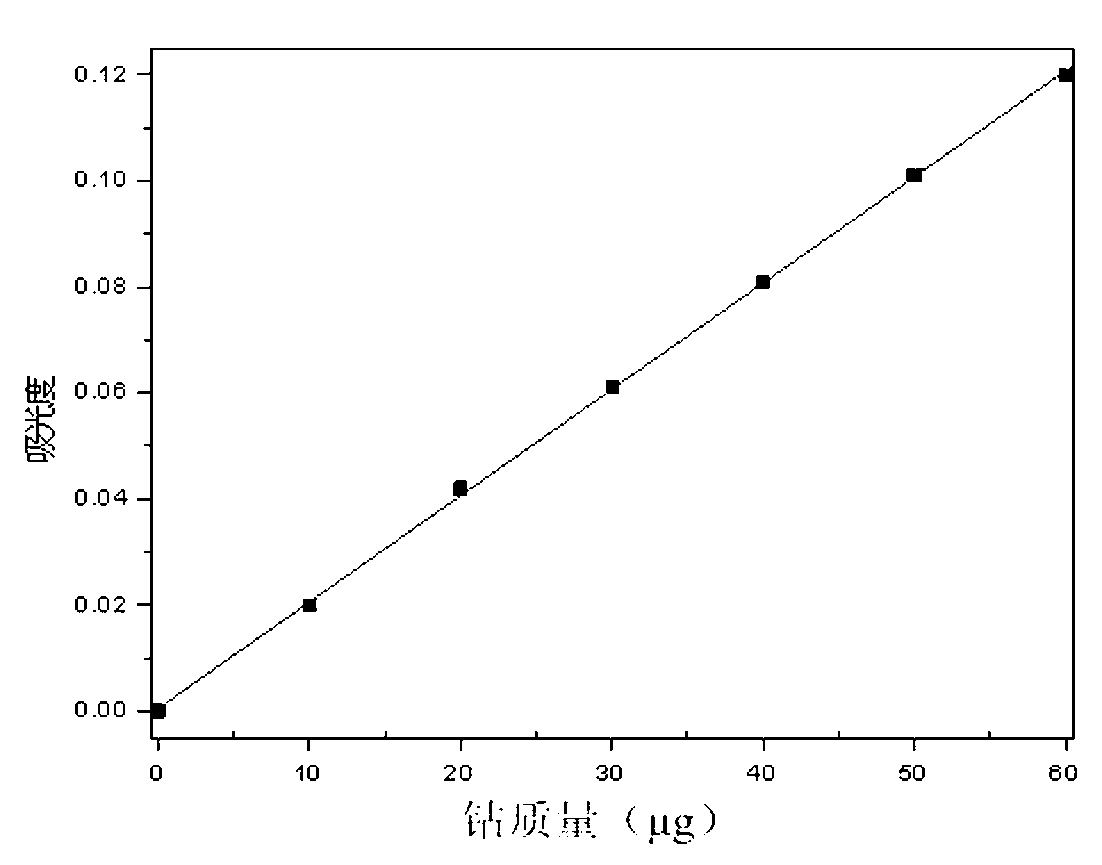

Determination method for cobalt content in high-copper high-iron cobalt ores

ActiveCN102353642AAvoid influenceAvoid effects, avoid iron ionsPreparing sample for investigationColor/spectral properties measurementsCopper highCobalt

Provided is a determination method for cobalt content in high-copper high-iron cobalt ores. The method comprises the following steps: (1) taking 0.0100 to 0.2500 g of cobalt ores to prepare an ore sample solution; (2) adding a mixed acid solution into the ore sample solution, and carrying out heating to prepare a shielding iron ore sample solution; (3) removing copper to obtain a copper removal solution; (4) carrying out chromogenic treatment on the copper removal solution to obtain a solution to be determined; (5) preparing a blank solution; (6) preparing a standard solution; (7) drawing a standard curve, and determining cobalt content in the solution to be determined based on the standard curve, thereby determining cobalt content in the a sample of cobalt ores. The method provided in the invention can be used for determining copper- and iron-rich cobalt ores which contain 5 to 35% of Fe, 15 to 30% of Cu and 0.001 to 5% of Co. In the process of determination, no toxic reagents are used, and a treating process is simple and is easy to popularize.

Owner:NORTHEASTERN UNIV

Copper aluminum welding method

InactiveCN101391347AEasy to weldSmooth connectionWelding/soldering/cutting articlesWelding apparatusHeating timeCopper high

The invention relates to a welding method, in particular to a copper aluminum welding method. The invention mainly solves the problems in the prior art that the technology is complex, the cost is high, and a third metal is required as a connecting metal to realize the copper aluminum welding. And the invention provides a copper aluminum welding method of simple operation, low cost, fast and firm welding. The technique proposal of the invention is as follows: the steps of the copper aluminum welding method comprise: the contacted copper and aluminum is respectively heated by a heating device simultaneously at different temperature, with the temperature applied to the copper higher than that to the aluminum; when the heating time is over 0.5 seconds, the copper aluminum welding is finished.

Owner:ZHEJIANG KANGSHENG CO LTD

Manufacturing method of thick-copper high-density interconnected printed board

InactiveCN112261788AAvoid enteringReduce thicknessPrinted circuit aspectsProcessing steps orderEtchingHigh density

The invention discloses a manufacturing method of a thick-copper high-density interconnected printed board. The method comprises the following steps of: manufacturing a blind hole windowing pattern ona production board, removing a copper layer at the windowing position by etching, and drilling a blind hole at the windowing position by using laser; drilling a plug hole in the production board after a film is removed, and then metallizing the blind hole and a plug hole; manufacturing a hole plating pattern on the production board, and thickening hole wall copper layers of the plug hole and theblind hole through electroplating; filling the plug hole and the blind hole with resin ink and performing curing after the film is removed, and flattening the board surface through a grinding plate; manufacturing a mask hole pattern on the production board, and thinning the thickness of the surface copper layer through micro-etching; flattening the board surface through the grinding plate after the film is removed; drilling a through hole and a through groove in the production board, and then metallizing the through hole and the through groove; and sequentially subjecting the production boardto subsequent processes, thus obtaining the thick-copper high-density interconnected printed board. According to the method, manufacturing of large-aperture blind holes and thick-copper high-density interconnected printed boards is achieved, and resin is prevented from entering through holes and grooves which do not need hole plugging.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Casting method of cast iron pan

InactiveCN110303140AEvenly heatedImprove drop resistanceMetallic material coating processesCopper highBreaking capacity

The invention discloses a casting method of a cast iron pan. The method comprises pig iron and copper block smelting, inner pan body workblank casting, roughening, pan body workblank casting, pan bodyworkblank heat treatment, grinding and polishing. Copper high in thermal conductivity is casted into an outer pan body to wrap an inner pan body casted through pig iron, all the positions of the whole inner pan body are evenly heated, the local high-temperature condition is avoided, and lampblack in the use process cannot be generated; and in addition, the cast iron pan is fragile, the copper layer wrapping the outer surface of the cast iron pan achieves the good protection effect, and the anti-breaking capacity of the cast iron pan is improved.

Owner:王冬华

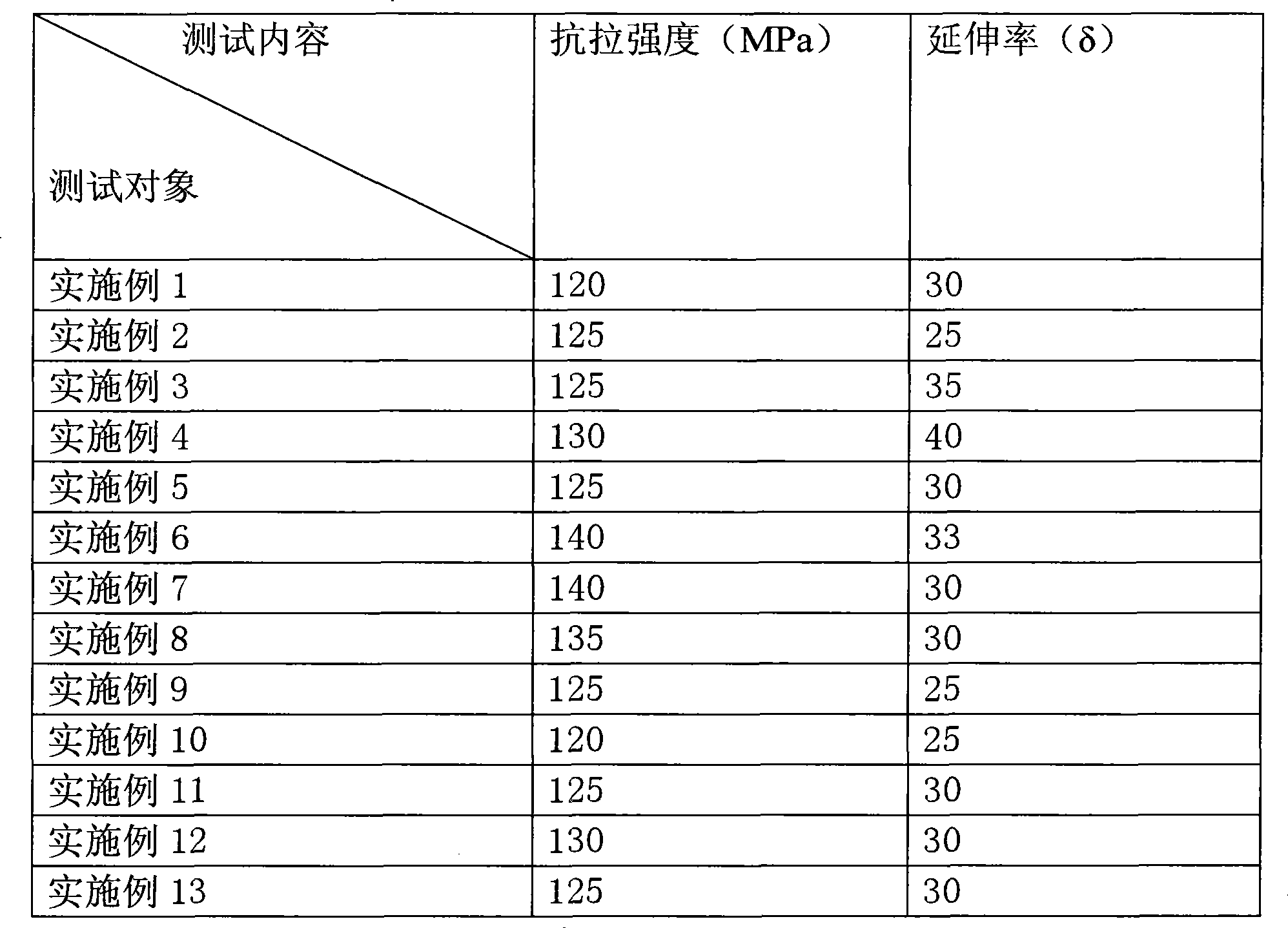

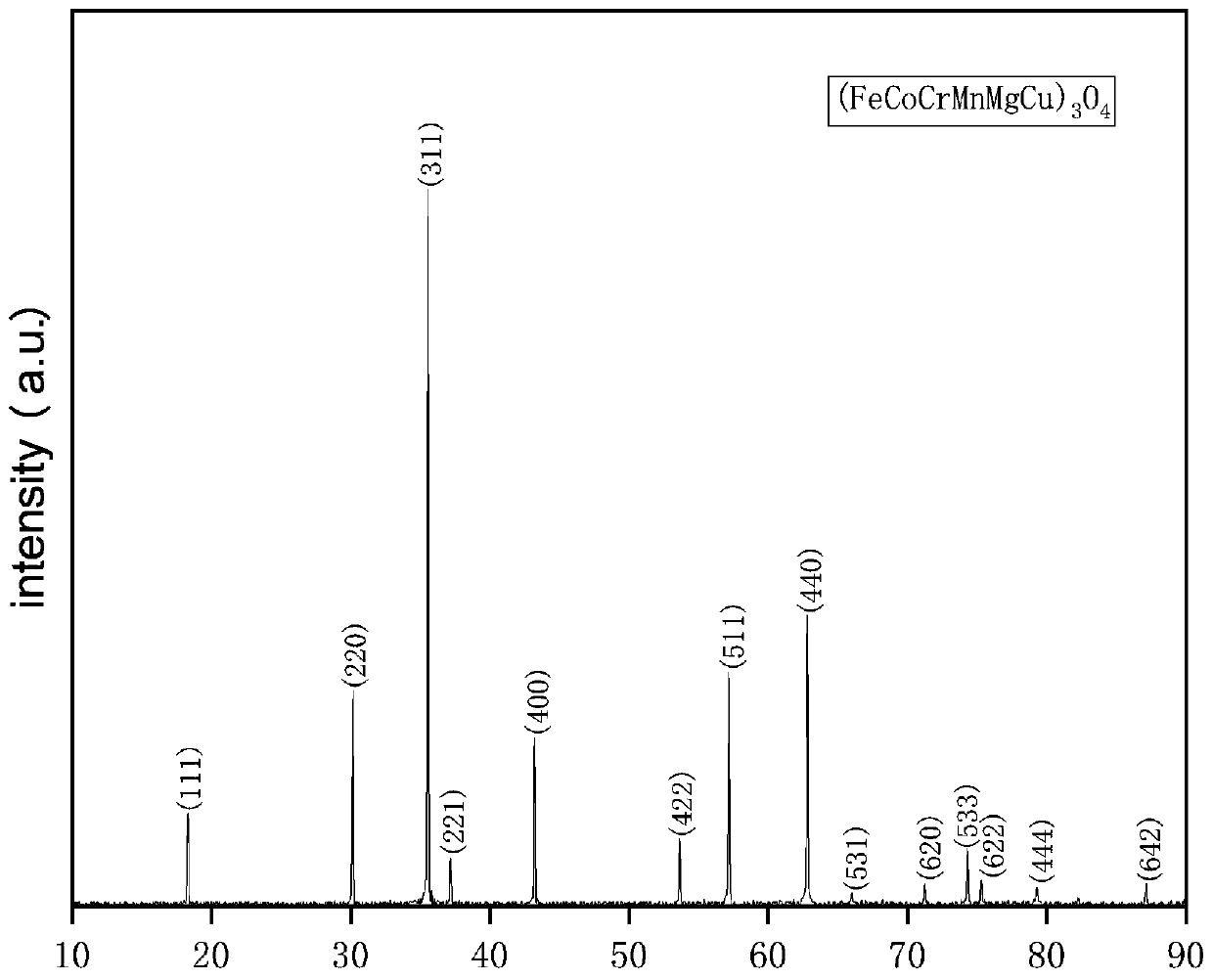

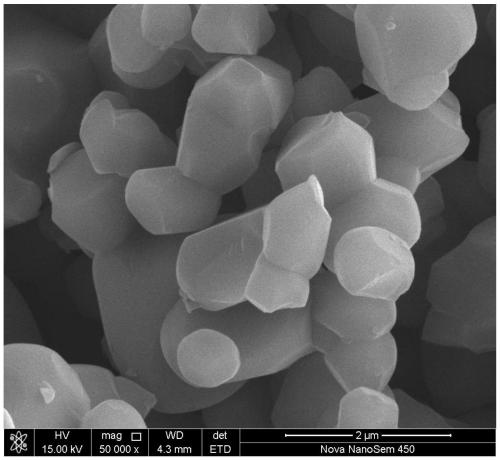

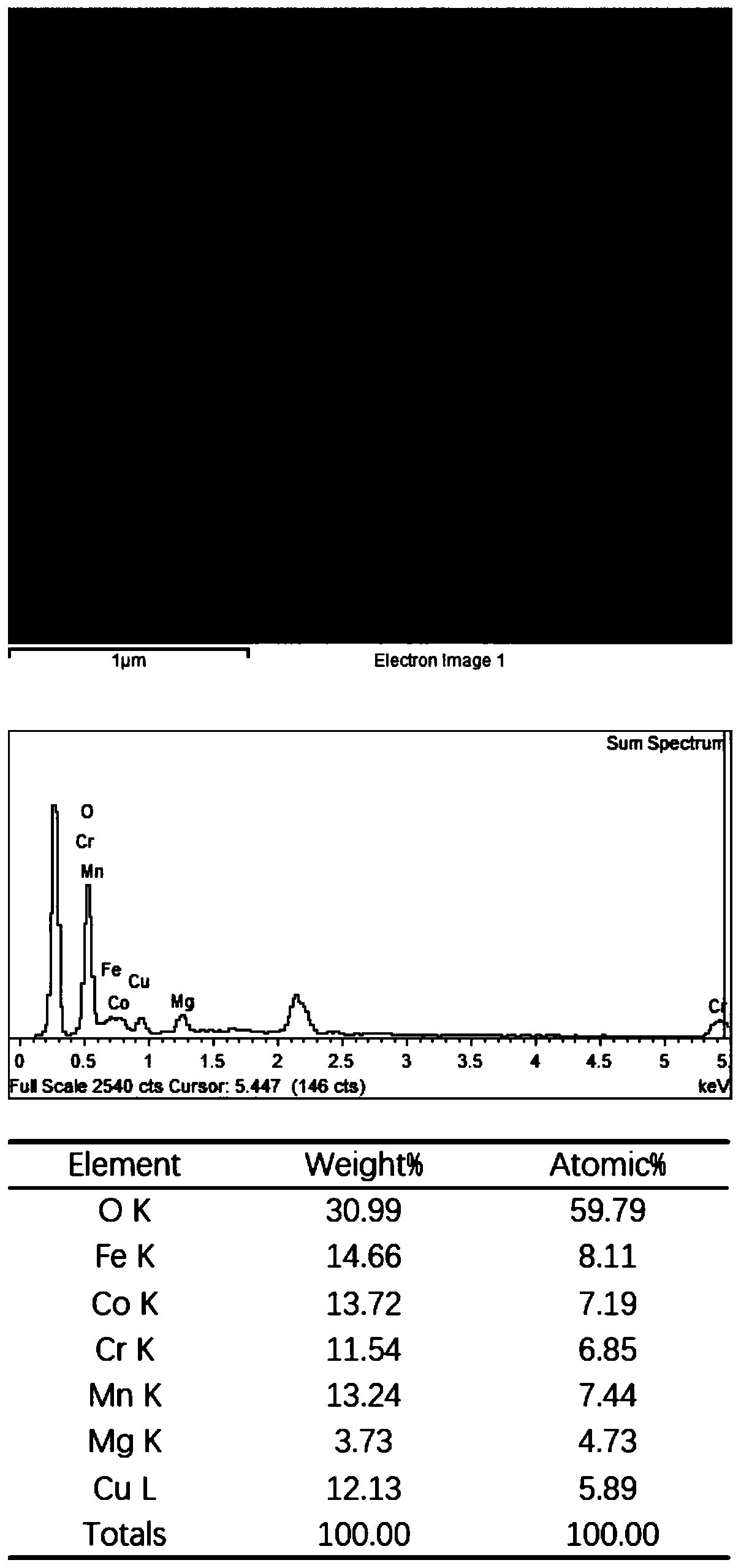

Preparation method of six-membered spinel type iron-cobalt-chromium-manganese-magnesium-copper high-entropy oxide and powder thereof

The invention discloses a preparation method of a six-membered spinel type iron-cobalt-chromium-manganese-magnesium-copper high-entropy oxide and powder thereof, and belongs to the field of high-entropy oxide powder materials. The chemical formula of the high-entropy oxide is (FeCoCrMnMgCu)3O4, the crystal structure of the high-entropy oxide is a face-centered cubic structure, and the space pointgroup of the high-entropy oxide is Fd-3m. The preparation method comprises following steps: firstly, ball-milling and uniformly mixing Fe2O3 powder, Cr2O3 powder, Co2O3 powder, MnO2 powder, MgO powderand CuO powder according to a molar ratio of 1: 1: 1: 2: 1: 1; drying, sieving, sintering for 1-3 hours at 800-1000 DEG C in a muffle furnace, calcining, and cooling in the furnace to the room temperature to obtain the single-phase spinel structure (FeCoCrMnMgCu)3O4 high-entropy oxide powder material. The preparation method has the advantages of low cost, short production period, industrial production, simple operation process, low energy consumption and the like, and the prepared powder is high in purity, small in particle size and uniform in distribution, and can be widely applied to the fields of super capacitor electrodes, lithium ion battery electrodes, water electrolysis hydrogen production and other novel energy materials.

Owner:NANCHANG HANGKONG UNIVERSITY

Refining method of crude copper

The invention relates to the technical field of non-ferrous metal metallurgy, in particular to a refining method of crude copper. The refining method comprises the following steps: adding a slag former into a refining furnace; then adding a crude copper melt for slagging operation; and after deslagging, reducing crude copper to obtain refined copper, wherein the slag former is quartz sand. By adopting the technical scheme, continuously blown crude copper high in content of Fe, Pb and Bi is refined by using a rotary anode furnace. The slag former is added first and then the crude copper melt isadded. In an oxidization slagging process, oxidized Fe in the crude copper is combined with SiO2 in the slag former and an oxide of copper Cu2O to form a Cu2O-FeO-SiO2 series slag melt, so that a Fe3O4 solid solution can be prevented from being separated out and adhered to a furnace wall and a furnace bottom to form furnace accretion, and therefore, normal rotation of the volume of a hearth and the furnace body is kept; moreover, the distribution coefficient of impurities such as Pb and Bi in the crude copper in silicate slag is much higher than that in ferrate slag, so that the impurities such as Pb and Bi are enriched to the silicate slag to be discharged, and therefore, the content of the impurities such as Pb and Bi in anode copper is reduced effectively.

Owner:铜陵有色金属集团股份有限公司

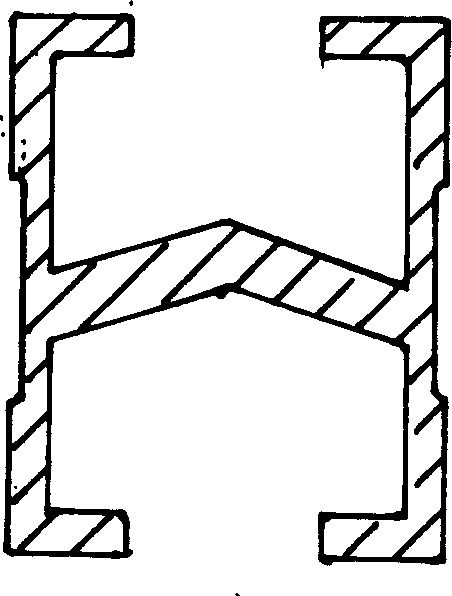

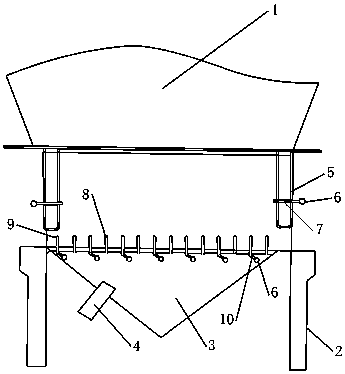

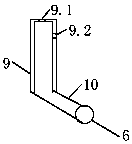

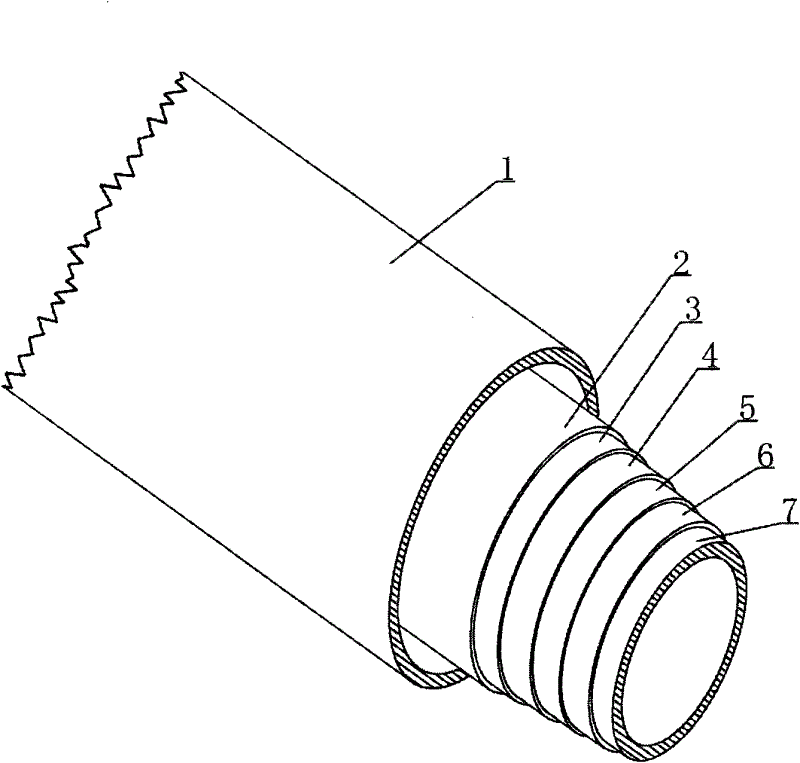

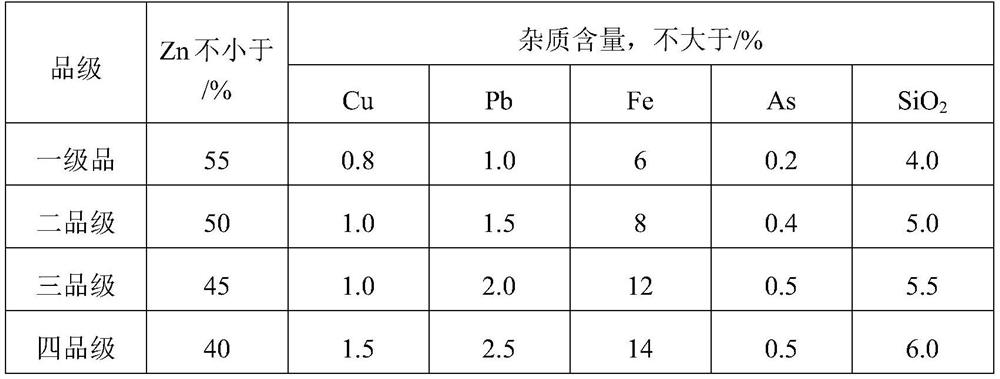

Fluidized bed roaster for treating high-copper high-lead zinc concentrates

The invention discloses a fluidized bed roaster for treating high-copper high-lead zinc concentrates. According to the fluidized bed roaster, supporting legs are arranged at the lower part of a fluidized bed roaster body; an air bellow is arranged at the position, among the supporting legs, of the lower part of the fluidized bed roaster body; an air blower air supply pipe is connected in the air bellow; a perforated pattern plate is arranged at the upper part of the air bellow; wind caps are arranged on the perforated pattern plate; the upper parts of the wind caps are provided with wind cap upper openings; water jackets are arranged on the periphery of the fluidized bed roaster body at intervals; water jacket air pipes are connected to the water jackets in a penetrating mode and are connected to auxiliary air pipes; the positions, at the lower part of the pattern plate, of the auxiliary wind caps are connected to the auxiliary air pipes through metal flexible connecting parts; the auxiliary wind caps are connected to the upper parts of the auxiliary air pipes and are provided with side openings; and the side openings face the center part of the fluidized bed roaster body. The fluidized bed roaster has the advantages that the auxiliary air pipes are arranged in the air bellow of the fluidized bed roaster body, the water jacket air pipes are additionally arranged at the water jackets, the auxiliary wind caps are additionally arranged, so that the boiling state of materials in the fluidized bed roaster body is good, slagging is reduced, discharging is smooth, and therefore the service life of the the fluidized bed roaster body is prolonged. The fluidized bed roaster is suitable for being used as a high-copper high-lead zinc concentrate fluidized bed roaster.

Owner:HULUDAO ZINC IND CO LTD

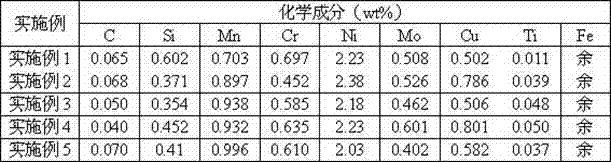

Low-carbon high-copper high-strength welding wire for gas protection welding

InactiveCN102962605AImprove cold cracking resistanceWelding arc concentrationWelding/cutting media/materialsSoldering mediaImpurityMetal

The invention discloses a low-carbon high-copper high-strength welding wire for gas protection welding, wherein the components of the welding wire are as follows: 0.04 to 0.07 wt% of C, 0.35 to 0.6 wt% of Si, 0.7 to 1.0 wt% of Mn, 0.45 to 0.7 wt% of Cr, 2.0 to 2.4 wt% of Ni, 0.40 to 0.60 wt% of Mo, 0.50 to 0.8 wt% of Cu, 0.01 to 0.05 wt% of Ti, the balance of Fe and inevitable impurities. With the adoption of the welding wire for the gas protection welding provided by the invention, when the MIG (Metal Inert-gas Welding) welding is adopted, the welding arc is concentrated and stable; a weld microstructure is a mixed microstructure of low-carbon equivalent acicular ferrite and bainite; a little dispersive retained austenite exists in the microstructure, thus being beneficial to the improvement of cold cracking resistance performance of weld metal; and in addition, the yield strength of deposited metal is more than 735MPa and the ballistic work is more than 60J at the temperature of -50 DEG C.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Process for producing tuning fork quartz crystal resonator

The invention relates to the field of crystal resonators, and discloses a process for producing a tuning fork quartz crystal resonator. The process comprises the following steps of: electroplating a sintered substrate which is not electroplated to obtain a tin copper high-temperature-resistant substrate, electroplating a stamped shell which is not electroplated to obtain a nickel-plated high-temperature-resistant shell, melting high-temperature-resistant soldering tin by using a hot air gun to weld a tuning fork wafer on a high-temperature-resistant support, adjusting the tuning fork wafer to the frequency point which is required by the tuning fork wafer by a frequency adjusting process, sorting by a high-temperature aging process, and performing surface mount type packaging to obtain a product. Due to the adoption of the technical scheme, the using range of the tuning fork quartz crystal resonator is widened.

Owner:HUBEI TKD ELECTRONICS TECH

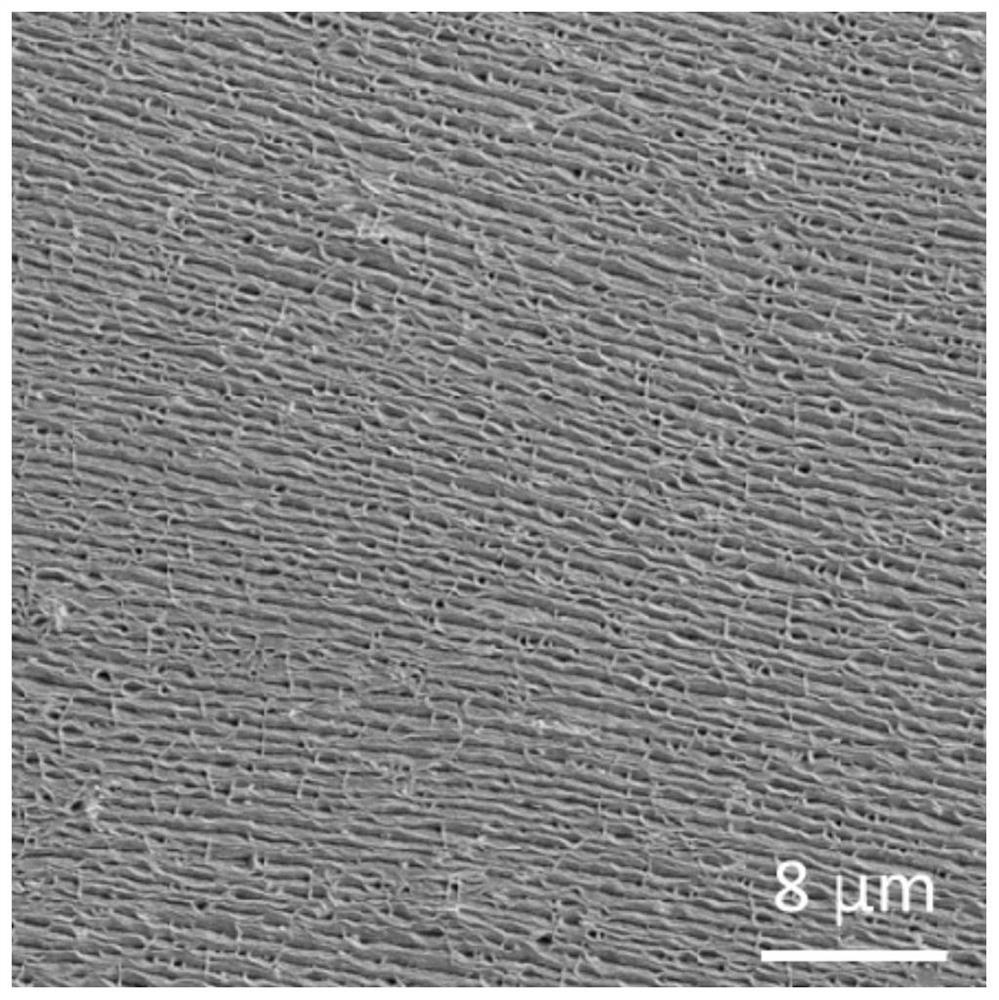

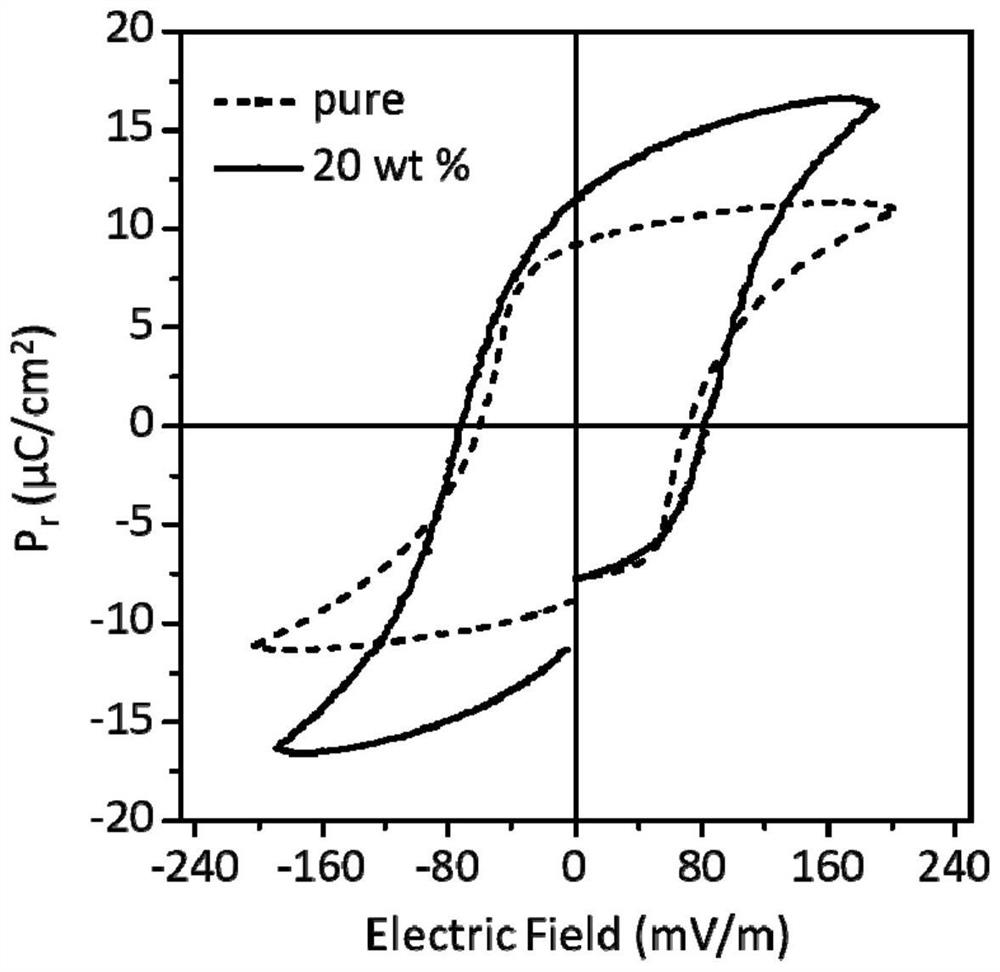

Preparation method of organic-inorganic ferroelectric polymer composite film

PendingCN114171674AImprove ferroelectric propertiesSimple preparation processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPolymer scienceComposite film

The invention discloses a preparation method of an organic-inorganic ferroelectric polymer composite film. The method comprises the following steps: by taking a graphene / copper high-index surface with one-dimensional periodic potential on the surface as a substrate, uniformly dissolving vinylidene fluoride-trifluoroethylene copolymer (P (VDF-TrFE)) powder in a tetrahydrofuran organic solvent, then adding a ground single crystal lead titanate (PbTiO3) mesoporous material, fully stirring, spin-coating a proper amount of solution on the substrate, and drying to obtain the graphene / copper composite mesoporous material. And carrying out vacuum drying and annealing treatment to obtain the organic-inorganic ferroelectric polymer composite film. The composite film prepared by the method is good in orientation, shows excellent ferroelectric properties, and has wide application prospects in flexible energy transducers, sensing devices and ferroelectric storage devices.

Owner:ZHEJIANG LAB

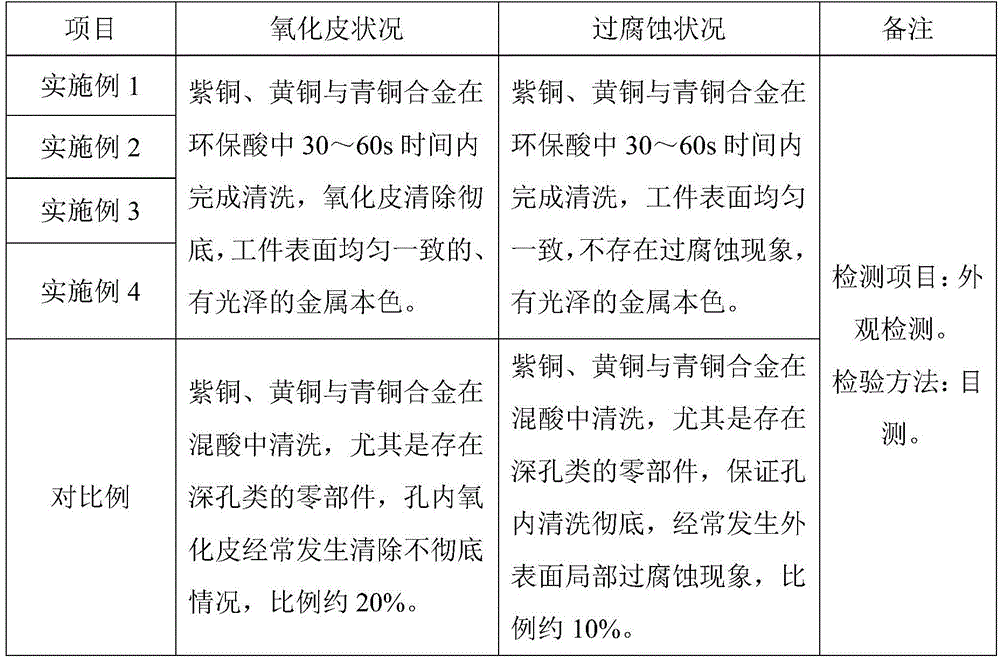

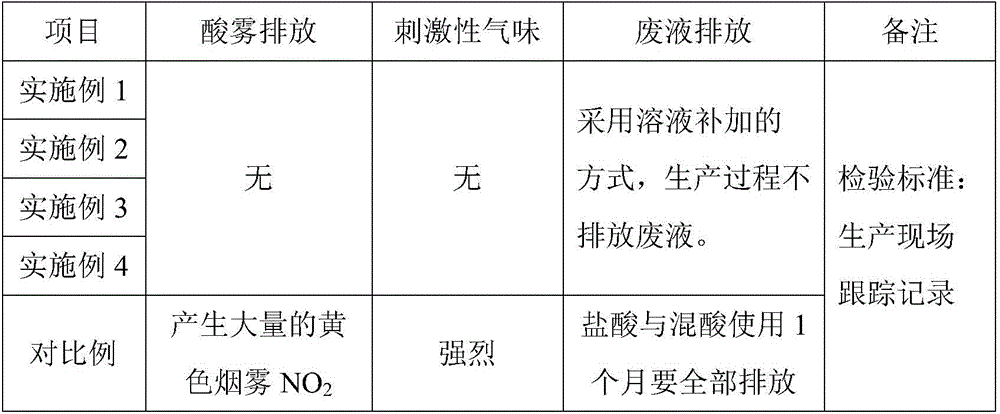

A kind of copper and copper alloy environment-friendly pickling agent, copper and copper alloy silver plating pretreatment method

The invention discloses an environmentally friendly pickling agent for copper and copper alloys, and a method for pre-treating copper and copper alloys for silver plating. The pickling agent comprises the following components by mass percentage: sulfuric acid 21.5%-44.0%, phytic acid 2.5%-15.5% %, sodium nitrate 2.5% to 10%, dispersant 0.5% to 2.0%, and the balance is water. The environmentally friendly pickling agent of the invention is clean and environmentally friendly, the solution does not volatilize, does not produce acid mist during the cleaning process, has low pollution, and can create a clean environment for the pretreatment process; Parts are not prone to over-corrosion; realize the pre-treatment and cleaning of various copper, copper-like and copper alloys that are widely used in high-voltage switches, improve the working environment and protect the health of employees; can be used repeatedly during the cleaning process, and the use cycle Compared with the traditional pickling solution, it is 2 to 3 times longer, greatly reduces the cleaning cost, and has significant comprehensive benefits, which is suitable for popularization and application.

Owner:HENAN PINGGAO ELECTRIC +2

Iron-cobalt-nickel-manganese-copper high-entropy cast iron and preparation method and application thereof

ActiveCN112725681ASmall shrinkageLower freezing temperatureAdditive manufacturing apparatusManganeseCopper high

The invention discloses iron-cobalt-nickel-manganese-copper high-entropy cast iron and a preparation method and application thereof. The alloy component of the iron-cobalt-nickel-manganese-copper high-entropy cast iron is FeaCobNicMndCueCfXg, wherein X is a microelement, a, b, c, d, e, f and g are the mole percentages of the corresponding elements, a is larger than 5%, b is larger than 5%, c is larger than 5%, d is larger than 5%, e is larger than 5%, the sum of a, b, c, d and e is larger than 90%, f is larger than 0.2% and smaller than 0.4%, and g is larger than or equal to 0%. According to the iron-cobalt-nickel-manganese-copper high-entropy cast iron and the preparation method and application thereof, a single principal element of original cast iron is replaced with multiple principal elements, a matrix structure can be composed of FCC and a compound or FCC and a graphite phase, and the excellent mechanical performance is obtained. In the alloy design process, the positive influences of the microelement on alloy oxidation resistance, corrosion resistance and high-temperature stability are fully utilized, and the alloy comprehensive performance is excellent.

Owner:CHINA UNIV OF MINING & TECH

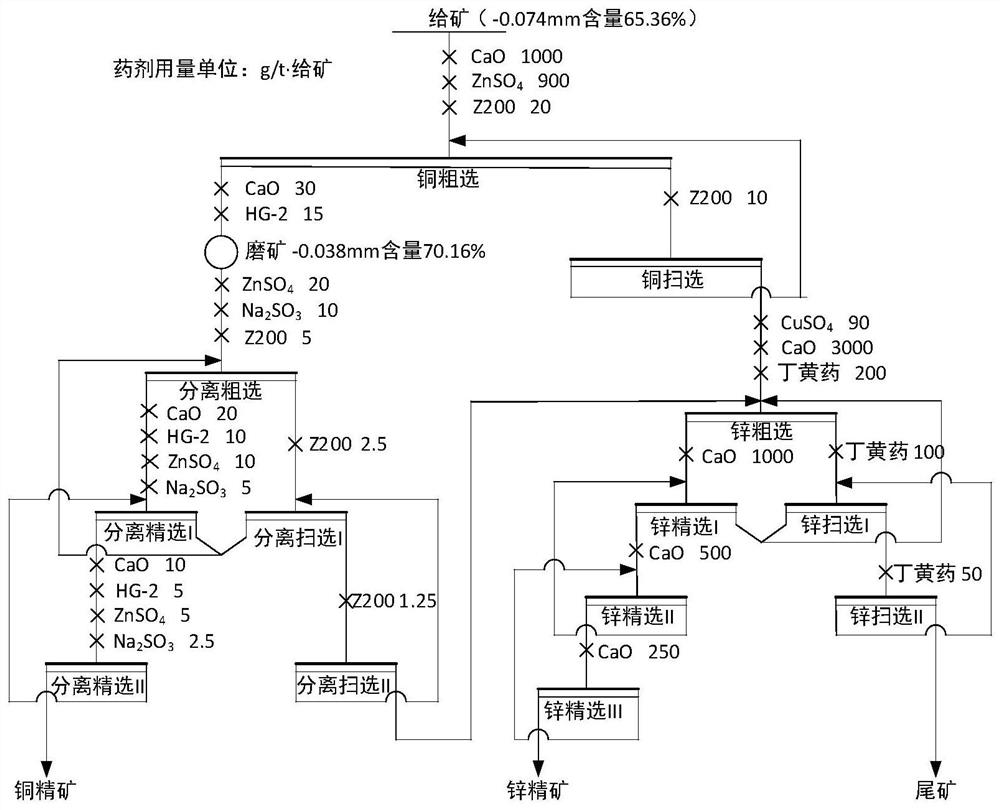

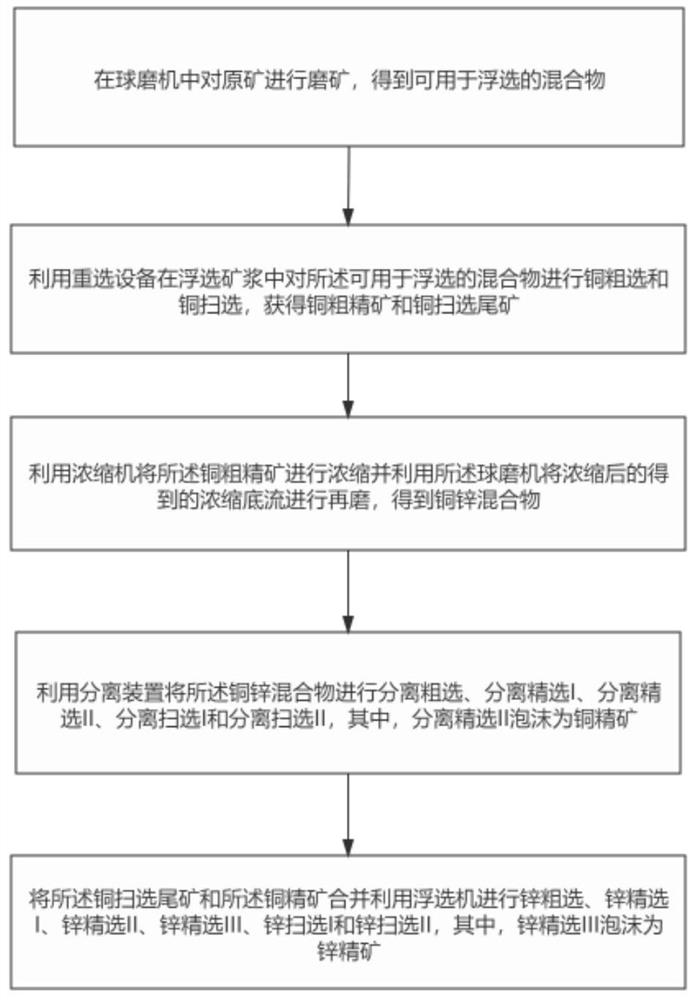

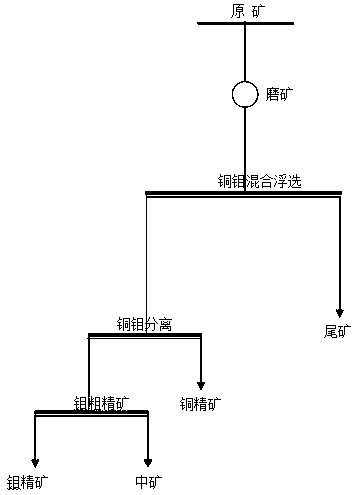

Beneficiation process for obtaining independent copper and zinc concentrate from low-copper high-zinc sulfide ore

ActiveCN112916196AEasy to separateIncrease stickinessFlotationProcess efficiency improvementSulfate zincSulfite salt

The invention relates to a beneficiation process for obtaining independent copper and zinc concentrate from low-copper high-zinc sulfide ore. The beneficiation process comprises the following steps of step 1, grinding raw ore to obtain a mixture which can be used for flotation; step 2, performing copper roughing and copper scavenging on the mixture which can be used for flotation, and obtaining copper rough concentrate and copper scavenging tailings; step 3, concentrating the copper rough concentrate, regrinding concentrated underflow obtained after concentration, and obtaining a copper-zinc mixture; step 4, subjecting the copper-zinc mixture to separation roughing, separation concentration I, separation concentration II, separation scavenging I and separation scavenging II through a separation device, where foam of separation concentration II is copper concentrate; and step 5, combining the copper scavenging tailings and the copper concentrate and subjecting the same to zinc roughing, zinc concentration I, zinc concentration II, zinc concentration III, zinc scavenging I and zinc scavenging II through a flotation machine, where foams of zinc concentration III are zinc concentrate. Therefore, the copper-zinc separation effect can be remarkably enhanced, and consumption of conventional inhibitors zinc sulfate and sodium sulfite is reduced.

Owner:内蒙古黄岗矿业有限责任公司

Vacuum collector tube and process for preparing coating thereof

InactiveCN102620448AHigh degree of anti-agingGood electrical and thermal conductivitySolar heat devicesVacuum evaporation coatingTitanium metalCopper high

The invention discloses a vacuum collector tube process, in particular to a vacuum collector tube and a process for preparing a coating thereof. The scheme of the preparation process includes sequentially plating an AlN-Al bonding layer, a pure copper high infrared reflection layer, an Aln-Ti high metal absorbing layer, an Aln-Ti low metal absorbing layer and an AlN antireflection layer on the outer surface of a glass inner tube. According to the vacuum collector tube and the preparation process for the coating thereof, titanium metal is used by the absorbing layer as the main coating material, defects of low stability, fast aging and short service life of vacuum tubes are overcome, the absorption ratio of vacuum collector tube is enabled to be over 96% due to the special coating structure, and the vacuum collector tube is capable of stably supplying industrial hot water for users.

Owner:DEZHOU XUNENG VACUUM TUBES

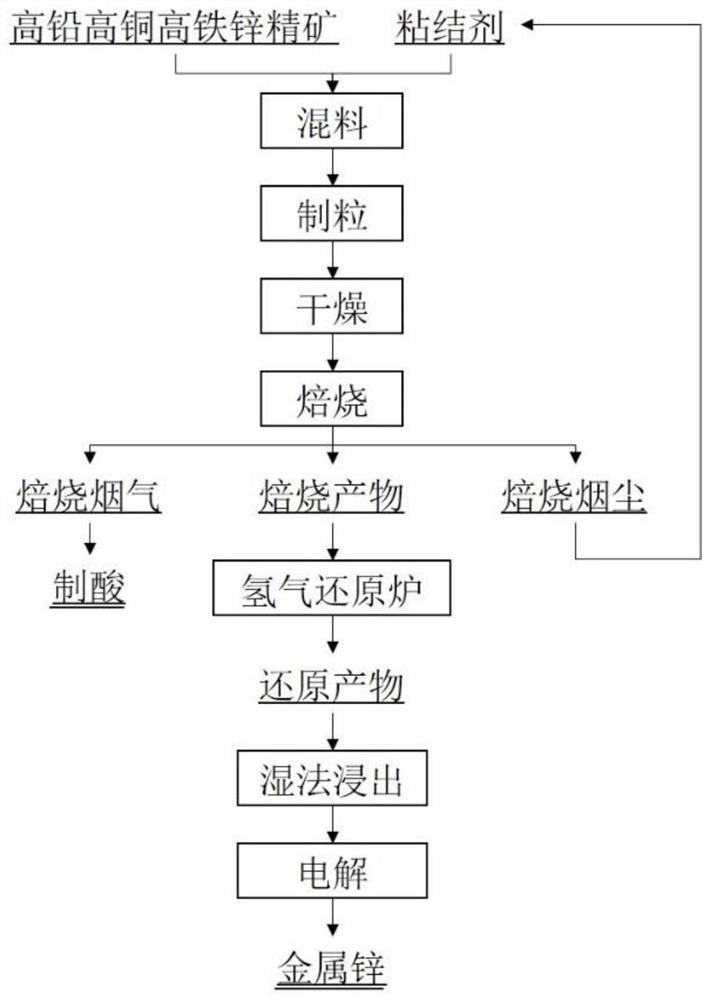

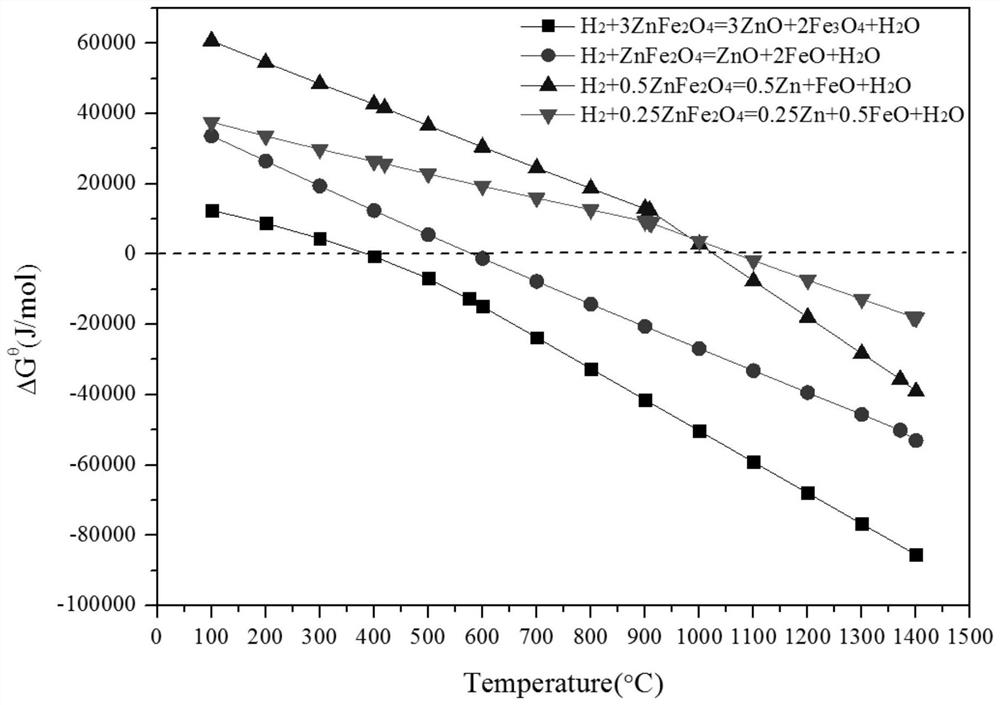

Roasting treatment method for high-lead, high-copper and high-iron zinc concentrate

PendingCN113736994AEfficient conversionSolve the baking sticking problemPhotography auxillary processesProcess efficiency improvementFluidized bedCopper high

The invention provides a roasting treatment method for high-lead, high-copper and high-iron zinc concentrate. The roasting treatment method comprises the following steps that S1, the high-lead, high-copper and high-iron zinc concentrate is mixed with a binder and granulated, and then drying is carried out to obtain zinc concentrate granules; S2, the zinc concentrate granules are added into a fluidized bed roaster or a fluidized bed to be subjected to oxidizing roasting treatment, and a roasted product is obtained; and S3, the roasted product is fed into a hydrogen reduction furnace for selective reduction, zinc ferrite in the roasted product is reduced into ZnO and Fe3O4, and a reduction product is obtained. According to the roasting treatment method for the high-lead, high-copper and high-iron zinc concentrate, the problem of roasting bonding of the high-lead high-copper high-iron zinc concentrate is effectively solved, the amount of smoke generated in the roasting process is reduced, and the bed capacity of the oxidizing roasting procedure is improved; and meanwhile, zinc ferrite in the roasted product is effectively converted into soluble zinc, and the roasted product meets the requirements of the subsequent wet leaching process.

Owner:CHINA ENFI ENGINEERING CORPORATION

Iron-based copper for treating organic sewage and sewage treatment method

InactiveCN102849824BImprove degradation efficiencyIncrease potential differenceWater/sewage treatmentElectrochemical degradationPrimary battery

The invention relates to an iron-based copper high-efficient microelectrolytic material which contains a lot of nonuniform iron-copper microelectrode primary batteries and is formed by coating copper on cast iron granular carrier surfaces in a crystal grain form by a chemical conversion method. When organic sewage flows through a fixed bed reactor formed by the material, the reaction efficiency is controlled by the flow rate. With the material and the fixed bed reaction technology, the problem of low electrochemical degradation efficiency of organic pollutant macromolecules in sewage by common granular iron-carbon microelectrolytic materials and granular iron-copper microelectrolytic materials in current sewage treatment process is solved.

Owner:WUHAN COMEON ENVIRONMENT ENG

Determination method for cobalt content in high-copper high-iron cobalt ores

ActiveCN102353642BAvoid reactionHigh precisionPreparing sample for investigationColor/spectral properties measurementsCopper highCobalt

Provided is a determination method for cobalt content in high-copper high-iron cobalt ores. The method comprises the following steps: (1) taking 0.0100 to 0.2500 g of cobalt ores to prepare an ore sample solution; (2) adding a mixed acid solution into the ore sample solution, and carrying out heating to prepare a shielding iron ore sample solution; (3) removing copper to obtain a copper removal solution; (4) carrying out chromogenic treatment on the copper removal solution to obtain a solution to be determined; (5) preparing a blank solution; (6) preparing a standard solution; (7) drawing a standard curve, and determining cobalt content in the solution to be determined based on the standard curve, thereby determining cobalt content in the a sample of cobalt ores. The method provided in the invention can be used for determining copper- and iron-rich cobalt ores which contain 5 to 35% of Fe, 15 to 30% of Cu and 0.001 to 5% of Co. In the process of determination, no toxic reagents are used, and a treating process is simple and is easy to popularize.

Owner:NORTHEASTERN UNIV LIAONING

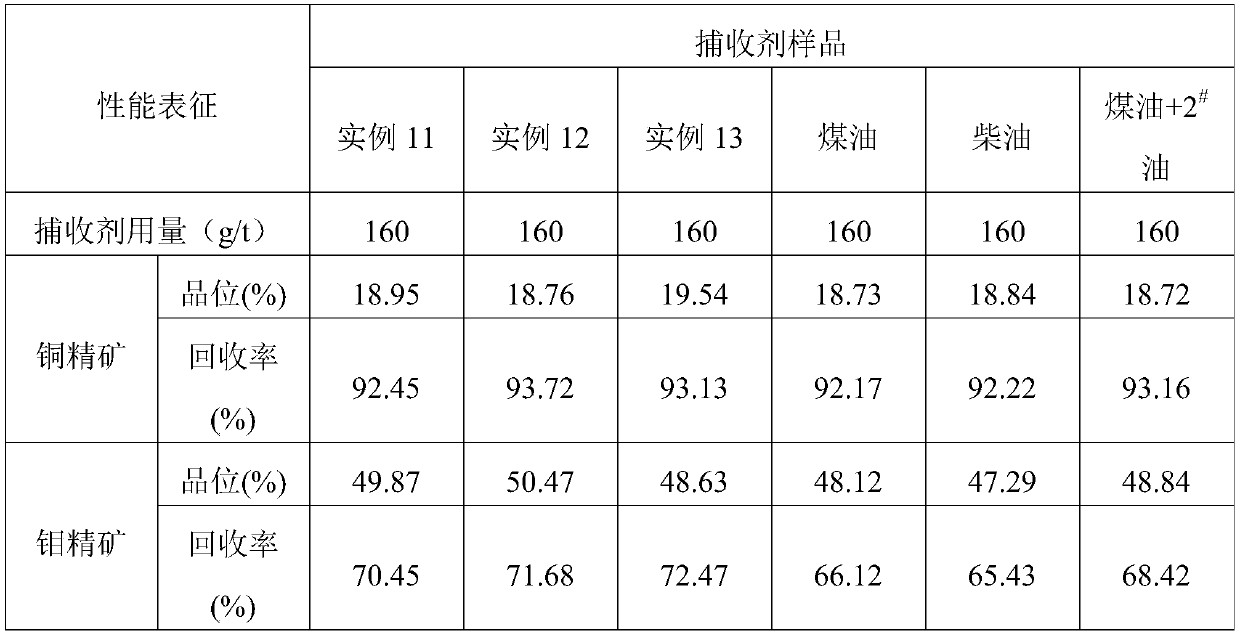

Low-copper high-molybdenum ore collecting agent and preparation method thereof

ActiveCN111558464AHigh viscosityLower synthesis costFlotationProcess efficiency improvementKerosenePhysical chemistry

The invention relates to a low-copper high-molybdenum ore collecting agent and a preparation method thereof. The low-copper high-molybdenum ore collecting agent comprises the following components in parts by weight: 20-25 parts of fractionation-grade kerosene higher than 220 DEG C, 6-9 parts of heavy wax, 2-3 parts of 100 / 100 motor oil, 1-2 parts of tricyclic aromatic hydrocarbon, and 1-3 parts ofv fatty acid polyglycolate serving as an emulsifier. Fractionation-grade kerosene with the temperature higher than 220 DEG C serves as a main body, a single collecting agent is synthesized into a composite collecting agent in an emulsifying mode, and the collecting agent has the advantages of being simple in preparation method, low in synthesis cost and the like. The collecting agent is good in stability, high in viscosity, high in collecting capacity and capable of effectively improving the recovery rate of molybdenum in the low-copper high-molybdenum ore, has a certain amount of macromolecular aromatic hydrocarbon and easily adsorbs coarse-particle ore.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

A manufacturing process of thick copper high aspect ratio small aperture motherboard

ActiveCN105682376BImprove conductivityPrinted element electric connection formationCopper platingCopper high

The invention discloses a manufacturing process for a thick-copper high-aspect-ratio and small-pore-diameter main board. The manufacturing process is characterized by comprising the following steps of step 1, performing board cutting; step 2, drilling holes; step 3, performing an electroless thick-copper plating operation; step 4, performing full-board electroplating for the first time; step 5, performing full-board electroplating for the second time; step 6, pattern transferring; step 7, pattern electroplating; step 8, etching an outer layer; and step 9, inspecting the outer layer; the manufacturing process is characterized in that in the step 3, the circuit board after being drilled in the step 1 is subjected to high-voltage water-washing processing for two times to ensure that dust in the holes is fully cleaned and the holes are clean; the pore diameter after thick-copper plating is determined based on that the thickness of the thick-copper plated in the circuit board hole achieves 45-70[mu]m; the high-aspect-ratio board hole wall copper is thickened by the electroless thick-copper plating process to strength the conductive performance in the full-board electroplating; the thickness in the hole is consolidated again through the way of full-board electroplating for the first time; the full-board electroplating for the second time is adopted to assist the full-board electroplating uniformity, so that the whole PNL PCB copper thickness uniformity process ensures that each region can satisfy the various standards of industrial IPC.

Owner:HUIZHOU XINGZHIGUANG TECH

Combined collecting agent for improving molybdenum recovery rate of low-copper high-molybdenum ore and application process thereof

ActiveCN111558463AImprove stabilityHigh viscosityFlotationProcess efficiency improvementKeroseneCopper high

The invention discloses a combined collecting agent for improving the molybdenum recovery rate of low-copper high-molybdenum ore and an application process of the combined collecting agent. The combined collecting agent is prepared from the following raw materials in parts by weight: 2-5 parts of fractionation-grade kerosene higher than 220 DEG C, 1-2 parts of heavy wax, 2-3 parts of motor oil, 1-2 parts of tricyclic aromatic hydrocarbon, and 1-3 parts of v fatty acid polyglycolate serving as an emulsifier. The process is simple, high in applicability, low in production cost, high in molybdenum recovery rate and easy to industrially popularize. A novel combined collecting agent which is good in stability, high in viscosity, capable of easily adsorbing coarse-particle ore and high in collecting capacity and has a certain number of large-molecule aromatic hydrocarbon is synthesized after emulsifying is conducted through the emulsifier, and the recovery rate of molybdenum in the low-copper high-molybdenum ore can be effectively increased. According to the application process, copper concentrate and molybdenum concentrate with good indexes are finally obtained through the steps of adding the combined collecting agent, conducting copper-molybdenum bulk flotation, conducting copper-molybdenum separation, conducting molybdenum rough concentrate concentration and the like, and efficient recovery of molybdenum in the low-copper high-molybdenum ore can be achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

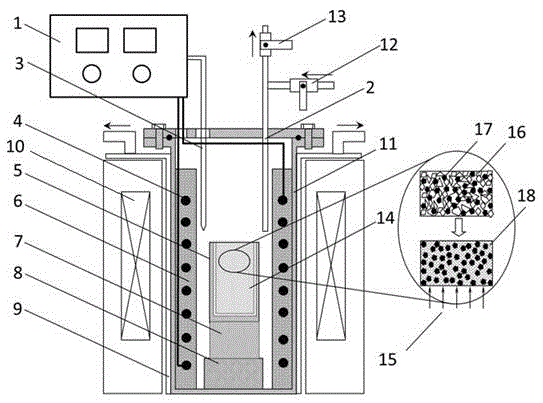

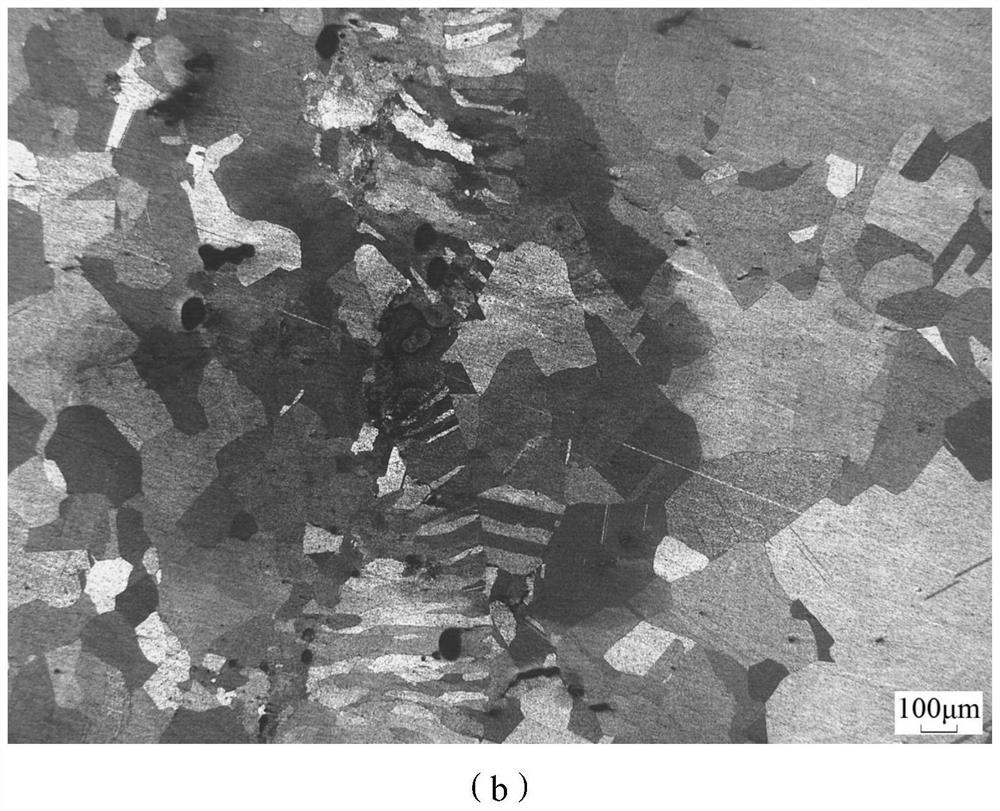

Liquid-phase sintering method for preparing high-melting-point hard material particle dispersion-strengthened copper-based composite material and electromagnetic sintering device

ActiveCN103451466BDifferent quality scoresDifferent performanceElectromagnetic shieldingCopper matrix composites

The invention discloses a liquid-phase sintering method for preparing high-melting-point hard material particle dispersion-strengthened copper-based composite materials, which comprises the preparation of mixed powder, the preparation of copper-based composite material preforms, liquid-phase sintering and densification under a constant magnetic field. The high-strength copper-based composite billet cooling consists of four main steps. The liquid-phase sintering is used to obtain the highest strength and density of the copper-based composite material. At the same time, a constant magnetic field is used to enhance the viscosity of the copper melt in the liquid-phase sintering. The Lorentz force suppresses the movement of high-melting-point hard material particles in copper liquid, prevents the agglomeration and delamination of high-melting-point hard material particles, and thus prepares high-strength and high-conductivity copper alloy blanks with better mechanical properties and electrical conductivity Ingot, the present invention also provides a high-strength and high-conductivity copper alloy sintering device, including a heating and heat preservation device, an atmosphere control device and a constant magnetic field generating device, which can realize the technical goal of both high strength and high conductivity of copper-based composite materials, and realize Huge industrial application value.

Owner:SHANGHAI UNIV +1

Uniform continuous iron phase reinforced copper high-speed train brake friction block and preparation method thereof

PendingCN113976859AManufacturing uniform and continuousOvercoming Process ComplexityAdditive manufacturing apparatusIncreasing energy efficiencyStress concentrationBrake

The invention discloses a uniform continuous iron phase reinforced copper high-speed train brake friction block and a preparation method thereof, and belongs to the field of new materials. The method comprises the steps that firstly, a three-dimensional digital model of a uniform continuous iron phase reinforcement is designed according to the appearance and size of the friction block, then the iron phase reinforcement is prepared through a powder bed melting additive manufacturing system, finally, the iron phase reinforcement is placed in a friction block mold, extrusion casting is combined with molten copper, and the uniform continuous iron phase reinforced copper high-iron brake friction block is obtained. The process is simple, and the continuous iron phase reinforcement of the friction block has the characteristics of continuous and uniform distribution, small stress concentration and difficulty in damage; the performance of the friction block can be effectively regulated and controlled by changing the components of the reinforcements, the shape and the wall thickness of the iron phase reinforcements and the components of the copper matrix, and the requirements of different working conditions are met.

Owner:KUNMING UNIV OF SCI & TECH

Method and device for welding copper components

ActiveCN112872574BClean thoroughlyAvoid obvious problems in low-performance areasNon-electric welding apparatusElectrical resistance and conductanceCopper high

The invention relates to a welding method and device for copper components. Aiming at the characteristics of high electrical conductivity and low resistance of electrical copper, gasification blasting is used to clean the welding end surface by local contact, and the welding end surface is flattened. A certain stress is applied after blasting for a period of time, and the deformation of copper is utilized. Increase the contact area of both ends, thereby linearly reducing the current density, using the interface resistance on the end surface for rapid heating, and the final joint surface is fully plastic deformation of the end surface to fit and extrude liquefied copper. The welding surface is at a temperature lower than the melting point of copper. At high temperature, deformation and recrystallization are used to form welds. The invention does not need solder and does not need to melt the welding zone, so the welding precision is high, no other impurity alloy elements are introduced, and there is no re-dissolved cast structure in the welded structure. The requirements for welding equipment are extremely low, which improves the efficiency of welding electrical copper components.

Owner:GUIZHOU GUDA CABLE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com